Patents

Literature

33results about How to "Good friendliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

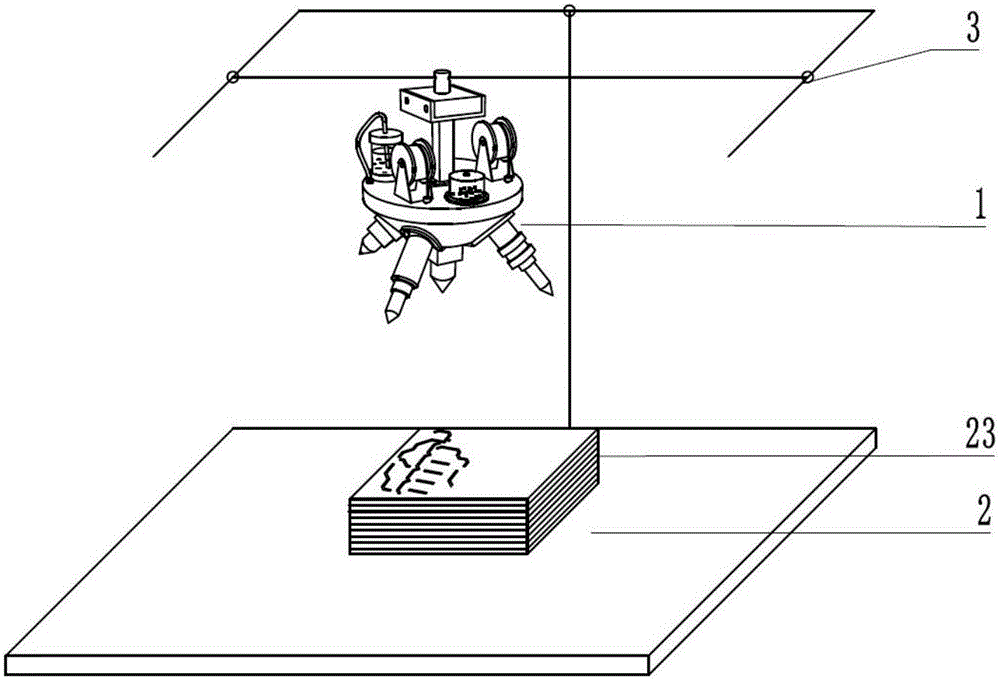

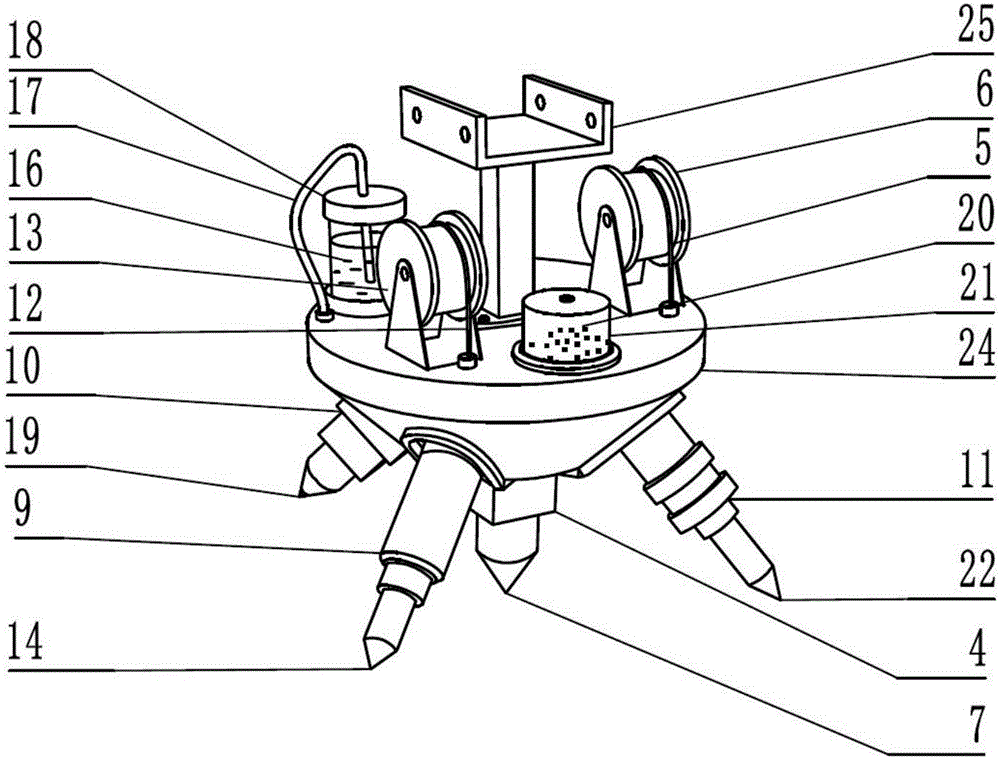

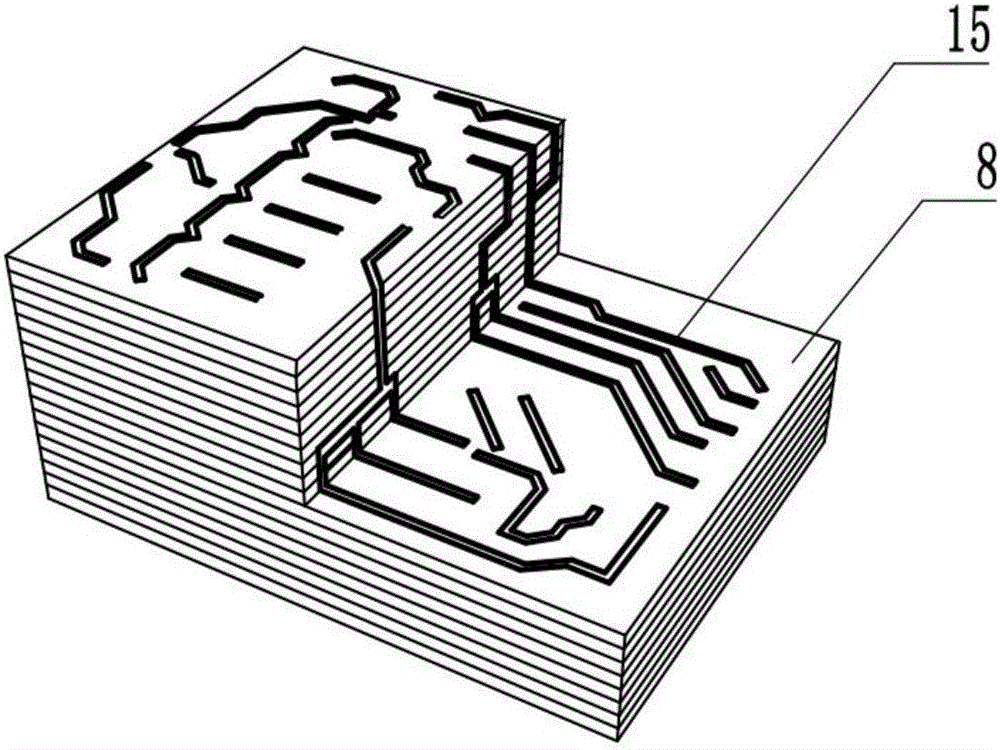

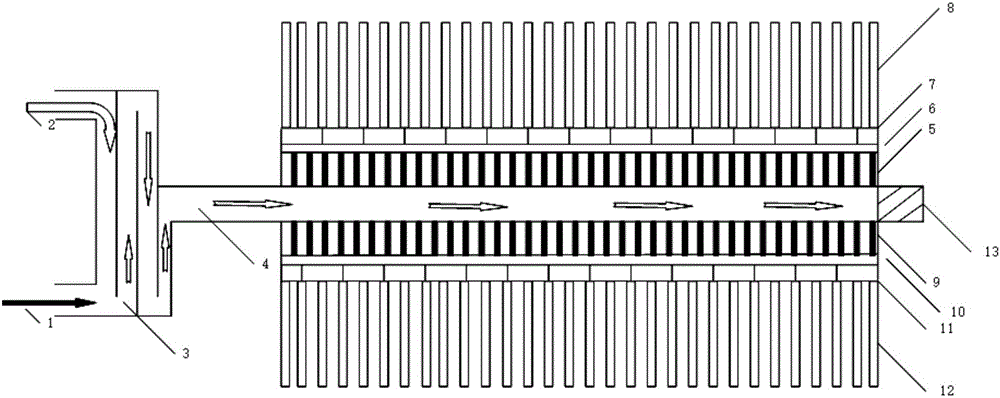

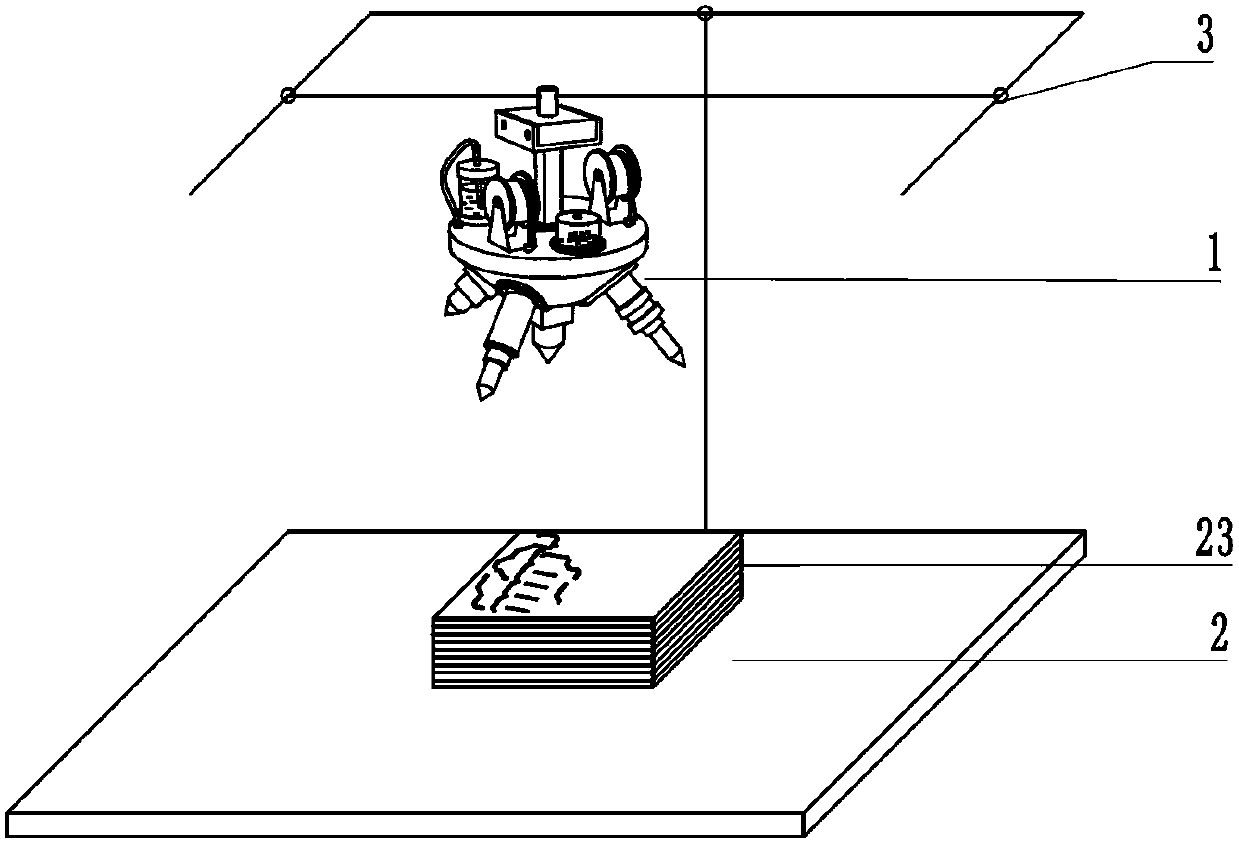

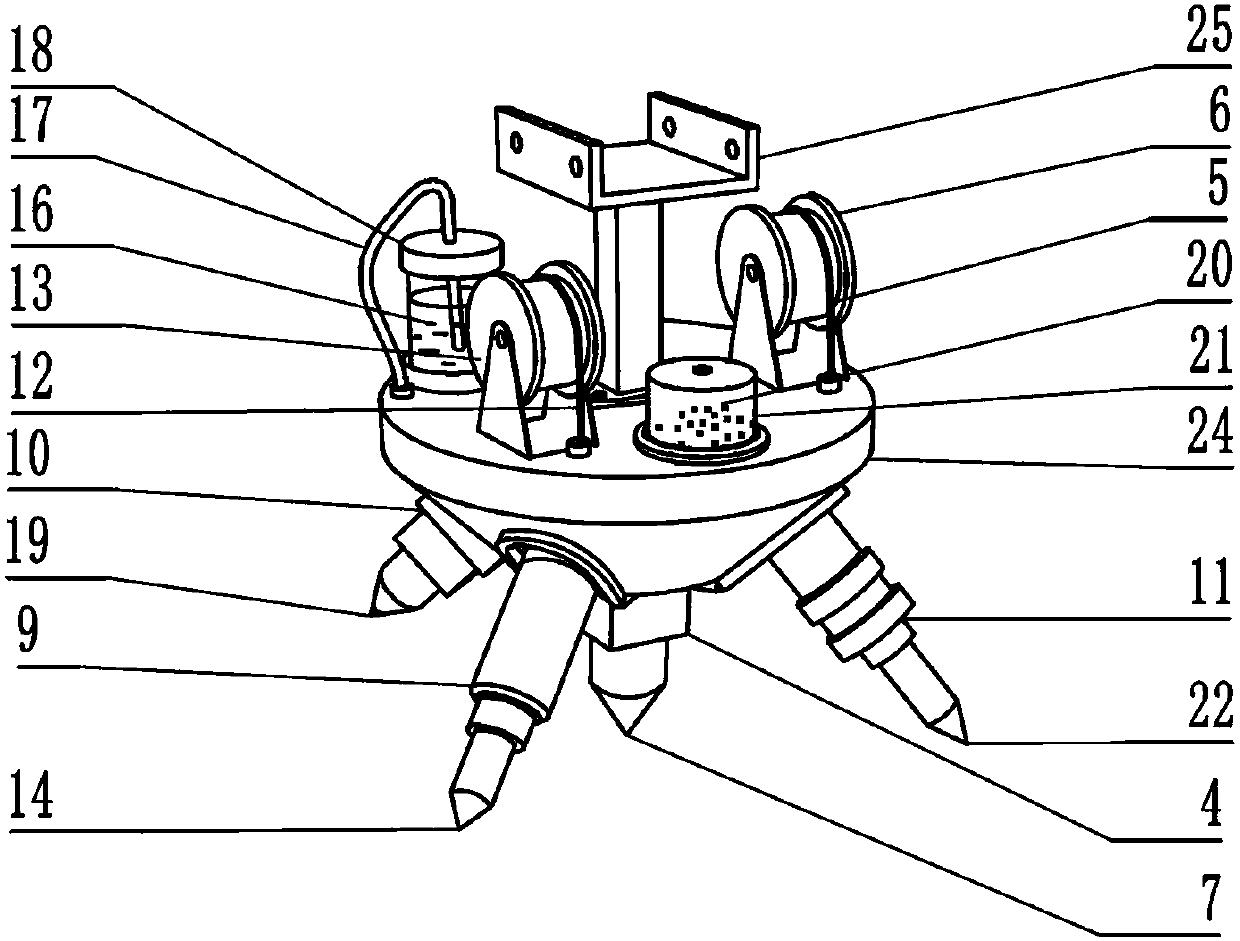

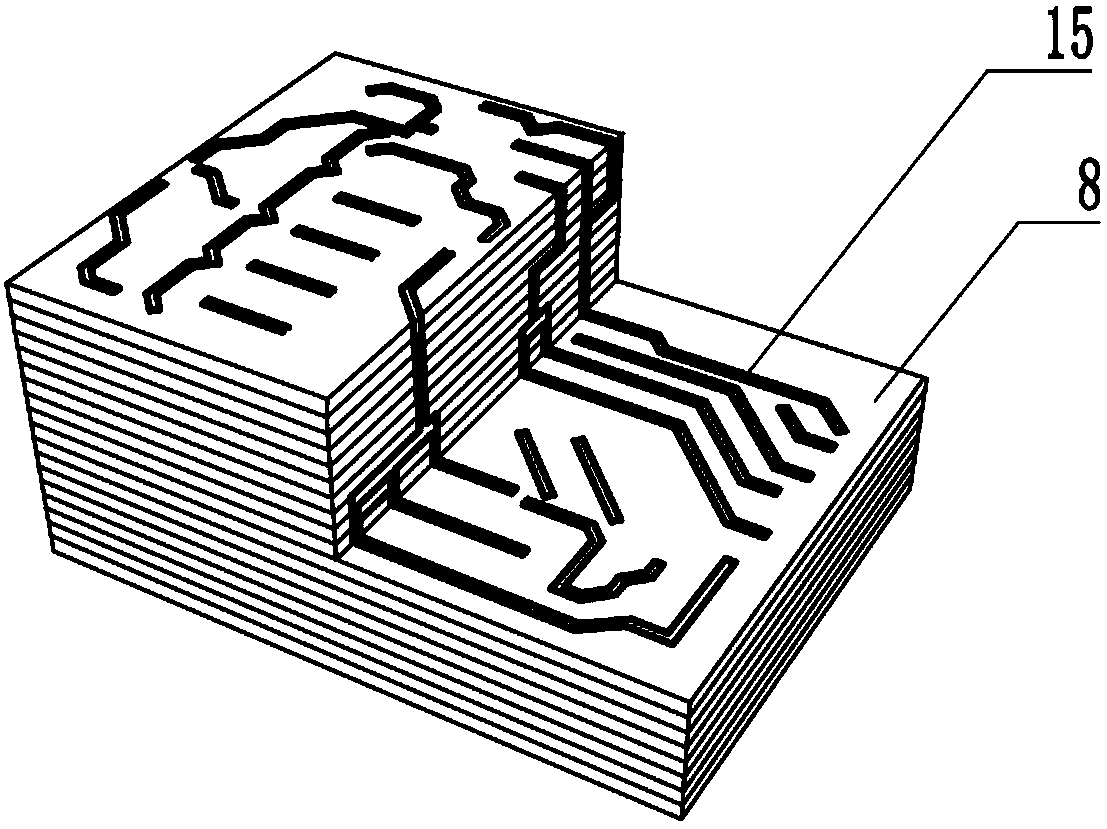

3D printing and manufacturing method for electronic device with three-dimensional structure

ActiveCN106111981ASmall footprintImprove friendlinessAdditive manufacturing apparatusMultilayer circuit manufactureThree-dimensional spaceRelative motion

The invention discloses a 3D printing and manufacturing method for an electronic device with a three-dimensional structure. The 3D printing and manufacturing method comprises the following steps: according to performance requirements of a to-be-formed part, designing spatial distribution of circuits and geometric dimensions of base structures in the electronic device with the three-dimensional structure, establishing a model of three-dimensional CAD, carrying out hierarchical processing on the model according to a processing direction to obtain material distribution of a section at each layer, and writing relative movement programs of a printing head integrated unit and a working platform; then, selecting a conducting wire printing material and a base material printing material which meet the performance requirements; printing a base material, forming the base structures on the working platform; switching the printing head; printing conducting wires; and driving the working platform to descend by a hierarchical thickness by a movement mechanism, repeating a printing process of printing the base material and the conducting wires until all base structures and conducting wires are printed, thereby obtaining the electronic device with the three-dimensional structure. The 3D printing and manufacturing method realizes synchronous printing of conducting wires and a base insulating medium, so that any layout of a three-dimensional space is realized.

Owner:XI AN JIAOTONG UNIV

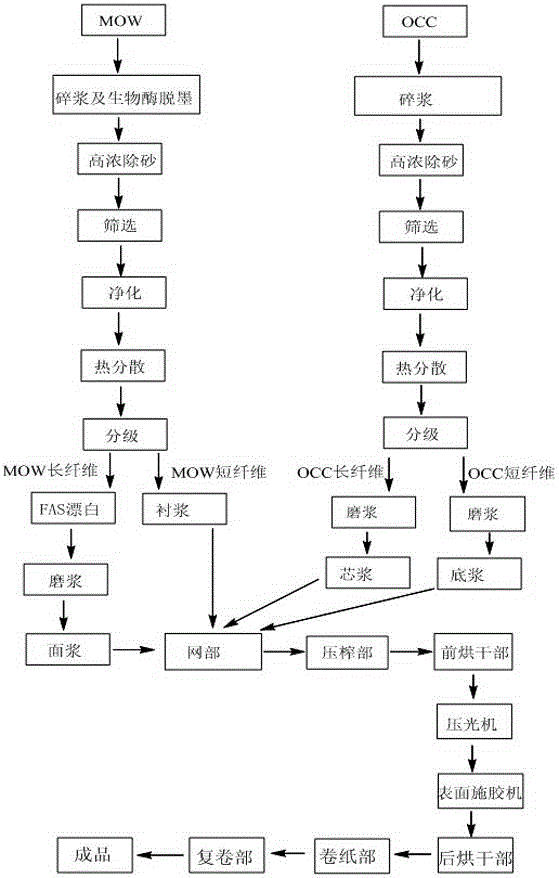

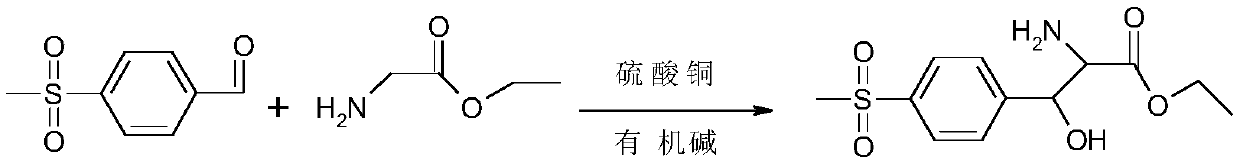

Production method for craft paper

ActiveCN104153230AHigh whitenessReduce yieldPaper recyclingWaste paper working-upPapermakingCellulase

The invention belongs to the technical field of papermaking, relates to a production method for craft paper, and aims to solve the problem of difficulty in the production of feather-weight, strong-strength and high-whiteness craft paper under the condition of not using wood pulp. The production method for the craft paper comprises steps of a MOW pretreatment step for forming surface pulp and lining pulp, an OCC pretreatment step for forming core pulp and prime pulp, and a step for subsequently treating the surface pulp, the lining pulp, the core pulp and the prime pulp, and is characterized in that the MOW pretreatment step comprises the following steps: a, simultaneously performing pulping and biological enzyme deinking on MOW, and b, performing heat dispersion on MOW, wherein the step a comprises a step of adding 1,600 to 1,800 IU / ml cellulase, Na2SiO3 and NaOH into MOW pulp at the mass concentration of 10 to 15 percent for pulping under the condition of 40 to 50 DEG C, wherein the mass concentration of the cellulase, the Na2SiO3 and the NaOH is 0.01 to 0.05 percent, 0.5 to 1.0 percent and 0.5 to 1.0 percent respectively, and the pulping time is 10 to 20 min. Due to the adoption of the technical scheme, the method can effectively solve the technical problem.

