Method for preparing single-layer or multi-layer graphene through chemical vapor deposition

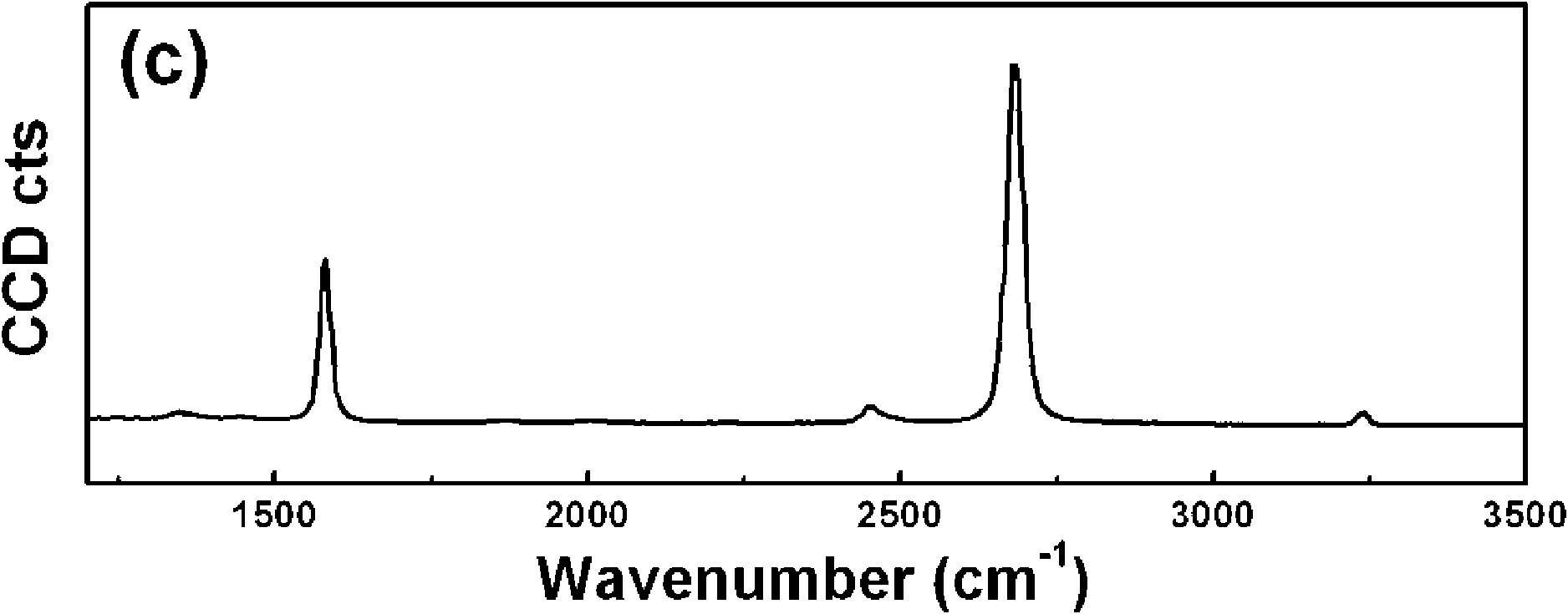

A technology of chemical vapor deposition and multi-layer graphene, which is applied in the direction of single-layer graphene, chemical instruments and methods, graphene, etc., to achieve the effect of good light transmission, extremely high crystal quality, and low defect peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

