Three-dimensional (3D) printing method and 3D printing system

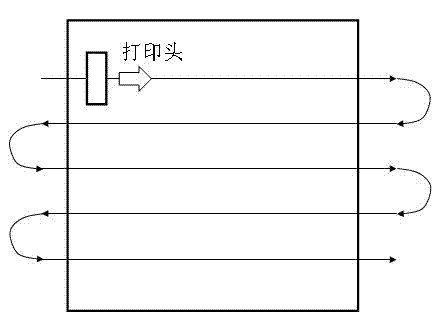

A 3D printing and printing head technology, applied in the field of 3D printing systems, can solve problems such as long time intervals and the influence of interlayer bonding force, and achieve the effects of shortening printing intervals, enhancing interlayer bonding force, and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

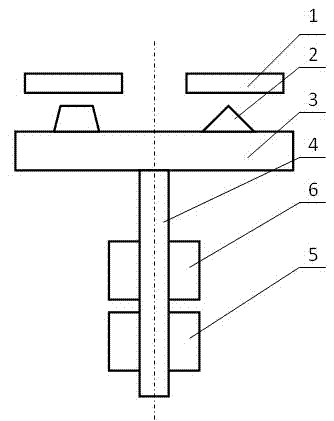

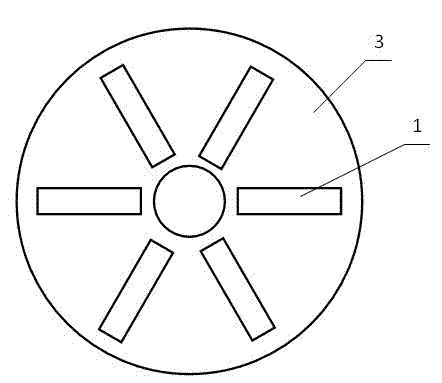

[0036] Embodiment one: see figure 2 As shown, a 3D printing system includes a circular printing platform 3, and the circular printing platform 3 is fixedly connected with a central support rod 4, and is provided with a rotary drive mechanism 5 and a lifting drive mechanism 6, and the rotary drive mechanism 5 The central support rod 4 is driven and connected, so that the circular printing platform 3 rotates around the rotation axis of the center of the circle, and the lifting drive mechanism 6 is driven and connected with the central support rod 4, so that the circular printing platform is raised and lowered in a direction parallel to the rotation axis ; A synchronous control mechanism is provided to connect and control the rotation drive mechanism 5 and the lifting drive mechanism 6 .

[0037] In this embodiment, the rotary drive mechanism 5 can be realized by any existing technology, for example, gear drive, synchronous belt drive, motor shaft direct drive, etc. In order to ...

Embodiment 2

[0041] Embodiment two: see Figure 4 As shown, a 3D printing system has the same basic structure as that of Embodiment 1. In this embodiment, the rotation drive mechanism 5 and the lift drive mechanism 6 are integrated and realized by a set of drive mechanisms.

Embodiment 3

[0042] Embodiment three: see Figure 5 As shown, a 3D printing system, the basic structure is the same as that of Embodiment 1, the difference is that the circular printing platform is fixedly connected with a central support rod 4, and the rotation drive mechanism 5 drives and connects the central support rod 4; A rotary sliding mechanism 7 is slidably connected to the bottom of the circular printing platform, and the lifting drive mechanism 6 drives the circular printing platform 3 to lift through the rotary sliding mechanism 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com