Owner:ZHEJIANG JINGXING PAPER

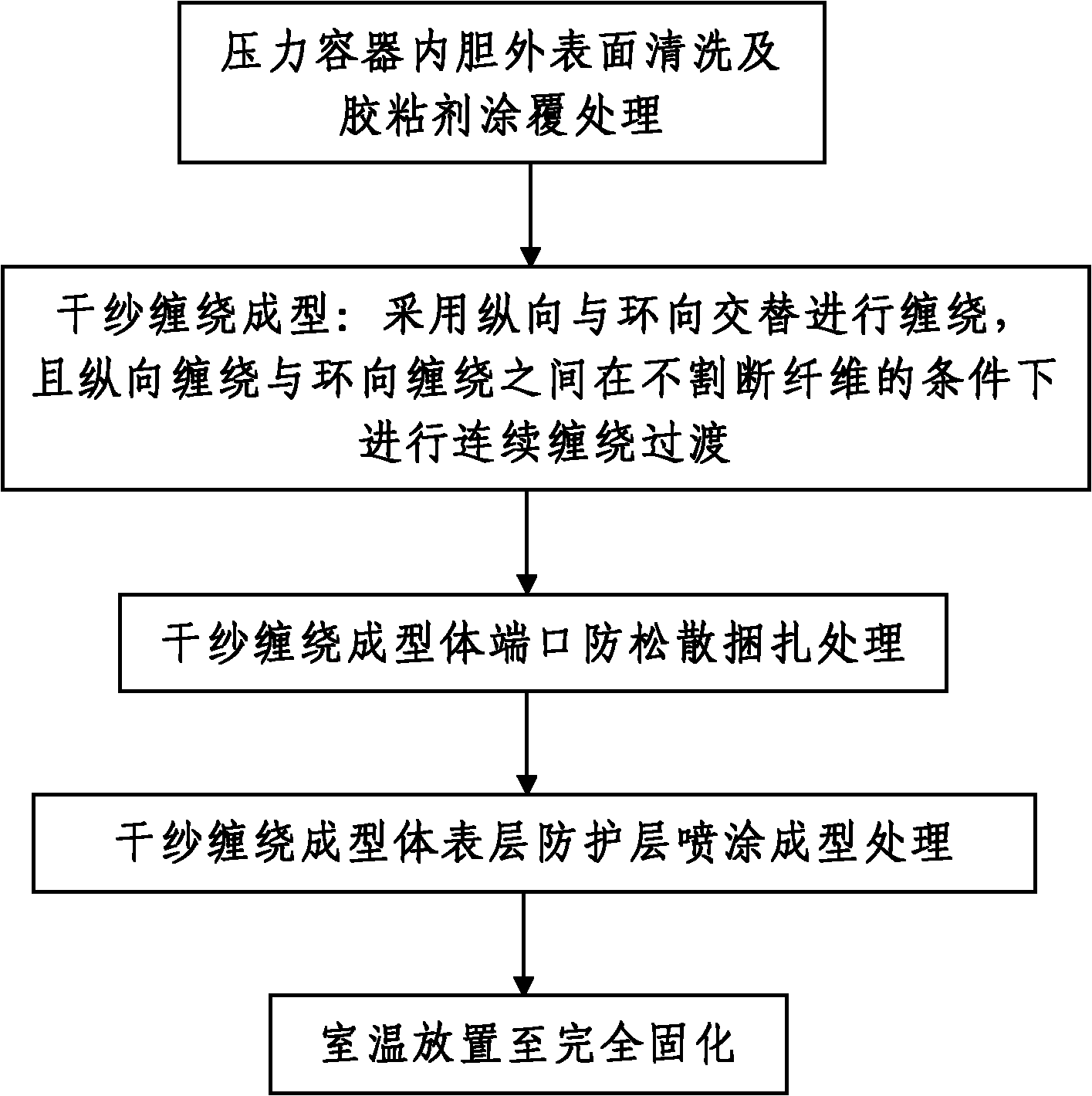

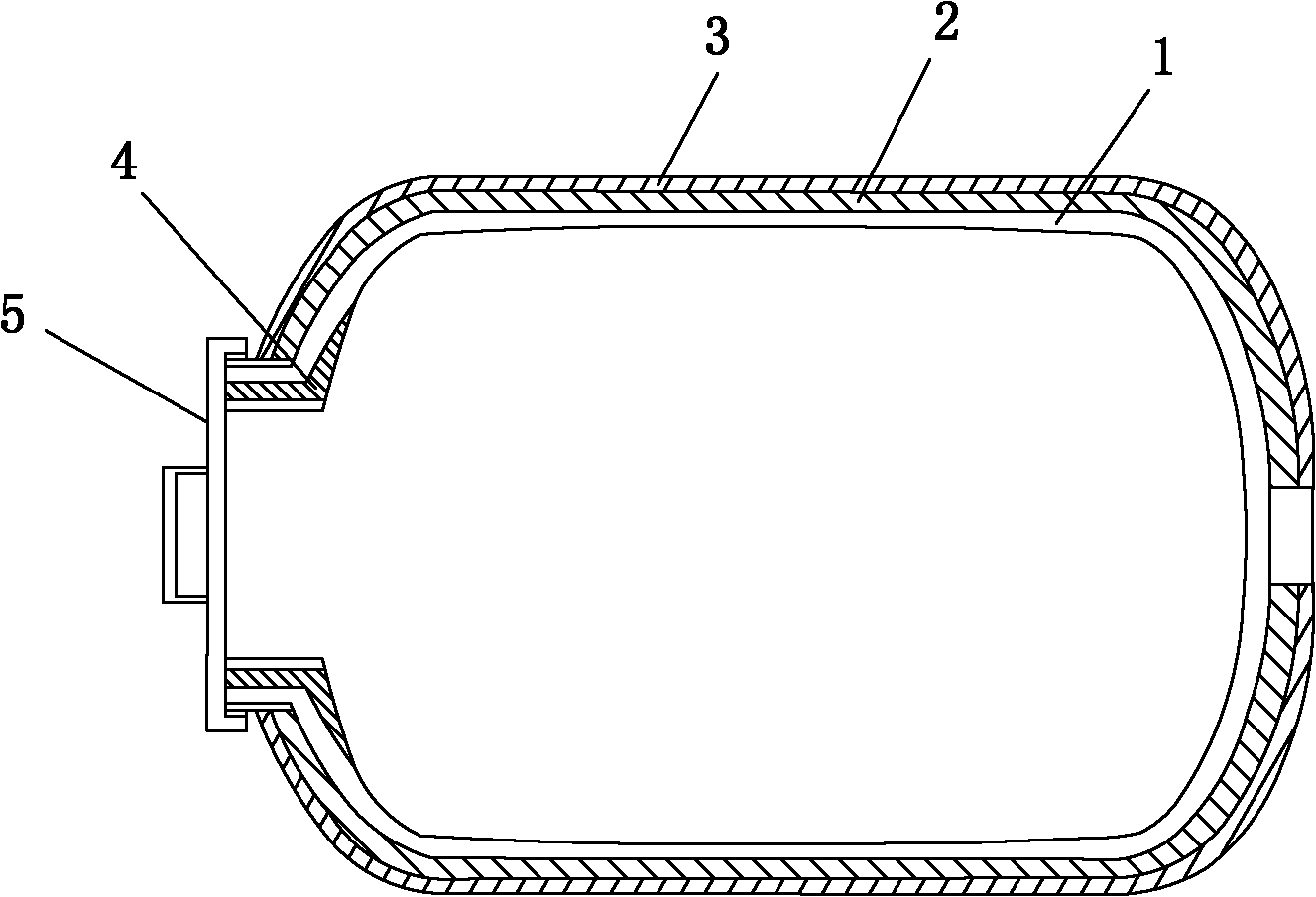

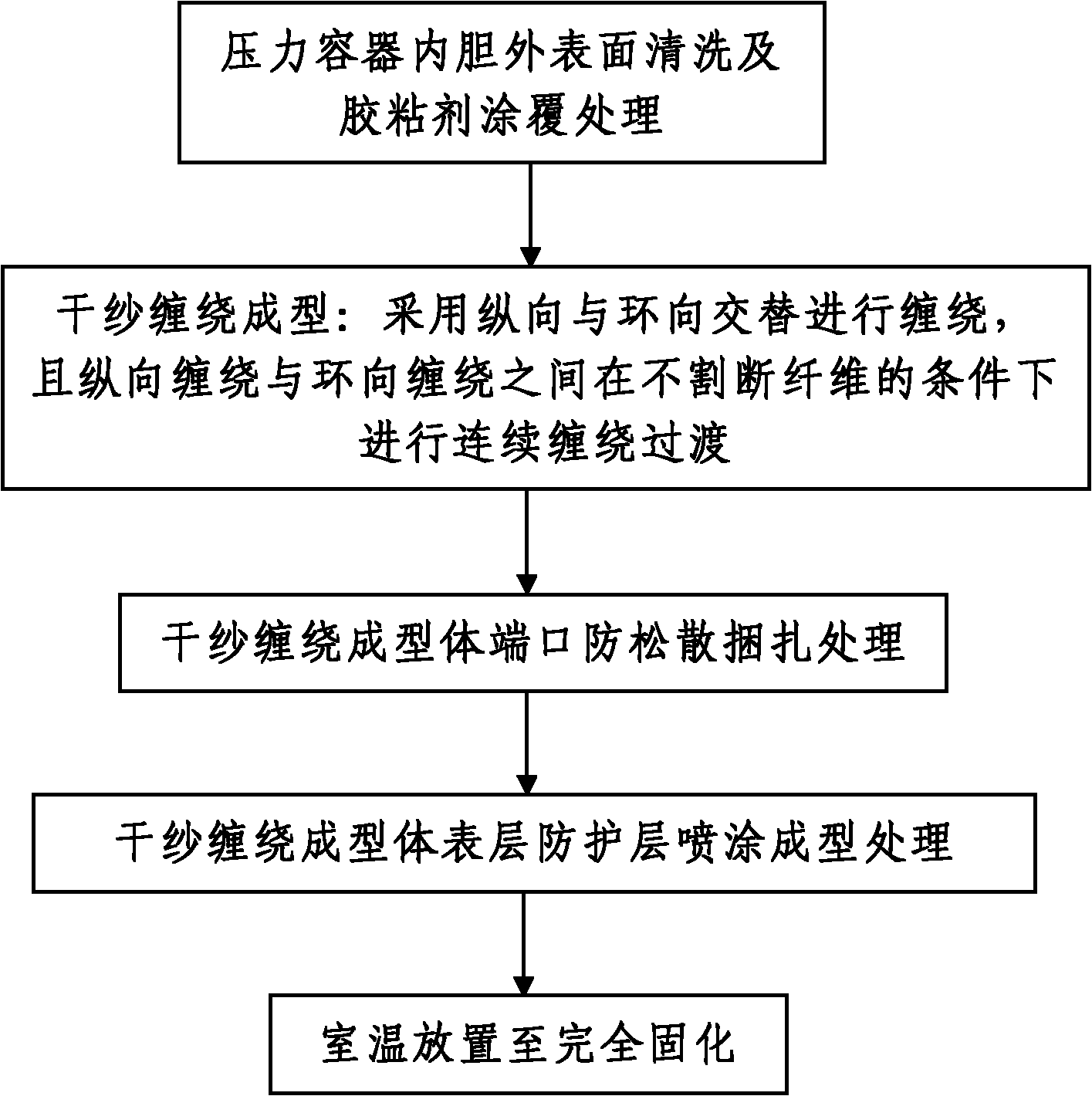

Dry yarn winding forming method for pressure container

The invention discloses a dry yarn winding forming method for a pressure container. The method comprises the following steps: 1. carrying out outer surface treatment on an inner container of the pressure container, namely coating an adhesive uniformly on the outer surface of the inner container of the cleaned pressure container; 2. carrying out dry yarn winding forming, namely winding on the outer surface of the inner container of the pressure container in a winding mode of alternative longitudinal winding and hoop winding, and carrying out continuous transition between the longitudinal winding and hoop winding under the condition that fibers are not cut off; 3. carrying out loose-proof strapping treatment on the port of a dry yarn winding forming body; 4. carrying out spraying forming treatment on a protective layer at the surface layer of the dry yarn winding forming body; and 5. placing and solidifying at room temperature. The dry yarn winding forming method for the pressure container provided by the invention has the advantages of reasonable design, simplicity and convenience in operation, convenience in control and good winding forming effect; and because an impregnation process and a solidifying process link are omitted, a plurality of practical problems, such as complex forming technology, longer production cycle, higher cost, no large scale of industrial production andthe like, of the existing winding forming process can be solved effectively.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

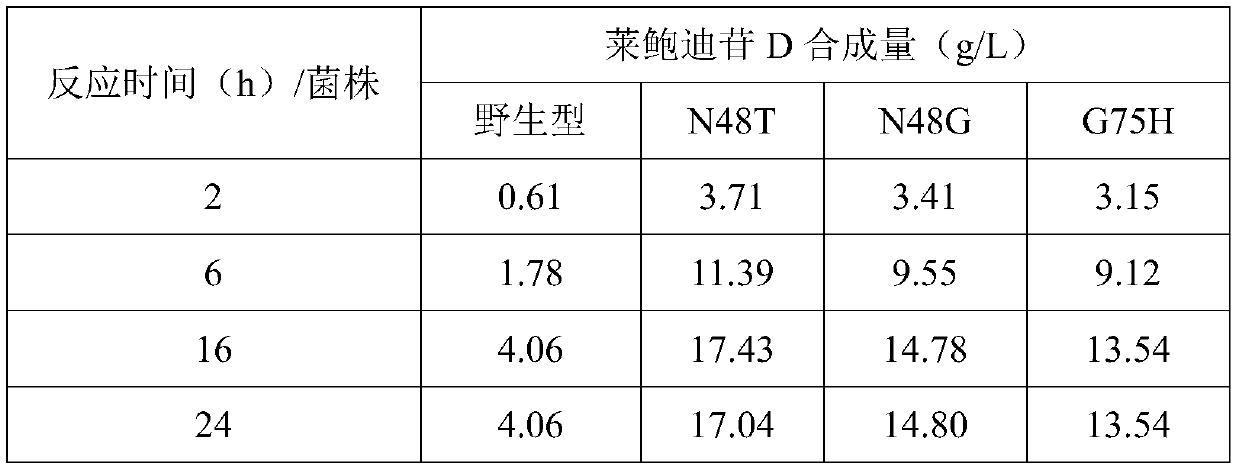

Glycosyltransferase UGTZJ1 mutant and application thereof

The invention discloses a glycosyltransferase UGTZJ1 mutant. The amino acid sequence of the mutant is shown as any one of SEQ ID NO.2-4, and a gene for encoding the mutant and a preparation method ofthe mutant are also disclosed. The invention also discloses a vector, a cell and a genetically engineered bacterium containing the mutant encoding gene. The invention also discloses applications of the glycosyltransferase UGTZJ1 mutant, the gene for encoding the mutant, the vector and a cell line comprising the mutant encoding gene, particularly the genetically engineered bacterium containing theglycosyltransferase UGTZJ1 mutant, and the like in the aspect of catalyzing rebaudioside A to generate rebaudioside D. The yield of the rebaudioside D, which is generated by catalyzing the rebaudioside A through the genetically engineered bacterium containing the mutant, is increased by about 4 times compared with that of a wild type, and the yield of the rebaudioside D can reach 47.56 g / L under the optimal reaction condition.

Owner:广东广业清怡食品科技股份有限公司 +2

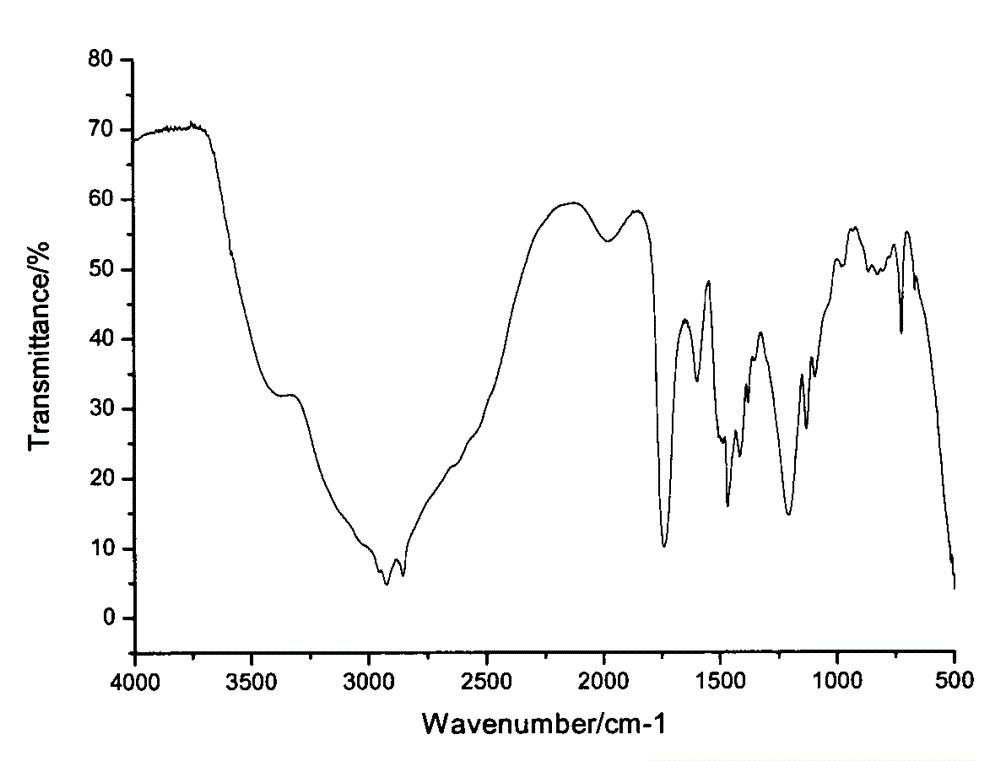

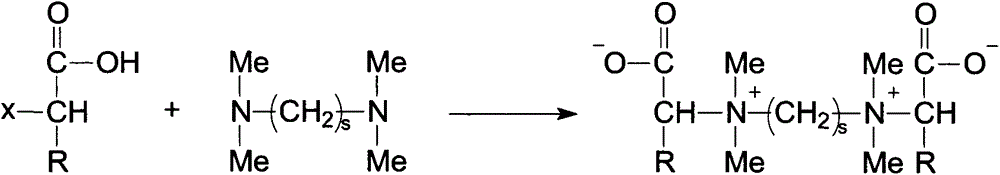

Alpha-lauryl betaine type dimeric surfactant and synthesis method thereof

InactiveCN105884638AShort synthetic routeMild reaction conditionsOrganic compound preparationTransportation and packagingCritical micelle concentrationSynthesis methods

The invention relates to an alpha-lauryl betaine type dimeric surfactant which is synthesized at a high yield through a reaction of alpha-halogenated aliphatic acid and binary tertiary amine. The synthesis reaction of the ampholytic ionic dimeric surfactant is a high-atom-economy reaction. The ampholytic ionic dimeric surfactant is short in synthesis route, easy and convenient to process, high in product yield and excellent in technological route synthesis performance. No corrosion or pollution is caused in the technological process, and no harmful compound is generated in the technological process, so that the synthesis technology is good in environmental friendliness. According to the method, raw materials are wide in source and low in cost, the technological route is short, production cost is low, and economy is good. The ampholytic ionic surfactant has extremely low critical micelle concentration and high capability for reducing surface tension and interfacial tension; the obtained product is excellent in lime soap dispersivity and can serve as a novel lime soap dispersant.

