Method for leaching manganese sulfate from low grade pyrolusite

A technology of pyrolusite and manganese sulfate, applied in electrolysis components, electrolysis process, etc., can solve the problems of complicated operation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

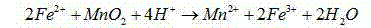

[0010] A method for leaching manganese sulfate with low-grade pyrolusite, the method comprising the steps of pulverizing low-grade pyrolusite and pyrite ore, and mixing them with sulfuric acid in a leaching tank to prepare ore slurry (1) . In the present invention, in the step (1), the mass fraction of manganese in the pyrolusite is 9% to 21%, the pyrite is flotation pyrite, and the particle size of the two ores is not greater than 0.150mm. The mass ratio of this pyrolusite and pyrite is 5~3: 1, the molar concentration of sulfuric acid is 1~1.2mol / L, and the mass ratio of sulfuric acid and two ores is 6~8: 1; After step (1), There are also the following steps:

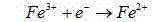

[0011] (2) Turn on the power supply to the leaching tank in step (1) to perform electrocatalytic reduction reaction on the ore slurry; wherein, the anode current density is 100-300A / m 2 , the leaching temperature is 50-90°C, and the leaching time is 2-4h;

[0012] (3) Solid-liquid separation is performed on the ore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com