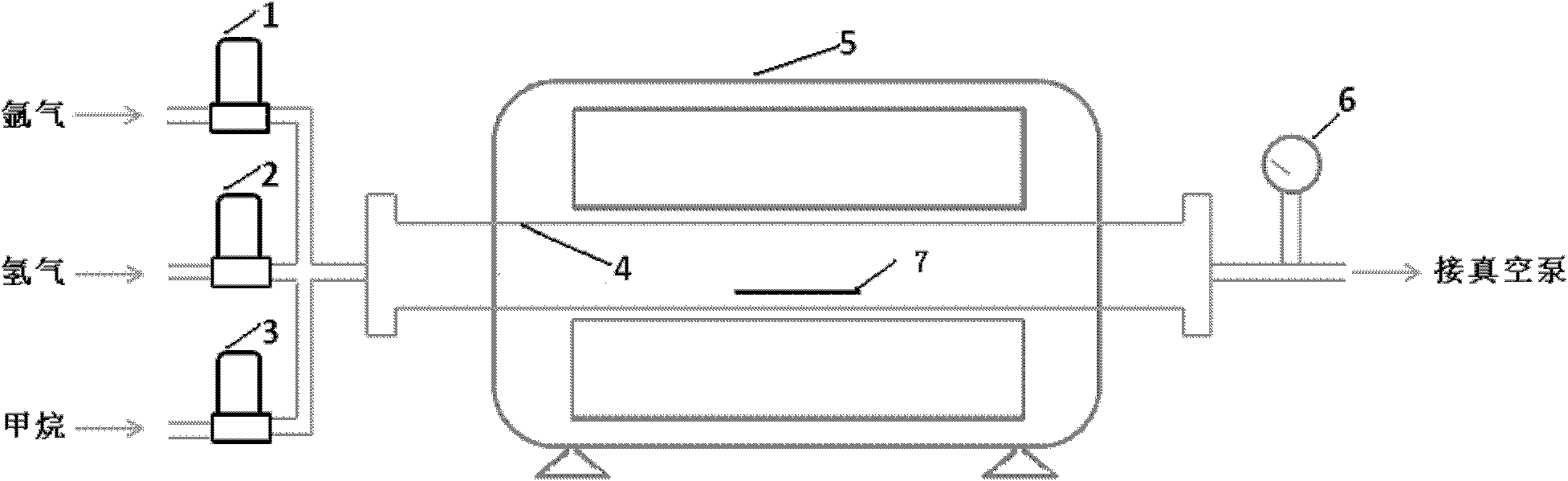

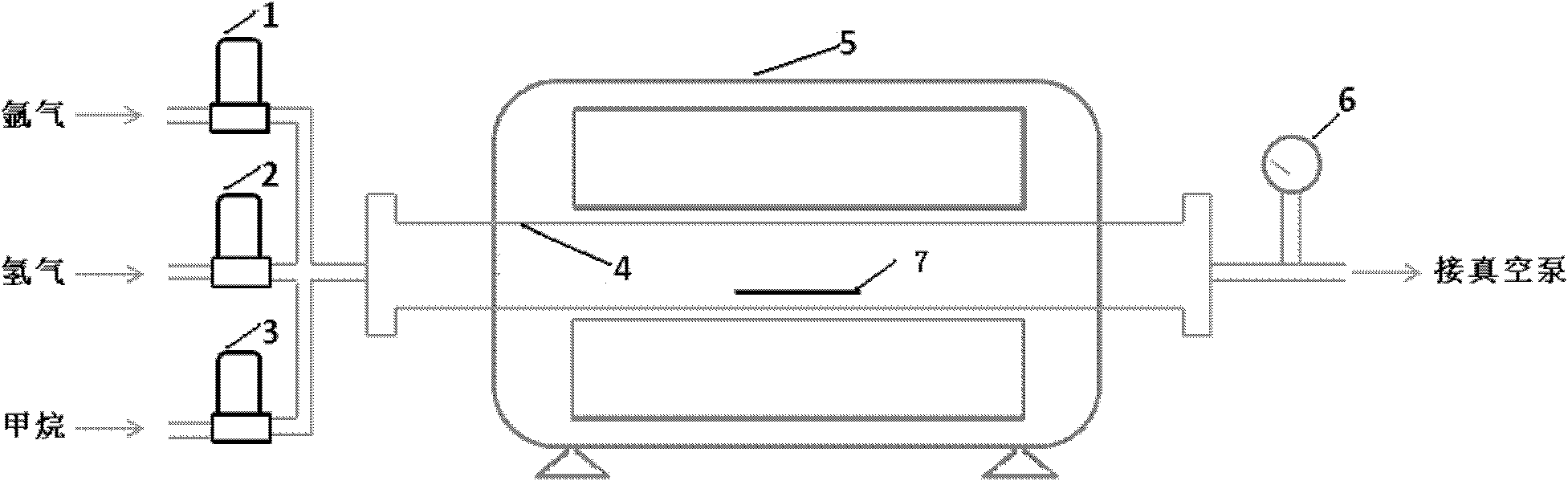

[0035] Prepare graphene thin film on copper foil by chemical vapor deposition, comprising the following preparation steps:

[0036] 1. Take a 25 micron thick copper foil substrate 7 and place it in the quartz tube 4;

[0037] 2. Turn on the vacuum pump to pump the air pressure of the quartz tube 4 to the ultimate vacuum state of 4×10 -2 Torr;

[0038] 3. Set the inert gas flowmeter 1 to 5 sccm, and inject argon into the vacuum chamber;

[0039] 4. After 5 minutes, close the valve of the inert gas flow meter 1, and pump the air pressure of the tube furnace 5 to the limit of 8×10 -2 Torr;

[0040] 5. Repeat step (3) and step (4) for 3 times; until the residual oxygen in the quartz tube 4 is driven off until the partial pressure of oxygen is less than 1×10 -6 Torr;

[0041] 6. Set the hydrogen flow meter 2 to 5 sccm, and inject hydrogen into the vacuum chamber;

[0042] 7. The temperature of the tube furnace 5 is raised to 1000 degrees Celsius;

[0043] 8. The carbon sou...

Embodiment 2

[0048] Prepare a graphene film on a nickel film by chemical vapor deposition, comprising the following preparation steps:

[0049] 1. Evaporate a nickel film with a thickness of 500 nm on the silicon substrate 7 by magnetron sputtering; place the silicon substrate 7 on which the nickel film has been evaporated in the quartz tube 4;

[0050] 2. Turn on the vacuum pump to pump the air pressure of the quartz tube 4 to the ultimate vacuum state of 8×10 -2 Torr;