Owner:JIANGNAN UNIV

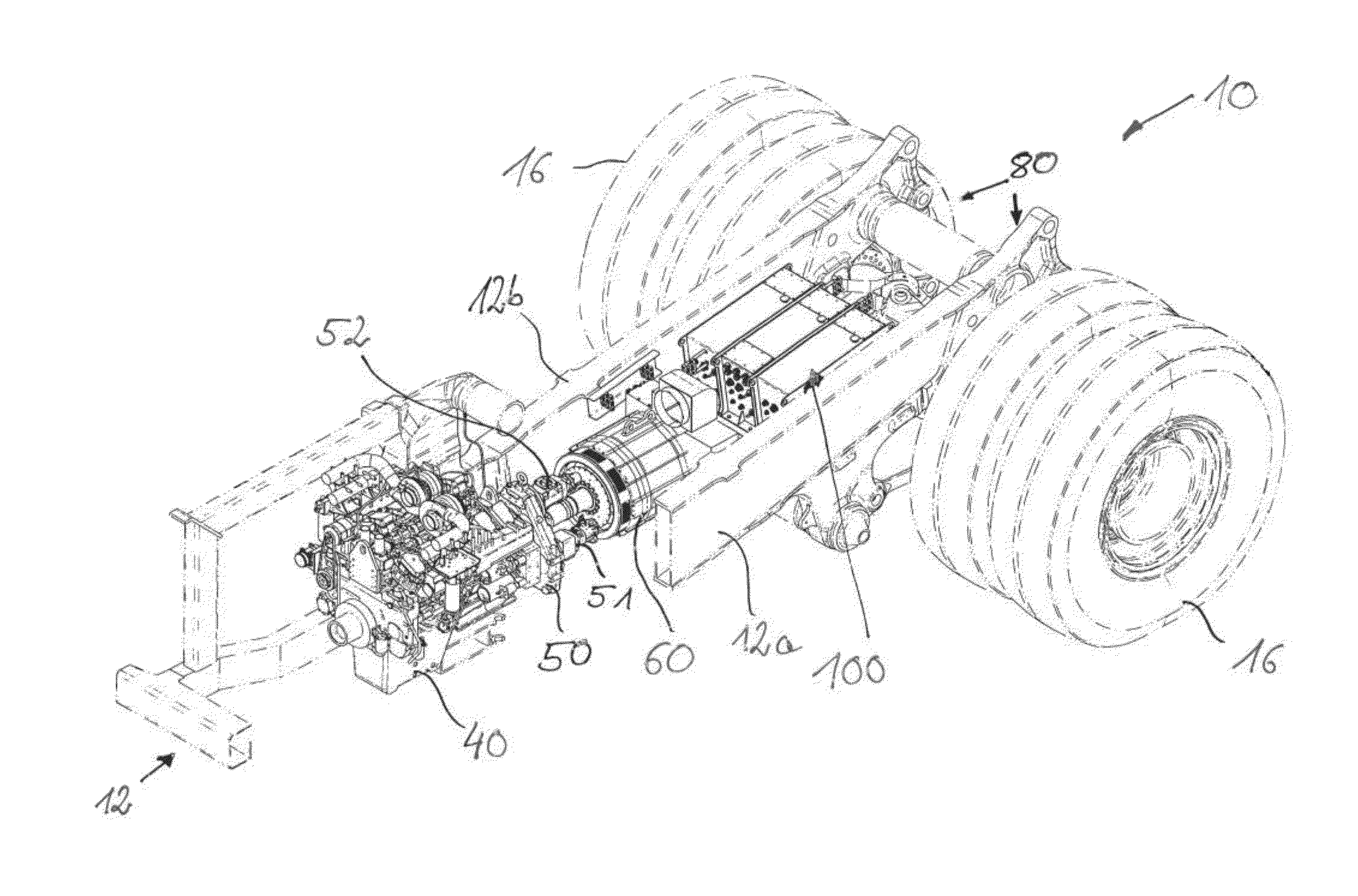

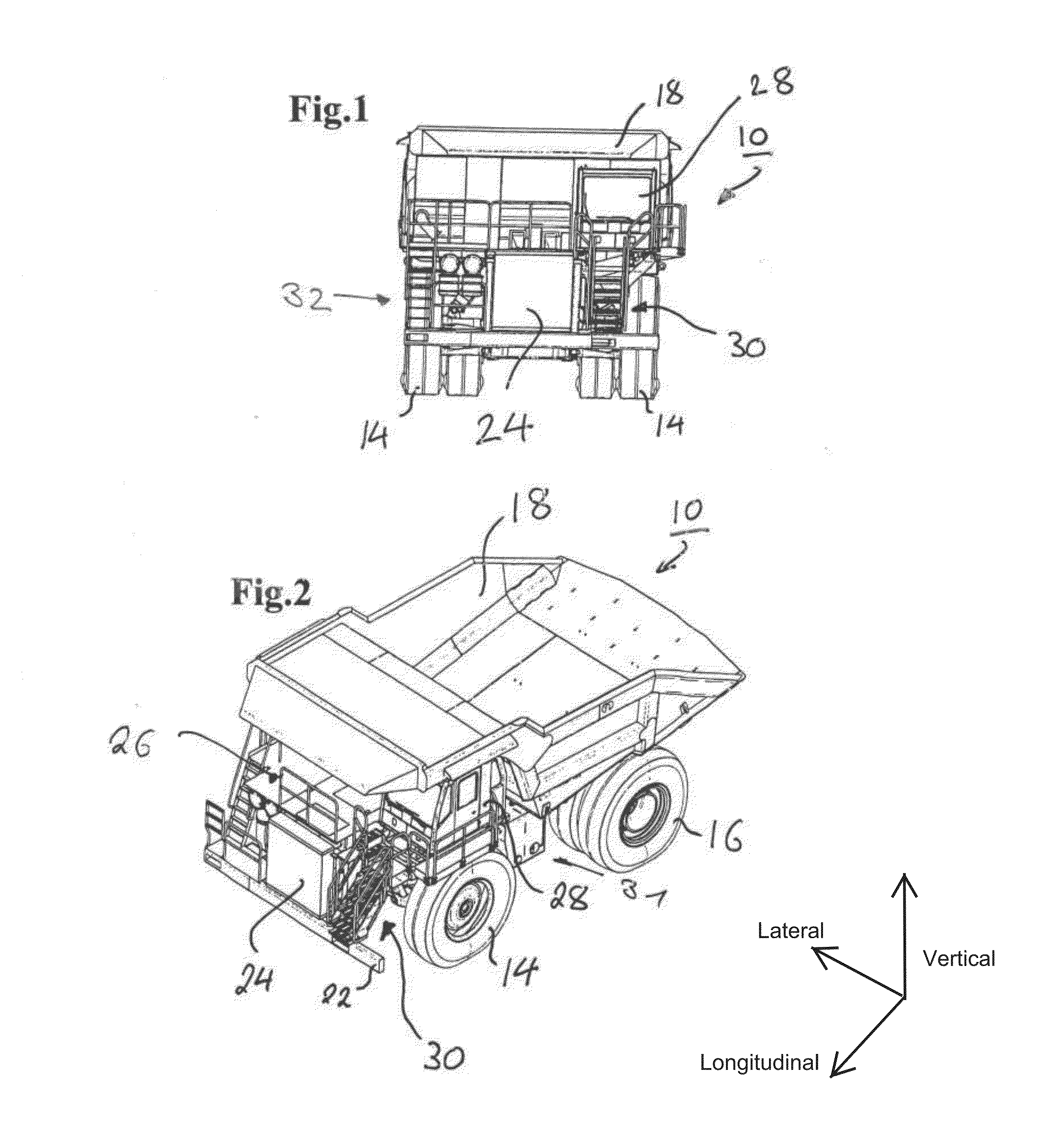

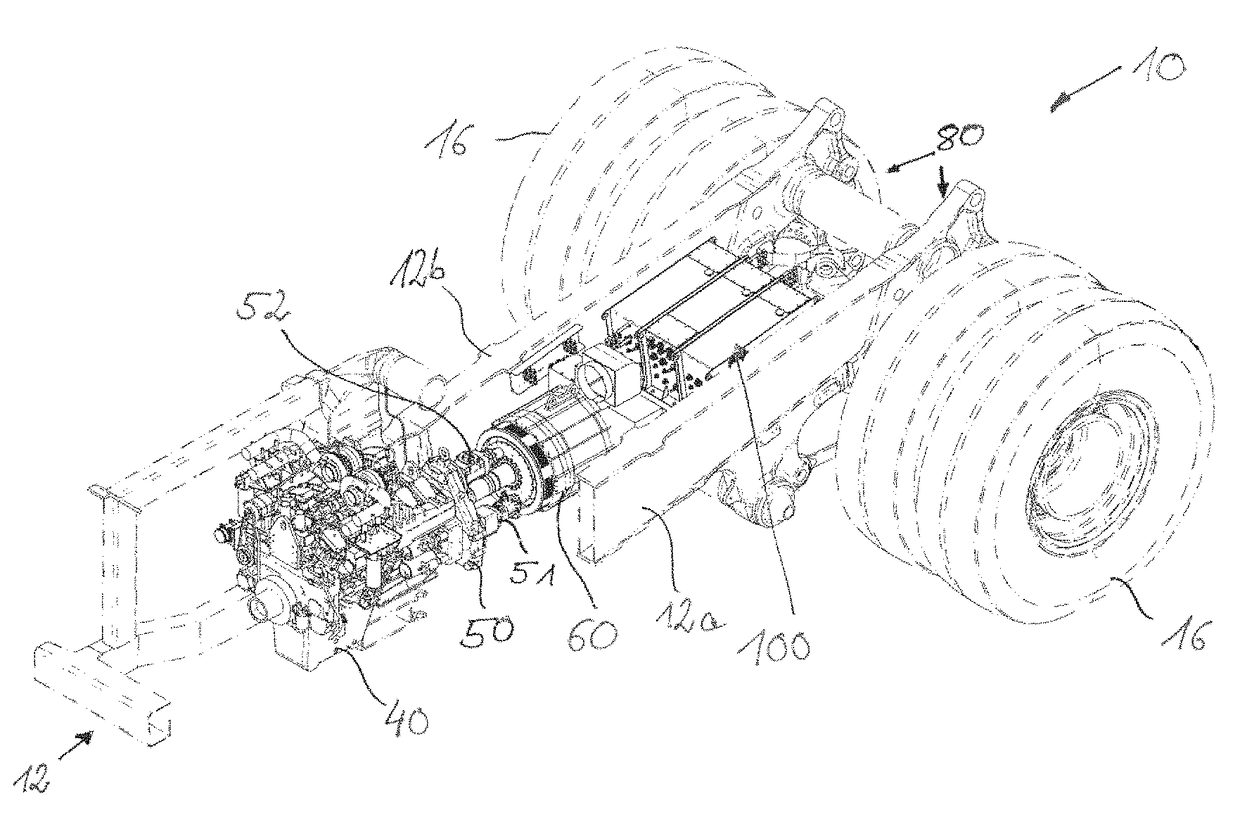

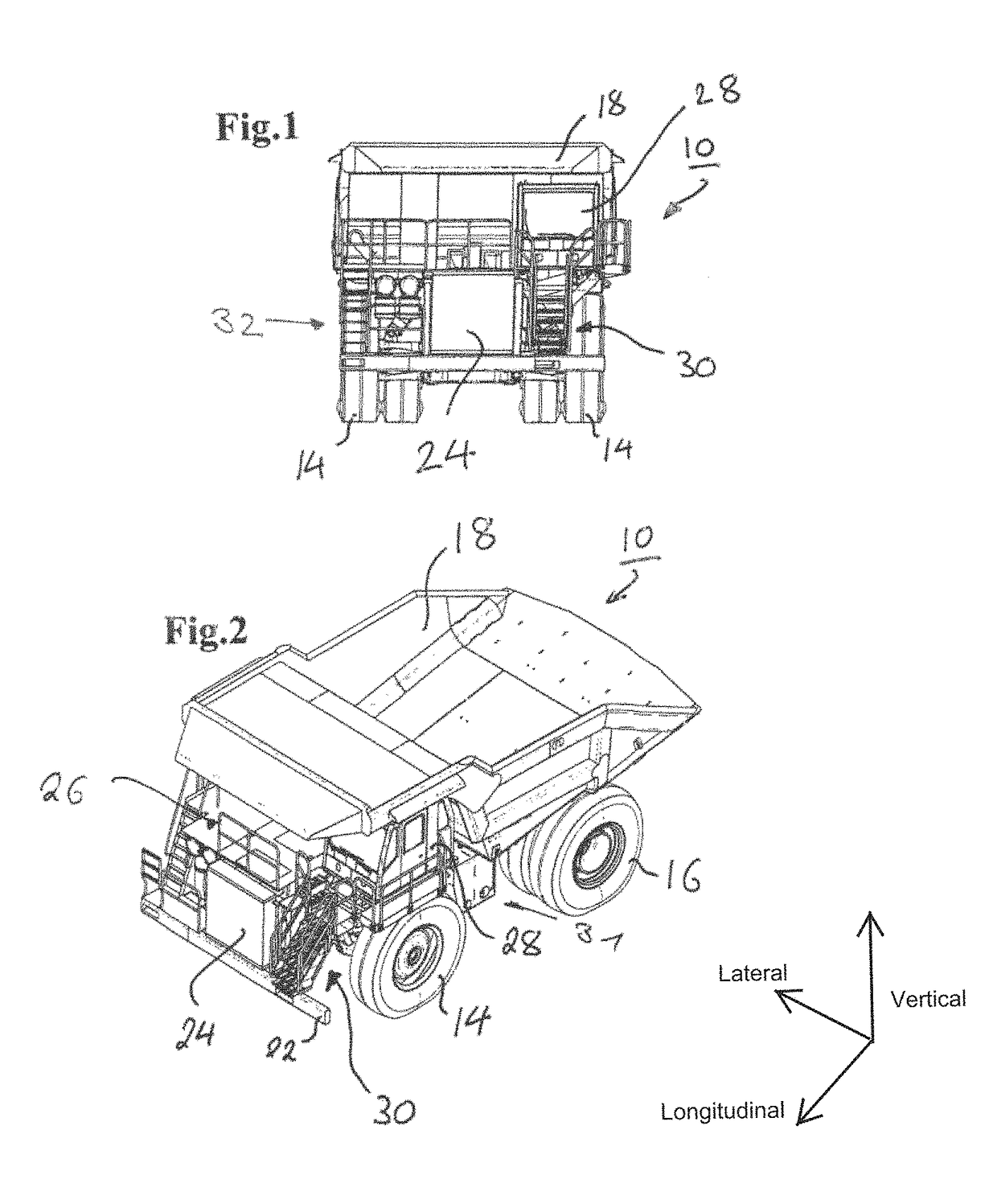

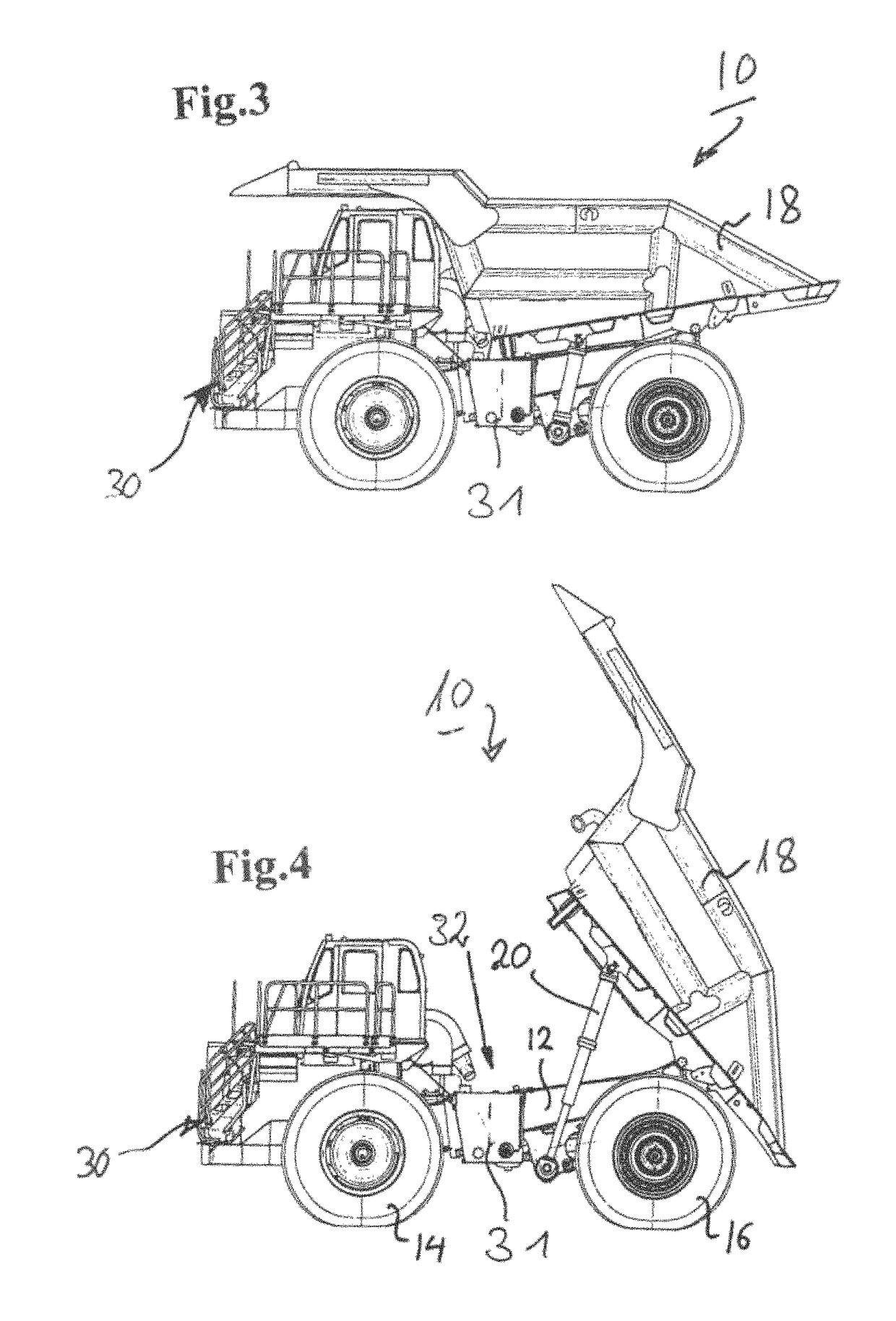

Work machine, in particular dump truck or truck

ActiveUS20150251610A1Easy accessSimplify workHybrid vehiclesElectric propulsion mountingAlternatorEngineering

The present disclosure relates to a work machine, in particular in the form of a dump truck or of a truck, having a diesel electric traction drive, comprising at least one internal combustion engine, at least one alternator, at least one set of power electronics as well as at least one electric motor, wherein the power electronics are arranged at least partially in the region of a driven driving axle of the work machine.

