Preparation method of amino acid-containing biological bacterial fertilizer

A technology of biological bacterial fertilizer and amino acid, which is applied in the field of preparation of amino acid-containing biological bacterial fertilizer, can solve the problems of inconvenient operation and high manufacturing cost, and achieve the effects of good environmental friendliness, control of diseases and insect pests, and simple raw material components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

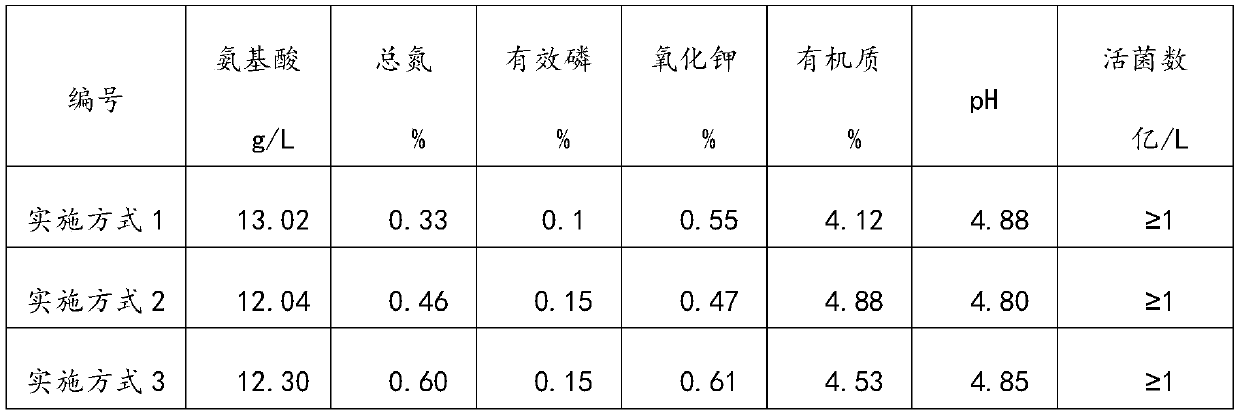

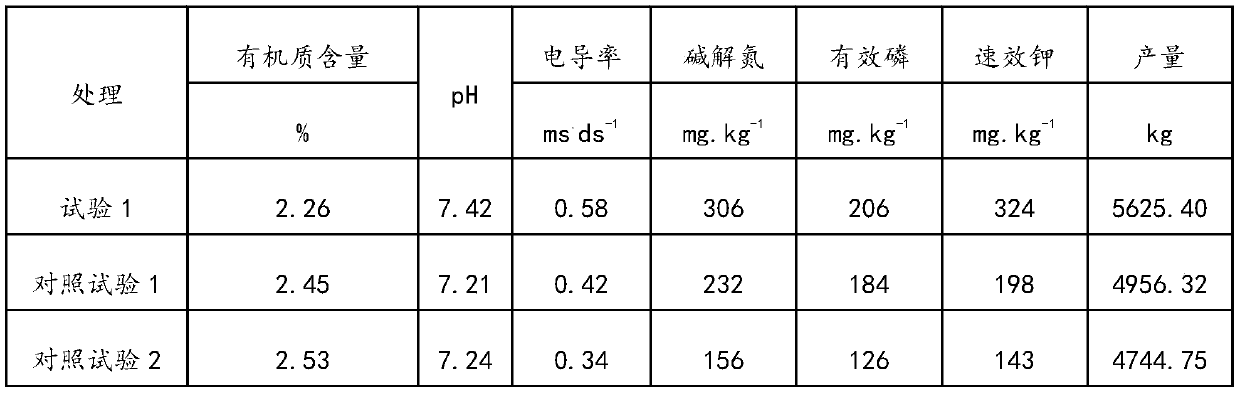

Examples

Embodiment approach 1

[0040] This embodiment provides a method for producing amino acid-containing biological bacterial fertilizer using vegetable stalks, including the following steps:

[0041] S1 Mix 12 parts by weight of fruit and vegetable waste, 30 parts by weight of brown sugar and 100 parts by weight of water, and then, under the temperature condition of 30°C, airtightly ferment for 30 days, and deflate once every other day during the airtight fermentation Process to obtain fermented material A;

[0042] S2 The fermented material A obtained in step S1 is subjected to solid-liquid separation treatment with a filter to obtain an enzyme liquid, and the particle diameter of the suspended solids in the enzyme liquid is ≤0.18 mm;

[0043] S3 weighs the soybean meal, then boils the soybean meal with a heating machine, and then cools it to normal temperature;

[0044] S4 adds the cooled soybean meal obtained in step S3 to the ferment liquid obtained in step S2, the viable Bacillus megaterium prepar...

Embodiment approach 2

[0046] This embodiment provides a method for producing amino acid-containing biological bacterial fertilizer by using vegetable stalks, which includes the following steps:

[0047] S1 Mix 16 parts by weight of fruit and vegetable waste, 35 parts by weight of molasses and 90 parts by weight of water, and then, under the temperature condition of 28°C, conduct airtight fermentation for 26 days, and deflate once every other day during the airtight fermentation Process to obtain fermented material A;

[0048]S2 The fermented material A obtained in step S1 is subjected to solid-liquid separation treatment with a filter to obtain an enzyme liquid, and the particle diameter of the suspended solids in the enzyme liquid is ≤0.18 mm;

[0049] S3 Weigh the soybean peptone, and homogenize the soybean peptone through a homogenizer, then boil the soybean peptone with a heating machine, and then cool to normal temperature;

[0050] S4 adds the cooled soy peptone obtained in step S3 to the fe...

Embodiment approach 3

[0052] This embodiment provides a method for producing amino acid-containing biological bacterial fertilizer by using vegetable stalks, which includes the following steps:

[0053] S1 Mix 10-16 parts by weight of fruit and vegetable waste, 30-35 parts by weight of sucrose and 90-100 parts by weight of water, and then ferment in a sealed container at a temperature of 32°C for 32 days. Carry out deflation once every 2 days to obtain fermentation material A;

[0054] S2 The fermented material A obtained in step S1 is subjected to solid-liquid separation treatment with a filter to obtain an enzyme liquid, and the particle diameter of the suspended solids in the enzyme liquid is ≤0.18 mm;

[0055] S3 Weigh the peanut meal, and homogenize the peanut meal through a homogenizer, then boil the peanut meal with a heating machine, and then cool to normal temperature;

[0056] S4 adds the cooled peanut meal, Bacillus megaterium live bacteria preparation and Trichoderma brevis live bacter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com