Production process for high purity manganese sulfate through reduction with pyrolusite powder as raw material

A production method and technology of manganese sulfate, applied in manganese sulfate and other directions, can solve the problems of consumption of impurity removal agent, disadvantage, and reduce production cost, and achieve high controllability and reproducibility of quality, convenient operation, and guaranteed quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

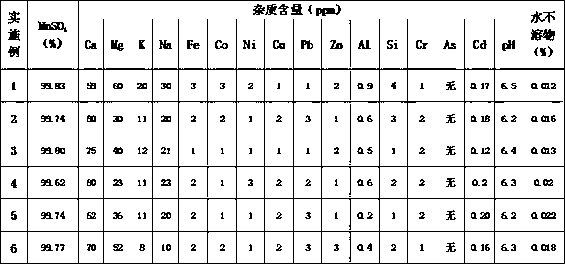

Examples

Embodiment 1

[0019] a. Removal of impurities such as calcium, magnesium, potassium and sodium: leaching pyrolusite with concentrated sulfuric acid and deionized water. The weight concentration of concentrated sulfuric acid is 98%, and the weight ratio of concentrated sulfuric acid, deionized water and soft iron ore is 1:1:2. Soak for 2 hours under stirring, filter, and wash the filter residue twice with hot deionized water at 40°C that is 4 times the weight of the filter residue;

[0020] b. Reduction leaching: add deionized water to make the filter residue washed twice in step a into a slurry, the weight of deionized water added is 1 times the weight of the filter residue, add 98% sulfuric acid and 20% hydrogen peroxide and stir for leaching for 1 hour, Filter to obtain manganese sulfate solution;

[0021] c. Primary crystallization: use the manganese sulfate solution that steam jacket heating step b obtains, evaporate water, concentrate the manganese sulfate solution to 600g / L, let sta...

Embodiment 2

[0024] a. Removal of impurities such as calcium, magnesium, potassium and sodium: leaching pyrolusite with concentrated sulfuric acid and deionized water. The weight concentration of concentrated sulfuric acid is 95%, and the weight ratio of concentrated sulfuric acid, deionized water and soft iron ore is 1:1:2. Soak for 2.5 hours under stirring, filter, and wash the filter residue twice with hot deionized water at 45°C that is 4 times the weight of the filter residue;

[0025] b. Reduction leaching: add deionized water to adjust the filter residue after twice washing in step a into a slurry, the weight of deionized water added is 1 times the weight of the filter residue, add concentrated sulfuric acid with a weight concentration of 90% and a weight concentration of 30% Hydrogen peroxide was stirred and leached for 2 hours, and the weight ratio added was sulfuric acid: hydrogen peroxide: filter residue = 0.7:1:1, filtered to obtain manganese sulfate solution;

[0026] C. Pri...

Embodiment 3

[0029] a. Removal of impurities such as calcium, magnesium, potassium and sodium: leaching pyrolusite with concentrated sulfuric acid and deionized water. The weight concentration of concentrated sulfuric acid is 95%, and the weight ratio of concentrated sulfuric acid, deionized water and soft iron ore is 1:1:2. Soak for 3 hours under stirring, filter, and wash the filter residue twice with hot deionized water at 50°C that is 4 times the weight of the filter residue;

[0030] b. Reduction leaching: add deionized water to make the filter residue after twice washing in step a into a slurry, add deionized water to 1 times the weight of the filter residue, add sulfuric acid with a weight concentration of 95% and 27% hydrogen peroxide and stir for leaching for 2.5 hours , filtered to obtain manganese sulfate solution;

[0031] c. Primary crystallization: use the manganese sulfate solution obtained in heating step b with a power supply, evaporate the water, concentrate the mangane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com