Owner:LIEBHERR MINING EQUIP COLMAR

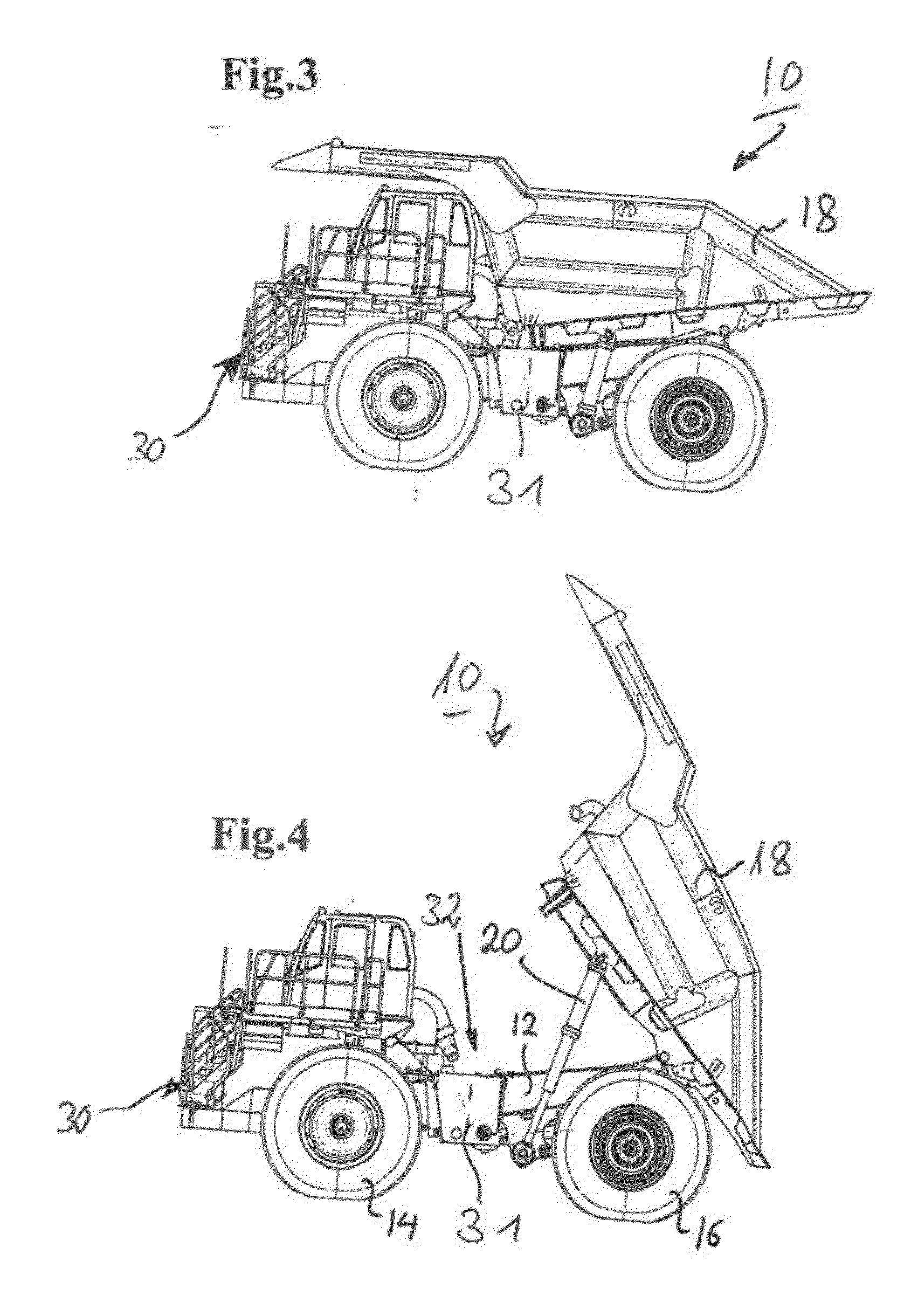

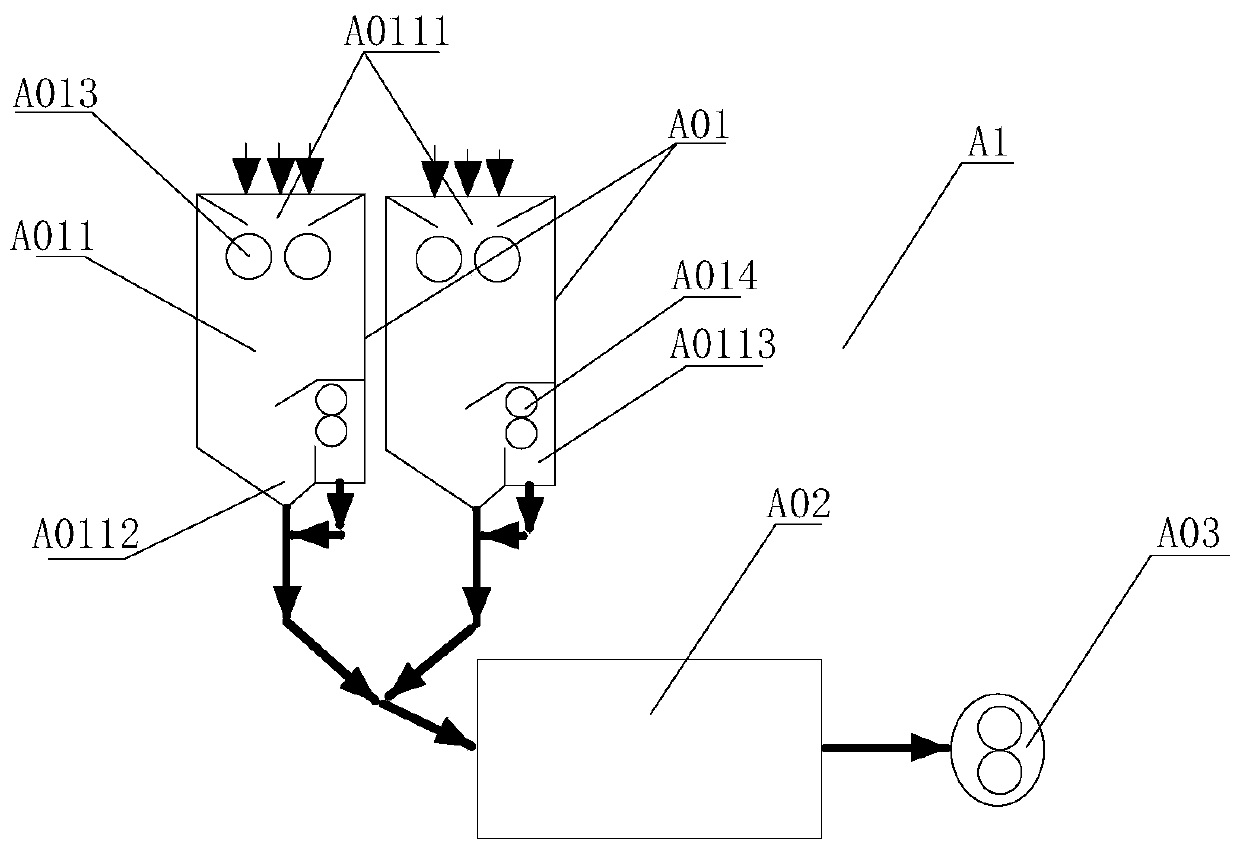

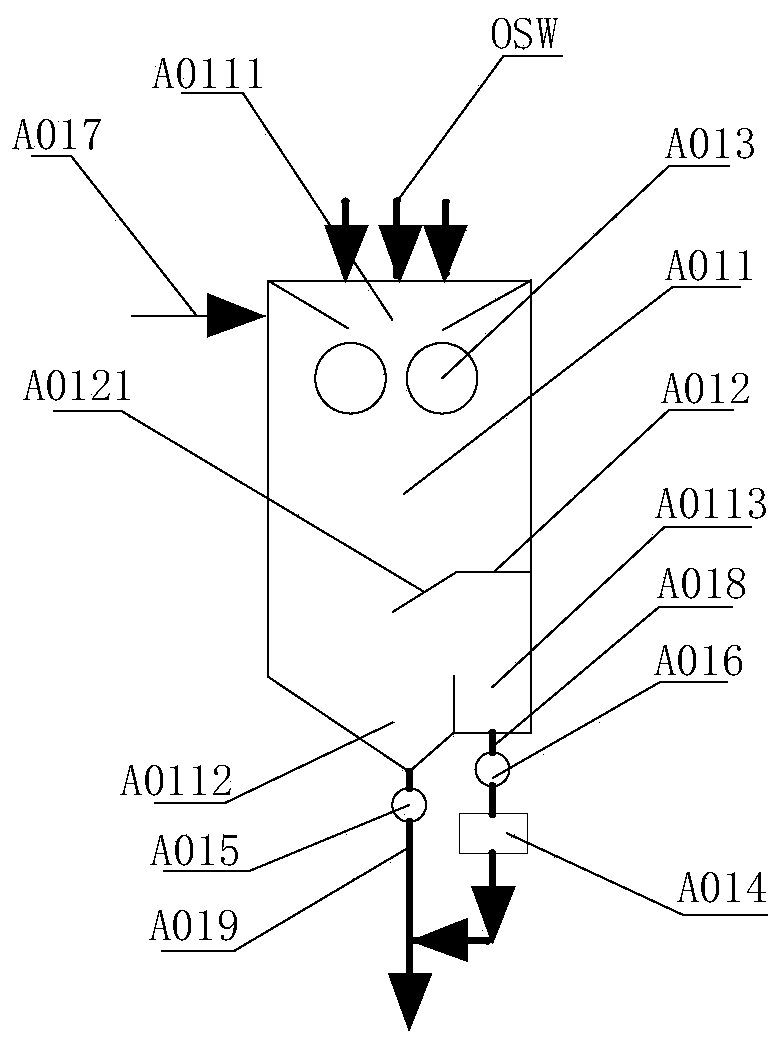

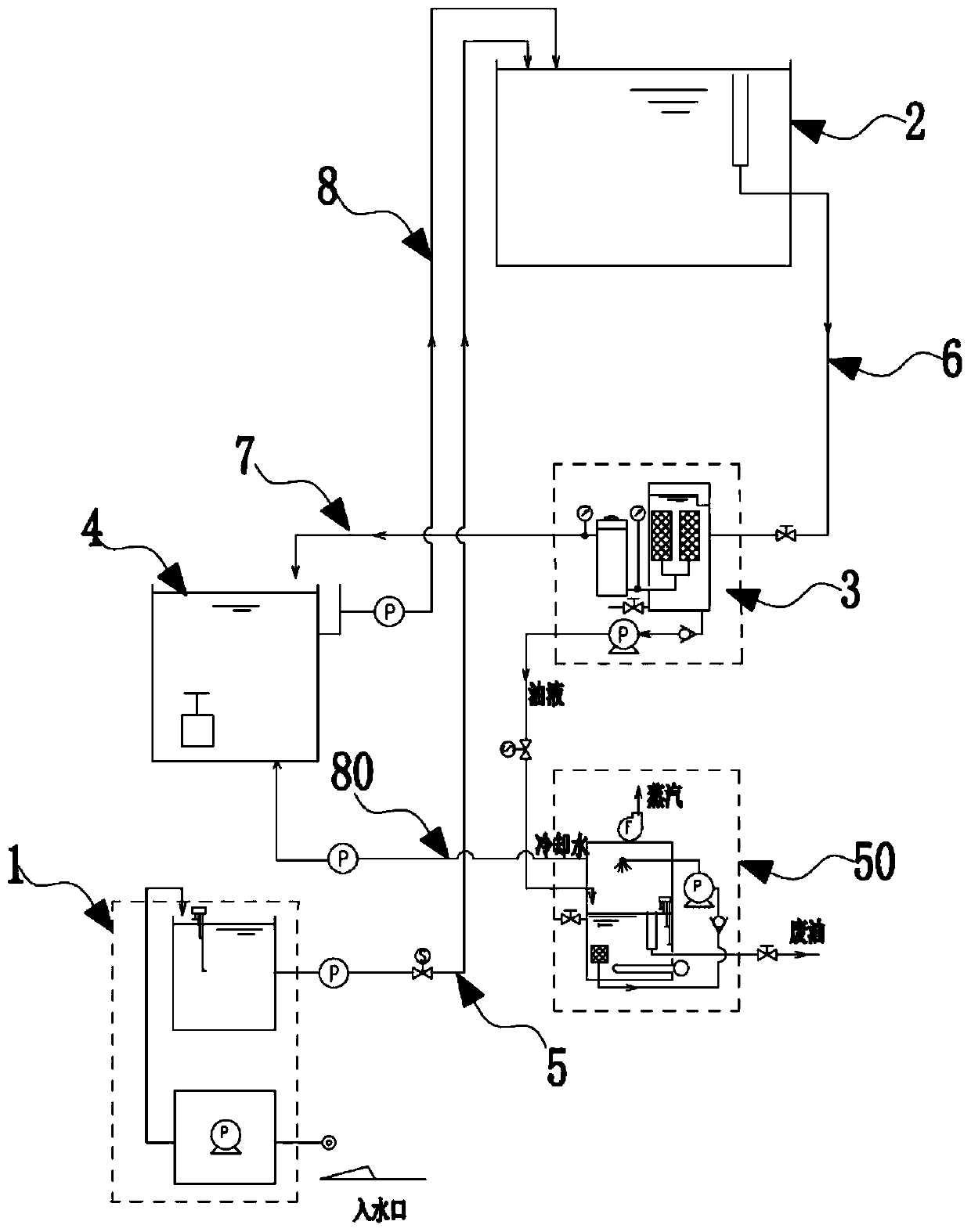

Organic solid waste pretreatment system and process and corresponding organic solid waste continuous hydrothermal treatment system and process

ActiveCN111346897ASave heating energyReduce energy costsWaste processingSolid waste disposalProcess engineeringEnvironmental engineering

The invention discloses an organic solid waste pretreatment system and process and a corresponding organic solid waste continuous hydrothermal treatment system and process. The organic solid waste pretreatment system comprises a weight sorting-smashing device and a ball milling device; the water weight sorting-smashing device comprises a sorting cavity and a second-stage smashing unit, separationof light materials and heavy materials can be achieved through the sorting cavity, smashing the light materials by the second-stage smashing unit is carried out to prepare primary mud, the ball milling device receives the primary mud and carries out ball milling to prepare mud containing impurities, the heavy materials separated by the sorting cavity can enter the ball milling device to be used asabrasive materials. The organic solid waste pretreatment system is simple and reasonable in structure, facilitates separation of light and heavy materials and utilization of heavy material waste, refines, homogenizes and fluidizes organic solid waste, can achieve organic solid waste synergism, high efficiency and continuous hydrothermal treatment, effectively prevents continuous hydrothermal technology blockage and the like, fully recovers heat energy in the technological process, and improves the utilization rate of organic solid waste, resource utilization of products can be realized, and obvious environment-friendly and economic benefits are obtained.

Owner:TSINGHUA UNIV

Thermal photovoltaic power generation device

InactiveCN105790680ALower working temperaturePrevent agingPV power plantsPhotovoltaic energy generationThermal energyEngineering

The invention discloses a thermal photovoltaic power generation device, which comprises air inlets, a premixer and a combustor, wherein radiators and photovoltaic cell assemblies are sequentially arranged on the periphery of the combustor; fuel enters the premixer and the combustor through the air inlets for premixing and combustion respectively; the radiators absorb heat energy from the combustor and release heat radiation to the photovoltaic cell assemblies; and the photovoltaic cell assemblies absorb the heat radiation and convert the heat radiation into electric energy. The thermal photovoltaic power generation device combines a thermo-photovoltaic technology, a near-field radiation technology and a metamaterial radiation technology, has a simple and stable mechanical structure, can relatively well adapt to an outdoor complex and volatile working environment, achieves miniaturization and modularization of equipment when ensuring stable power supply, and has the advantages of being simple in structure, convenient to carry, high in power generation power per unit volume, high in safety, long in lifetime and the like; and the energy conversion efficiency and the portability of the equipment are considered.

Owner:SUZHOU UNIV

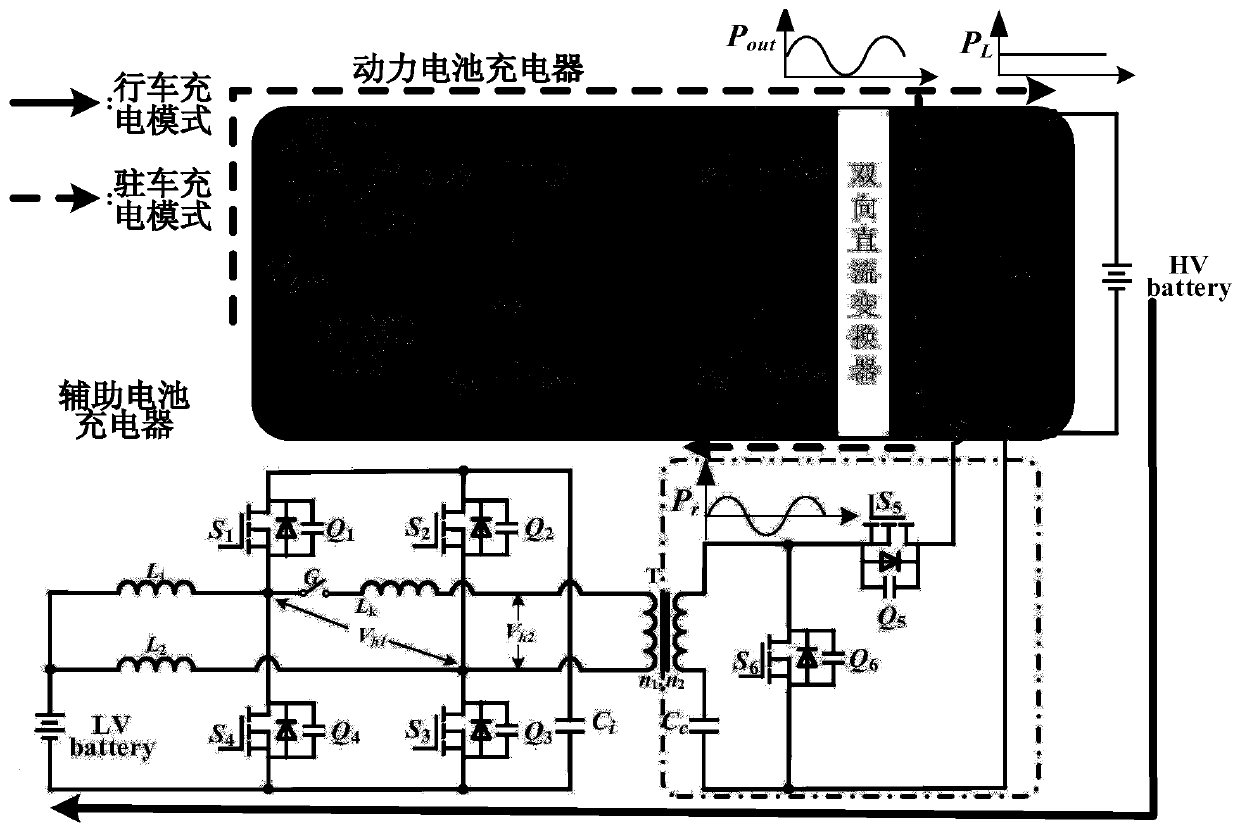

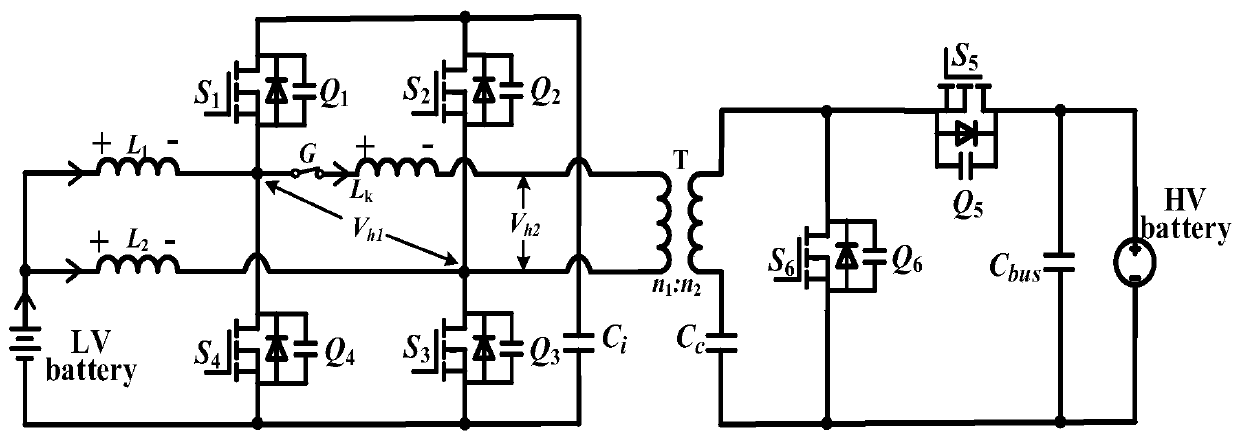

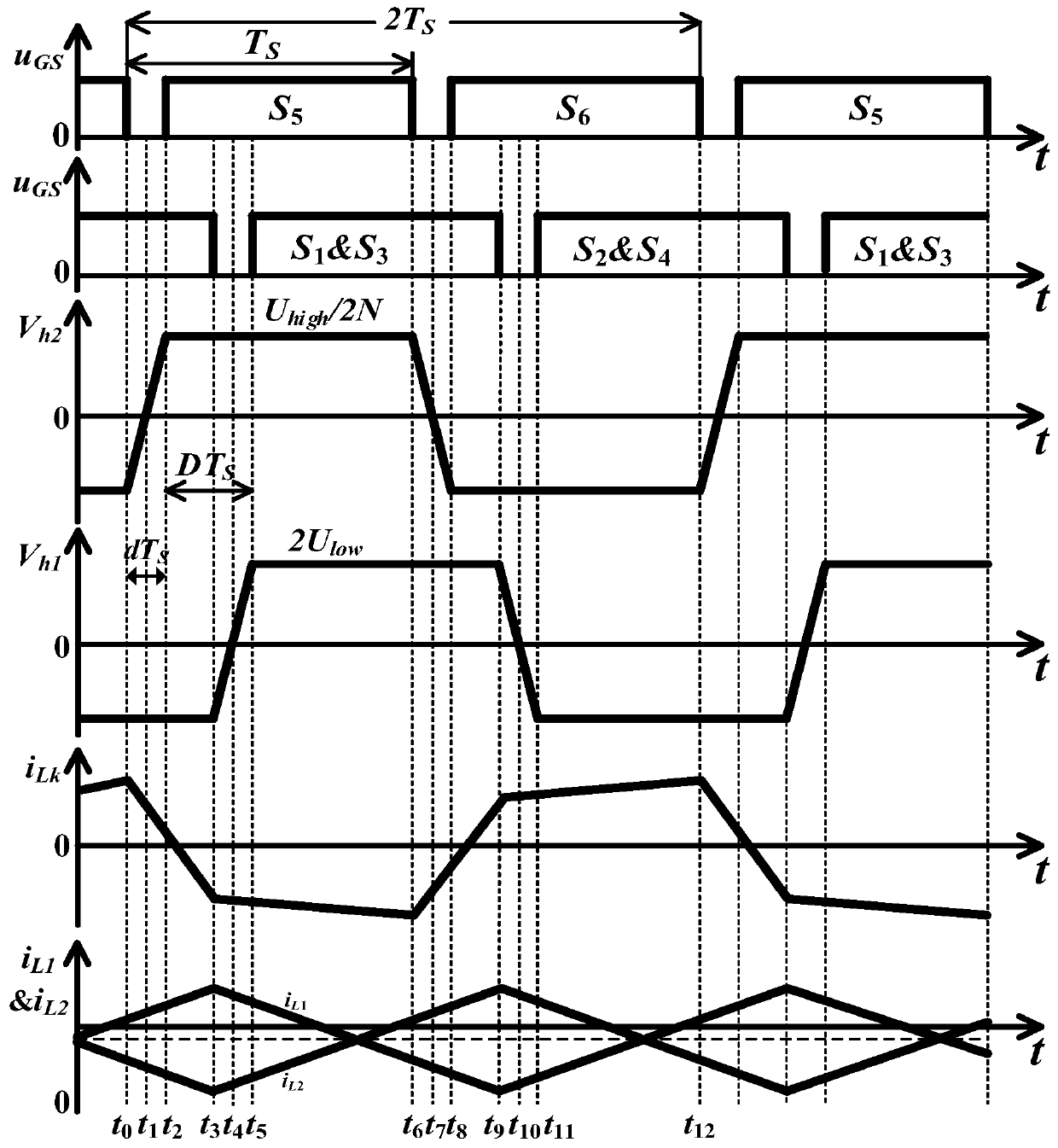

High and low frequency ripple current suppression method in electric vehicle in-vehicle single-phase charging system

ActiveCN110445227ASuppression of low frequency/secondary ripple currentGood friendlinessBatteries circuit arrangementsCharging stationsIn vehicleCapacitive energy storage

The invention discloses a high and low frequency ripple current suppression method in an electric vehicle in-vehicle single-phase charging system. The high and low frequency ripple current suppressionmethod in the electric vehicle in-vehicle single-phase charging system comprises the following steps: an electric vehicle in-vehicle single-phase charging system consisting of a power battery chargerand an auxiliary battery charger is constructed; the auxiliary battery charger is composed of a multi-function and isolated DC / DC converter; in a driving charging mode, a two-phase staggered parallellow-voltage side topological structure is constructed based on a Buck-Boost basic conversion unit in the auxiliary battery charger, zero output of current ripple is achieved through phase shifting by180 degrees between the basic units, and meanwhile, the low-voltage side topological structure can realize high-frequency rectification; the high-voltage side topological structure realizes the high-frequency inversion through the charge and discharge of an energy-storage capacitor and the cooperation of a power switch based on the Buck-Boost basic conversion unit; and in a parking charging mode,the active energy filtering of the capacitive energy storage type is realized by a high-voltage side bidirectional Buck-Boost unit in an isolated charging topology of the auxiliary battery, so as toachieve the charge and discharge of the energy-storage capacitor, and achieve the purpose of suppressing the secondary ripple voltage.

Owner:TIANJIN UNIV

Work machine, in particular dump truck or truck

ActiveUS9771037B2Optimize advantageGood friendlinessElectric propulsion mountingPropulsion using engine-driven generatorsAlternatorInternal combustion engine

The present disclosure relates to a work machine, in particular in the form of a dump truck or of a truck, having a diesel electric traction drive, comprising at least one internal combustion engine, at least one alternator, at least one set of power electronics as well as at least one electric motor, wherein the power electronics are arranged at least partially in the region of a driven driving axle of the work machine.

Owner:LIEBHERR MINING EQUIP COLMAR

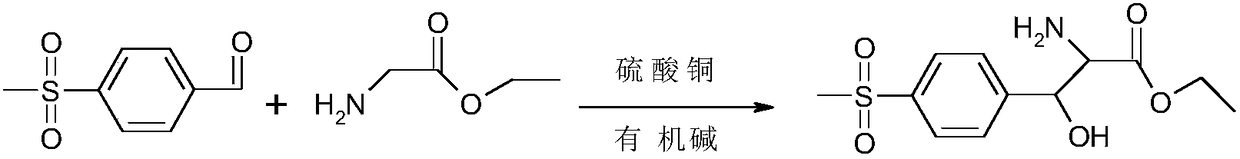

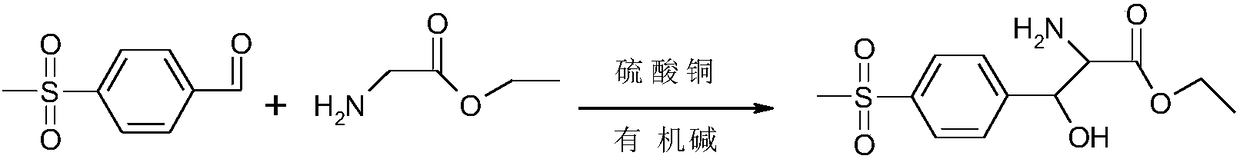

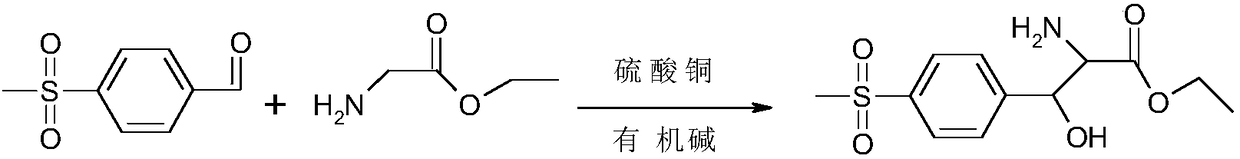

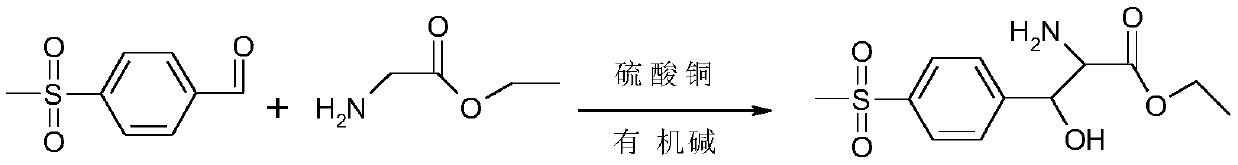

P-Methyl sulfone phenyl ethyl serinate and synthetic method thereof

ActiveCN108373430AExquisite designSimple processOrganic chemistryOrganic compound preparationBenzaldehydeMethyl sulfones

The invention discloses a synthetic method of P-methyl sulfone phenyl ethyl serinate, comprising the steps of S1, adding ethyl glycinate hydrochloride into methanol, and heating to dissolve to form afirst solution; S2, adding copper sulfate pentahydrate in the first solution to form a second solution by dissolving; S3, adjusting PH value of the second solution to meet the condition for alkaline reaction, adding P-methylsufonyl benzaldehyde to allow reaction, and holding the temperature and controlling the PH value to keep reaction condition values during reaction; S4, recycling methanol in the reacted materials, adding water to the residue to form a third solution, cooling, and centrifugally separating to obtain P-methyl sulfone phenyl ethyl serinate. The ethyl glycinate hydrochloride andP-methylsufonyl benzaldehyde are subjected to further reaction under the catalytic action of copper sulfate and an organic base to generate a target product; no sulfuric acid is used in the reactionprocess, the amount of waste acid in waste water is decreased, and the environment is protected; dangers that may occur during sulfuric acid transport and production are avoided, better safety is provided, and operating efficiency can be improved.

