Preparation method of real silk fabric having uvioresistant function

A silk fabric, anti-ultraviolet technology, applied in the direction of animal fiber, textiles, papermaking, fiber treatment, etc., can solve the problems that have not been reported before, and achieve the effect of good compatibility, good safety and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

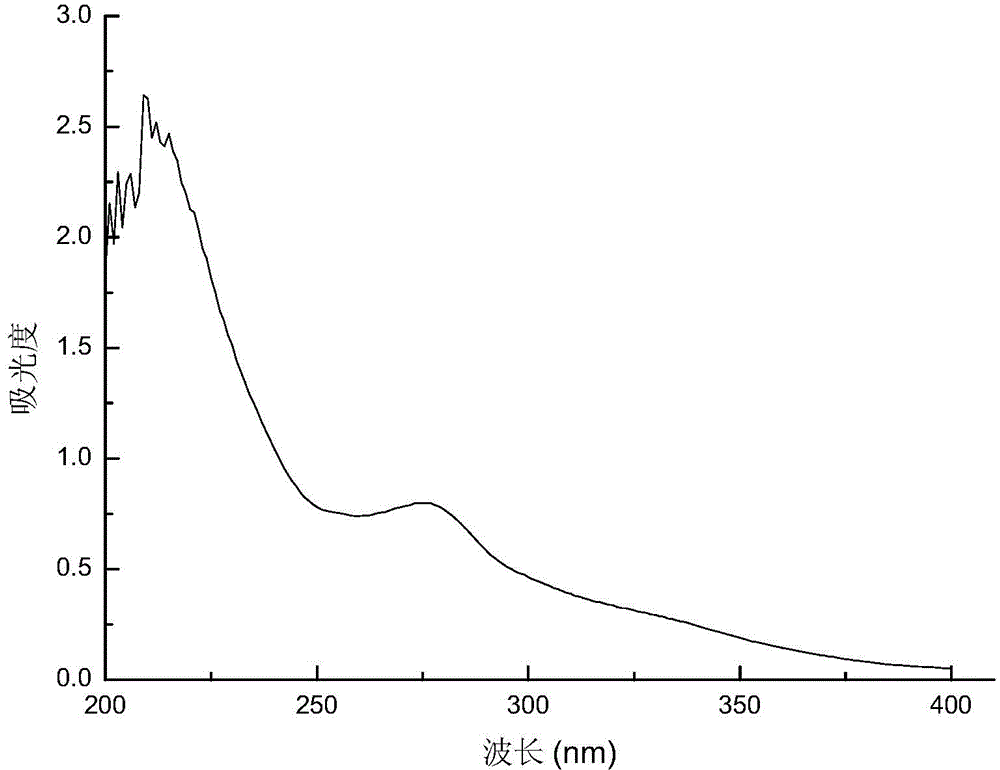

Image

Examples

Embodiment 1

[0029] (1) Add 0.05g Burnet extract to 300ml water, add 3g Yuanming powder, and add glacial acetic acid to adjust the pH value to 4; add 10g real silk fabric to the above solution, at a temperature of 60°C and a liquor ratio of Treat for 50min under the condition of 1:30; then take out the silk fabric, wash it, and dry it;

[0030] (2) Measure 300ml of distilled water, add 0.3g of ferrous sulfate; add the washed and dried silk fabric in step (1) to the solution obtained above, at a temperature of 60°C and a bath ratio of 1:30 Down treatment for 30min; then the silk fabric is taken out, washed and dried to obtain a silk fabric with anti-ultraviolet function. After testing, the UPF value of the silk fabric is 50.29.

Embodiment 2

[0032] (1) Add 0.12g Burnet extract to 450ml water, add 4.95g Yuanming powder, and add glacial acetic acid to adjust the pH value to 5; add 10g real silk fabric to the above solution, at a temperature of 80°C and a bath ratio Treat for 40 minutes under the condition of 1:45; then take out the real silk fabric, wash it, and dry it;

[0033] (2) Measure 450ml of distilled water and add 1.35g of alum; add the washed and dried silk fabric in step (1) to the solution obtained above, and treat it at a temperature of 80°C and a bath ratio of 1:45 25min; then the real silk fabric is taken out and washed and dried to obtain a real silk fabric with anti-ultraviolet function. After testing, the UPF value of the silk fabric is 82.41.

Embodiment 3

[0035] (1) Add 0.2g Burnet extract to 600ml water, add 7.2g Yuanming powder, add glacial acetic acid to adjust the pH to 6; Treat for 60 minutes under the condition of 1:60; then take out the silk fabric and wash and dry it;

[0036] (2) Measure 600ml of distilled water and add 1.2g of ferrous sulfate; add the washed and dried silk fabrics in step (1) to the mixed solution obtained above, at a temperature of 70°C and a bath ratio of 1:60 Under the condition of treatment for 40min; then take out the real silk fabric, wash it, and dry it to obtain the real silk fabric with anti-ultraviolet function. After testing, the UPF value of the silk fabric is 115.92.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com