A 3D printing manufacturing method of a three-dimensional structure electronic device

A technology of electronic devices and three-dimensional structures, applied in the direction of multilayer circuit manufacturing, additive processing, etc., can solve the problems that cannot meet the requirements of the structural electronic device manufacturing of function-structure integration, and achieve the reduction of occupied space and environmental friendliness The effect of good and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] A 3D printing manufacturing method for a three-dimensional structure electronic device, comprising the following steps:

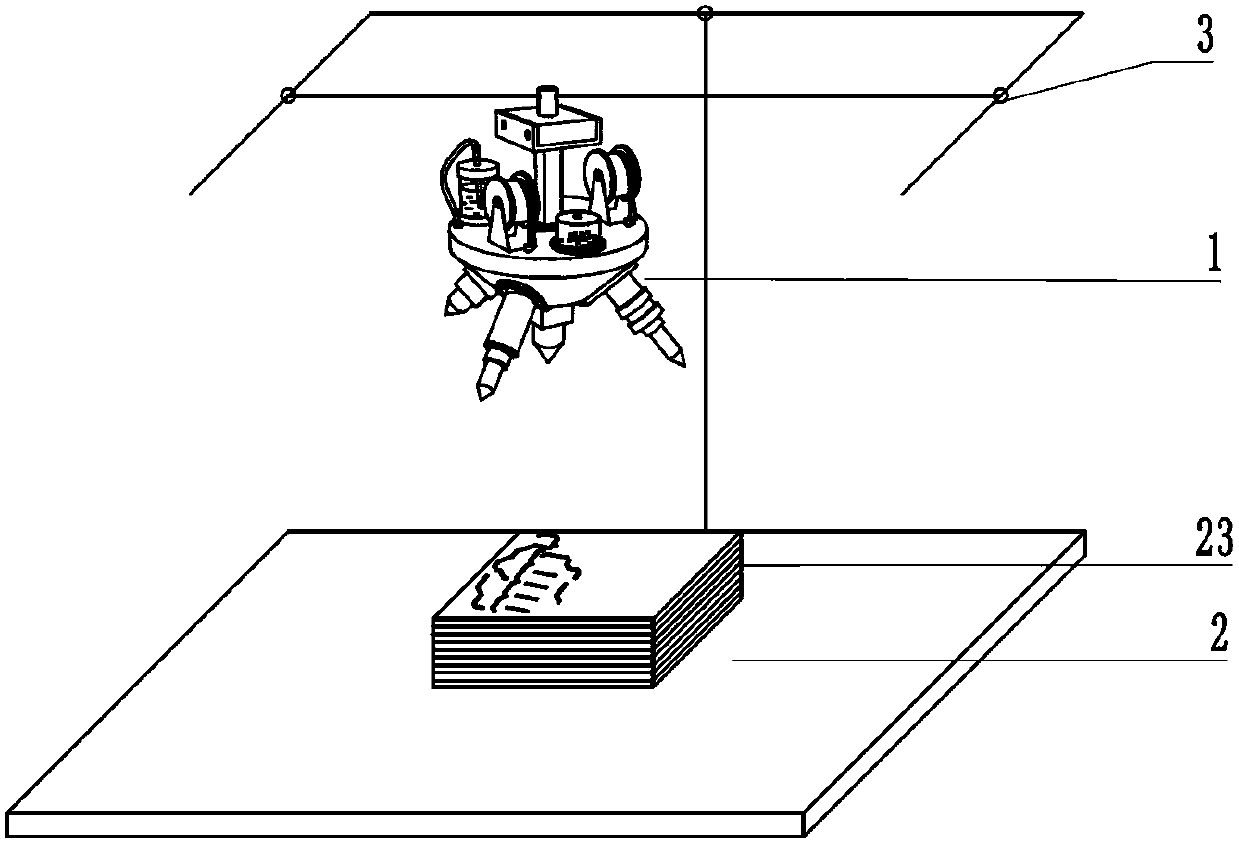

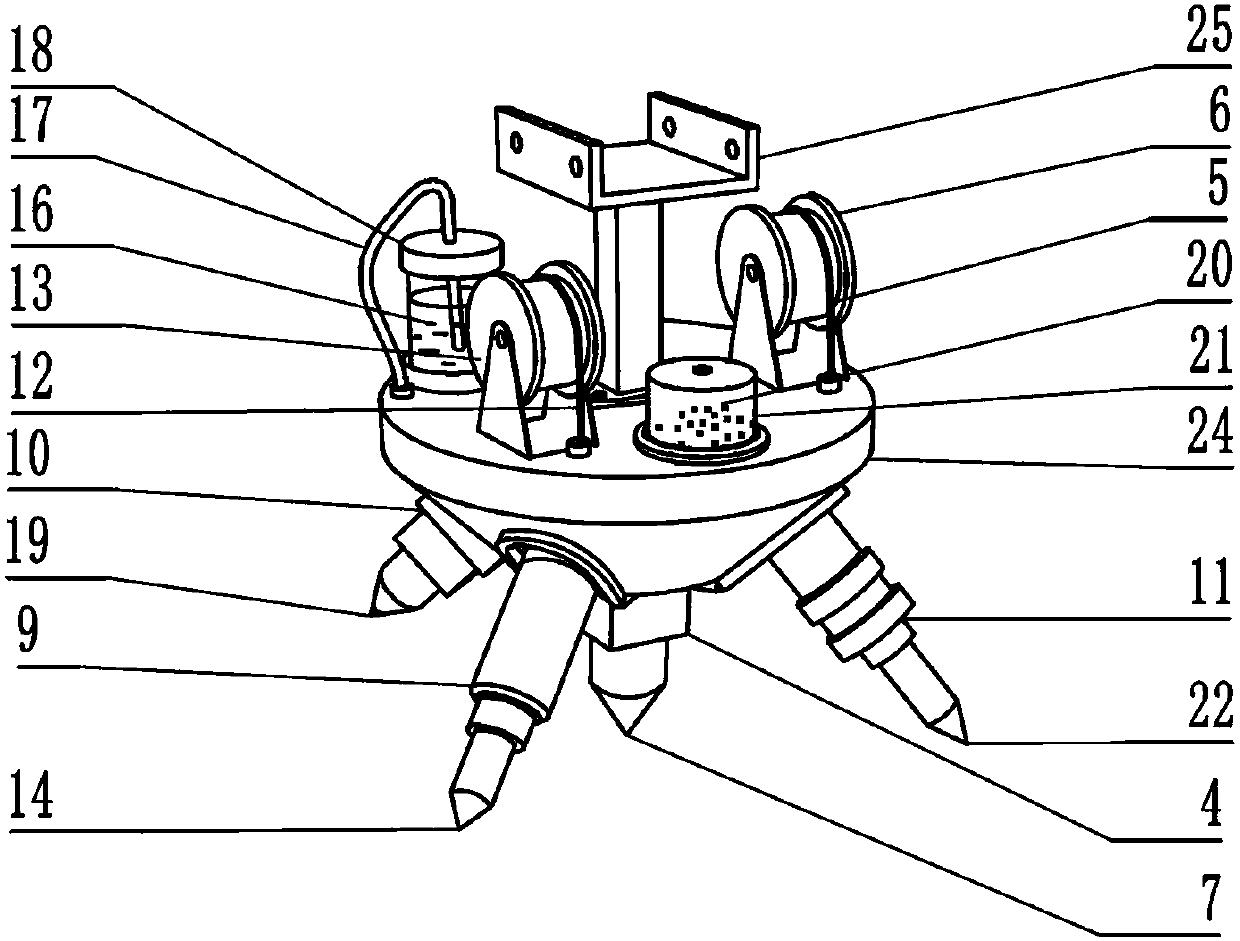

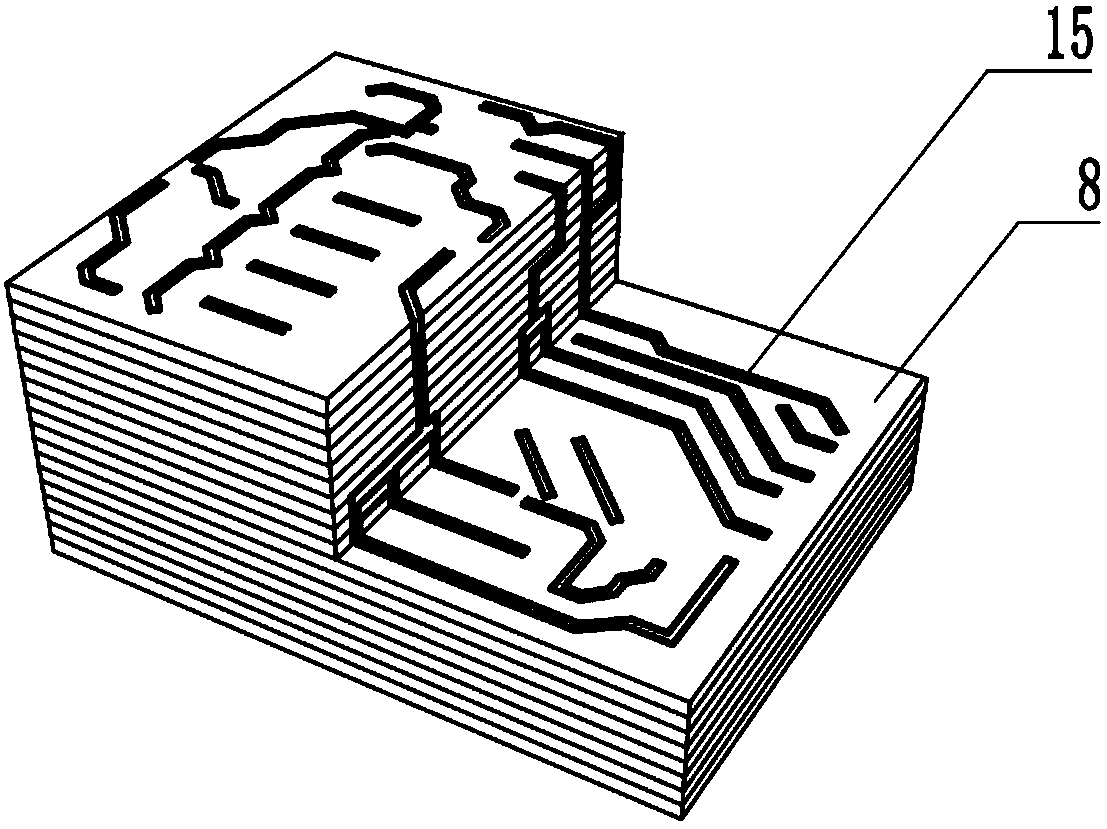

[0025] 1) Refer to figure 1 , according to the performance requirements of the parts to be formed, design the spatial distribution of the circuit in the three-dimensional structure electronic device and the geometric size of the matrix structure, and establish a three-dimensional CAD model; process the model in layers according to the processing direction to obtain the material distribution of each layer section, Write the relative motion program of the print head integrated device 1 and the working platform 2;

[0026] 2) Select wire printing materials and matrix structure printing materials that meet the performance requirements. Wire printing materials are copper-tin alloys, silver-tin alloys, tin-lead alloys with low melting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com