Owner:SUZHOU KAIYUAN MINSHENG SCI & TECH CORP

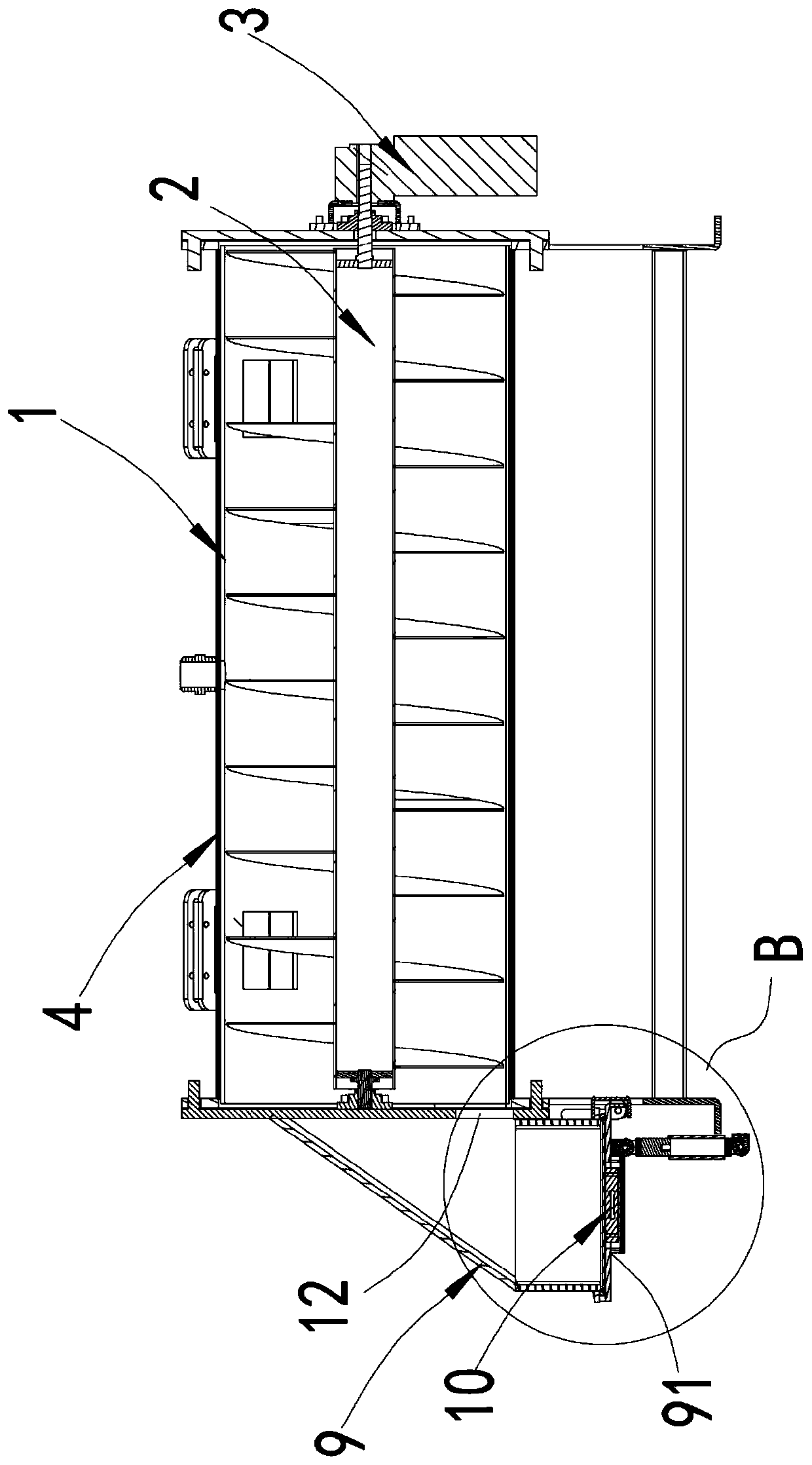

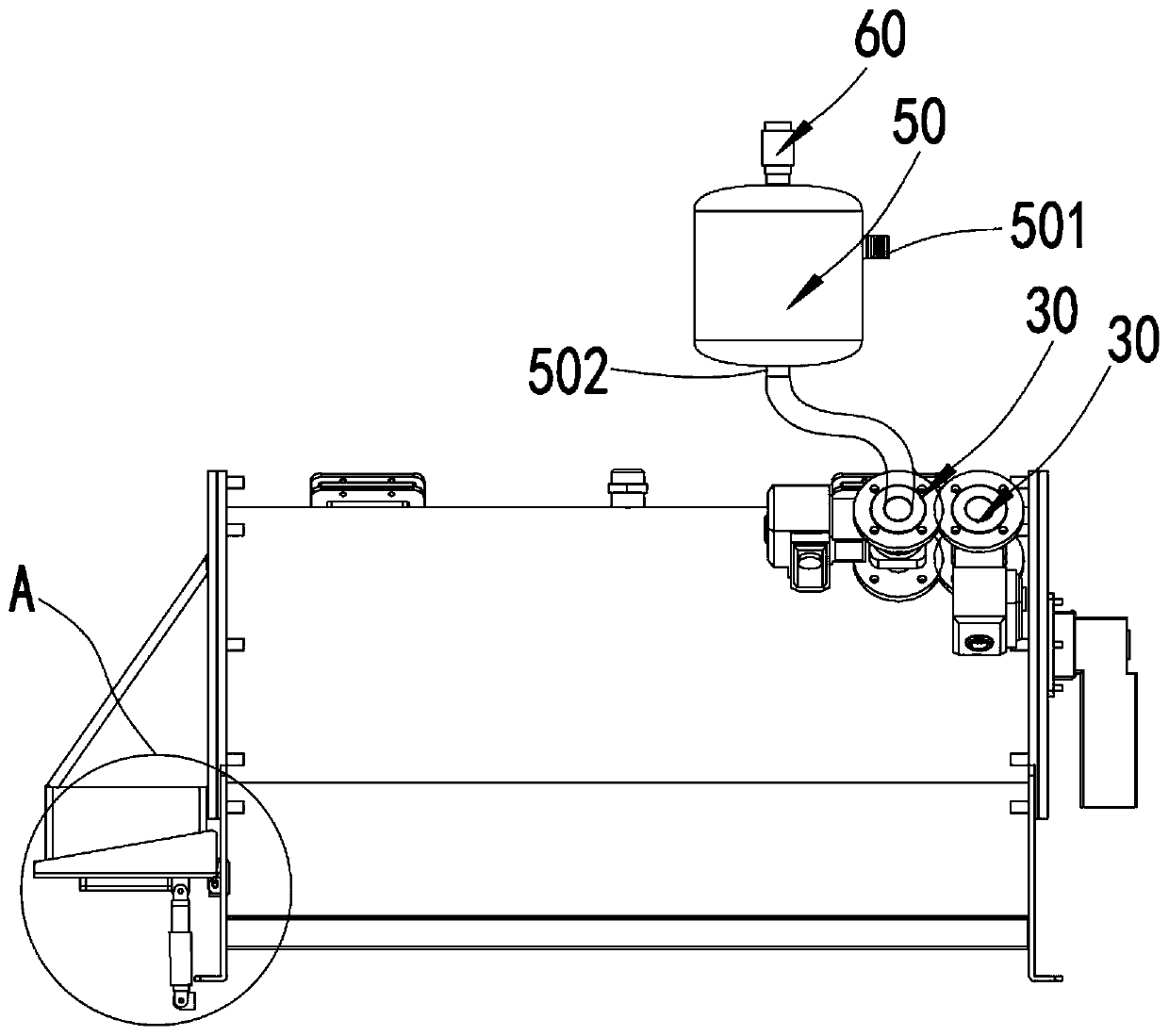

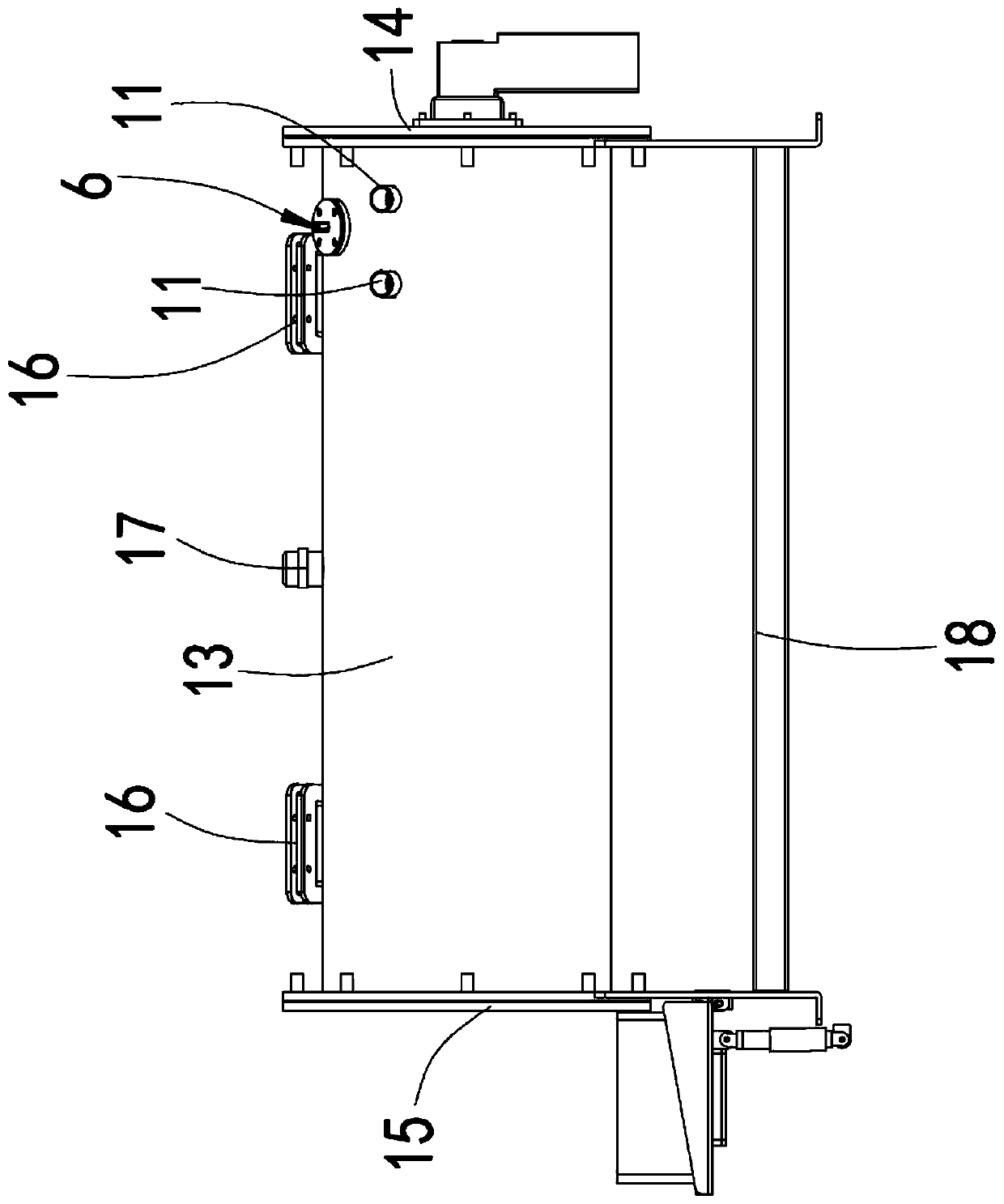

Quantitative discharging type fermentation equipment and fermentation method thereof

PendingCN111196741ARealize moving forwardImplement backDrying solid materials without heatClimate change adaptationProcess engineeringMechanical engineering

The invention discloses quantitative discharging type fermentation equipment and a fermentation method thereof. The quantitative discharging type fermentation equipment comprises a barrel, a spiral conveying shaft, a driving device, a heating device and a material receiving bin, wherein the barrel is provided with a feeding port and a discharging port which are located in the two ends; the spiralconveying shaft is arranged in the barrel body in the axis direction of the barrel body in a self-rotating mode; the driving device drives the spiral conveyor to rotate; the heating device is positioned on the barrel body; and the material receiving bin is arranged at the discharge port, a weighing sensor is integrated on a bottom plate of the material receiving bin, and the bottom plate of the material receiving bin can be opened and closed. According to the scheme, spiral horizontal conveying is adopted; forward movement and backward movement of materials can be realized; the standing time of the materials is controlled; the materials are turned over; the barrel body does not need an outlet capable of being automatically opened and closed, the internal structure is greatly simplified, the material receiving bin integrated with weighing equipment is arranged at the discharging port, a bottom plate of the material receiving bin can be opened, online quantitative discharging is effectively achieved, quantitative packaging is easy, and compared with the prior art, a feasible automatic weighing and discharging mode is provided.

Owner:SUZHOU HUANCHUAN ENERGY SAVING EQUIP CO LTD

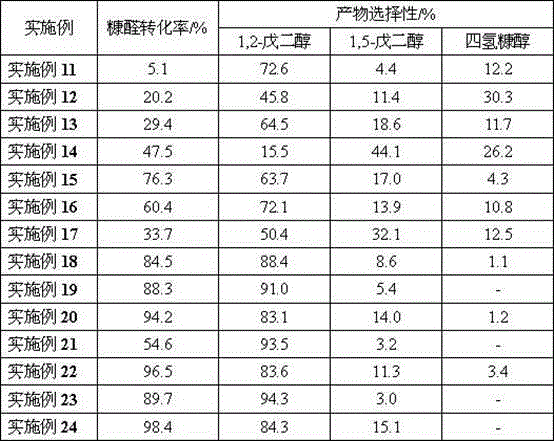

Catalyst containing Cu (I) and method for catalyzing furfural hydrogenation through catalyst

InactiveCN106268823AConducive to high value-added development and utilizationLow costOrganic compound preparationHydroxy compound preparationFiberSulfite salt

The invention relates to a non-noble metal catalyst and application thereof in catalysis of high-selectivity furfural hydrogenation to synthesize 1,2-pentanediol. Copper (I or II) salts and copper (I) oxides, nickel (II) salts and aluminum (III) salts and / or oxides thereof are taken as raw materials, glucose or sodium sulfite or sodium thiosulfate is taken as a reducing agent, the raw materials and the reducing agent are subjected to a co-precipitation reaction with sodium hydroxide and sodium carbonate, and precipitates are roasted to obtain the Cu (I)-Ni (II)-Al (III) ternary inorganic composite catalyst. The invention further discloses a method for synthesizing 1,2-pentanediol by selectively catalyzing furfural hydrogenation and reduction through the ternary composite catalyst. The catalyst is a non-noble metal inorganic compound and is low in raw material cost, simple in preparation process and low in cost; the raw material for synthesizing 1,2-pentanediol is furfural which comes from wood fiber waste materials, belongs to a natural product derivative and is low in cost, easy to obtain, sustainable and beneficial for high-added-value development and utilization of a large amount of waste wood fiber; the obtained product is high in selectivity and easy to separate and purify.

Owner:FOSHAN DEPINT ADVANCED MATERIALS CO LTD

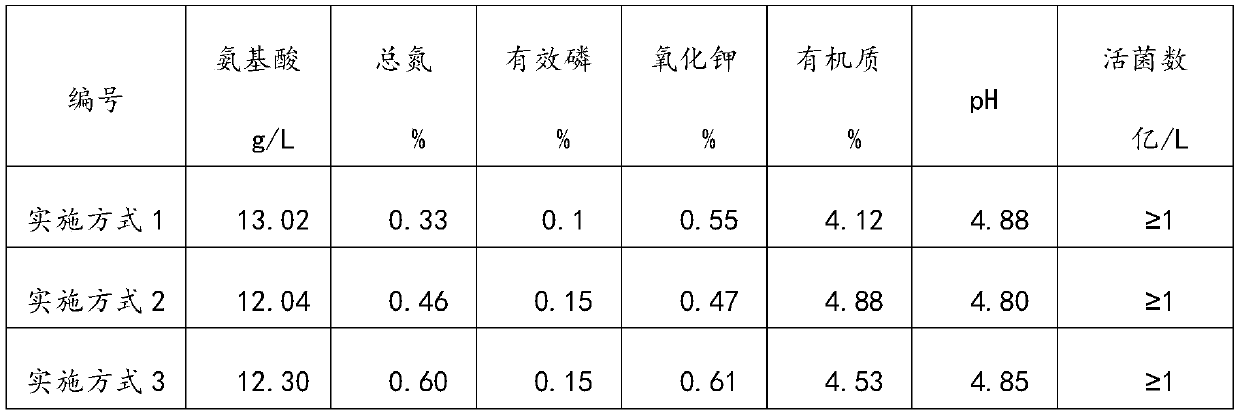

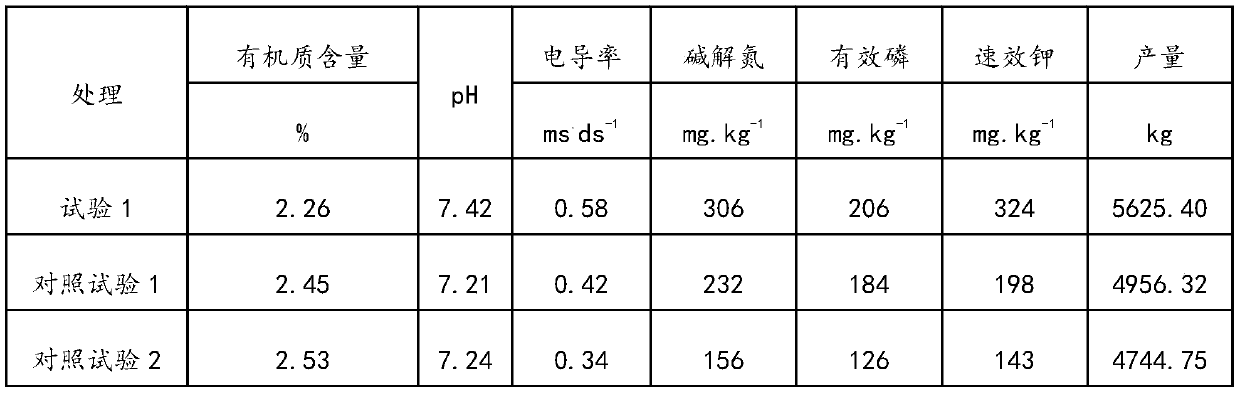

Preparation method of amino acid-containing biological bacterial fertilizer

InactiveCN110627544AOvercoming stubble diseaseImprove qualityBio-organic fraction processingBioloigcal waste fertilisersBacillus megateriumNutrients substances

The invention relates to a preparation method of amino acid-containing biological bacterial fertilizer, and belongs to the technical field of biological fertilizers. The method comprises the followingsteps of S1, uniformly mixing fruit and vegetable wastes, an organic carbon source and water, and performing sealed fermentation at the temperature of 28-32 DEG C for 25-35 days to obtain a fermentedmaterial A; S2, performing solid-liquid separation treatment on the fermented material A obtained in the step S1 to obtain enzyme liquid; S3, weighing an organic nitrogen source to perform boiling treatment, and then performing cooling to the normal temperature; and S4, adding the cooled organic nitrogen source obtained in the step S3, a bacillus megaterium live bacteria preparation and a brevicompactum live bacteria preparation into the enzyme liquid obtained in the step S2, performing mixing, and performing sealed fermentation for 7-10 days to obtain the amino acid-containing biological bacterial fertilizer. According to the method, raw material components are simple and easy to obtain, operation is convenient, the prepared amino acid-containing biological bacterial fertilizer has relatively high amino acid content and is rich in nutrient substances such as organic matters, trace elements and the like, and the crop yield can be effectively improved.

Owner:WEIFANG UNIV OF SCI & TECH

Synthesizing method for phenylacetic acid

ActiveCN109574825AEliminate security concernsAvoid askingPreparation from carboxylic acid esters/lactonesMass ratioPhenylacetic acid

The invention discloses a synthesizing method for phenylacetic acid. The synthesizing method comprises the following steps: enabling benzene and glycolide or oligoglycolic acid in the mass ratio of (25 to 5) to 1 to react for 1 to 24 hours at the temperature of 35 to 80 DEG C under the catalysis of Lewis acid with the amount-of-substance of 1.0 to 1.3 times that of oxyacetyl; performing quenchingreaction by using water, adding an inorganic strong acid for acidifying, performing oil-water phase stratifying, removing a solvent by distilling, and drying to obtain the phenylacetic acid product. According to the synthesizing method, highly toxic chemicals, such as hydrogen cyanide and carbon monoxide, are not selected and used so as to eliminate product safety concerns caused by micro-raw material residue or trace raw material residue; extremely high reactive pressure conditions are also not adopted, so that high-pressure reaction equipment is not required to be used; therefore, the safetyin a production process is improved; meanwhile, the raw materials used in the synthesizing method is high in biodegradability, green and safe; and synthesized reaction atoms have high economical efficiency and good economical efficiency.

Owner:TAIXING LINGFEI CHEM TECH CO LTD

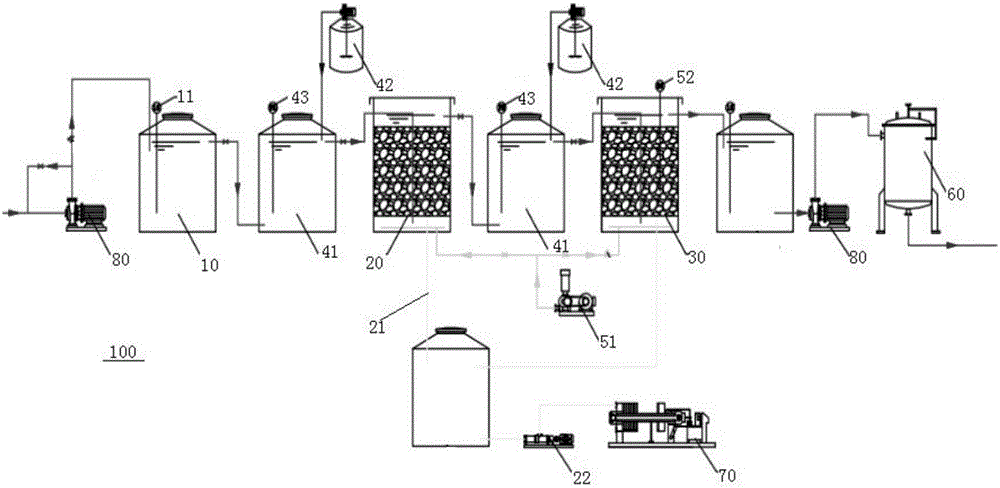

Comprehensive wastewater treatment device for physical and chemical laboratory

InactiveCN105948380AAdvanced technologyShort processBiological treatment apparatusMultistage water/sewage treatmentParticulatesElectrolysis

The invention discloses a comprehensive wastewater treatment device for a physical and chemical laboratory. The comprehensive wastewater treatment device comprises a wastewater collecting device, a microelectrolysis detoxification module, a solid microorganism degrading and purifying module, an automatic pH regulating module, an automatic dissolved oxygen adjusting module, a terminal particle separation module, a solid-liquid separation device and a control module, wherein the microelectrolysis detoxification module is connected with the wastewater collecting device to perform electrolytic treatment on wastewater; the solid microorganism degrading and purifying module is connected with the microelectrolysis detoxification module to perform biological degradation on the wastewater after electrolytic treatment; the automatic pH regulating module is connected with the microelectrolysis detoxification module and the solid microorganism degrading and purifying module to perform pH regulation on the wastewater entering the microelectrolysis detoxification module and the solid microorganism degrading and purifying module; the solid-liquid separation device is connected with the microelectrolysis detoxification module and the solid microorganism degrading and purifying module. According to the wastewater treatment device of the embodiment of the invention, the technology is advanced, the process is short, and the secondary pollution is small.

