White carbon black-loaded xanthogenate as well as preparation method and application thereof

A technology of xanthate and silica, applied in the fields of rubber additives and rubber vulcanization, to avoid surface and volatilization, less dosage and less solvent toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

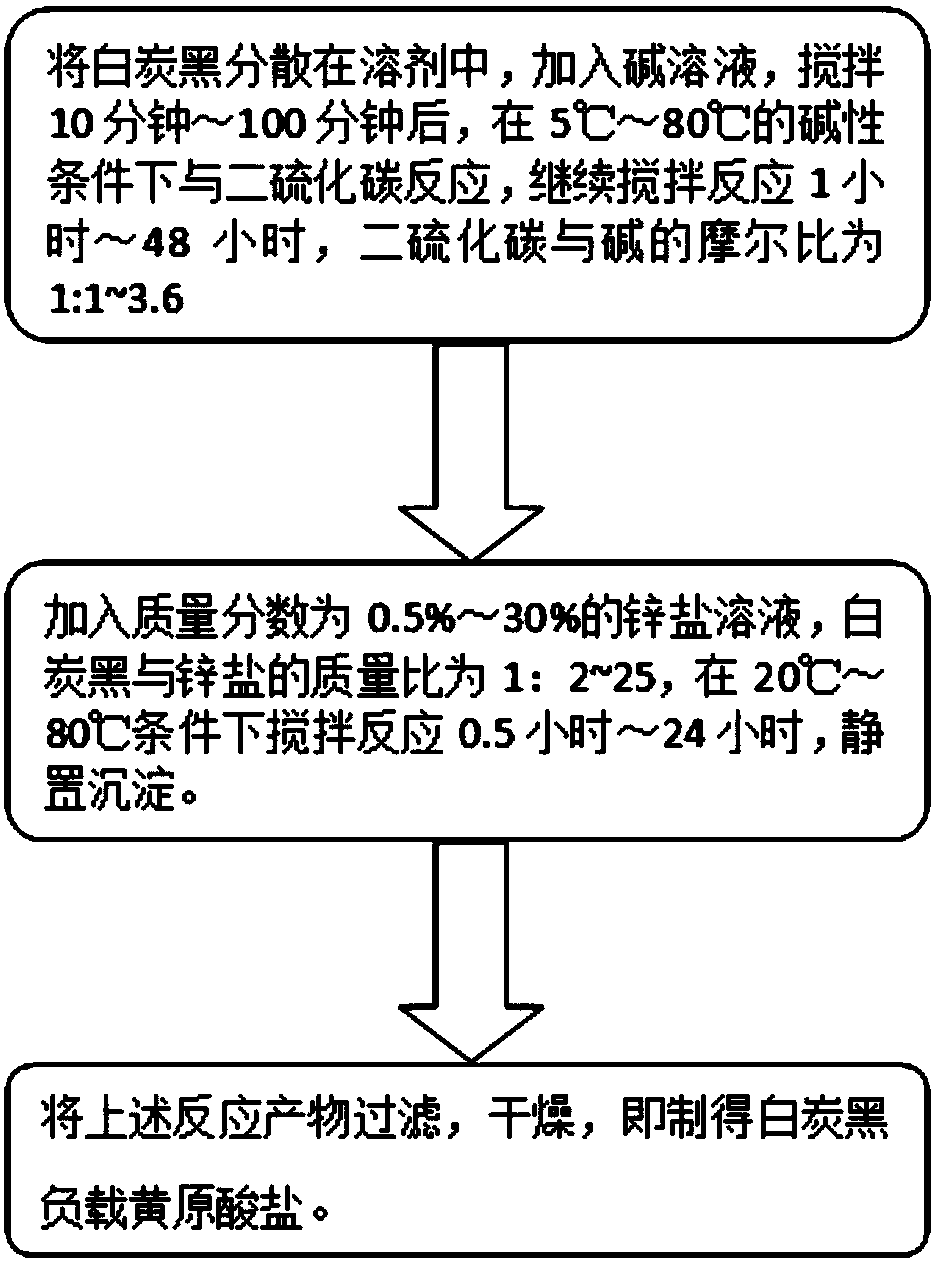

Method used

Image

Examples

Embodiment 1

[0046] See Table 1 for the basic formulation of the rubber prepared with the vulcanization accelerator white carbon black-loaded xanthate and the comparative accelerator M, the vulcanization characteristic parameters of the prepared rubber are shown in Table 2, and the physical and mechanical properties of the prepared rubber are shown in Table 3 .

[0047] It can be seen from Table 2-4 that silica-loaded xanthate can promote vulcanization, basically achieving the same effect as accelerator M.

[0048] Table 1

[0049]

[0050] The unit in Table 1 is parts by mass (phr), and X in formula No. 2 is xanthate loaded with white carbon black.

[0051] Table 2

[0052]

[0053] table 3

[0054]

Embodiment 2

[0056] Compared with Example 1, in Example 2, the amount of Accelerator X in Sample No. 2 was adjusted to 2.5. The basic formulation of the rubber prepared with vulcanization accelerator white carbon black-loaded xanthate and the comparative accelerator M is shown in Table 4, the vulcanization characteristic parameters of the prepared rubber are shown in Table 5, and the physical and mechanical properties of the prepared rubber are shown in Table 6 .

[0057] It can be seen from Table 5 that compared with the accelerator M, the silica-loaded xanthate can significantly increase the vulcanization rate and shorten the normal vulcanization time, and at the same time the minimum torque and maximum torque of the prepared rubber are increased .

[0058] It can be seen from Table 6 that, compared with accelerator M, silica-loaded xanthate has a better effect on improving the mechanical properties of rubber such as tensile strength, tear strength and elongation at break.

[0059] Tab...

Embodiment 3

[0067] Compared with Example 1 and Example 2, in Example 3, the amount of accelerator X in sample No. 2 was adjusted to 5. The basic formula for preparing rubber with vulcanization accelerator white carbon black-loaded xanthate and comparative accelerator M is shown in Table 7, the vulcanization characteristic parameters of the prepared rubber are shown in Table 8, and the physical and mechanical properties of the prepared rubber are shown in Table 9 .

[0068] It can be seen from Table 8 that compared with the accelerator M, the silica-loaded xanthate can significantly increase the vulcanization rate and shorten the normal vulcanization time. At the same time, the minimum torque and maximum torque of the prepared rubber are different. Increase; Compared with Example 2, the vulcanization rate decreased, the positive vulcanization time increased, and the minimum torque and maximum torque both decreased.

[0069] It can be seen from Table 9 that, compared with accelerator M, si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com