Molded surface fastener and cushion body formed integrally with the molded surface fastener

a technology of molded surface and cushion body, which is applied in the field of surface fasteners, can solve the problems that the rock wool that requires a number of manufacturing processes cannot meet the demand, the invasion of the forming region of the engaging element is completely blocked, and the forming region of the engaging element is likely to be damaged, so as to achieve the effect of increasing the engagement ratio, improving the engagement force, and increasing the binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

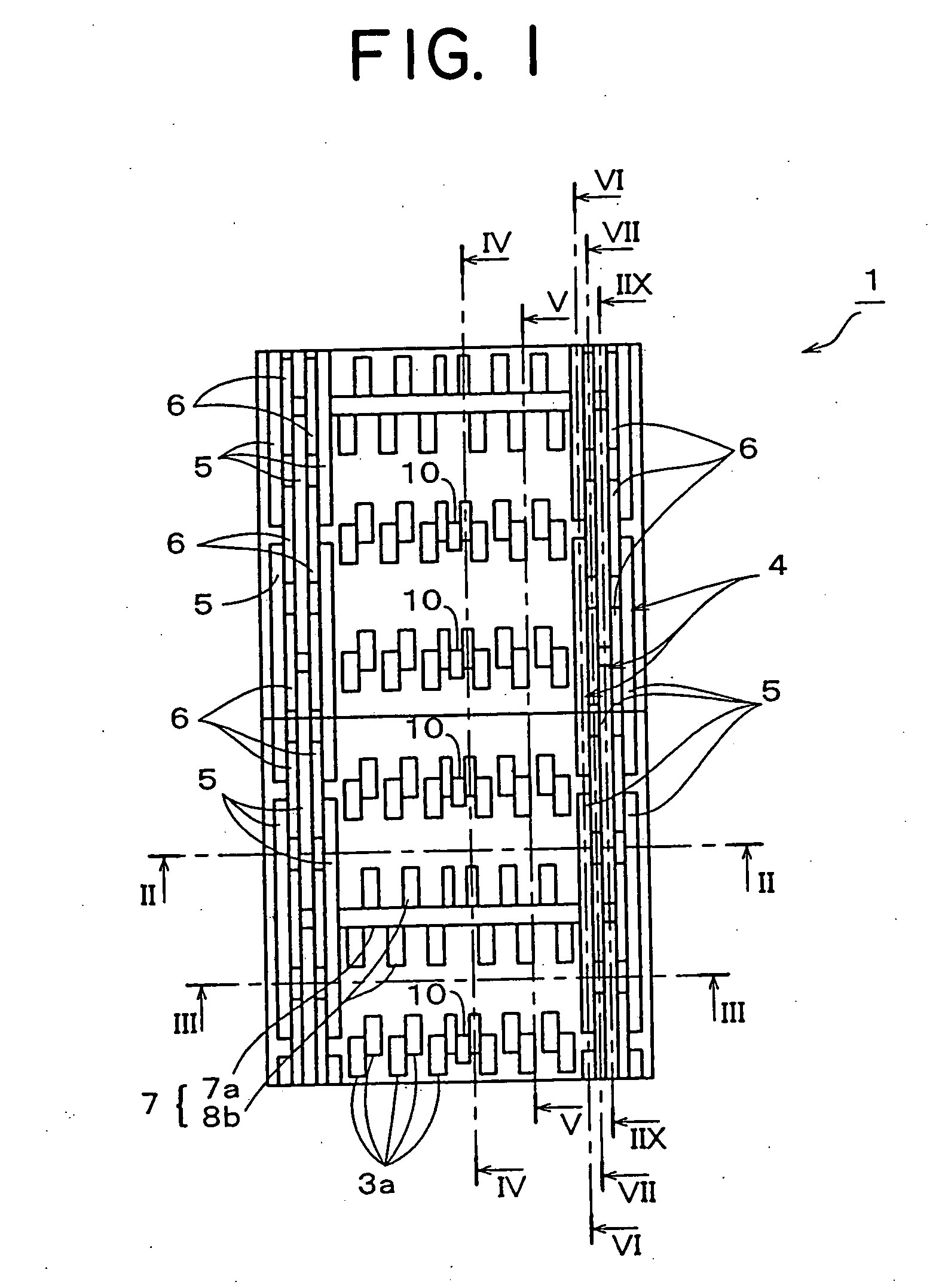

[0043] Hereinafter, embodiments of the present invention will be described specifically with reference to the accompanying drawings. FIGS. 1 to 8 show the present invention.

