Method for extracting manganese from manganese-enriched slag

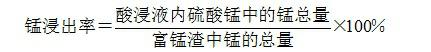

A manganese-rich slag and leaching technology, applied in the direction of improving process efficiency, can solve problems such as affecting manganese leaching rate, complex separation process, and difficulty in manganese salt separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A method for leaching manganese from manganese-rich slag, the leaching agent of the method is sulfuric acid, characterized in that the method comprises the following steps:

[0013] ① Put manganese-rich slag into the stirring tank, add sodium hydroxide solution, heat and stir at a constant speed; wherein, the concentration of sodium hydroxide solution is 6-9 mol / L, manganese-rich slag: sodium hydroxide solution = 1kg: 5~ 12L, the temperature during stirring is controlled between 60-90°C;

[0014] Those skilled in the art know that in most cases, before putting the manganese-rich slag into the stirring tank, the manganese-rich slag to be used should be pulverized. In the following verification example, the manganese-rich slag used in the test will be crushed to a particle size of 200 mesh sieve (75 microns). Those skilled in the art can understand that when the concentration of sodium hydroxide solution is selected as a lower limit or a value close to the lower limit, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com