Process for dyeing cotton cheese by using natural dye

A technology of natural dyes and cheese yarn, applied in the field of textile printing and dyeing, achieves the effects of simple dyeing equipment, solving the problem of levelness and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

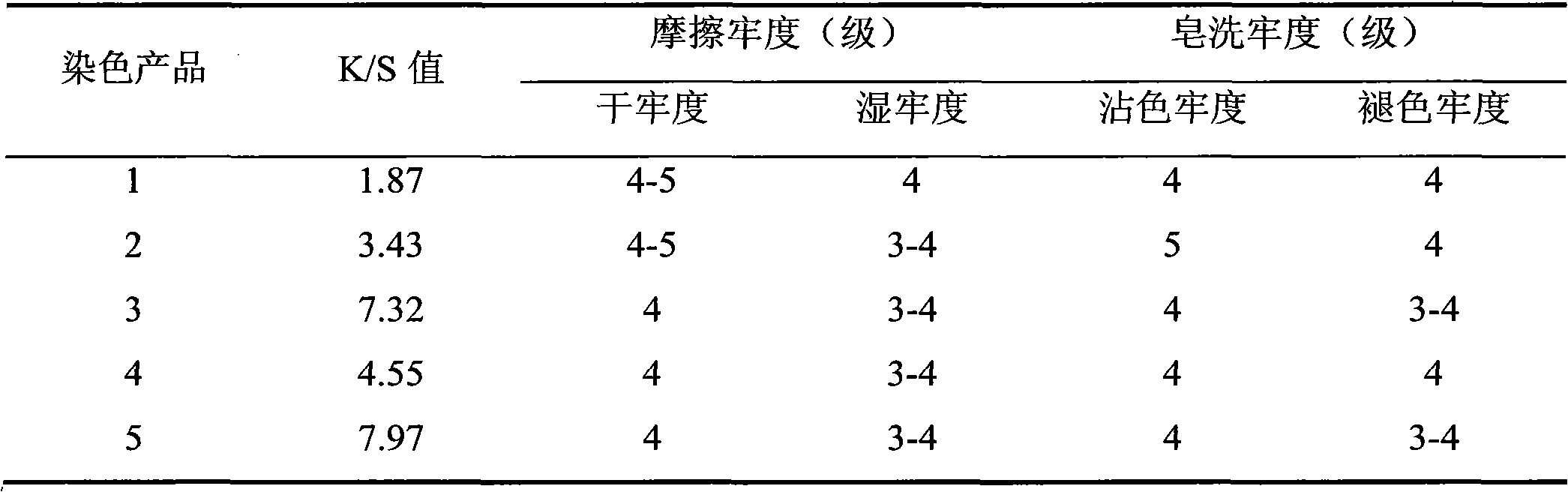

Examples

Embodiment 1

[0024] Cotton cheese 500g; modified solution 2.5kg, of which modifier: 0.5g, copper sulfate: 2.5g, Pingpingjia: 2.5g. The modification of the cotton cheese is done in the cheese dyeing machine. Put the modification bath in the cheese dyeing machine, raise the temperature to 60°C at a rate of 2°C / min, then dip the cotton cheese into the dyeing bath, spray it outward for 3 minutes, and spray it inward. Cotton cheese was modified with a 2 minute spray cycle. Keep warm for 30 minutes, wash 2 times with water.

[0025] Dyeing solution 2.5kg, including purple sweet potato red: 25g, Pingpingjia: 2.5g, ammonia water: 12.5g. Dyeing of cotton cheese is done in a cheese dyeing machine. Place the dyeing bath in the cheese dyeing machine, raise the temperature to 90°C at a rate of 2°C / min, then dip the modified cotton cheese into the dyeing bath, spray it outward for 3 minutes, Cotton cheeses were dyed in a 2-minute cycle with internal jets. Dyeing time is 60 minutes, washed twice wit...

Embodiment 2

[0027] Cotton cheese 200g; modified solution 4kg, including modifier: 4g, ferrous sulfate: 10g, Tween 80: 4g. The modification of the cotton cheese is done in the cheese dyeing machine. Put the modification bath in the cheese dyeing machine, raise the temperature to 60°C at a rate of 2°C / min, then dip the cotton cheese into the dyeing bath, spray it outward for 4 minutes, and spray it inward. Cotton cheeses were modified with a 6 minute spray cycle. Modification time is 10 minutes, washed twice with water.

[0028] Dye solution 4kg, including tea dye: 20g, Tween 80: 32g, triethanolamine: 12g. Dyeing of cotton cheese is done in a cheese dyeing machine. Place the dyeing bath in the cheese dyeing machine, raise the temperature to 60°C at a rate of 2°C / min, then dip the modified cotton cheese into the dyeing bath, spray outward for 3 minutes, Cotton cheeses were dyed in a 2-minute cycle with internal jets. The dyeing time is 120 minutes, washed twice with water. Obtain dyed ...

Embodiment 3

[0030] Cotton cheese 400g; modified solution 4kg, including modifier: 4g, aluminum sulfate: 4g, Span 20: 20g. The modification of the cotton cheese is done in the cheese dyeing machine. Put the modified bath in the cheese dyeing machine, raise the temperature to 80°C at a rate of 2°C / min, then dip the cotton cheese into the dyeing bath, spray it outward for 4 minutes, and spray it inward. Cotton cheeses were modified with a 6 minute spray cycle. Modification time is 30 minutes, washed twice with water.

[0031] Dye solution 4kg, including sorghum red dye: 20g, Span 20: 16g, hydrochloric acid: 8g. Dyeing of cotton cheese is done in a cheese dyeing machine. Place the dyeing bath in the cheese dyeing machine, raise the temperature to 70°C at a rate of 2°C / min, then dip the modified cotton cheese into the dyeing bath, spray it outward for 3 minutes, Cotton cheeses were dyed in a 2-minute cycle with internal jets. Dyeing time 30 minutes, wash 2 times. Obtain dyed product 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com