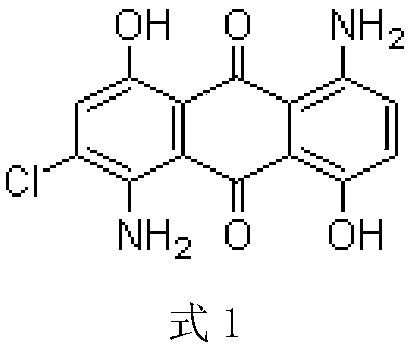

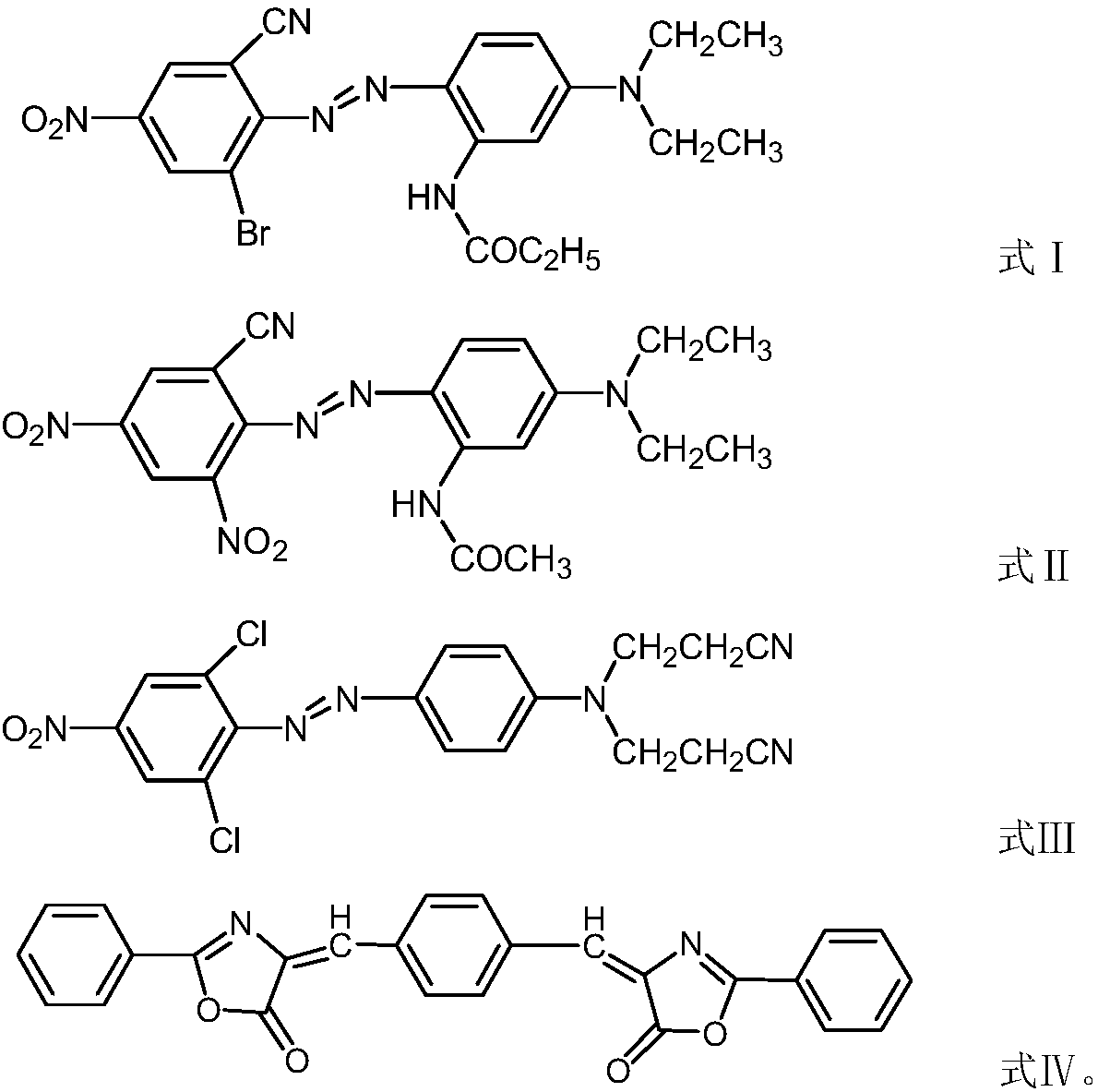

Disperse dye composition and preparation and application methods thereof

A technology for disperse dyes and compositions, applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve the problems of poor washing fastness and sublimation fastness of dyes, complicated production process, high production cost and market price, and achieve High washing fastness and sublimation fastness, simple synthesis steps, excellent performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Add 38.58g of component A, 10.80g of component B, 0.33g of component C, 0.62g of component D, 40g of diffusing agent NNO and 60g of dispersing agent MF, add 100g of water, stir and mix well, grind and disperse with a sand mill, Then spray-dry to obtain the blue disperse dye composition that the strength part is 295%.

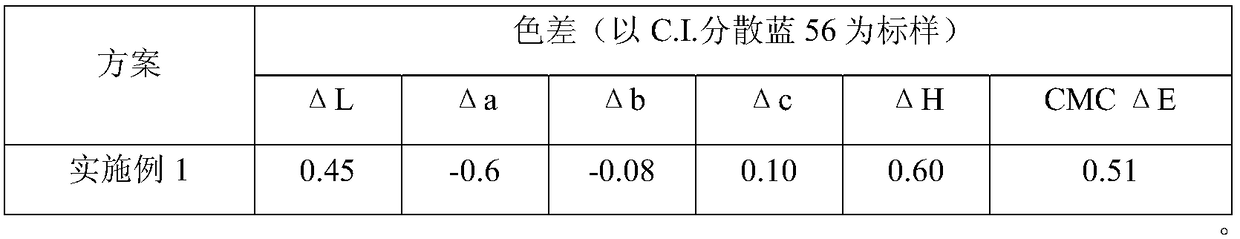

[0051] Shade detection:

[0052] Use the blue disperse dye composition that above-mentioned method obtains, when its consumption is 0.32% o.w.f, can be dyed with the C.I. disperse blue 56 that consumption is 1.00% o.w.f on the polyester fabric consistent shade and color depth, as shown in table 1 below Show.

[0053] Table 1, Example 1 and C.I. Color contrast of disperse blue 56

[0054]

[0055] Note: the color data is a standard sample with C.I. disperse blue 56 (100%) dyed polyester fabric, and the blue dye composition of the present invention is a batch sample, which is obtained by testing on a Datacolor color measuring and matching instrument in...

Embodiment 2~8

