Method for microwave-assisted synthesis of Z-type heterojunction catalytic material

A catalytic material and microwave-assisted technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as hazards, adverse effects on the environment and ecosystems, and achieve reduced side reactions and good stability performance and reusability, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

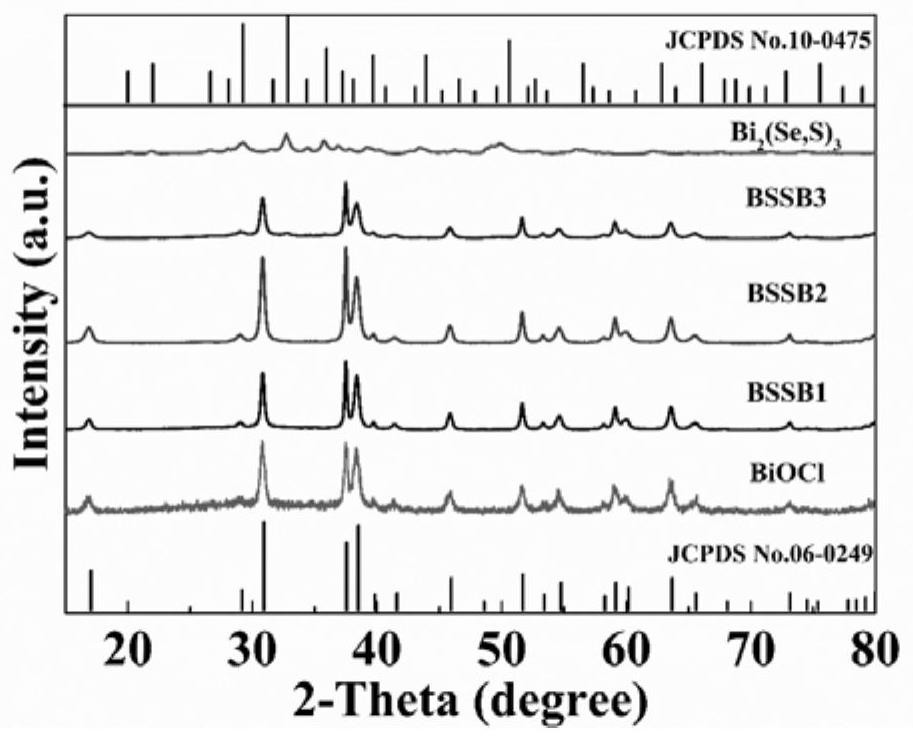

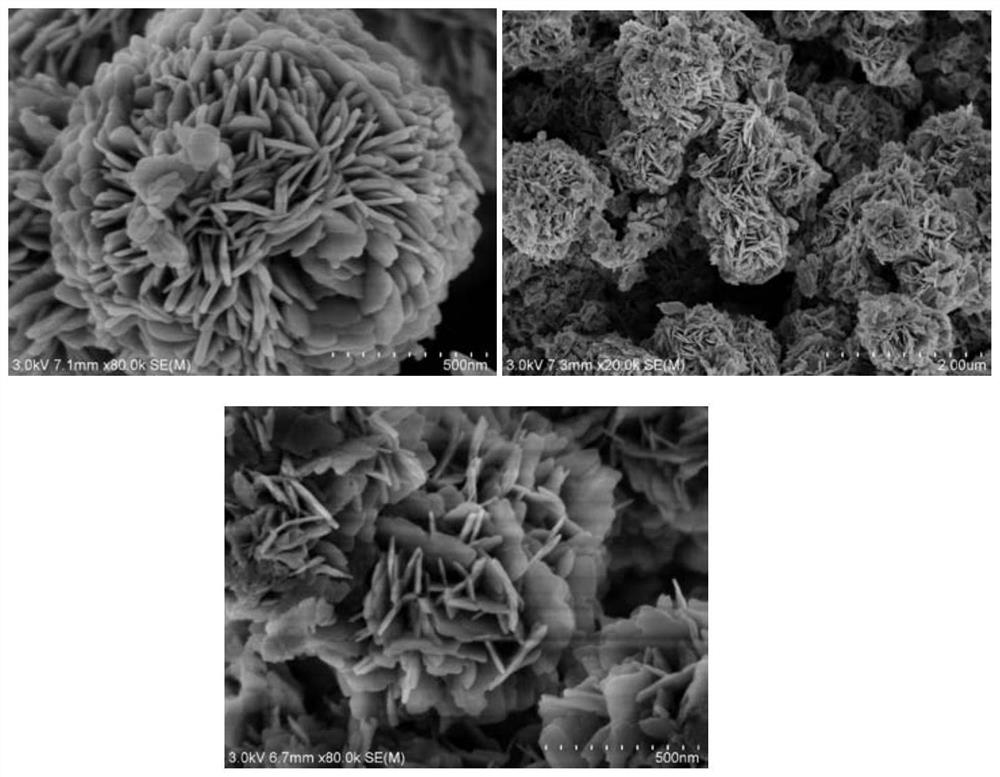

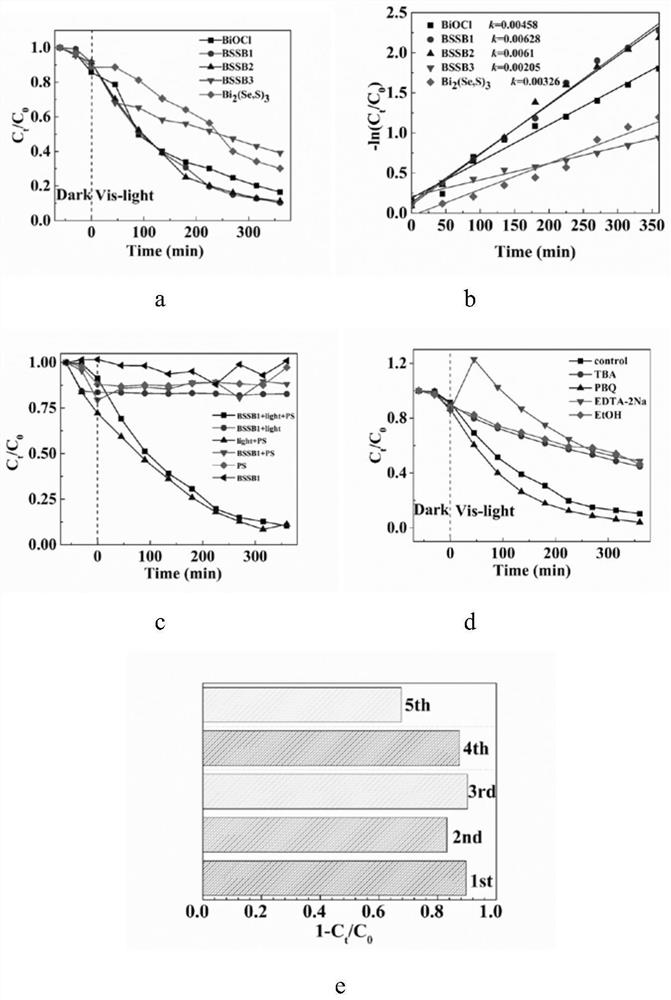

Embodiment 1

[0051] 0.2425g of bismuth nitrate pentahydrate, 0.1g of L-cysteine, 0.5g of sodium tartrate and 0.2335g of sodium selenite were placed in a special flask, and 30mL of ethylene glycol was added to it; the flask was placed in a stirrer Stir with 500rmp for 5min; put the flask into the microwave reactor, under the condition of 1000W, microwave heating to 180°C and then maintain the temperature with 300W, the total reaction is 20min, and the precipitate is obtained. After the reaction was completed, the flask was placed in a stirrer and stirred at 600 rmp for 15 min. The obtained precipitation was transferred into a beaker, and was washed several times with deionized water and ethanol; put into a drying temperature of 80 ° C vacuum drying oven, can obtain (Bi 2 (Se, S) 3 ). Then weigh 0.01g of Bi 2 (Se, S) 3 Put 0.2425g of bismuth nitrate pentahydrate, 0.1g of potassium chloride and 30mL of ethylene glycol into a special flask;

[0052] Placed on a magnetic stirrer, stirred a...

Embodiment 2

