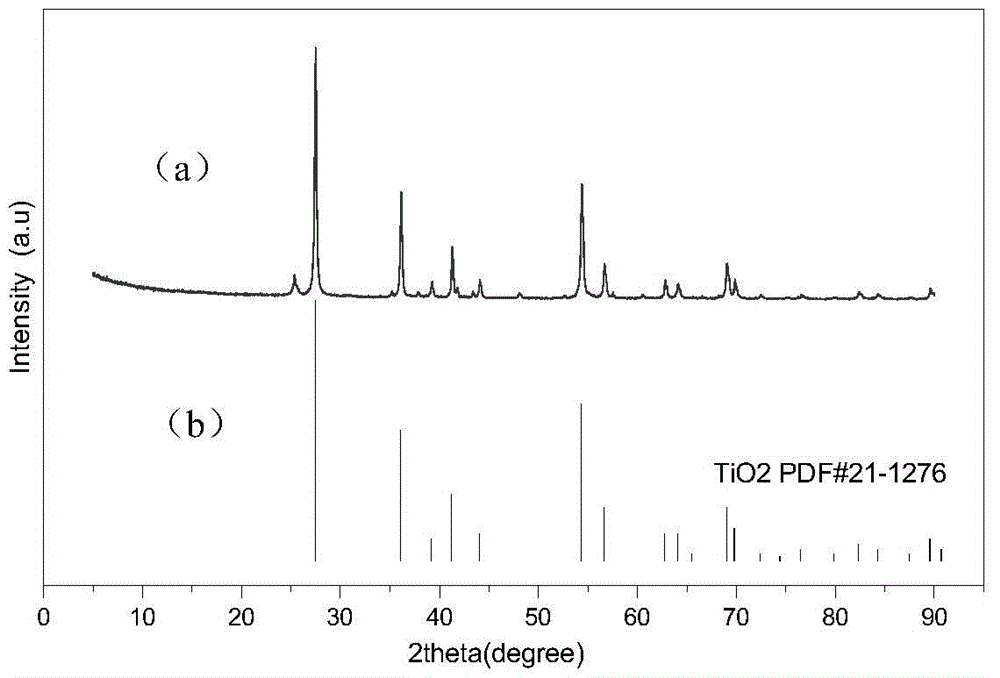

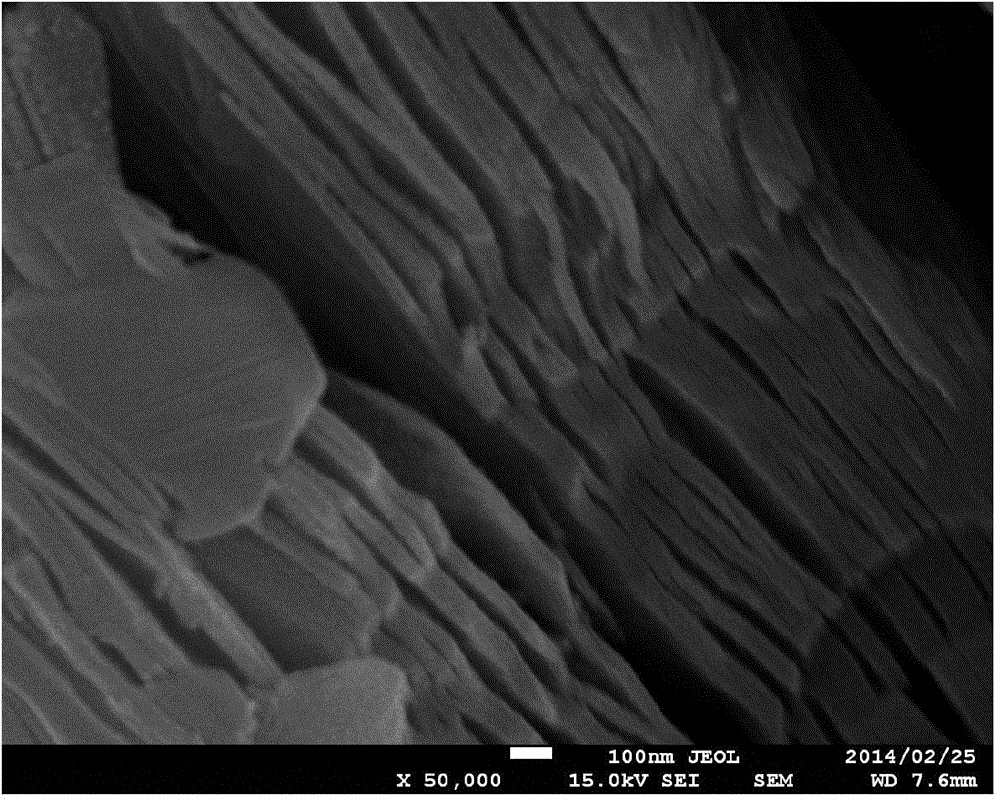

Preparation method for two-dimensional sheet-shaped titanium dioxide nanosheet material

A technology of titanium dioxide and nanosheets, which is applied in the field of two-dimensional sheet titanium dioxide nanomaterials and its preparation, can solve the problems of complex process flow, easy agglomeration of nanopowder, and difficult operation, and achieve stable process parameters, good crystallinity, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Three-dimensional layered Ti with a particle size of 100 mesh 3 AlC 2 Soak 6g of the powder into 100ml of 45wt% HF aqueous solution at room temperature, and stir magnetically at 1000r / min for 20 hours to obtain a suspension. Leave the suspension to separate layers, remove the supernatant with a straw, and then add 100ml of water, then stir evenly, then let it stand until the layers are separated, use a straw to remove the supernatant, then add about 100ml of water, stir evenly, and then centrifuge at 3000r / min for 30min to remove large particles. Then centrifuge at 8000r / min for 10min, collect the powder and dry it. Place the dried powder in an alumina crucible (other ceramic crucibles are also available, such as zirconia crucibles, as long as they can be used at 1000 ° C and do not react with the powder, the same is true in the remaining embodiments), and then Place the crucible in a clean tube furnace. The vacuum degree of the tube furnace is set to 5Pa, the heating...

Embodiment 2

