Hydrothermal preparation method for carbon cladded nanometer ferriferrous oxide particles

A carbon-coated ferric oxide and nanoparticle technology, which is applied in the preparation/purification of carbon, iron oxide/iron hydroxide, nanotechnology, etc., can solve the problems of large product particle size and complicated preparation process, and achieve the goal of preparation The method has the advantages of simple process, reversible lithium storage characteristics, and the effect of improving water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

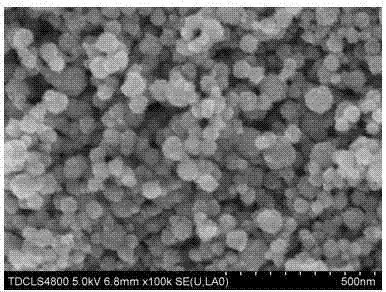

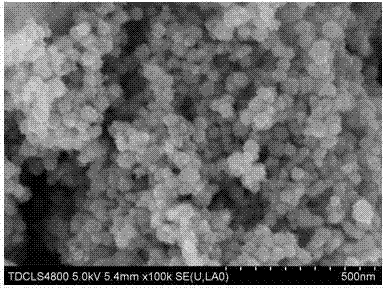

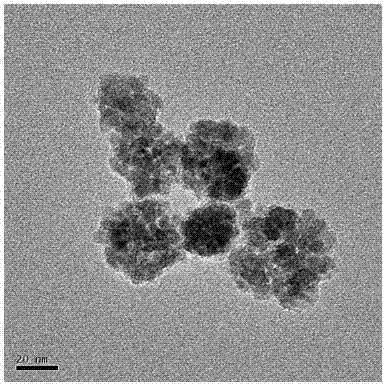

[0024] Weigh 0.9g of glucose and dissolve in 40ml of deionized water, weigh 1.212g of ferric nitrate and dissolve in 2ml of deionized water, quickly mix the above two solutions to form a solution, and use an ultrasonic device with a power of 400W for 15min to mix evenly . Take 30ml of the mixed solution and put it into a reaction kettle with polytetrafluoroethylene as the substrate, and react at a constant temperature of 180°C for 3h. After the reaction was completed, the reaction solution in the reactor was cooled to room temperature. Put the reaction solution into a centrifuge, centrifuge at a speed of 10000 r / min for 10 min, remove the supernatant and add deionized water, then centrifuge at a speed of 8000 r / min for 15 min, then remove the supernatant and add deionized water Finally, after centrifugation at a speed of 8000 r / min for 15 min, the supernatant was removed, and the precipitate obtained by centrifugation was redispersed in deionized water, and then freeze-dried ...

Embodiment 2

[0026] Weigh 0.9g of glucose and dissolve in 40ml of deionized water, weigh 1.212g of ferric nitrate and dissolve in 2ml of deionized water, quickly mix the above two solutions to form a solution, and use an ultrasonic device with a power of 400W for 15min to mix evenly . Take 30ml of the mixed solution and put it into a reaction kettle with polytetrafluoroethylene as the substrate, and react at a constant temperature of 190°C for 3h. After the reaction was completed, the reaction solution in the reactor was cooled to room temperature. Put the reaction solution into a centrifuge, centrifuge at a speed of 10000 r / min for 10 min, remove the supernatant and add deionized water, then centrifuge at a speed of 8000 r / min for 15 min, then remove the supernatant and add deionized water Finally, after centrifugation at a speed of 8000 r / min for 15 min, the supernatant was removed, and the precipitate obtained by centrifugation was redispersed in water, and after freeze-drying, a monod...

Embodiment 3

[0028]Weigh 0.9g of glucose and dissolve in 40ml of deionized water, weigh 1.212g of ferric nitrate and dissolve in 2ml of deionized water, quickly mix the above two solutions to form a solution, and use an ultrasonic device with a power of 400W for 15min to mix evenly . Take 37.5ml of the mixed solution and put it into a reaction kettle with polytetrafluoroethylene as the substrate, and react at a constant temperature of 190°C for 5h. After the reaction was completed, the reaction solution in the reactor was cooled to room temperature. Put the reaction solution into a centrifuge, centrifuge at a speed of 10000 r / min for 10 min, remove the supernatant and add deionized water, then centrifuge at a speed of 10000 r / min for 10 min, then remove the supernatant and add deionized water Finally, after centrifugation at a speed of 8000 r / min for 15 min, the supernatant was removed, and the precipitate obtained by centrifugation was redispersed in water, and monodisperse carbon-coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com