Owner:上海惠源水处理设备有限公司

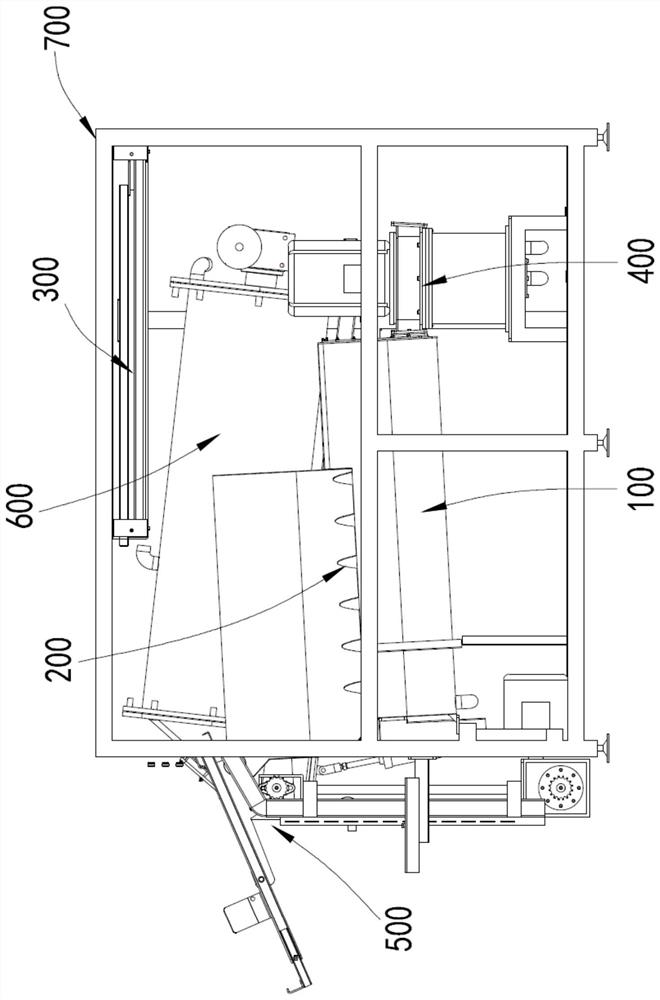

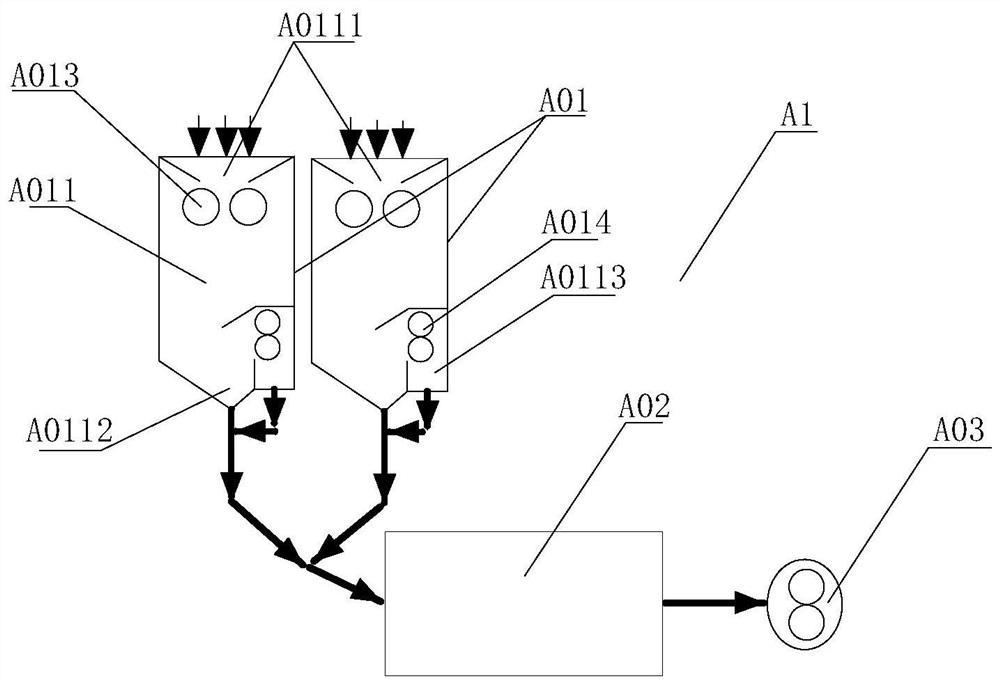

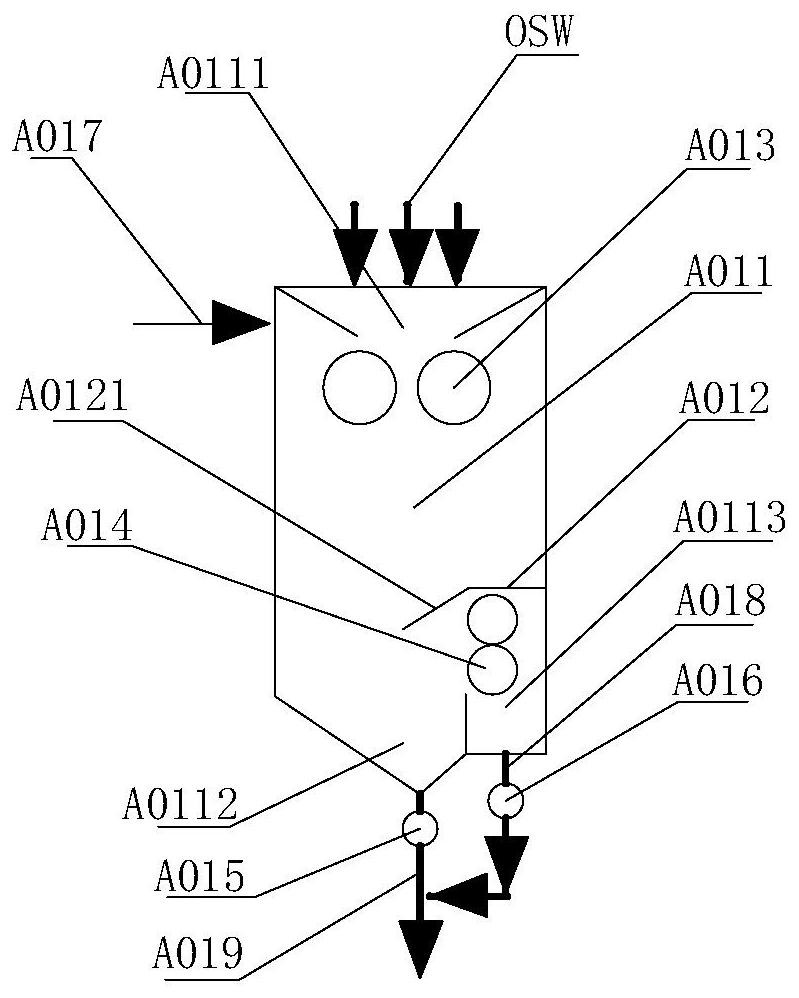

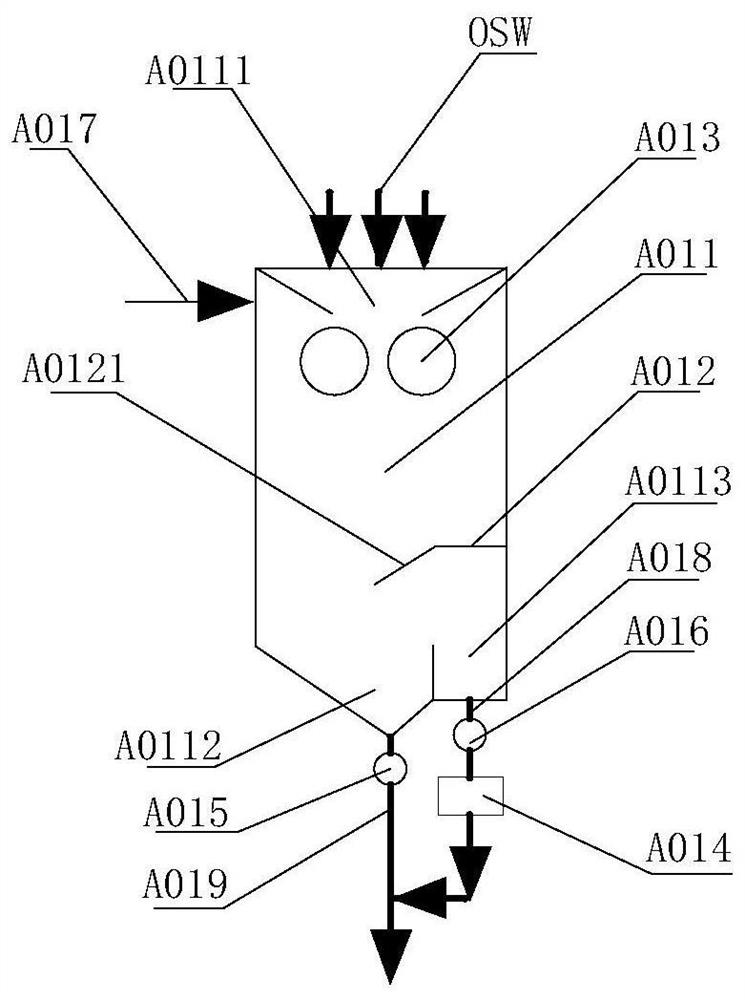

Wet garbage treatment device and wet garbage treatment method

PendingCN111659696AExquisite designHighly integratedSolid waste disposalBottle emptyingRefuse collectorRefuse Disposals

The invention discloses a wet garbage treatment device and a wet garbage treatment method. The treatment device comprises a garbage can dumping machine, a garbage collector, a purification device, a garbage conveyor, a garbage crusher, and a garbage fermentation device, wherein the garbage can dumping machine has a structure for dumping a garbage can; the garbage collector has a structure for storing garbage and separating solids from liquid; the purification device at least has a structure which can output ozone-dissolved water into the garbage collector; the garbage conveyor has a structurefor discharging the garbage located in the garbage collector; the garbage crusher is connected to the garbage collector and has a structure for crushing the garbage in the garbage collector; and the garbage fermentation device is connected to the garbage crusher and at least has a structure for drying and outputting garbage slurry entering the garbage fermentation device. The wet garbage treatmentdevice has relatively high overall integration level, omits solid-liquid separation equipment and occupies a small area; and the purification device is used for generating water with a large amount of dissolved ozone for washing the garbage, can achieve the disinfection, sterilization, deodorization and the like with no need for additional substances, and has high purification efficiency, high purification quality and good environmental friendliness.

Owner:环川环保设备(苏州)有限公司

A kind of synthetic method of phenylacetic acid

ActiveCN109574825BEliminate security concernsAvoid askingPreparation from carboxylic acid esters/lactonesPhenylacetic acidStrong acids

The invention discloses a synthesizing method for phenylacetic acid. The synthesizing method comprises the following steps: enabling benzene and glycolide or oligoglycolic acid in the mass ratio of (25 to 5) to 1 to react for 1 to 24 hours at the temperature of 35 to 80 DEG C under the catalysis of Lewis acid with the amount-of-substance of 1.0 to 1.3 times that of oxyacetyl; performing quenchingreaction by using water, adding an inorganic strong acid for acidifying, performing oil-water phase stratifying, removing a solvent by distilling, and drying to obtain the phenylacetic acid product. According to the synthesizing method, highly toxic chemicals, such as hydrogen cyanide and carbon monoxide, are not selected and used so as to eliminate product safety concerns caused by micro-raw material residue or trace raw material residue; extremely high reactive pressure conditions are also not adopted, so that high-pressure reaction equipment is not required to be used; therefore, the safetyin a production process is improved; meanwhile, the raw materials used in the synthesizing method is high in biodegradability, green and safe; and synthesized reaction atoms have high economical efficiency and good economical efficiency.

