Natural dye and dyeing method thereof

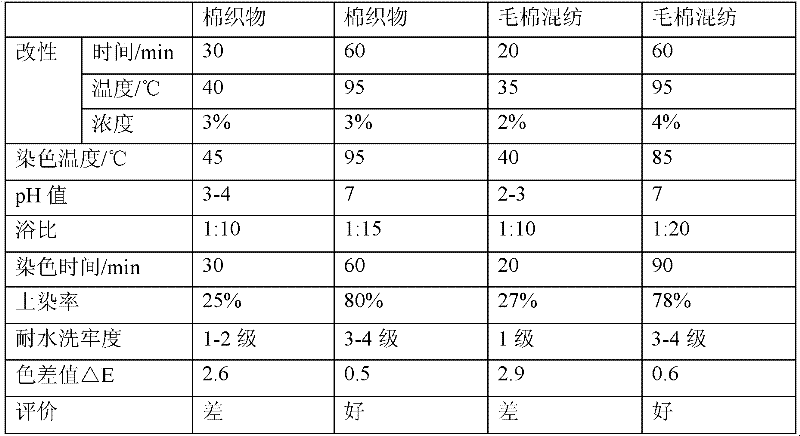

A technology of natural dyes and dyeing methods, applied in the field of natural dyes and dyeing of Ophiopogon japonicus flower stems, can solve problems such as no reports, and achieve the effects of good washing fastness, simple method and small color difference value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First, take the fresh stems of Ophiopogon japonicus broadleaves, wash them, and dry them at 70°C for 5 hours, weigh 20 g of the dried stems of Ophiopogon japonicus broadleaves, grind them mechanically to 20 mesh, place them in a four-neck flask, add Ethanol aqueous solution with volume percentage concentration of 30%, mass ratio of solid to liquid is 1:20, reflux leaching at 60°C for 5 hours, then filter; leaching filter residue with 50% ethanol aqueous solution for 3 hours, then filter again , after combining the two filtrates, concentrate and recover part of the ethanol under reduced pressure to obtain a dark green slurry-like natural dye for the stems of Ophiopogon japonicus broadleaves.

Embodiment 2

[0025] First, take the fresh flower stems of Ophiopogon japonicus broadleaves, wash them, dry them at 80°C for 4 hours, weigh 20g of dried Ophiopogon japonicus broadleaf stems, grind them mechanically to 50 mesh, place them in a four-neck flask, add 80% ethanol aqueous solution with a concentration of 80% by volume, the mass ratio of solid to liquid is 1:50, reflux leaching at a temperature of 90°C for 3 hours, and then filter; leaching the filter residue with 60% ethanol aqueous solution for 3 hours, and then filter again , after combining the two filtrates, concentrate and recover part of the ethanol under reduced pressure to obtain a dark green slurry-like natural dye for the stems of Ophiopogon japonicus broadleaves.

Embodiment 3

[0026] Embodiment three: the dyeing of Ophiopogon japonicus flower stem natural dye on real silk fabric

[0027] First, soak the silk fabric in water for 2 minutes, take it out, wring it dry, and set it aside. The mass ratio of the dye to the medium to be dyed is 2%, the pH value is 4, and the bath ratio is 1:20. Put the above-mentioned treated real silk fabrics into the dyed silk fabrics at a temperature of 60°C for 30 minutes, then take out the fabrics and undergo acidic soaping. The lotion is a solution composed of soap flakes and water with a mass ratio of 1:1000, the pH value is 7, and it is washed with water and then dried. The obtained silk fabric has uniform color, the color difference value ΔE is less than 0.4, the dye uptake rate reaches 75%, and the color fastness to washing reaches 3-4 grades. The washing fastness in all the examples of the present invention is determined according to the method of "GB / T 12490-2007 Textile Color Fastness to Home and Commercial Was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color price | aaaaa | aaaaa |

| color price | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com