Pressurizing and reductive leaching method of pyrolusite powder

A technology of pyrolusite powder and leaching, which is applied in the field of manganese hydrometallurgy and hydrometallurgy, can solve the problems of unsuitable low-grade pyrolusite treatment, serious environmental pollution, and strong corrosion of materials, and achieve low material prices and high process efficiency. Simple process and high leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

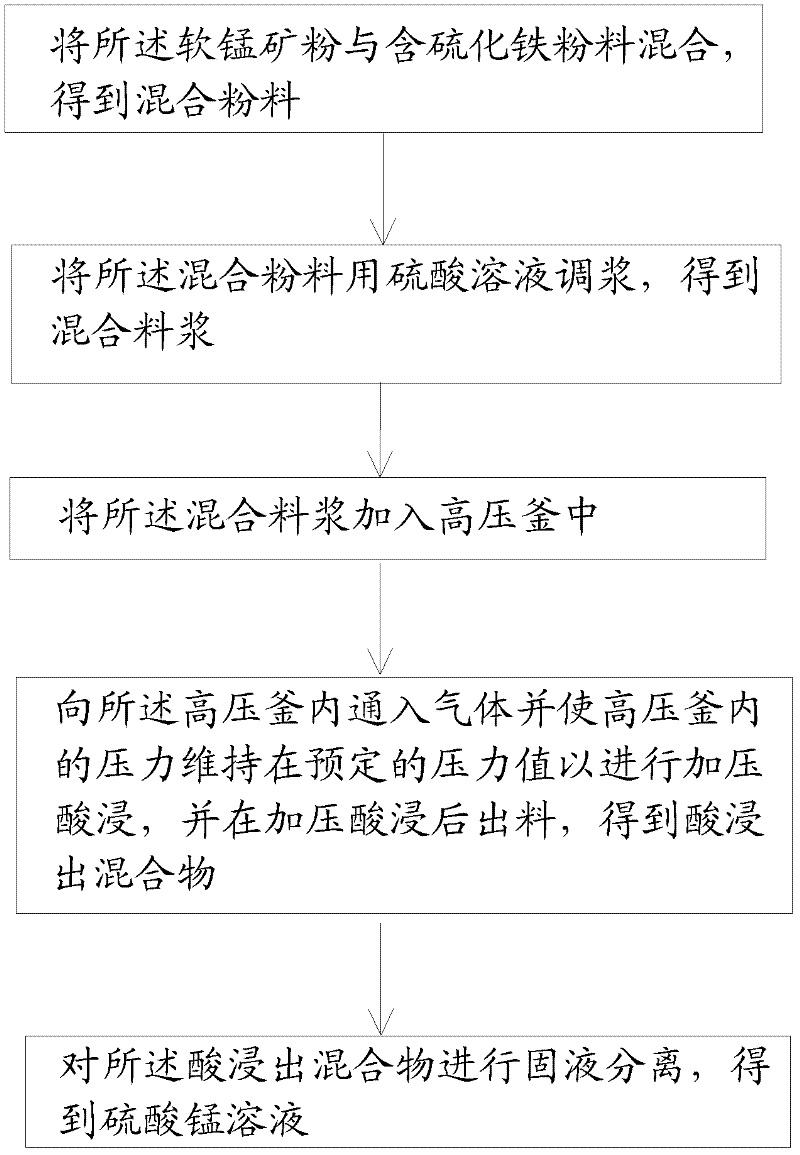

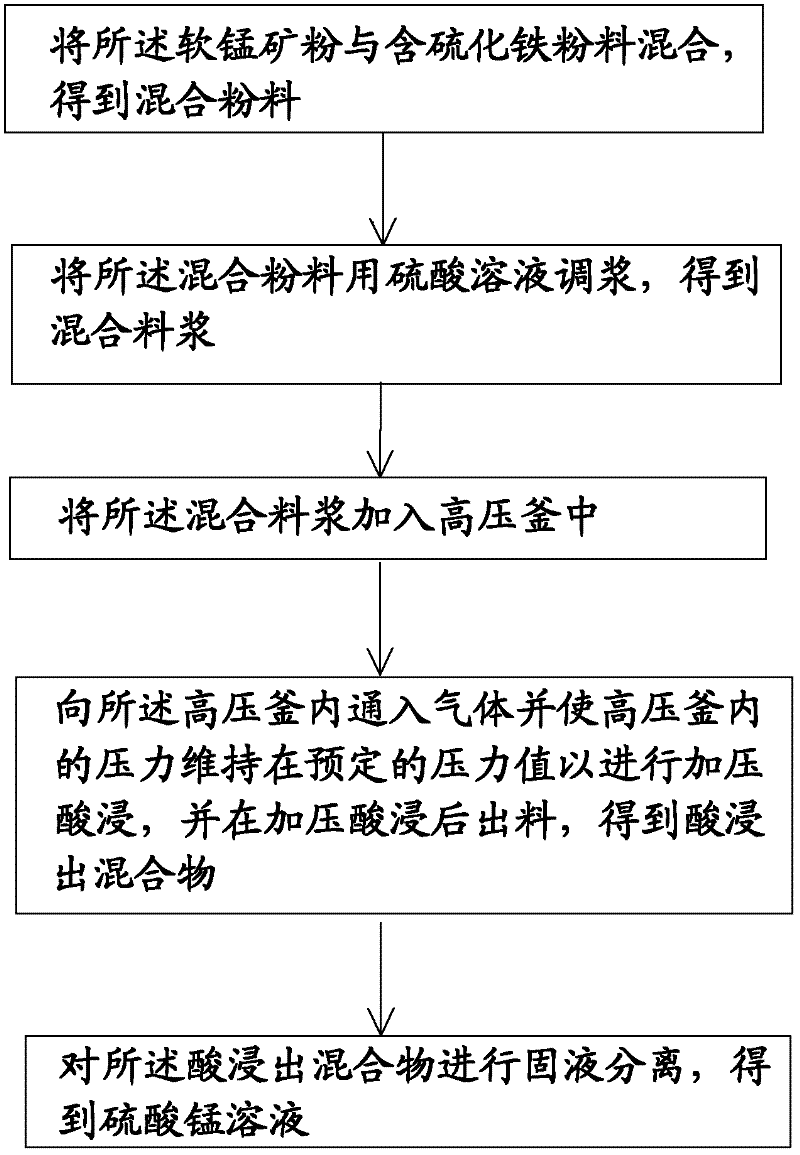

Method used

Image

Examples

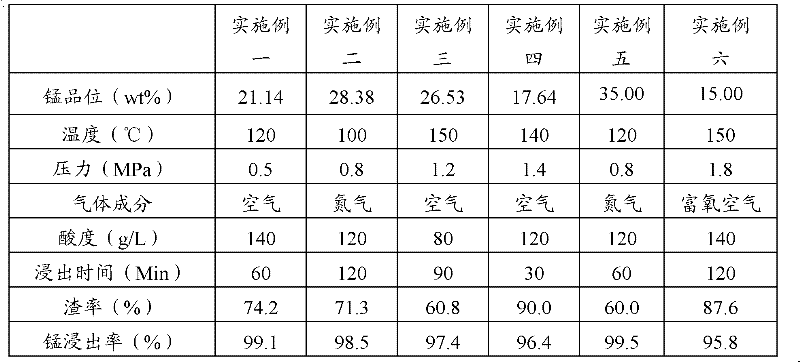

Embodiment 1

[0054] Embodiment 1: The low-grade pyrolusite contains 21.14wt% manganese.

[0055] Mix low-grade pyrolusite powder containing 21.14% manganese with finely ground pyrite powder, and mix the mixed mineral powder with a sulfuric acid solution with an acid concentration of 140g / L; add the slurry to 2L of titanium In the acid-resistant autoclave, continuously feed compressed air to maintain the pressure in the autoclave at 0.5MPa and the temperature at 120°C for pressure leaching, and the leaching time is 60min. After leaving the kettle, solid-liquid separation is carried out to obtain manganese sulfate solution.

Embodiment 2

[0056] Example 2: The low-grade pyrolusite contains 28.38% manganese. .

[0057] Mix low-grade pyrolusite powder containing 28.38% manganese with finely ground pyrite powder, and mix the mixed mineral powder with a sulfuric acid solution with an acid concentration of 120g / L; add the slurry to 2L of titanium In the acid-resistant autoclave, continuously feed nitrogen to maintain the pressure in the autoclave at 0.8Mpa and the temperature at 100°C, and perform pressure leaching for 120 minutes. After leaving the kettle, solid-liquid separation is carried out to obtain manganese sulfate solution.

Embodiment 3

[0058] Example 3: The low-grade pyrolusite contains 26.53% manganese.

[0059] Mix the low-grade pyrolusite powder containing 26.53% manganese with the finely ground pyrite powder, and mix the mixed mineral powder with a sulfuric acid solution with an acid concentration of 80g / L; add the slurry to 2L of titanium In the acid-resistant autoclave, continuously feed compressed air to maintain the pressure in the autoclave at 1.2Mpa and the temperature at 150°C, and perform pressure leaching for 90 minutes. After leaving the kettle, solid-liquid separation is carried out to obtain manganese sulfate solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com