[0054] Weigh 0.2425g of bismuth nitrate pentahydrate, 0.1g of L-cysteine, 0.5g of sodium tartrate, 0.2335g of sodium selenite, and 30mL of ethylene glycol into a special flask; put the flask into a stirrer with 500rmp Stir for 5min; put the flask into a microwave reactor and heat it to 180°C with a power of 1000W, then maintain the temperature with 300W, and the total reaction is 20min. After the reaction, put the flask into a stirrer and stir at 600 rmp for 15 min; transfer the solution in the flask into a beaker, wash it several times with deionized water and ethanol; put the sample into a vacuum drying oven, and the drying temperature is 80 ° C; Treat the dried samples as pharmaceuticals (Bi 2 (Se, S) 3 ), provides raw material for the next step synthesis; Weigh the Bi of 0.05g 2 (Se, S) 3 , 0.2425g of bismuth nitrate pentahydrate, 0.2335g of sodium selenite, 0.1g of potassium chloride, and 30mL of ethylene glycol were put into a special flask; the flask was placed in a ...

Embodiment 3

[0056] Weigh 0.2425g of bismuth nitrate pentahydrate, 0.1g of L-cysteine, 0.5g of sodium tartrate, 0.2335g of sodium selenite, and 30mL of ethylene glycol into a special flask; put the flask into a stirrer with 500rmp Stir for 5min; put the flask into a microwave reactor and heat it to 180°C with a power of 1000W, then maintain the temperature with 300W, and the total reaction is 20min. After the reaction, the flask was put into a stirrer and stirred at 600 rmp for 15 min; the solution in the flask was transferred to a beaker, and washed several times with deionized water and ethanol; the sample was placed in a vacuum drying oven, and the drying temperature was 80 °C. Treat the dried samples as pharmaceuticals (Bi 2 (Se, S) 3 ), provides raw material for the next step synthesis; Weigh the Bi of 0.1g 2 (Se, S) 3 , 0.2425g of bismuth nitrate pentahydrate, 0.1g of potassium chloride and 30mL of ethylene glycol were put into a special flask; the flask was put into a stirrer and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com