[0027] Three-dimensional layered Ti with a particle size of 250 mesh 3 AlC 2Soak 8g of the powder in 100ml of 55wt% HF aqueous solution at room temperature, and stir magnetically at 2500r / min for 30 hours to obtain a suspension. Leave the suspension to separate layers, suck off the supernatant with a straw, and then add to the precipitate Add 80ml of water to the sediment, then stir evenly, then let it stand until the layers are separated, suck the supernatant with a straw, then add about 80ml of water to the sediment, stir evenly, let it stand again until the layers are separated, and suck up the supernatant with a straw. Remove the supernatant, then add about 80ml of water to the sediment, centrifuge at 4500r / min for 20min to remove large particles, then centrifuge at 9500r / min for 20min, collect the powder and dry it. Put the dried powder in an alumina crucible, and then put it into a clean tube furnace. The vacuum degree of the tube furnace is set to 15Pa, the temperature...

Embodiment 3

[0029] Three-dimensional layered Ti with particle size less than 200 mesh 3 AlC 2 Soak 8g of the powder in 100ml of 50wt% HF aqueous solution at room temperature, stir magnetically at 3000r / min for 20 hours to obtain a suspension, leave the suspension to separate layers, use a straw to remove the supernatant, and then add to the sediment Add 100ml of water, then stir evenly, then let it stand until the layers are separated, use a straw to remove the supernatant, then add about 100ml of water, stir evenly, centrifuge at 4000r / min for 20min to remove large particles, then 9000r / min Centrifuge for 20 min, collect the powder and dry it. Put the dried powder in an alumina crucible, and then put it into a clean tube furnace. The vacuum degree of the tube furnace is set to 10Pa, the temperature rise rate is 10°C / min, the temperature is raised to 750°C, and then passed through different The inlet pipe is fed with argon and oxygen mixed gas, the total pressure in the furnace is 800Pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com