Alpha-lauryl betaine type dimeric surfactant and synthesis method thereof

An alkyl betaine, gemini surface technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of poor selectivity of double long chain tertiary amines, product purity and product performance discount, short chain binary The source of secondary amine raw materials is not easy to achieve the effect of good environmental friendliness, good industrial application prospects, and low raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

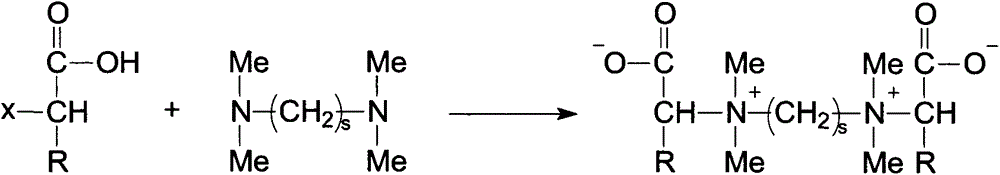

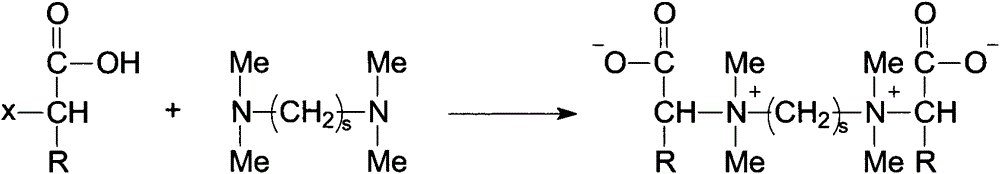

Method used

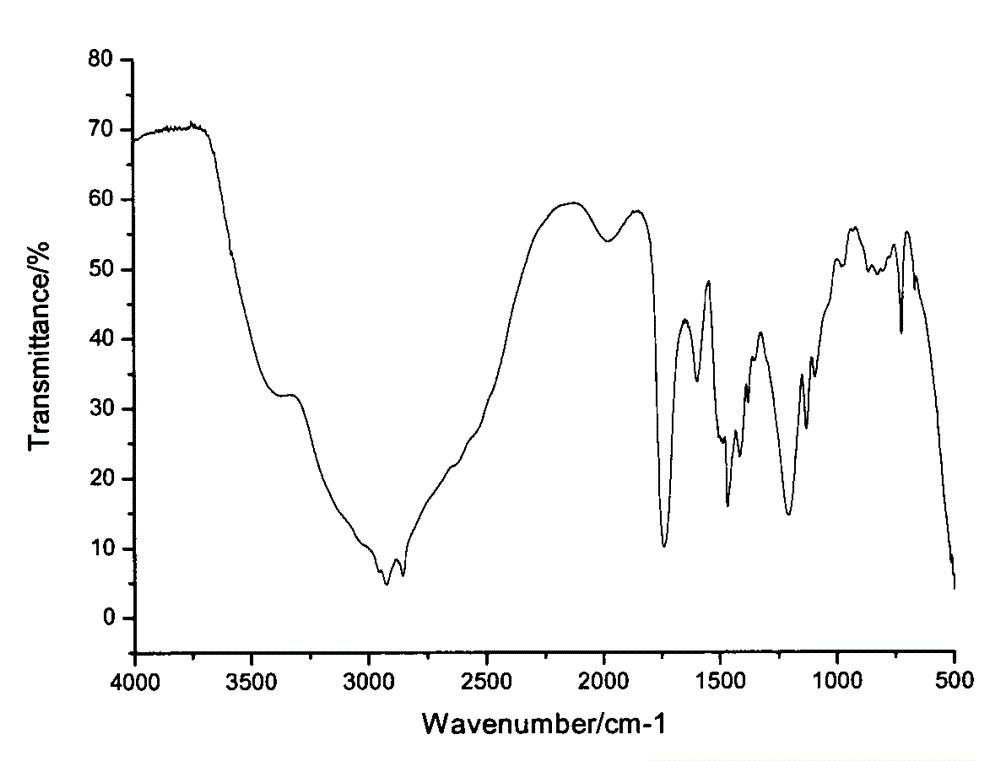

Image

Examples

Embodiment 1

[0028] The synthesis of embodiment 1 α-decyl betaine type gemini surfactant

[0029] Add 5.0g α-chlorododecanoic acid and 20mL deionized water in a 50mL flask, neutralize the mixed solution to pH 7 with sodium hydroxide solution; slowly add 0.27g tetramethylpropylenediamine dropwise to the system, and The reaction was incubated at ℃ for 48 hours. After the reaction, adjust the acidity and alkalinity of the system to pH 7; after volatilizing the water in the system, add an appropriate amount of absolute ethanol to remove the generated sodium chloride; wash the filter cake with a small amount of water, and the reaction crude product yield is 97.5%; The filter cake was recrystallized with ethanol to obtain a pure product with a yield of 97.5%. The calcium soap of this product has good dispersibility, and its calcium soap dispersion index LSDP is 1%. The foaming performance and foam stabilizing performance of this product are good, and the foam height measured by the Roche foam ...

Embodiment 2

[0030] Embodiment 2 Synthesis of α-hexadecyl betaine type gemini surfactant

[0031] Add 7.7g α-bromo octadecanoic acid and 20mL deionized water in a 50mL flask, neutralize the mixed solution to pH 10 with sodium hydroxide solution; slowly add 0.22g tetramethylethylenediamine dropwise to the system, and The reaction was incubated at ℃ for 48 hours. After the reaction, adjust the acidity and alkalinity of the system to pH 7; after volatilizing the water in the system, add an appropriate amount of absolute ethanol to remove the generated sodium chloride; wash the filter cake with a small amount of water, and the reaction crude product yield is 99.3%; The filter cake was recrystallized with ethanol to obtain a pure product with a yield of 75.4%. The critical micelle concentration of the pure product after crystallization is extremely low, which is 2.5*10 -5 mol / L.

Embodiment 3

[0032] Embodiment 3 The synthesis of α-dodecyl betaine type gemini surfactant

[0033] Add 7.1g of α-chlorotetradecanoic acid and 20mL of absolute ethanol in a 50mL flask, neutralize the mixed solution to pH 9 with solid sodium hydroxide; slowly add 0.22g of tetramethylethylenediamine dropwise to the system, and The reaction was incubated at ℃ for 24 hours. After the reaction was finished, the pH of the system was adjusted to neutral and the generated sodium chloride was removed by filtration. The yield of the crude product was 87.0%; the filter cake was recrystallized with ethanol to obtain a pure product, and the yield of the reaction was 50.6%. The calcium soap of this product has good dispersibility, and its calcium soap dispersion index LSDP is 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com