Owner:TAIXING LINGFEI CHEM TECH CO LTD

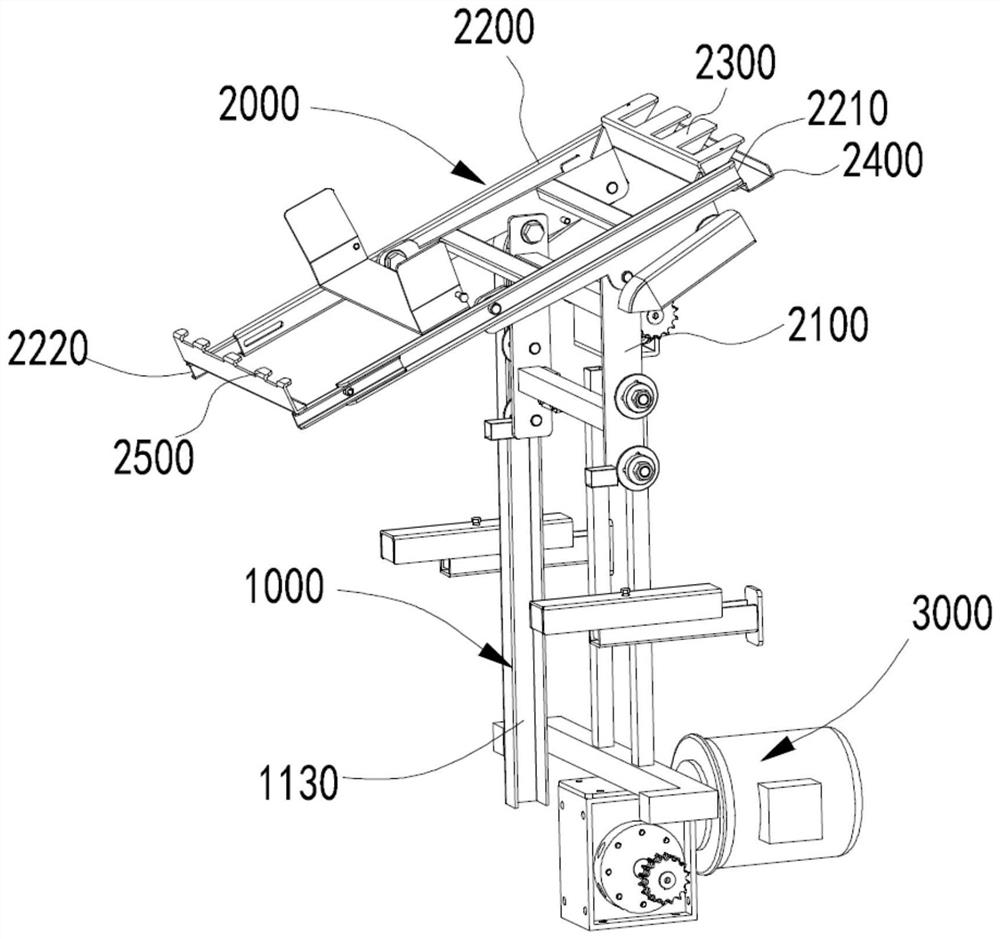

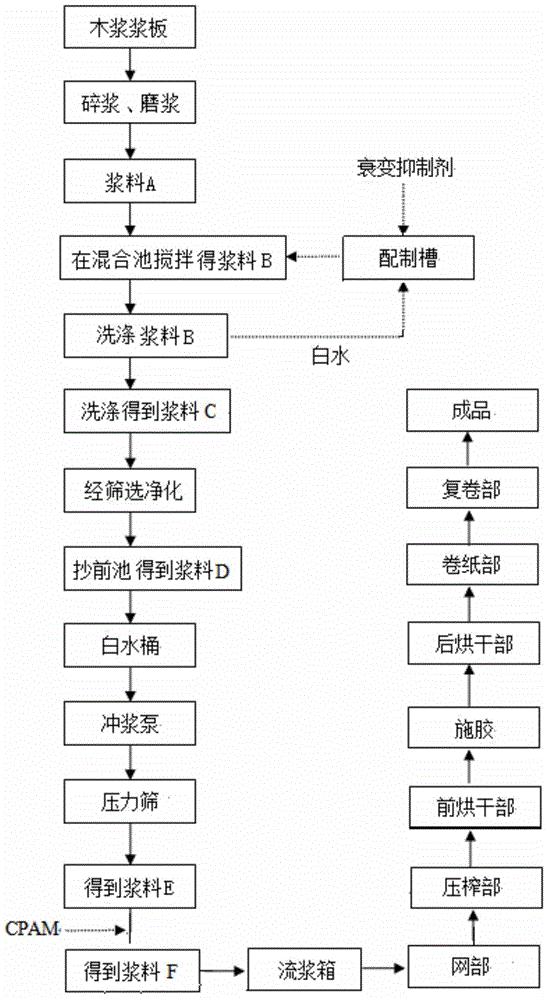

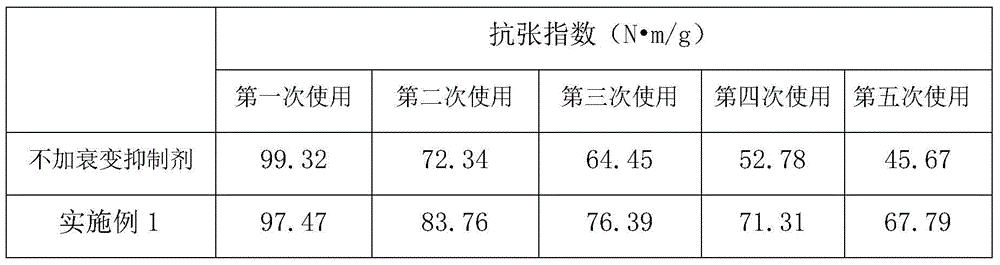

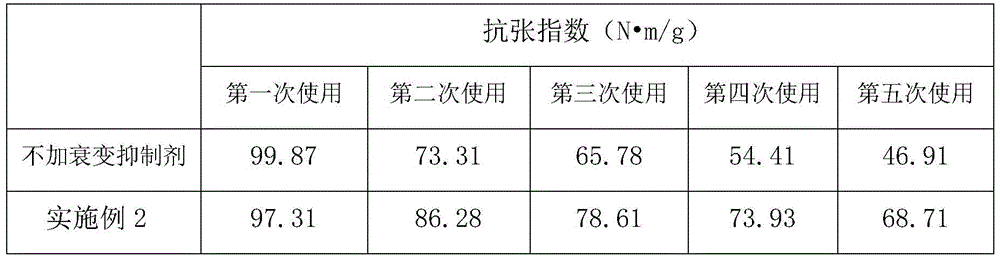

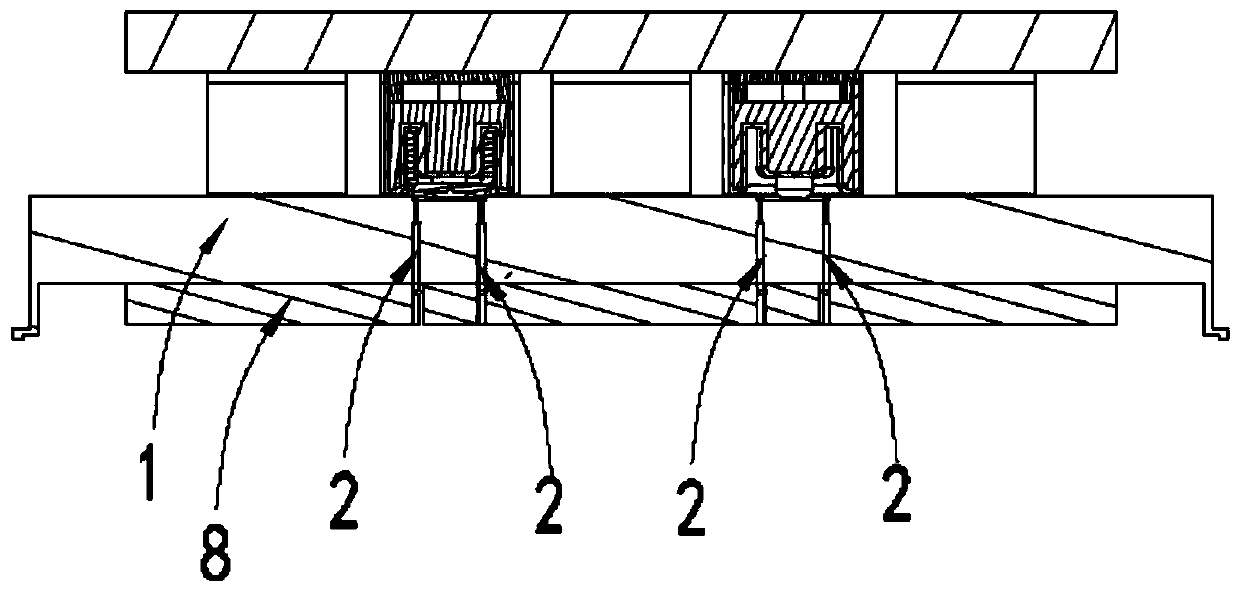

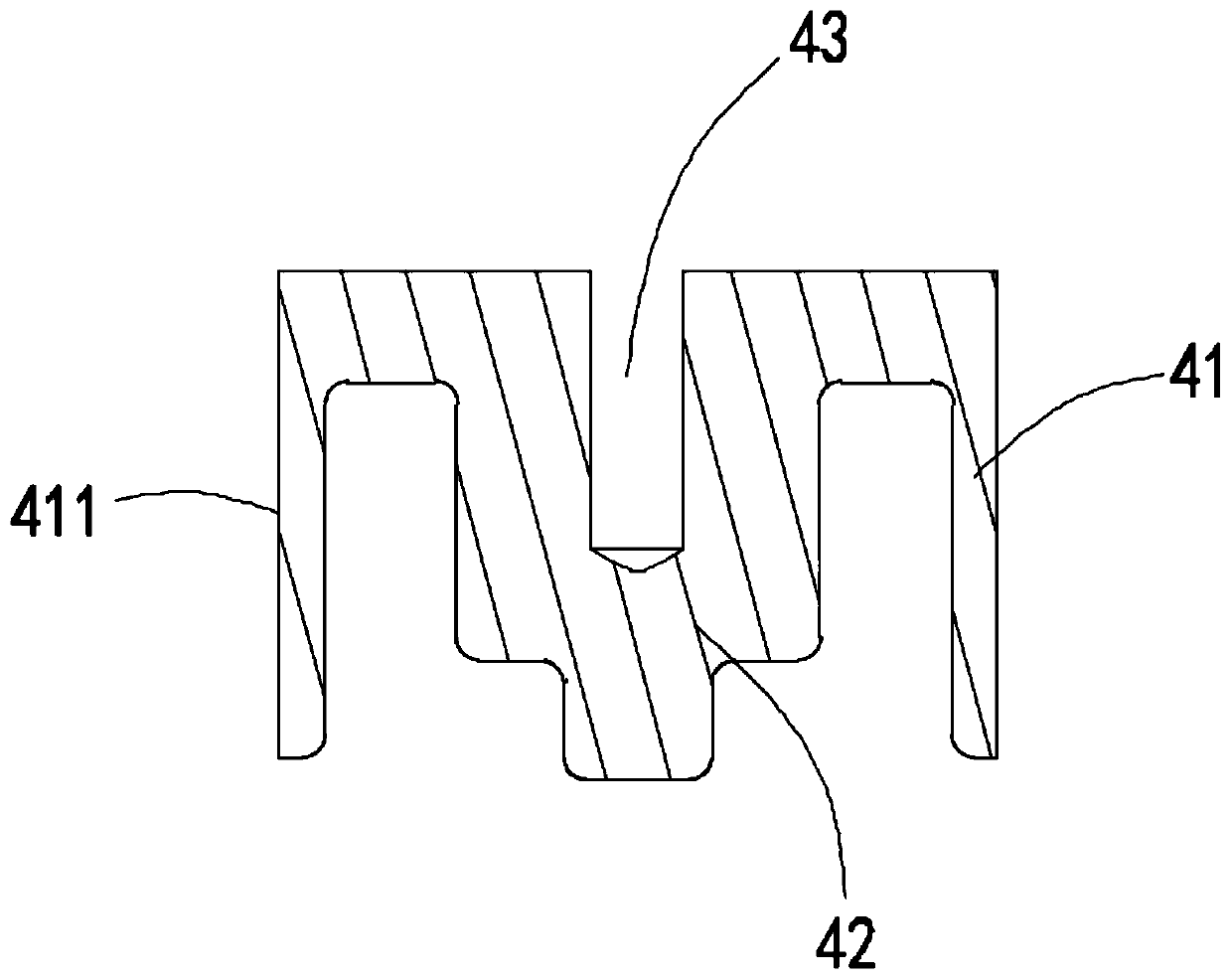

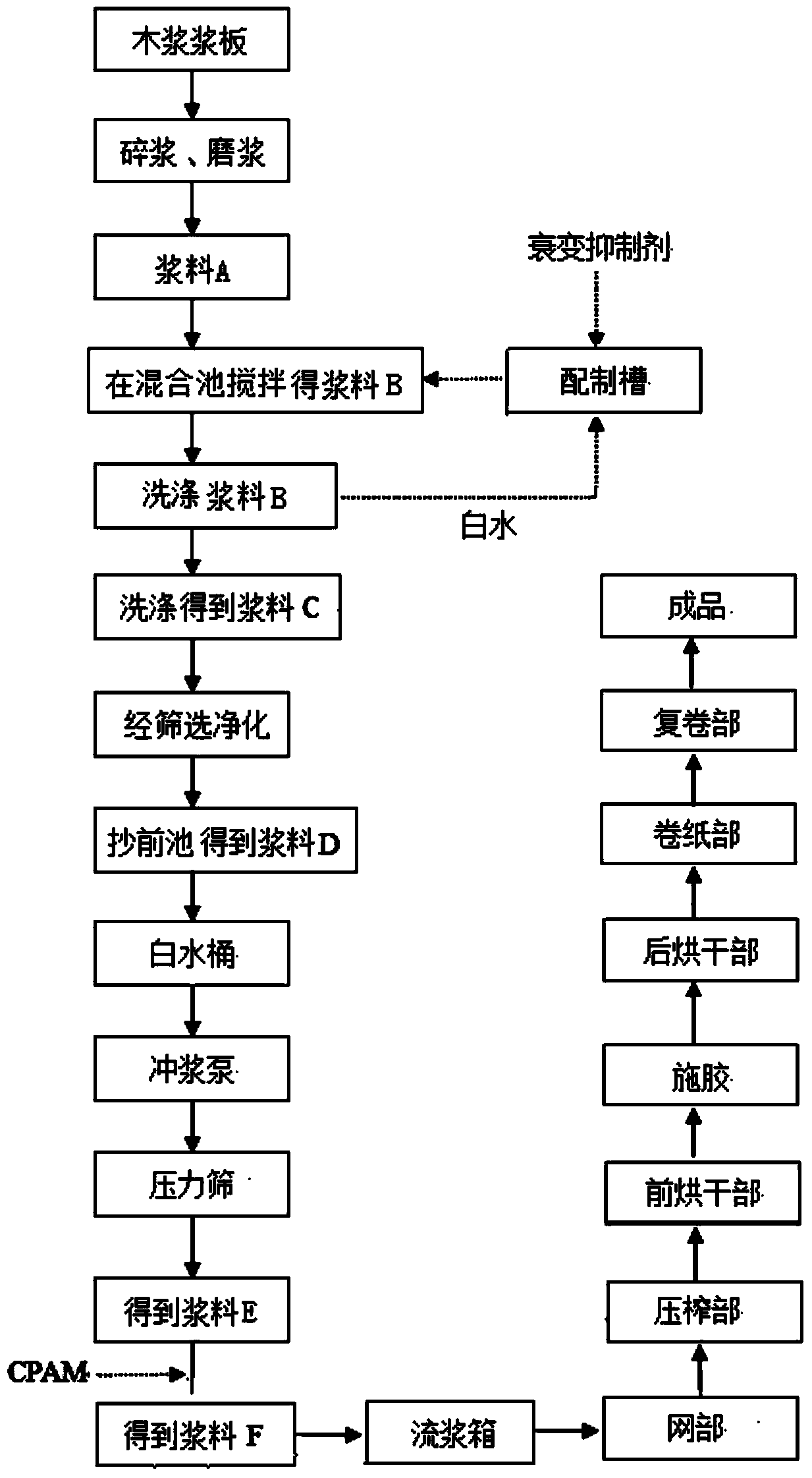

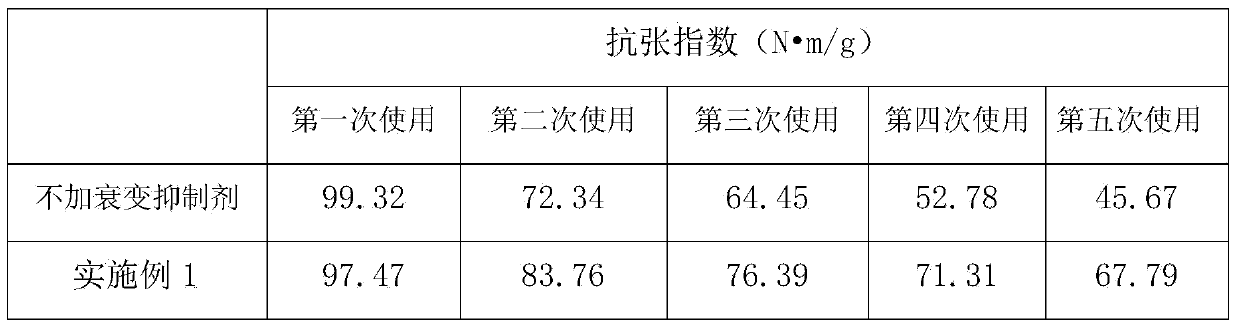

A papermaking method for inhibiting plant fiber decay

ActiveCN104179069BDecay inhibitionImprove retentionWashing/displacing pulp-treating liquorsPaper forming aids additionFiber bundleSlurry

The invention relates to a papermaking method for inhibiting plant fiber decay. The method comprises the steps of pulping and refining wood pulp boards to obtain slurry A; preparing fiber decay inhibitor suspension in a preparation tank; mixing slurry A with the prepared The suspension is stirred at a high speed in the mixing tank to obtain a uniformly mixed slurry B; after washing the slurry B, the slurry C is obtained; the slurry C is screened and purified and enters the forebay tank to obtain the slurry D, and then passes through a white water bucket, washed Slurry pump, enter the pressure screen, remove fiber bundles and impurities in the pressure screen to obtain slurry E, add CPAM retention aid to obtain slurry F; slurry F enters the headbox for slurry distribution, and dehydrates in the wire part to form wet paper After pressing, pre-drying, surface sizing, and post-drying; the master roll is formed in the roll paper part, and then rewinded and cut into products of required specifications. The method of the invention has the advantages of simple production process, the suppression of fiber decay can be realized from the source and the suppression effect is long-lasting, and the additives added are good in environmental friendliness and the like.

Owner:WUHAN IND TECH RES INST OF GEO RESOURES ENVIRONMENT CO LTD

A kind of catalyst containing cu(i) and method for catalyzing furfural hydrogenation therewith

InactiveCN106268823BConducive to high value-added development and utilizationLow costOrganic compound preparationHydroxy compound preparationFiberSulfite salt

The invention relates to a non-noble metal catalyst and application thereof in catalysis of high-selectivity furfural hydrogenation to synthesize 1,2-pentanediol. Copper (I or II) salts and copper (I) oxides, nickel (II) salts and aluminum (III) salts and / or oxides thereof are taken as raw materials, glucose or sodium sulfite or sodium thiosulfate is taken as a reducing agent, the raw materials and the reducing agent are subjected to a co-precipitation reaction with sodium hydroxide and sodium carbonate, and precipitates are roasted to obtain the Cu (I)-Ni (II)-Al (III) ternary inorganic composite catalyst. The invention further discloses a method for synthesizing 1,2-pentanediol by selectively catalyzing furfural hydrogenation and reduction through the ternary composite catalyst. The catalyst is a non-noble metal inorganic compound and is low in raw material cost, simple in preparation process and low in cost; the raw material for synthesizing 1,2-pentanediol is furfural which comes from wood fiber waste materials, belongs to a natural product derivative and is low in cost, easy to obtain, sustainable and beneficial for high-added-value development and utilization of a large amount of waste wood fiber; the obtained product is high in selectivity and easy to separate and purify.

Owner:FOSHAN DEPINT ADVANCED MATERIALS CO LTD

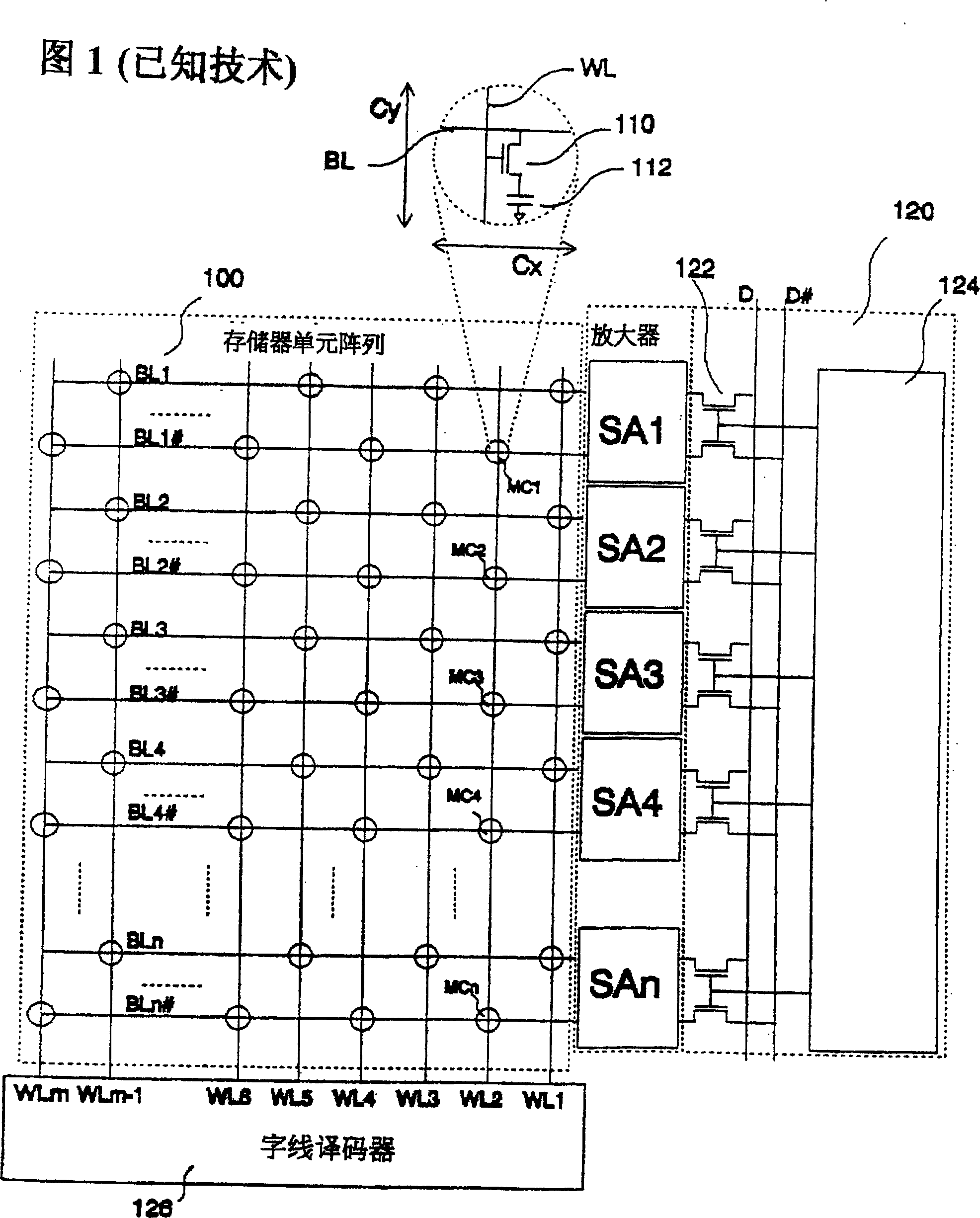

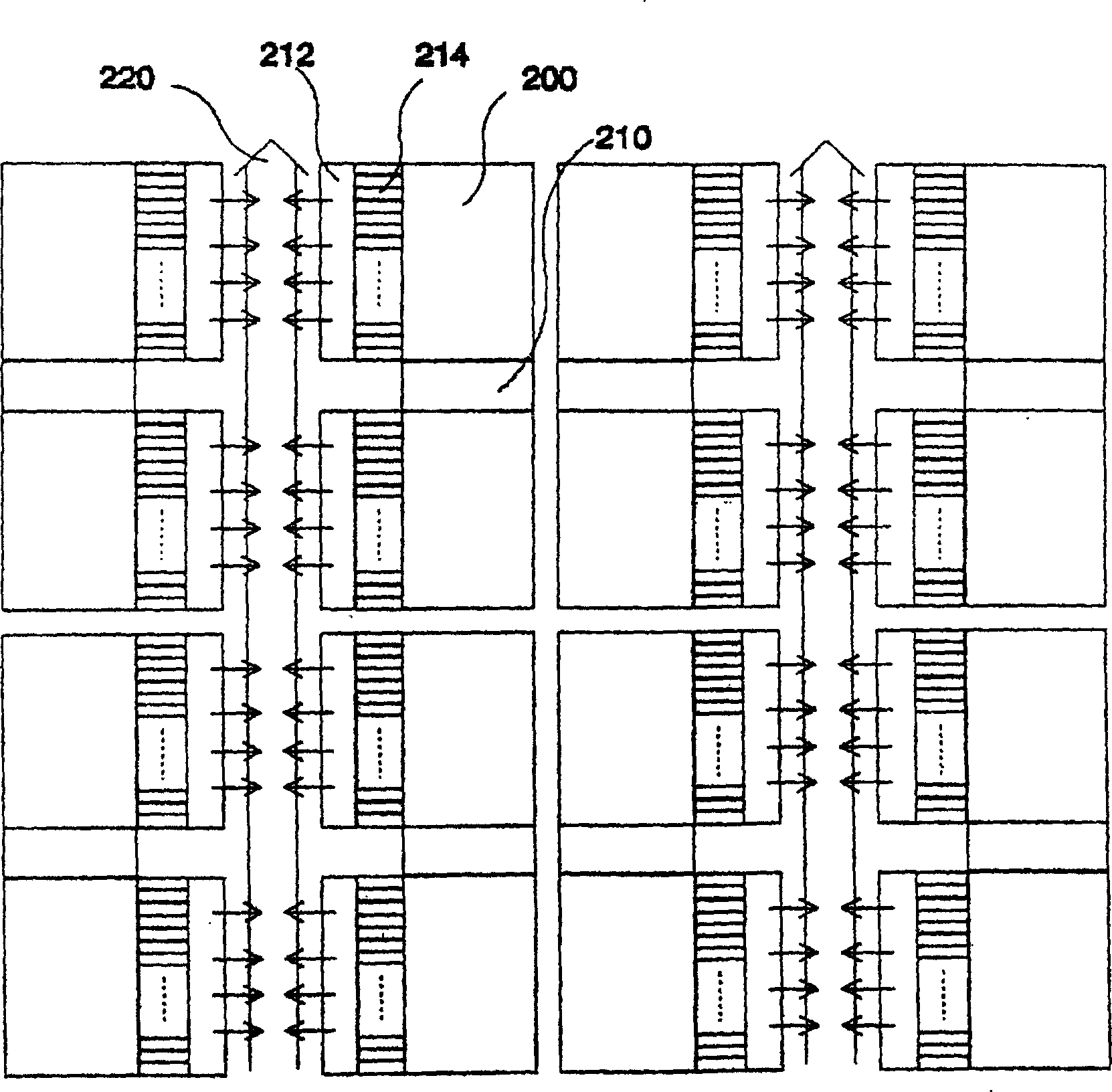

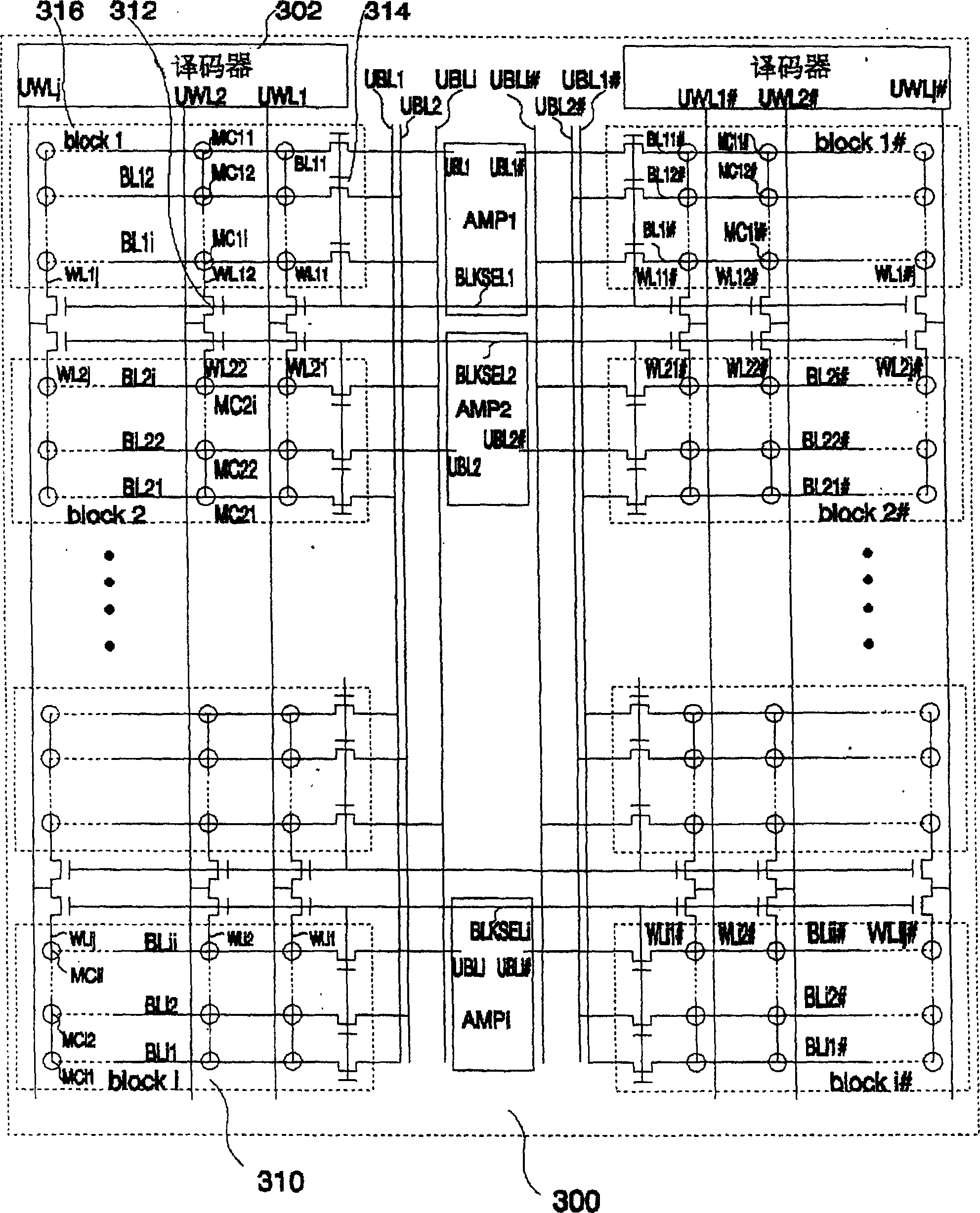

Method for producing embedded DRAM unit array with selected transistor

InactiveCN1280828CReduce bit line parasitic loadingImprove performanceDigital storageBit lineInternal memory

A dynamic random access memory disclosed by the invention adopts a multi-dimensional bit line structure to solve the long-standing problem of excessively dense distribution intervals of memory devices. Improvements in decoder design have further reduced the overall area of such memory devices. The invention also discloses a new memory access method, which can make external users completely unaware of the data update operation performed inside the memory. By using this memory structure, DRAM with higher performance can be manufactured without reducing memory density. Moreover, the memory requirements for system support are greatly simplified.

Owner:萧正杰

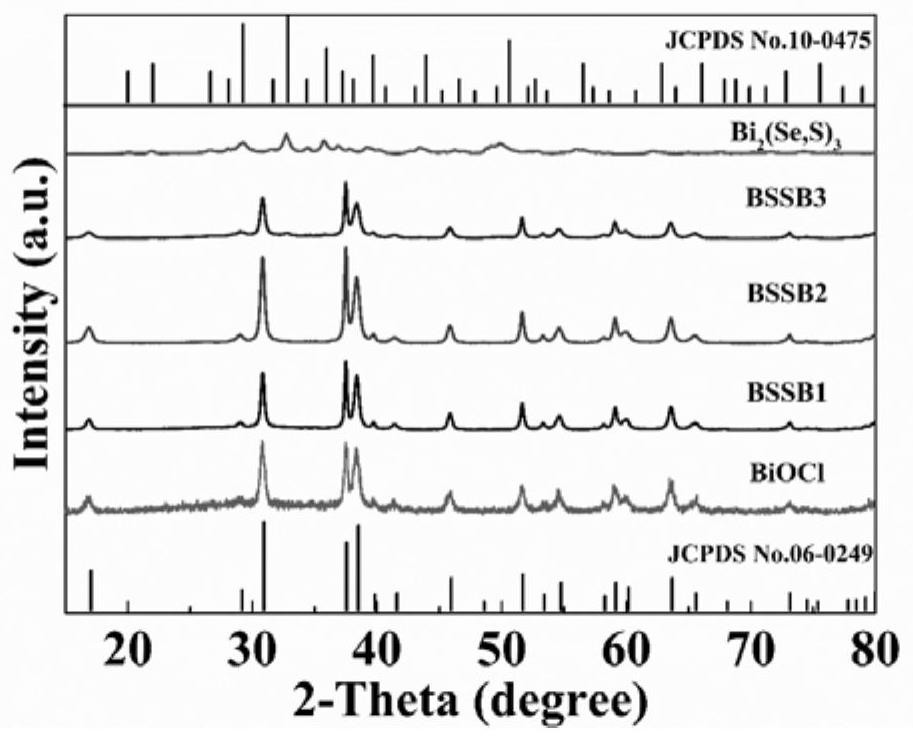

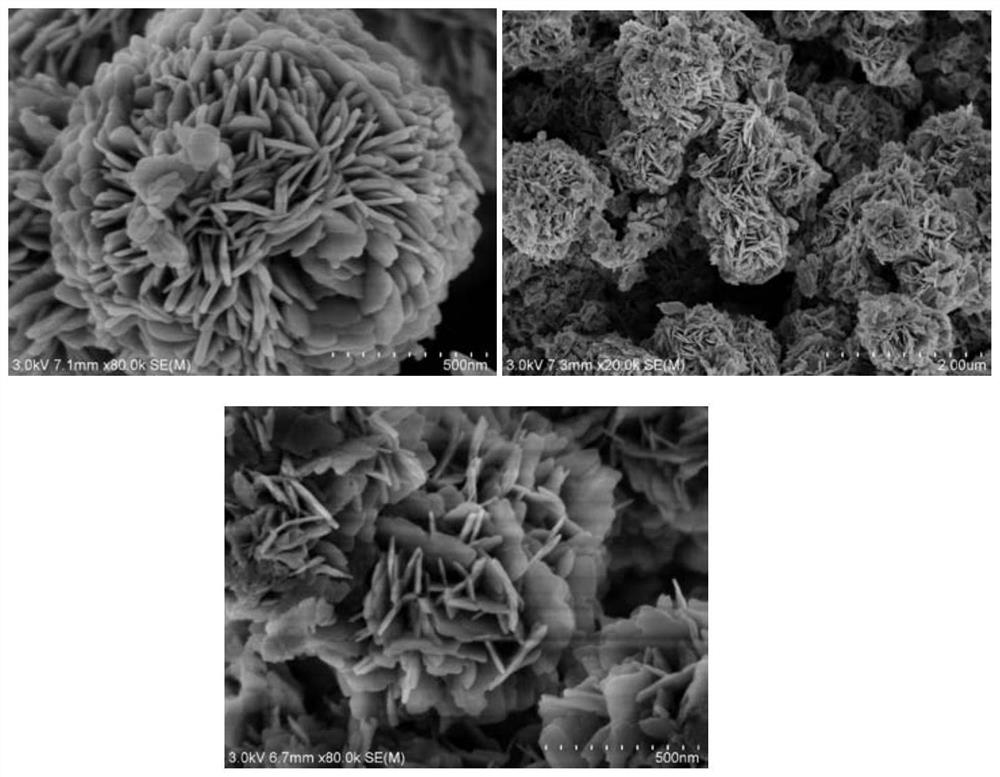

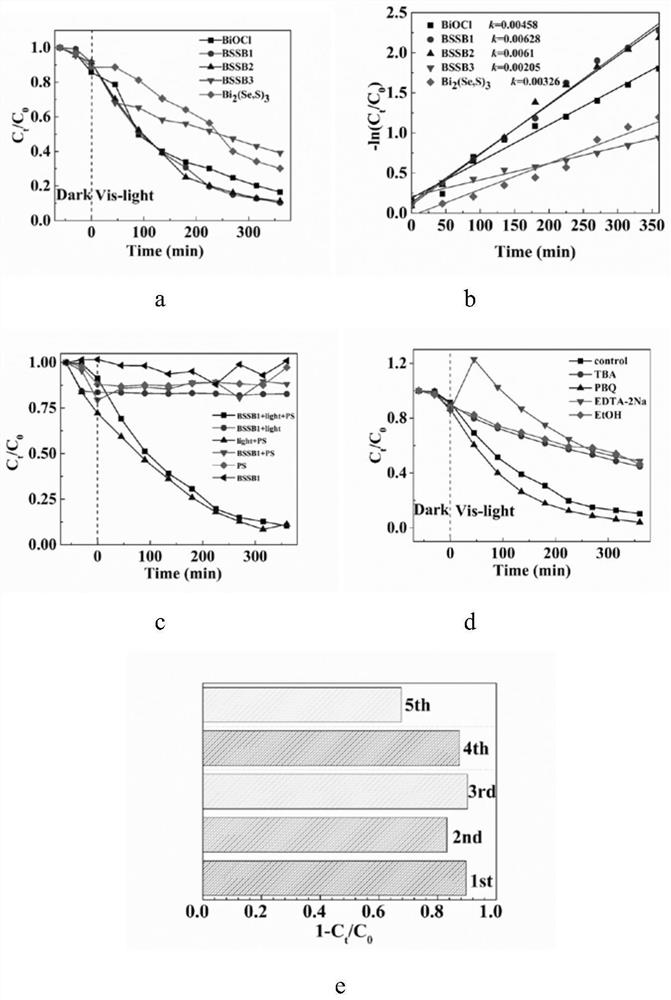

Method for microwave-assisted synthesis of Z-type heterojunction catalytic material

