Production method for craft paper

A production method and technology for kraft paperboard, applied in the field of papermaking, can solve the problems of insufficient compression resistance of cartons, high production cost and high power consumption, and achieve the effects of highlighting environmental protection advantages, increasing production costs and reducing yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

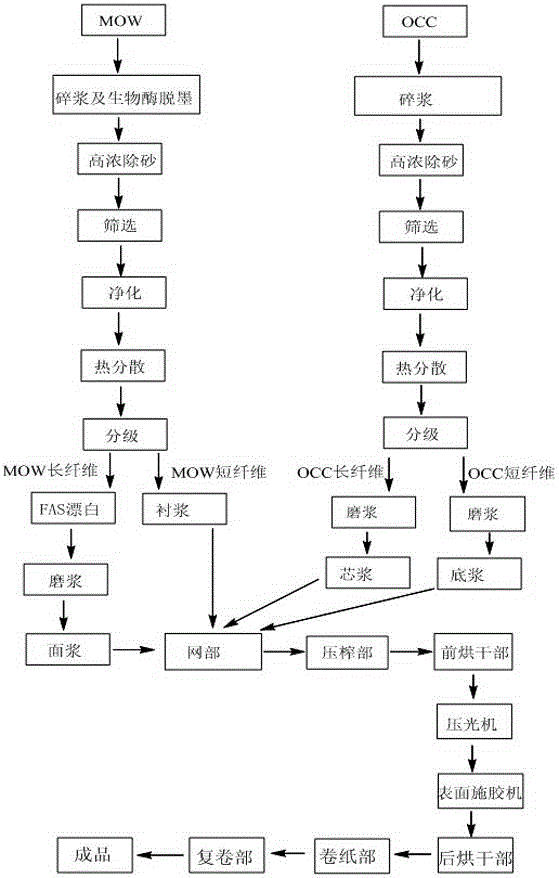

Method used

Image

Examples

Embodiment 1

[0116] Kraft cardboard is produced according to the method steps of the specific embodiment, wherein the MOW concentration in the first step is 10%-15%, the cellulase activity is 1700IU / ml, the pulping and deinking temperature is 40°C-50°C, and the pulping The time is 15-20min, the concentration of cellulase is 0.02-0.03%, Na 2 SiO 3 The concentration of NaOH is 0.5-0.7%, and the concentration of NaOH is 0.5-0.8%.

[0117] The average length of MOW long fibers in step 4 is 2.5mm, the average length of MOW short fibers is 0.5mm-1.5mm, the concentration of MOW long fiber pulp in step 5 is 13-15%, and the bleaching temperature is 60°C-65°C , the concentration of FAS is 0.3%-0.4%, the concentration of NaOH is 0.8%-1.0%, and the bleaching time is 40-50min. The wet weight of lining pulp is 2.5-3g, and the beating degree is 43-45°SR

[0118] In step 6, the concentration of the MOW long fiber pulp is 4.5%-4.7%, the wet weight of the refined MOW long fiber pulp is 5g-5.5g, and the b...

Embodiment 2

[0123] Other steps are all identical with embodiment 1, and only difference is that the proportion of surface slurry, liner slurry, core slurry and base slurry is 20%, 20%, 44%, 16%.

[0124]

Embodiment 3

[0126] Other steps are the same as in Example 1, the only difference is that the amount of cellulase is 0.03-0.04%, and the MOW pulping time is 10-15min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com