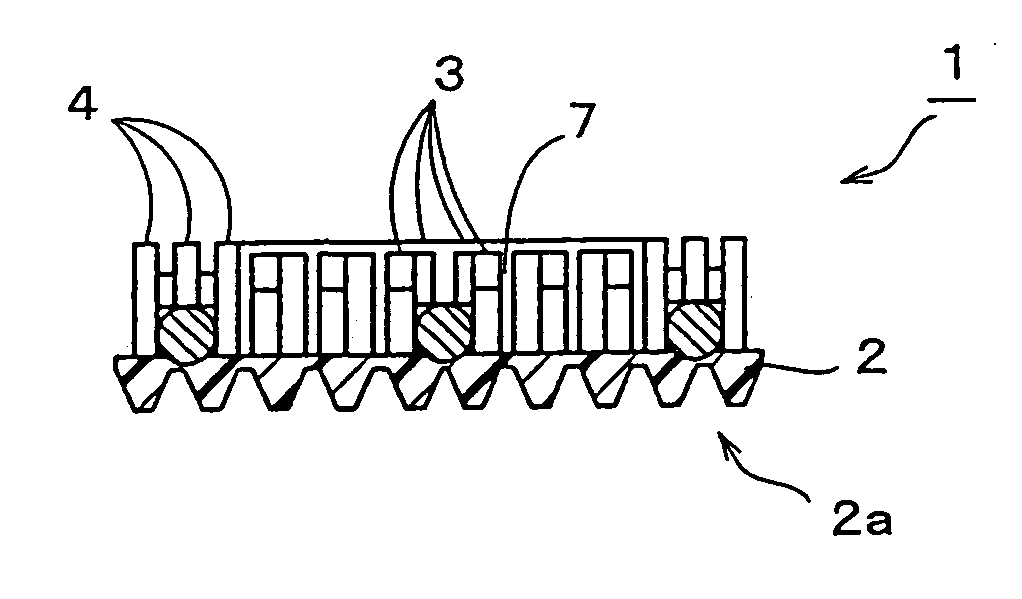

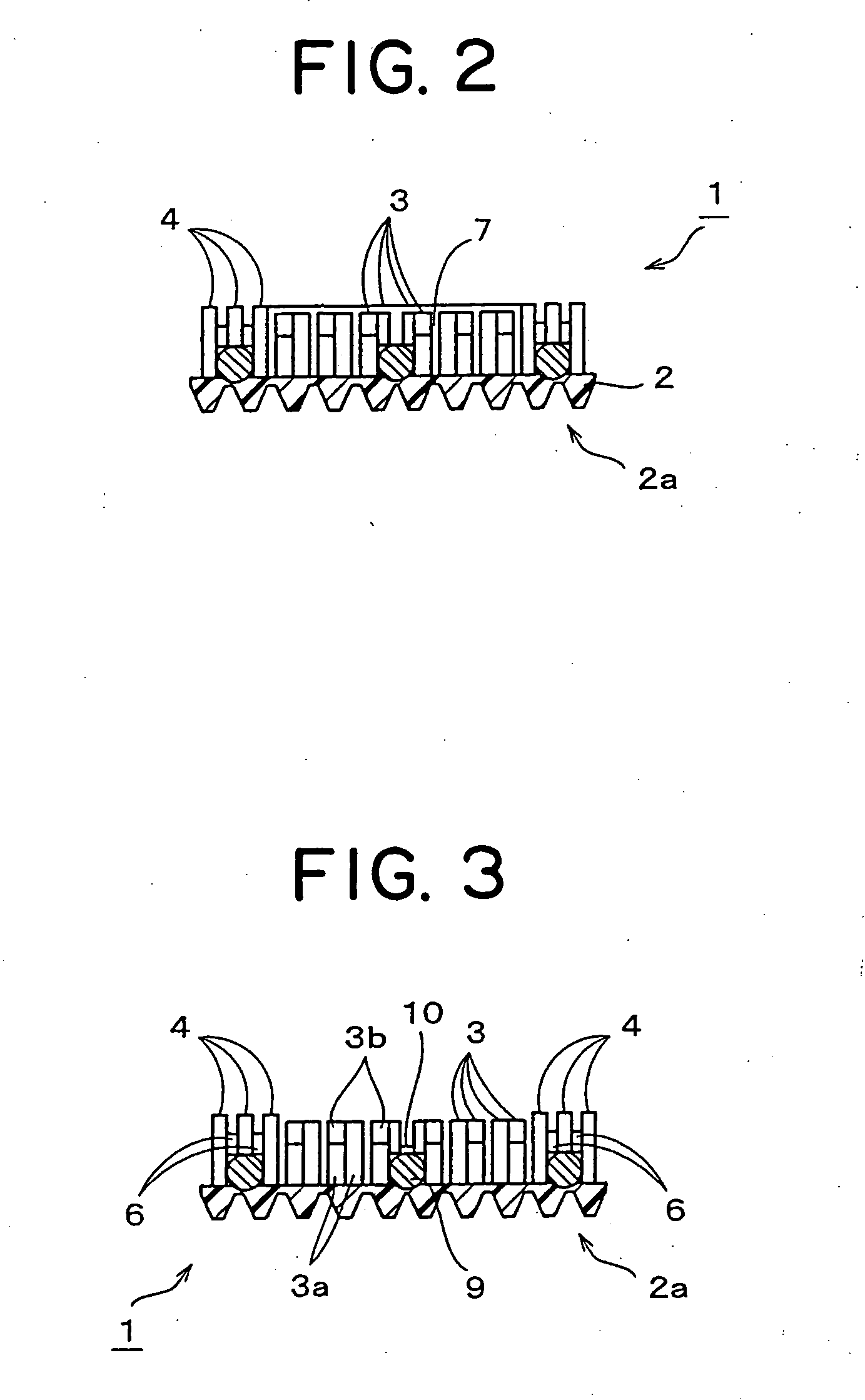

[0044] As shown in FIG. 1, a number of engaging elements 3 in a hook-like shape are formed in an engaging-element forming region except both side edge portions on one surface of a base member 2 in a flat shape of a molded surface fastener 1 in a tape-like shape of this embodiment, and three rows of longitudinal wall portions 4 are erected as first resin invasion preventing means of the present invention on both side edge portions of the base member 2 along a longitudinal direction such that they are arranged linearly in parallel. As shown in FIGS. 1-3, 6 and 8, these longitudinal wall portions 4 are constituted of a number of division wall portions 5 divided at a predetermined pitch along the longitudinal direction. The three rows of the longitudinal wall portions 4 are deflected about half a pitch in terms of th...

second embodiment

[0062] FIGS. 9 to 12 show the present invention. This second embodiment is different from the first embodiment in structures of the division wall pieces 6 and the engaging elements 3 disposed in a pair such that they are arranged in the width direction. Because another structure is substantially not different from the first embodiment, the same designations and reference numerals as the first embodiment are used as designations and reference numerals of components other than the different ones in a following description.

[0063] According to this embodiment, instead of the division wall pieces 6, a block piece 11 equal to the block piece 10 for joining two pairs of engaging elements 3 disposed in the central portion in the width direction of the molded surface fastener 1 of the first embodiment is formed. As shown in FIGS. 9 and 11, two rows of the division wall portions 5 on outermost and innermost sides of the three longitudinal wall portions 4 located on extensions of the engaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com