Method for extracting natural dye from rubia cordifolia as well as natural dye prepared by the method and dyeing method

A technology of natural dyes and madder, applied in the field of natural dyes and dyeing, can solve the problems of poor dyeing effect, achieve good dyeing effect of natural dyes, simple extraction process, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

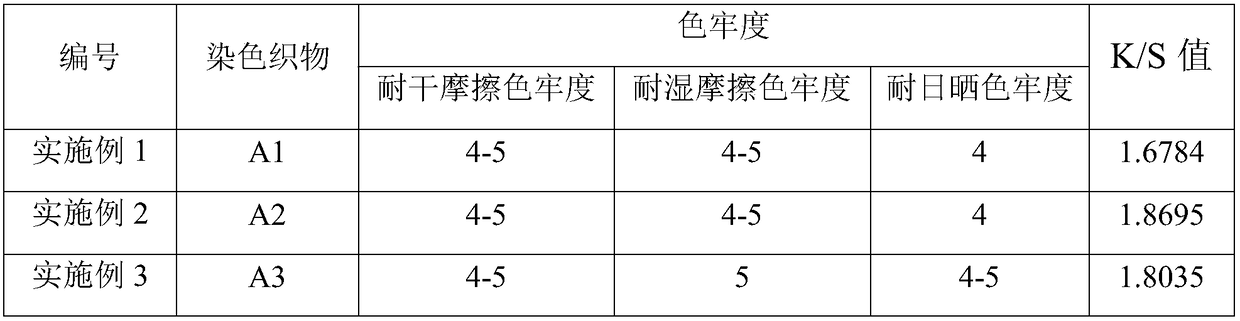

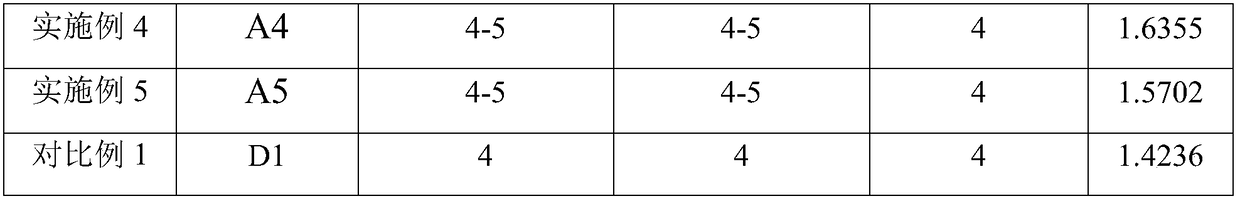

Embodiment 1

[0032] The madder root is washed, dried, and mechanically crushed to obtain crushed objects with a size of 0.5-3 mm. Weigh 10 g of crushed madder root, add to 200 mL of NaOH solution with a concentration of 0.1 g / L, and stir at 70° C. for 60 min. Then, the extract was vacuum filtered, distilled under reduced pressure to 50 mL, and then freeze-dried to obtain a red block-shaped madder natural dye.

[0033] The silk to be dyed is put into the dyeing liquor that is made up of madder natural dyestuff, mordant aluminum potassium sulfate and water and is dyed, wherein weighs 2g silk, the quality of madder natural dyestuff accounts for 4% of silk quality, mordant aluminum potassium sulfate The mass of the silk accounts for 2% of the silk mass, the liquor ratio during dyeing is 1:40, the dyeing temperature is 70°C, the dyeing time is 60min, and the pH of the dye solution is 5. The dyed silk was washed and dried to obtain dyed sample A1.

Embodiment 2

[0035] The madder root is washed, dried, and mechanically crushed to obtain crushed objects with a size of 0.5-3 mm. Weigh 10 g of crushed madder, add to 300 mL of NaOH solution with a concentration of 0.5 g / L, and stir at 80° C. for 80 min. Then, the extract was vacuum filtered, distilled under reduced pressure to 50 mL, and then freeze-dried to obtain a red block-shaped madder natural dye.

[0036] The silk to be dyed is put into the dye solution that is made up of madder natural dyestuff, mordant aluminum potassium sulfate and water and is dyed, wherein weighs 2g silk, the quality of madder natural dyestuff accounts for 3% of silk quality, mordant aluminum potassium sulfate The quality of the dye accounts for 3% of the cotton yarn quality, the liquor ratio during dyeing is 1:30, the dyeing temperature is 70°C, the dyeing time is 60min, and the pH of the dye solution is 4.5. The dyed silk was washed and dried to obtain dyed sample A2.

Embodiment 3

[0038] The madder root is washed, dried, and mechanically crushed to obtain crushed objects with a size of 0.5-3 mm. Weigh 10 g of crushed madder, add to 300 mL of NaOH solution with a concentration of 1 g / L, and stir at 90° C. for 90 min. Then, the extract was vacuum filtered, distilled under reduced pressure to 50 mL, and then freeze-dried to obtain a red block-shaped madder natural dye.

[0039] The silk to be dyed is put into the dye solution that is made up of madder natural dyestuff, mordant aluminum potassium sulfate and water and is dyed, wherein weighs 2g silk, the quality of madder dye accounts for 3% of silk mass, the mordant aluminum potassium sulfate The mass accounts for 4% of the silk mass, the liquor ratio during dyeing is 1:20, the dyeing temperature is 70°C, the dyeing time is 60min, and the pH of the dyeing solution is 4. The dyed silk was washed and dried to obtain dyed sample A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com