PendingCN114653384ASimple methodEasy to operateWater/sewage treatment by irradiationWater treatment compoundsPtru catalystCatalytic oxidation

The technical scheme belongs to the field of environmental engineering, and relates to the technical field of advanced catalytic oxidation water treatment, in particular to a microwave-assisted synthesis method of a Z-type heterojunction catalytic material, bismuth nitrate, sodium selenite, L-cysteine and sodium tartrate are taken as raw materials, a microwave reaction system is assisted, and a Bi2 (Se, S) 3 / BiOCl Z-type heterojunction catalyst is obtained. According to the preparation method provided by the technical scheme, green and safe raw materials are used, the method is simple, the process is easy to operate, and continuous production can be realized; meanwhile, the preparation method is low in temperature requirement and low in energy consumption during reaction.

Owner:银睿(浙江)环保科技有限公司

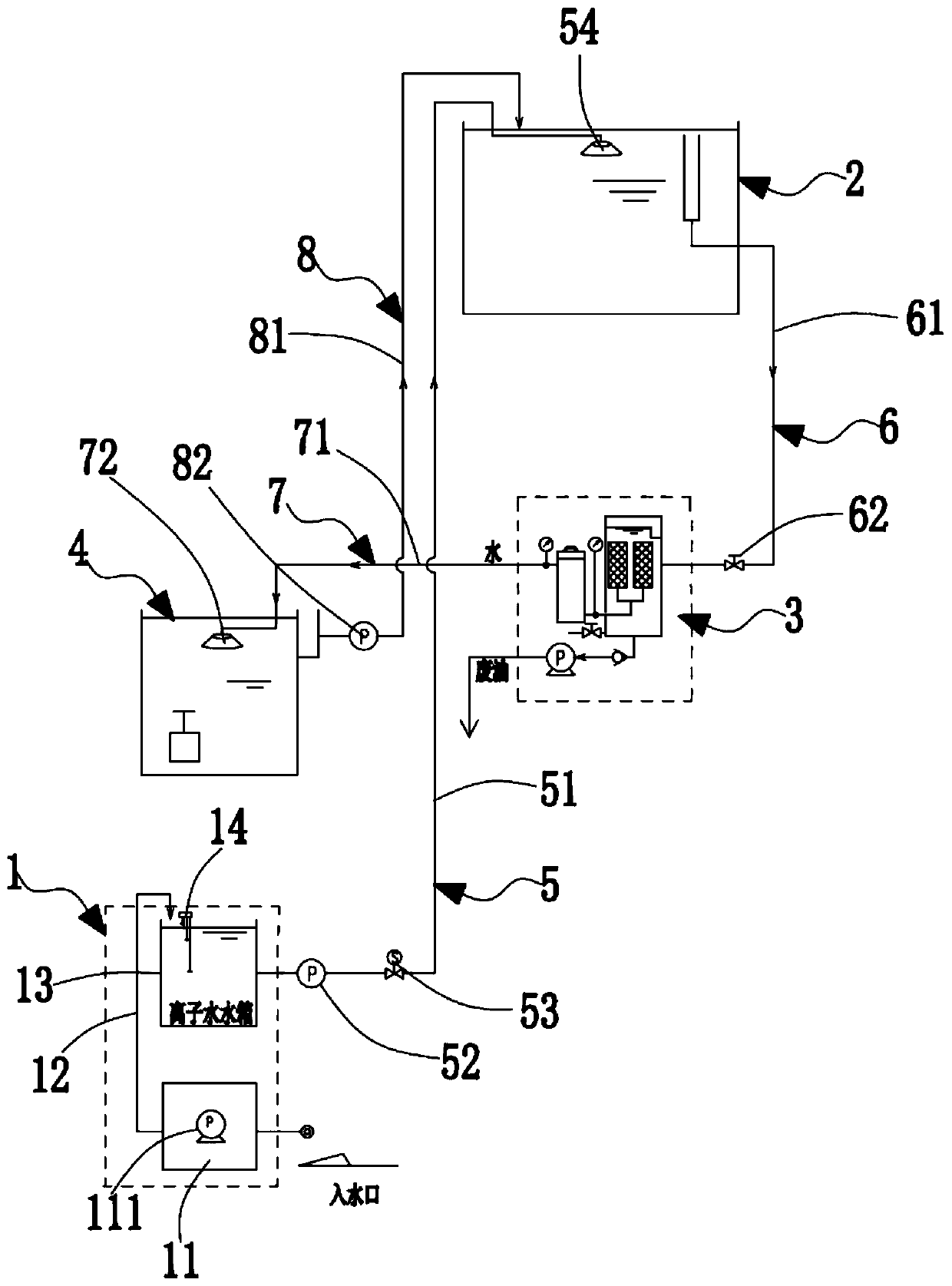

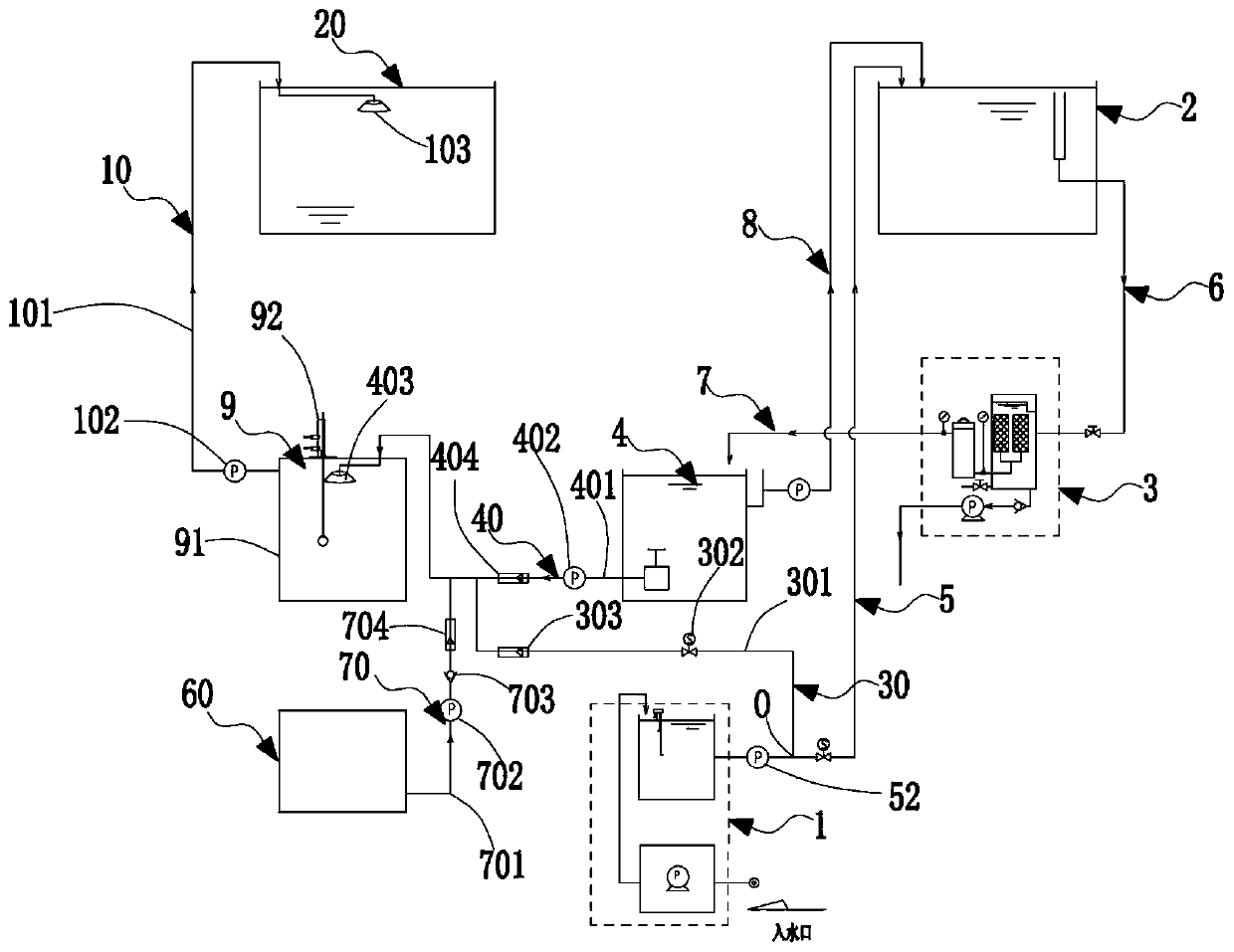

Liquid volume reduction device and energy saving and emission reduction type machining water treatment system

PendingCN109748348AReduce the amount of waterSmall volumeWater/sewage treatmentMultistage water/sewage treatmentWater treatment systemEnvironmental engineering

The invention discloses a liquid volume reduction device and an energy saving and emission reduction type machining water treatment system, wherein the liquid volume reduction device comprises a liquid feed pipeline, the liquid feed pipeline is connected with a heating tank, the heating tank heats a liquid in the heating tank through a heater, the heating tank is further provided with a water pumping pipeline connected with a nozzle in an atomizing chamber, the atomizing chamber is connected with an exhaust fan, an air outlet of the exhaust fan is connected with the atmosphere. The scheme usesthe characteristic that liquids of different densities are layered, the waste liquid is heated, then the different substances are layered, the heated water on the lower layer is atomized and discharged, so that the quantity of water in the waste liquid is reduced, the volume of the waste liquid is efficiently reduced, the discharged vapor is directly blended into the atmosphere, no pollution is caused, meanwhile, not like discharging water directly, no extra pipeline needs to be configured to transport, the environmentally friendliness is good, the whole equipment is compact in structure andlow in energy consumption, and the effective implementation means is provided for the volume reduction of the liquid.

Owner:TAKAHASHI METAL MFG SUZHOU

An organic solid waste pretreatment system and process, and a corresponding organic solid waste continuous hydrothermal treatment system and process

ActiveCN111346897BIncrease the surface area of oxidative heat hydrolysisImprove uniformityWaste processingTransportation and packagingProcess engineeringSlurry

Owner:TSINGHUA UNIV

The synthetic method of p-thymphenyl phenyl serine ethyl ester and p-thymphenyl phenyl serine ethyl ester

ActiveCN108373430BReduce contentImprove protectionOrganic chemistryOrganic compound preparationOrganic baseBenzaldehyde

The invention discloses a synthetic method of P-methyl sulfone phenyl ethyl serinate, comprising the steps of S1, adding ethyl glycinate hydrochloride into methanol, and heating to dissolve to form afirst solution; S2, adding copper sulfate pentahydrate in the first solution to form a second solution by dissolving; S3, adjusting PH value of the second solution to meet the condition for alkaline reaction, adding P-methylsufonyl benzaldehyde to allow reaction, and holding the temperature and controlling the PH value to keep reaction condition values during reaction; S4, recycling methanol in the reacted materials, adding water to the residue to form a third solution, cooling, and centrifugally separating to obtain P-methyl sulfone phenyl ethyl serinate. The ethyl glycinate hydrochloride andP-methylsufonyl benzaldehyde are subjected to further reaction under the catalytic action of copper sulfate and an organic base to generate a target product; no sulfuric acid is used in the reactionprocess, the amount of waste acid in waste water is decreased, and the environment is protected; dangers that may occur during sulfuric acid transport and production are avoided, better safety is provided, and operating efficiency can be improved.

Owner:SUZHOU KAIYUAN MINSHENG SCI & TECH CORP

A kind of production method of kraft cardboard

ActiveCN104153230BTake advantage ofGood friendlinessPaper recyclingWaste paper working-upHeifer calfPapermaking

Owner:ZHEJIANG JINGXING PAPER

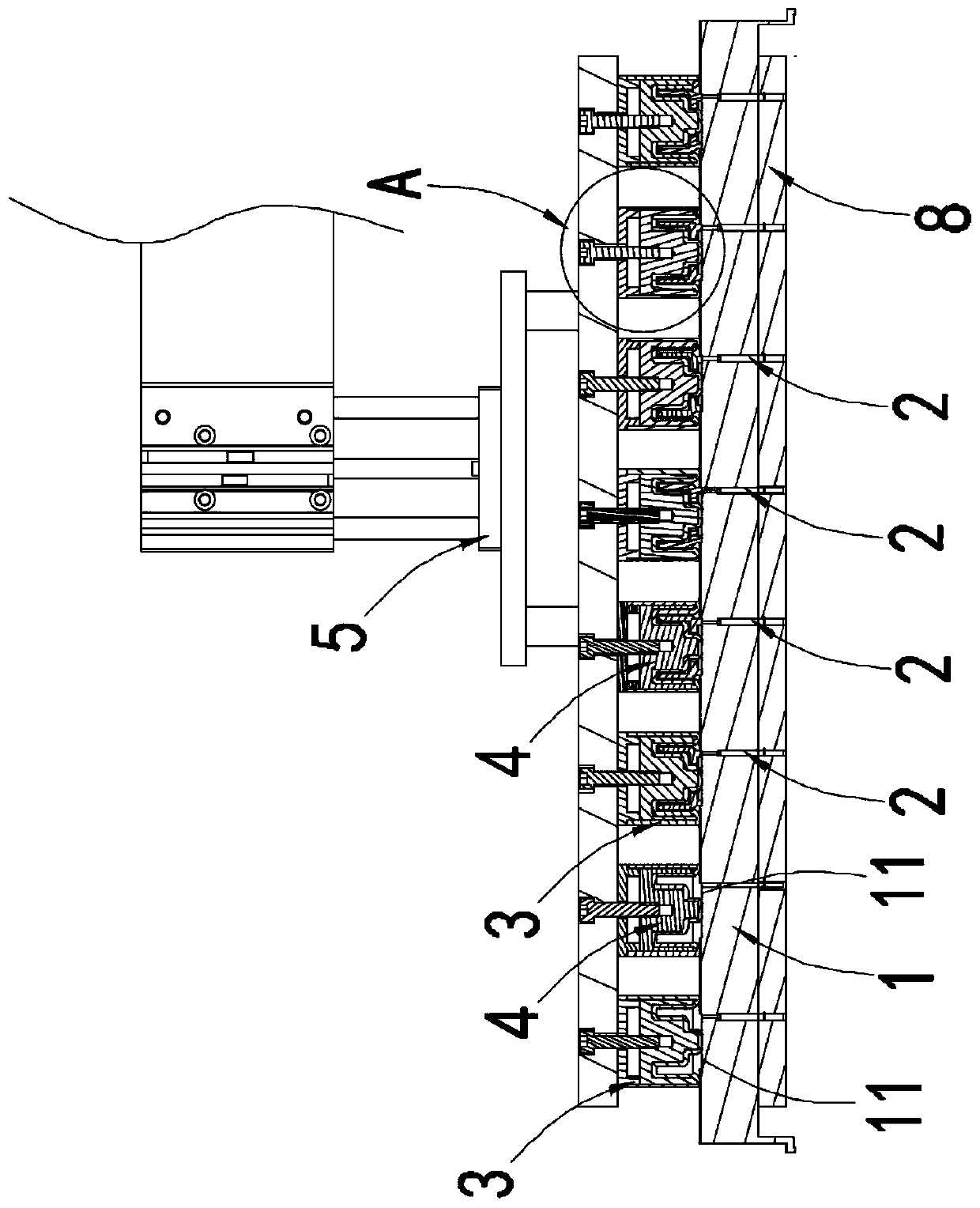

Dielectric barrier discharge plasma passivation device and passivation method thereof

PendingCN111112236AImprove corrosion resistanceExtended service lifeCleaning processes and apparatusPlasma techniqueMaterials scienceCorrosion resistant

The invention discloses a dielectric barrier discharge plasma passivation device and a passivation method thereof, wherein the passivation device comprises an insulated support plate, a negative electrode, a barrier dielectric sleeve, a positive electrode and a moving device, at least one limiting groove is formed in the surface of the insulated support plate, the negative electrode is arranged onthe insulated support plate, is corresponding to the limiting groove in position and extends to a part above the bottom of the limiting groove, the barrier dielectric sleeve is located above the insulated support plate, the opening area at the lower end of the barrier dielectric sleeve can cover a notch of the limiting groove, the positive electrode is arranged in the barrier dielectric sleeve, and the moving device drives the barrier dielectric sleeve to move to a part right above the limiting groove and maintains a certain discharge air gap. In the solution, a workpiece can be used as the negative electrode, and is combined with the positive electrode that can be raised and lowered and the barrier dielectric sleeve, so that a plasma generated continuously between the metal workpiece andthe barrier dielectric sleeve under the constant pressure condition can directly clean the surface of the metal workpiece and forms a passivation layer on the surface of the workpiece by effectivelyusing the dielectric barrier discharge plasma priciple, which can greatly improves the corrosion resistance of the workpiece and prolong the service life of the workpiece.

Owner:SUZHOU CHUANGRUI MACHINERY & ELECTRICAL TECH

Papermaking method capable of inhibiting decay of plant fibers

ActiveCN104179069AAccurate control of adding ratioImprove qualityWashing/displacing pulp-treating liquorsPaper forming aids additionFiberRolling paper

The invention relates to a papermaking method capable of inhibiting decay of plant fibers. The method comprises the steps of pulping a wood pulp board, and grinding into thick liquid to obtain pulp A; preparing fiber decay inhibitor suspension liquid in a preparation tank; mixing the pulp A and the prepared suspension liquid at high speed in a mixing tank to obtain evenly mixed pulp B; washing the pulp B to obtain pulp C; screening the pulp C, purifying, and obtaining pulp D before the pulp C enters a former copy tank; enabling the pulp D to enter a pressure screen after the pulp D passes through a white water bucket and a slushing pump; removing a fiber bundle and impurities in the pressure screen to obtain pulp E, and feeding a cationic polyacrylamide (CPAM) retention aid into the pulp E to obtain pulp F; enabling the pulp F to enter a flow box for distributing the pulp, and carrying out dehydration at a net part to form a wet paper web; carrying out squeezing, primary drying, surface sizing and post-drying; forming a mother roll at a roll paper part, and carrying out rewinding cutting to obtain a product with the needed specification. The method has the advantages that a production technology is simple, the inhibition of the fiber decay can be foundationally realized, the inhibiting effect is lasting, added auxiliary agents are good in environmental friendliness, and the like.

Owner:WUHAN IND TECH RES INST OF GEO RESOURES ENVIRONMENT CO LTD

A 3D printing manufacturing method of a three-dimensional structure electronic device

ActiveCN106111981BSmall footprintImprove friendlinessAdditive manufacturing apparatusMultilayer circuit manufactureThree-dimensional spaceRelative motion

A 3D printing manufacturing method of a three-dimensional structure electronic device. First, according to the performance requirements of the workpiece to be formed, the spatial distribution of the circuit in the three-dimensional structure electronic device and the geometric size of the matrix structure are designed, a three-dimensional CAD model is established, and the model is processed according to the processing direction. Layered processing, to obtain the material distribution of each layer section, write the relative motion program of the print head integrated device and the working platform, and then select the wire printing material and matrix structure printing material that meet the performance requirements, and then print the substrate, on the working platform Form the matrix structure, then switch the print head, print the wire, the movement mechanism drives the working platform to drop a layer thickness, repeat the printing process of printing the base material and printing wire, until the entire matrix structure and wire are printed, and the structural electronics are obtained. The invention realizes The synchronous printing of wires and base insulating medium can realize arbitrary arrangement in three-dimensional space.

Owner:XI AN JIAOTONG UNIV

Special admixture for steam curing concrete in winter and its production method

InactiveCN104496260BReduce production processGuarantee normal productionLiquid productCarboxylic acid

A special additive for steam curing of concrete in winter and a production method thereof. The additive is characterized by comprising the following raw materials by weight: 10%-15% of aluminum sulfate, 0.2%-0.5% of citric acid, 4%-7% of sodium nitrate, 0.1%-0.2% of methyl cellulose, 25%-30% of a poly carboxylic acid water reducing agent with solid content of 20% and 47.3%-60.7% of water. The preparation method is as below: first adding water in a feed mixer; then adding aluminum sulfate, citric acid and sodium nitrate according to the proportion into the feed mixer, and stirring for 20-30 min to practically dissolve solid particles; then adding the methyl cellulose and the poly carboxylic acid water reducing agent according to the proportion into the feed mixer, and stirring for 20-30 min until to practically dissolve solid particles, so as to obtain a colorless transparent liquid product. The invention has the advantage that aiming at the problems of easy cracking and reduced strength and durability in steam curing of concrete in winter in severe cold areas, a multiple-ingredient compounding way is employed, and the ratio of raw materials and dosage can be adjusted according to the change of environmental temperature, so as to ensure the normal production of steam curing of concrete under the minimum temperature of below 0 DEG C and to ensure strength and durability of the concrete. The invention has good environment-friendliness.

Owner:SHENYANG JIANZHU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com