Zinc layer surface passivating treatment liquid

A passivation treatment, zinc layer technology, applied in the direction of metal material coating process, etc., can solve the problems of inability to meet the requirements of bright white color of galvanized layer, inability to meet the requirements of working conditions, environmental pollution, etc. Excellent, good anti-white rust performance, excellent corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

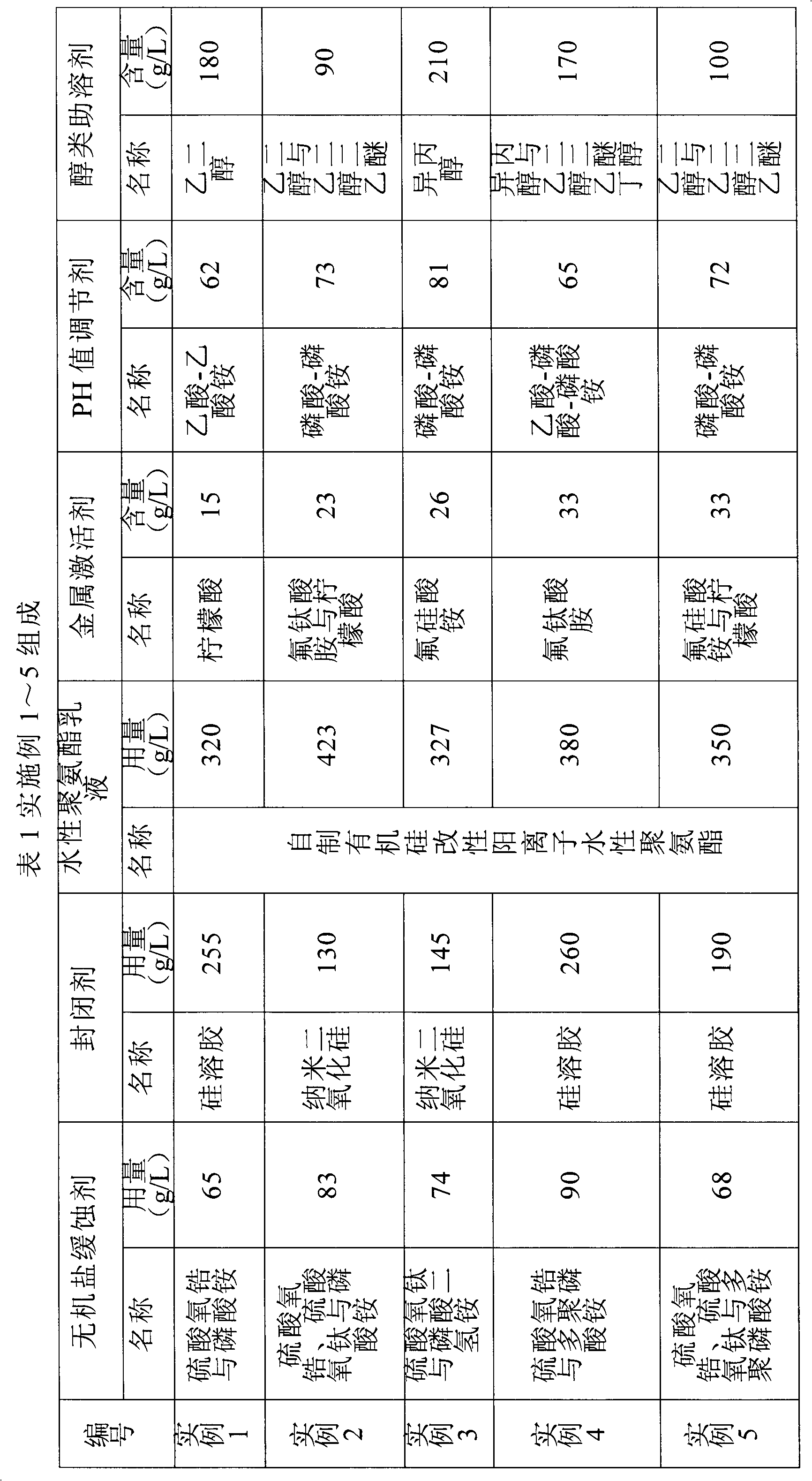

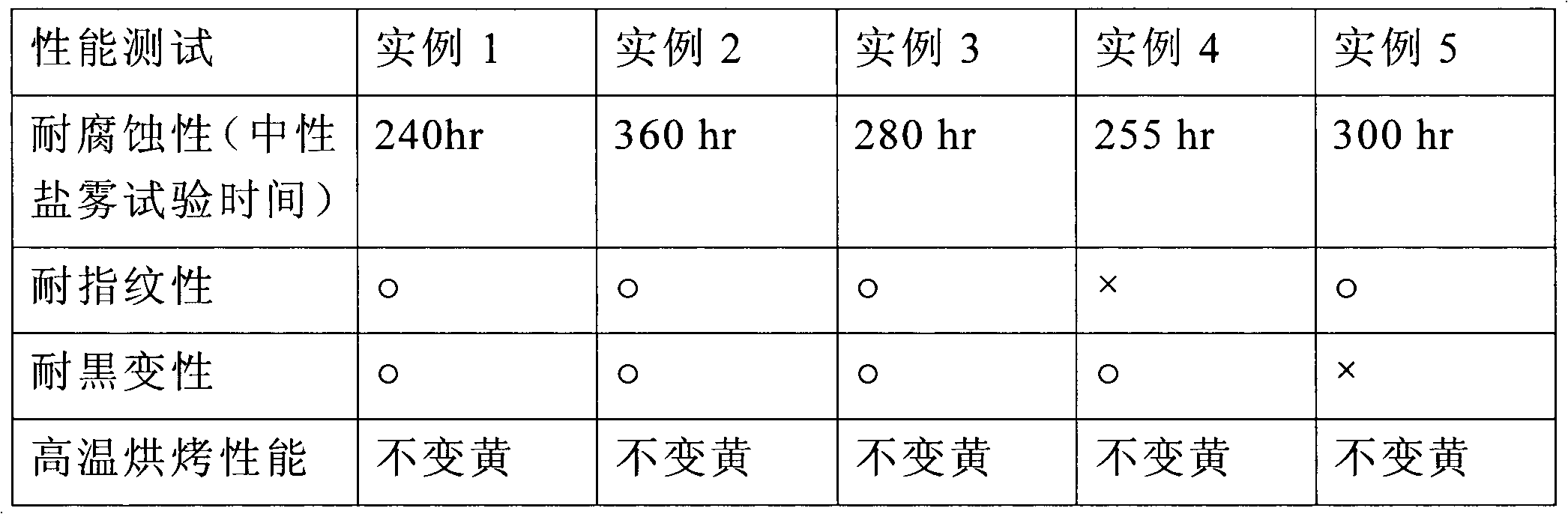

[0030]The composition of specific examples 1 to 5 of the present invention is listed in Table 1, and the specific examples of the present invention are shown in Table 1, g) components in Examples 1 to 5, thickening agent added 0.5g / l, all U.S. The SN-636 thickener of Rohm and Haas Company, the added dispersant 3g / l is the BYK-P104S type dispersant of German BYK chemical company, and the added defoamer 2g / l is the BYK-141 type defoamer Add 2g / l wetting agent, which is German Dow Chemical x-405 wetting agent, and make up the rest with distilled water.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com