Rare metal-based sludge activated carbon and application thereof in removal of sulfur, ammonia and phosphorus

A technology of sludge activated carbon and rare metals, applied in water/sludge/sewage treatment, water pollutants, separation methods, etc., can solve rare problems, achieve well-developed pore structure, good application prospects, and adsorption active points bit more effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

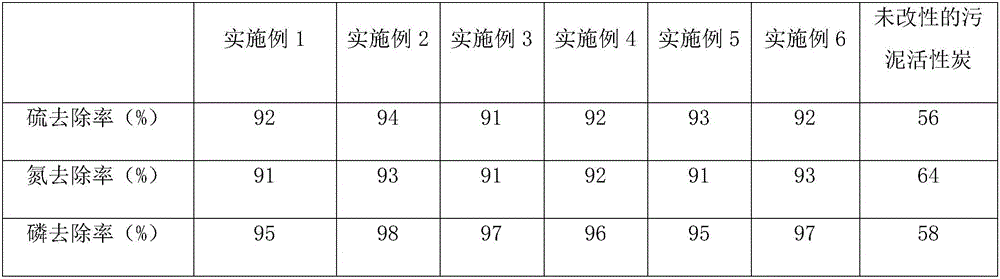

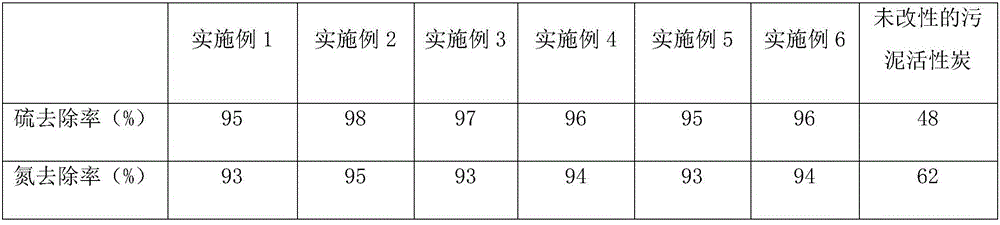

Examples

Embodiment 1

[0029] (1) After drying the remaining dilute sludge with a moisture content of 85% and an ash content of 35% for 24 hours, grind it into a sludge powder of 200-300 mesh, and mix the mass ratio of 0.1:45 with a particle size of 150 mesh. Mix manganese ore powder and sludge powder evenly, add zinc chloride and dilute sulfuric acid composite activator, wherein the volume of zinc chloride and dilute sulfuric acid is 3:1, the concentration of zinc chloride is 4mol / L, the mass fraction of dilute sulfuric acid 20%, ultrasonically mixed for 1 hour, allowed to stand for 24 hours, dried and activated at 80°C for 24 hours, placed in a tube furnace at 550°C, high-temperature carbonization reaction for 1 hour, cooled and washed until neutral to obtain soft manganese composite sludge activated carbon.

[0030] (2) 200 mesh sludge powders are pyrolyzed under an ammonia atmosphere to form sludge activated carbon powders, and by weight, the sludge activated carbon powders with a mass ratio of 4...

Embodiment 2

[0033](1) After drying the dewatered cake with a moisture content of 90% and an ash content of 50% for 24 hours, it is ground into a 300-mesh sludge powder, and the mass ratio is 5:45, and the particle size is a 300-mesh pyrolusite powder and Mix the sludge powder evenly, add a composite activator of zinc chloride and dilute sulfuric acid, wherein the volume of zinc chloride and dilute sulfuric acid is 6:1, the concentration of zinc chloride is 6mol / L, and the mass fraction of dilute sulfuric acid is 45% , ultrasonically mixed for 6 hours, left to stand for 24 hours, dried and activated at 130°C for 72 hours, placed in a tube furnace at 650°C, carbonized at high temperature for 5 hours, cooled and washed to neutral to obtain soft manganese composite sludge activated carbon.

[0034] (2) 300 purpose sludge powders are pyrolyzed under an ammonia atmosphere to form sludge activated carbon powders, and by weight, the sludge activated carbon powders with a mass ratio of 45 parts are...

Embodiment 3

[0037] (1) After drying the remaining dilute sludge with a moisture content of 88% and an ash content of 45% for 24 hours, grind it into a 250-mesh sludge powder, and make a mass ratio of 1:45 and a particle size of 200-mesh pyrolusite powder Mix evenly with sludge powder, add zinc chloride and dilute sulfuric acid composite activator, wherein the volume of zinc chloride and dilute sulfuric acid is 4:1, the concentration of zinc chloride is 5mol / L, and the mass fraction of dilute sulfuric acid is 25 %, ultrasonically mixed for 3 hours, left to stand for 24 hours, dried and activated at 100°C for 36 hours, placed in a tube furnace at 600°C, carbonized at high temperature for 2 hours, cooled and washed to neutral to obtain soft manganese composite sludge activated carbon.

[0038] (2) 250 purpose sludge powders are pyrolyzed under an ammonia atmosphere to form sludge activated carbon powders, and by weight, the sludge activated carbon powders with a mass ratio of 45 parts are imm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com