[0051] 3. Set the inert gas flow meter 1 to 50 sccm, and inject helium into the vacuum chamber;

[0052] 4. After 5 minutes, close the valve of the inert gas flow meter 1, and pump the air pressure of the tube furnace 5 to the limit of 4×10 -2 Torr;

[0053] 5. Repeat step (3) and step (4) twice; until the residual oxygen in the quartz tube 4 is driven off until the oxygen partial pressure is less than 1×10 -6 Torr;

[0054] 6. Set the hydrogen flow meter 2 to 50 sccm, and inject hydrogen into the vacuum chamber;

...

Embodiment 3

[0061] Prepare a graphene film on a nickel film by chemical vapor deposition, comprising the following preparation steps:

[0062] 1. Evaporate a nickel film with a thickness of 500 nm on the silicon substrate 7 by magnetron sputtering; place the silicon substrate 7 on which the nickel film has been evaporated in the quartz tube 4;

[0063] 2. Turn on the vacuum pump to pump the air pressure of the quartz tube 4 to the ultimate vacuum state of 6×10 -2 Torr;

[0064] 3. Set the inert gas flow meter 1 to 100 sccm, and inject nitrogen into the vacuum chamber;

[0065] 4. After 5 minutes, close the valve of the inert gas flow meter 1, and pump the air pressure of the tube furnace 5 to the limit of 6×10 -2 Torr;

[0066] 5. Repeat step (3) and step (4) twice; until the residual oxygen in the quartz tube 4 is driven off until the oxygen partial pressure is less than 1×10 -6 Torr;

[0067] 6. Set the hydrogen flow meter 2 to 100 sccm, and inject hydrogen into the vacuum chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com