Preparation method of biomass-based nitrogenous porous carbon, porous carbon prepared by method and use thereof

A biomass, porous carbon technology, applied in the preparation/purification of carbon, chemical instruments and methods, carbon compounds, etc., can solve the problems of complicated synthesis process, large amount of use, high cost, etc. Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

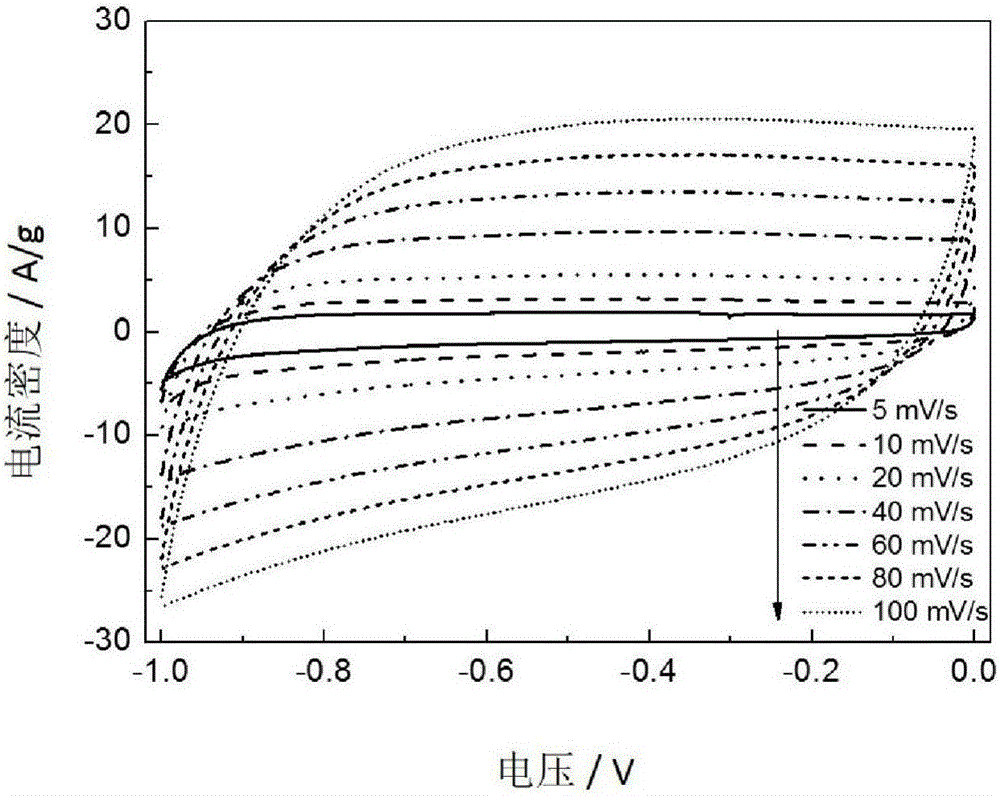

[0030] The preparation method of the nitrogen-doped porous carbon material according to the present invention is a hydrothermal method, and the porous nitrogen-doped carbon material synthesized by this method has a large specific surface area and abundant micro-mesoporous structure. The method uses renewable protein-rich biomass as raw material, without adding nitrogen source, to prepare nitrogen-doped porous carbon material in situ in one step, and the porous nitrogen-containing material has excellent electric double layer capacitance performance and good cycle stability.

[0031] Alkali is used as an activator in the chemical activation method of the prior art, but in order to make the final activated carbon product have sufficient micropore or mesoporous structure, it is often necessary to use a large amount of alkali as an activator, and the activator is usually doubled, or even several times the amount of biomass raw material. In comparison, the present invention adopts ...