[0058] According to the preparation method of the dye composition described in Example 1, adjust the amount of each component and additive, mix component A, component B, component C and component D with the additive evenly, add water to stir and grind to disperse, spray After drying, various blue disperse dye composition finished products (Table 1) were obtained. When they are dyed with C.I. Disperse Blue 56 (100%) adjusted to the same strength, the color difference with the latter is also shown in Table 2.

[0059] Table 2. Shade comparison under different components and additives

[0060]

[0061]

[0062] As can be further seen from Table 2, when the four components of the blue disperse dye of the present invention are blended with additives in different amounts in selected proportions, the finished dye compositions with different strengths are obtained, and these dye compositions are all It can dye the same shade as C.I. Disperse Blue 56, and the color difference va...

Embodiment 9

[0064] The polyester fabrics were dyed with the dye compositions described in Examples 1-8 respectively.

[0065] The dyeing method is as follows: put 500 kilograms of pure polyester knitted fabrics (pretreated) into a dyeing bath prepared at a liquor ratio of 1:10 at room temperature, run for 3-5 minutes, and add the blue disperse dye composition 5 of the present invention. kg, run for 5-10 minutes, adjust the pH value of the dyeing bath to 4.5-5.5 with glacial acetic acid, then raise the temperature to 80°C at a heating rate of 2°C / min, and then raise the temperature to 130°C at a heating rate of 1.0°C / min and run for 50 minutes. After the dyeing is completed, cool down to 80°C to drain the liquid, perform reduction cleaning, water washing, dehydration and drying.

[0066] According to the national standard GB / T3921.C3-2013, GB / T3920-2013, GB / T5718-2008 and GB / T8427-2008 respectively test the washing fastness, rubbing fastness and sublimation fastness of the polyester fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com