Glycosyltransferase UGTZJ1 mutant and application thereof

A glycosyltransferase and mutant technology, applied in the field of genetic engineering, can solve the problems of high enzyme production cost, large amount of recombinant bacteria, energy consumption and high cost of preparation, so as to simplify the process, increase the yield and avoid separation and purification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

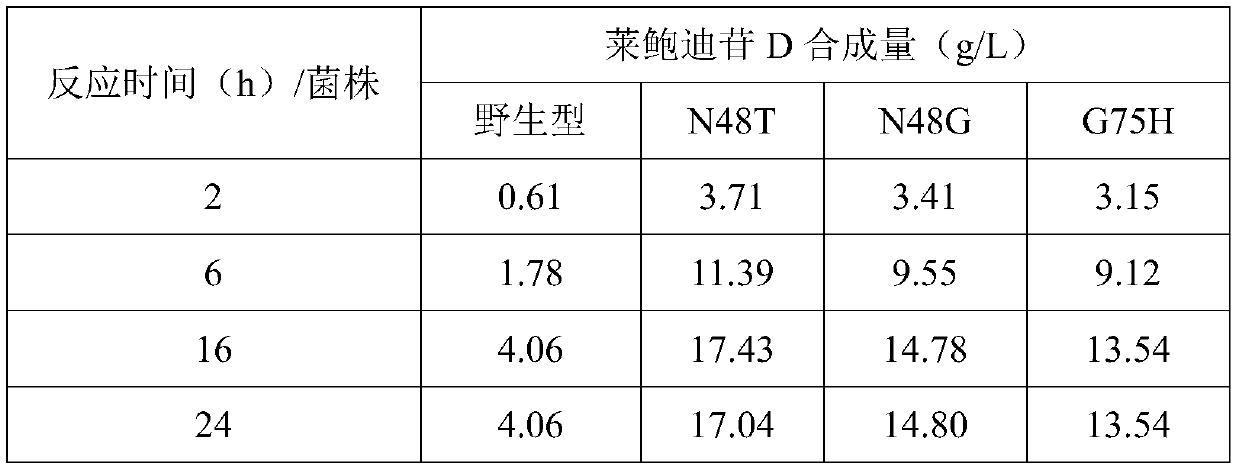

[0034] The construction of embodiment 1 glycosyltransferase UGTZJ1 mutant

[0035] The amino acid sequence of the glycosyltransferase UGTZJ1 mutant provided in this example is shown in any one of SEQ ID NO.2-4.

[0036] Genes encoding the above mutants.

[0037]The preparation method of the above-mentioned glycosyltransferase UGTZJ1 mutant, the 48th asparagine in the amino acid sequence of the glycosyltransferase UGTZJ1 shown in SEQ ID NO.1 is mutated into threonine or glycine, or the 75th glycine Mutated to histidine.

[0038] It can also be a carrier or cell line carrying the above-mentioned genes and genetically engineered bacteria.

[0039] The genetically engineered bacterium uses Escherichia coli as a host and simultaneously expresses the sucrose synthase gene and the above-mentioned glycosyltransferase UGTZJ1 mutant.

[0040] The sucrose synthase gene of the present invention can be a gene with sucrose synthase activity from any source, such as the sucrose synthase S...

Embodiment 2

[0056] Induced expression of embodiment 2 genetically engineered bacteria and preparation of crude enzyme solution

[0057] The different genetically engineered bacteria that 4 strains appearing in embodiment 1 respectively contain wild-type UGTZJ1 gene and mutant gene thereof are respectively inoculated into 5mL LB liquid culture medium (LB (g / L): peptone 10 , sodium chloride 10, and yeast extract 5) in a 50-mL shaking tube, cultured on a shaker at 37° C. for 8 hours at a constant temperature of 200 rpm. Then insert the culture solution into a 500mL shake flask containing 100mL induction medium TB (TB (g / L): yeast powder 25, tryptone 15, sodium chloride 10, glucose 2, lactose 3) according to 4% inoculum Incubate at 200rpm, 37°C for 2h, until OD 600 When it reaches about 0.2, turn to 16°C to induce 24h and centrifuge to collect the bacteria. Sonicate the bacteria, centrifuge and take the supernatant as a crude enzyme solution, and store it in a 4°C refrigerator for later use...

Embodiment 3

[0062] The influence of embodiment 3 temperature on catalytic reaction

[0063] The crude enzyme solution obtained after the induced expression of the genetically engineered bacteria E.coli BL21(DE3) / pET28a-UGTZJ1(N48T)-StSUS1 with the highest yield obtained in Example 2 was used for the reaction. In a 50mL Erlenmeyer flask, 10mL of the reaction mixture contained 20g / L rebaudioside A, 60g / L sucrose, 50mM sodium phosphate buffer at pH 7.0, 3mg / mL crude enzyme solution, and reacted at 20°C, 30°C, Carried out at 37°C, 42°C, 50°C and 200rpm. The reaction was started by adding crude enzyme solution, and after 16 hours of reaction, samples were taken and heated at 95°C for 5 minutes to inactivate the enzyme, and the supernatant was collected by centrifugation. The content of rebaudioside D in the reaction solution at different reaction temperatures was measured.

[0064] The content of rebaudioside D in the reaction solution under the different reaction temperatures of table 2

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com