Method for preparing durable cellulose fiber fabric with super-hydrophobic surface

A technology of cellulose fibers and super-hydrophobic surfaces, which is applied in fiber treatment, plant fibers, textiles and papermaking, etc., can solve the problems of high equipment requirements, unfavorable industrial production, and easy damage of rough surfaces, and achieve good durability, The effect of widening the range of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a durable cellulose fiber fabric with a superhydrophobic surface, using the following steps:

[0034] a.Modified SiO2 2 Preparation of composite sol

[0035](1) Mix the silicon source with the silane coupling agent and stir well to obtain a homogeneous transparent solution, wherein the silicon source is tetraethyl orthosilicate or sodium silicate, and the silane coupling agent is selected from γ-aminopropyl One of trimethoxysilane, γ-glycidyloxypropyltrimethoxysilane or γ-methacryloxypropyltrimethoxysilane;

[0036] (2) Fully mix deionized water and absolute ethanol to obtain a mixed transparent solvent;

[0037] (3) In the state of vigorous stirring, control the reaction temperature at 20°C to 60°C, slowly drop the solution obtained in step (1) into the solution obtained in step (2), and slowly Add the first catalyst, stabilize the pH value of 8-10, control the dropping speed, continue to stir vigorously for 2-4 hours, and obtain transparent m...

Embodiment 1

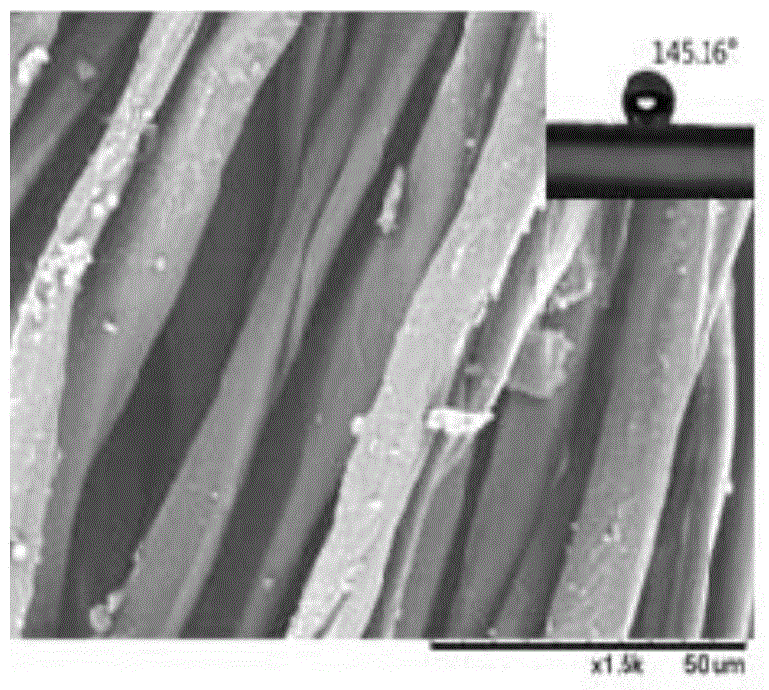

[0044] Under normal pressure at 30°C and under vigorous stirring, gradually drop the tetraethyl orthosilicate solution into the mixed solution of alcohol and water, and gradually add ammonia water to stabilize the pH value at 8-10, then add low surface energy substances, and continue to vigorously Stir for 1~2h to get SiO 2 Composite sol, cotton fabric impregnated with SiO 2 In the composite sol, the hydrophobic cotton fabric was obtained by two dipping and two padding, pre-baking at 80°C for 5 minutes, and baking at 150°C for 2 minutes. See the SEM image of cotton fabric and the superhydrophobic performance index figure 1 and shown in Table 1.

Embodiment 2

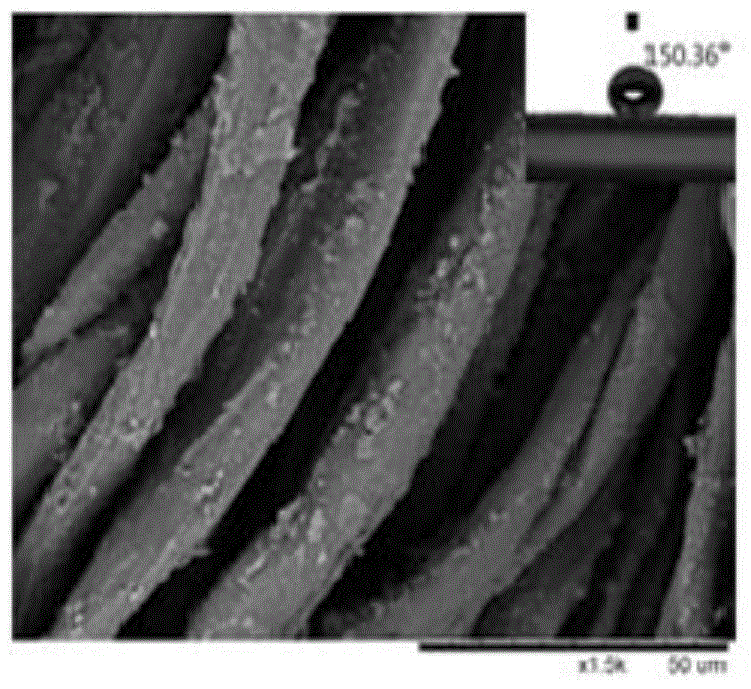

[0046] Under normal pressure at 30°C and under vigorous stirring, gradually drop tetraethyl orthosilicate and silane coupling agent solution into the mixed solution of alcohol and water, and gradually add ammonia water to stabilize the pH value of 8-10, and then add low surface Energy substances, continue to stir vigorously for 1 to 2 hours to obtain modified SiO 2 Composite sol, cotton fabric impregnated with modified SiO 2 In the composite sol, the superhydrophobic cotton fabric was obtained by two dipping and two padding, pre-baking at 80°C for 5 minutes, and baking at 150°C for 2 minutes. See the SEM image of cotton fabric and the superhydrophobic performance index figure 2 and shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com