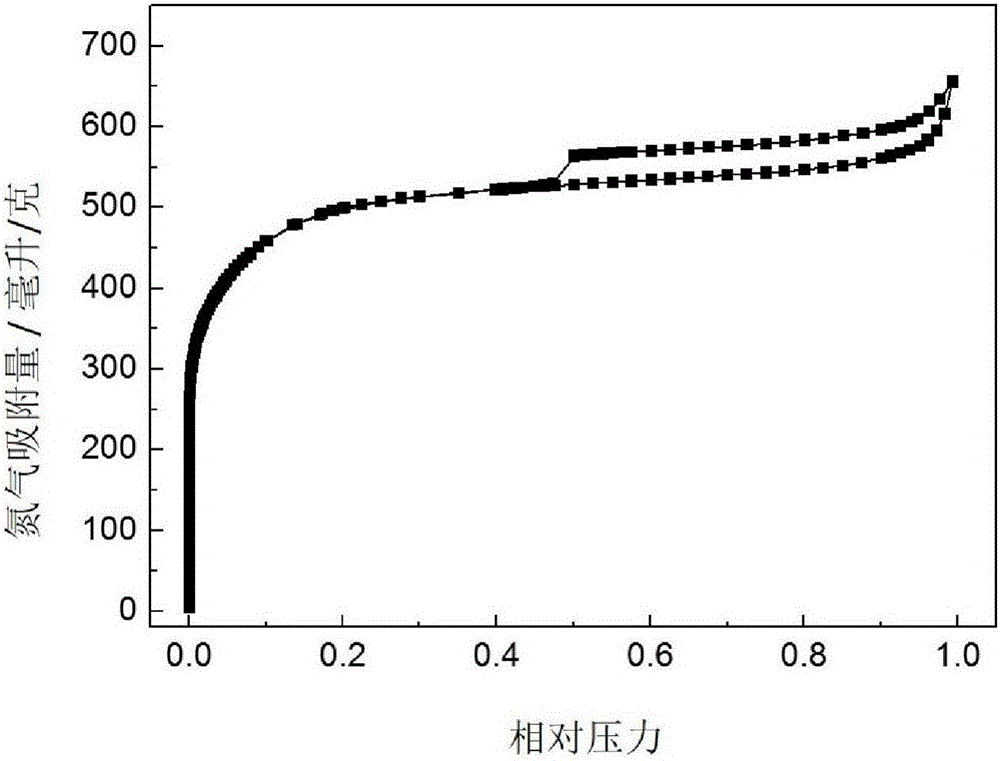

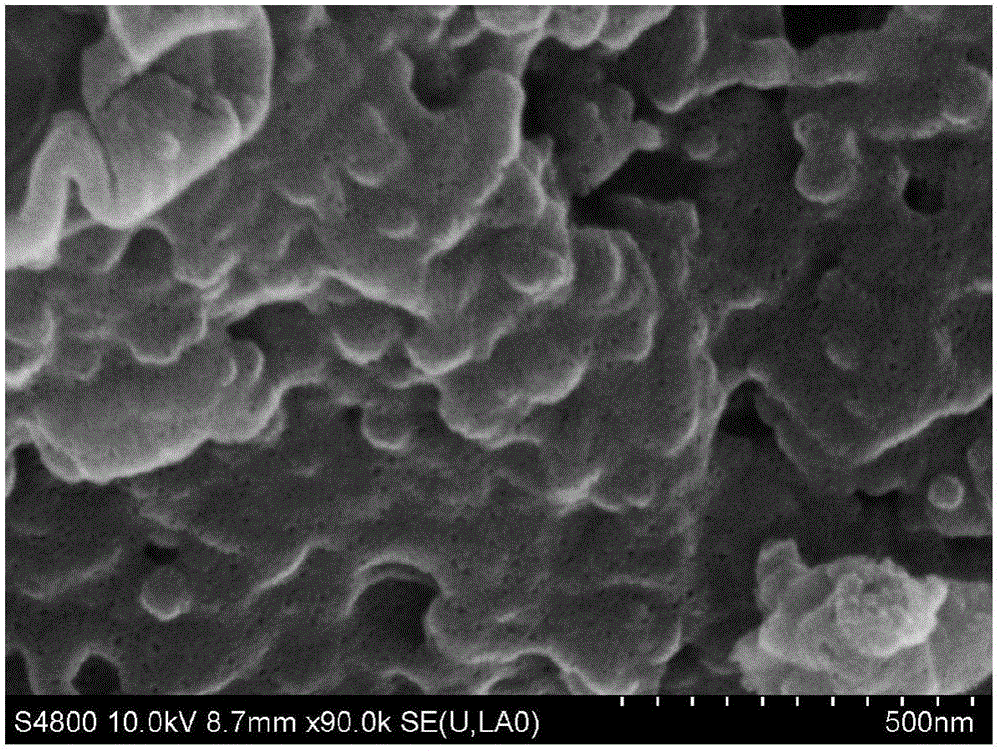

Embodiment 1

[0037] 1 kg of cleaned bamboo shoots was cut into pieces, heated to dryness in an oven at 70° C., and the obtained solid was ground into powder. Take 2g of powder and add it to 20mL of dilute sulfuric acid with a weight percentage of 0.5%, stir and mix evenly, then move to a hydrothermal reaction kettle, react at 210°C for 12 hours, filter, wash, and dry to obtain a brown solid. Afterwards, the obtained dried solid was calcined in a tube furnace in a nitrogen gas atmosphere, and kept at 800° C. for 8 hours. After the tube furnace dropped to room temperature, the sample was taken out to obtain a nitrogen-doped porous carbon material with a nitrogen content of about 2.9% and a specific surface area of 1893m 2 / g. figure 1 with figure 2 It is the BET and SEM result figure of the nitrogen-doped porous carbon material prepared according to the present embodiment, such as figure 1 with figure 2 As shown by the data, the material contains a well-developed micro- and meso-poro...

Embodiment 2

[0039] 1 kg of cleaned bamboo shoots was cut into pieces, heated to dryness in an oven at 70° C., and the obtained solid was ground into powder. Take 2g of powder and add it to 20mL of water (without adding acid), stir and mix evenly, then move to a hydrothermal reaction kettle, react at 210°C for 12 hours, filter, wash, and dry to obtain a brown solid. Afterwards, the obtained dried solid was calcined in a tube furnace in a nitrogen gas atmosphere, and kept at 900° C. for 8 hours. After the tube furnace dropped to room temperature, the sample was taken out to obtain a nitrogen-doped porous carbon material with a specific surface area of 935m 2 / g, the nitrogen content is 1.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com