Catalyst containing Cu (I) and method for catalyzing furfural hydrogenation through catalyst

A catalyst and furfural technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as low product purity, difficult product purification, and difficult reaction. Achieve the effects of high product selectivity, good environmental friendliness, and easy separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

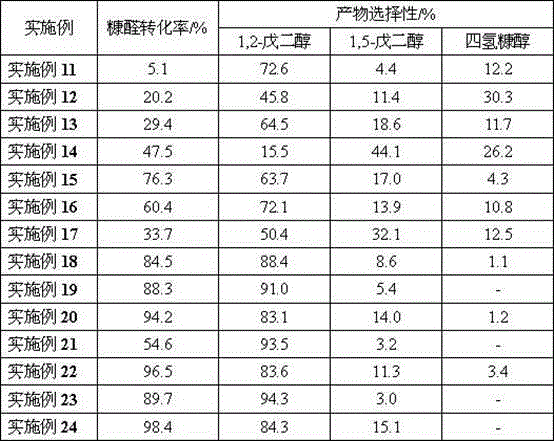

Examples

Embodiment 1

[0053] 28.8 g of cuprous oxide, 26 g of nickel chloride and 134 g of aluminum chloride were mixed evenly and ground, transferred to 5L of deionized water and dispersed evenly, and then 32 g of sodium hydroxide and 42.4 g of sodium carbonate were added in turn to maintain the pH of the system at 11 -12; the above mixture at 80 o C under constant temperature and slow stirring for 12h; o Dry in a C oven to constant weight; dry the filter cake in a nitrogen-protected muffle furnace at 350 o C and roasted for 5 hours to obtain 75 g of soil gray catalyst A.

Embodiment 2

[0055] 125.5g of cuprous nitrate, 183g of nickel nitrate and 214g of aluminum nitrate were mixed evenly and ground and then transferred to 5L of deionized water containing 18g of glucose to disperse evenly, then adding 40g of sodium hydroxide and 159g of sodium carbonate in turn to make the pH of the system Maintain at 9-10; the above mixture is at 70 o C under constant temperature and slow speed stirring for 48 h; filter cake after filtration at 60 o Dry in a C oven to constant weight; dry the filter cake in a nitrogen-protected muffle furnace for 500 o Calcined at C for 2 h to obtain 230 g of soil gray catalyst B.

Embodiment 3

[0057] 67.2 g of cuprous sulfate, 77.5 g of nickel sulfate and 400 g of aluminum sulfate octadecahydrate were mixed uniformly and ground and then transferred to 5L of deionized water containing 5.8 g of sodium thiosulfate to disperse evenly, then adding 80 g of sodium hydroxide and 53 g of sodium carbonate keeps the pH of the system at 9-10; o C under constant temperature and slow stirring for 24 h; filter to get filter cake, filter cake at 60 o Dry in a C oven to constant weight; dry the filter cake in a nitrogen-protected muffle furnace at 400 o Calcined at C for 5 h to obtain 182 g of soil gray catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com