Production process of pure coffee yarn spun fabric

A production process, coffee yarn technology, applied in the production process field of coffee yarn pure spinning fabrics, can solve the problems of less research and development of coffee yarn fabric knitting, weaving and dyeing and finishing processes, so as to ensure color fastness, improve dyeing rate, and yarn The effect of less thread hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

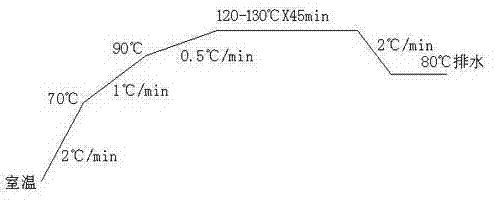

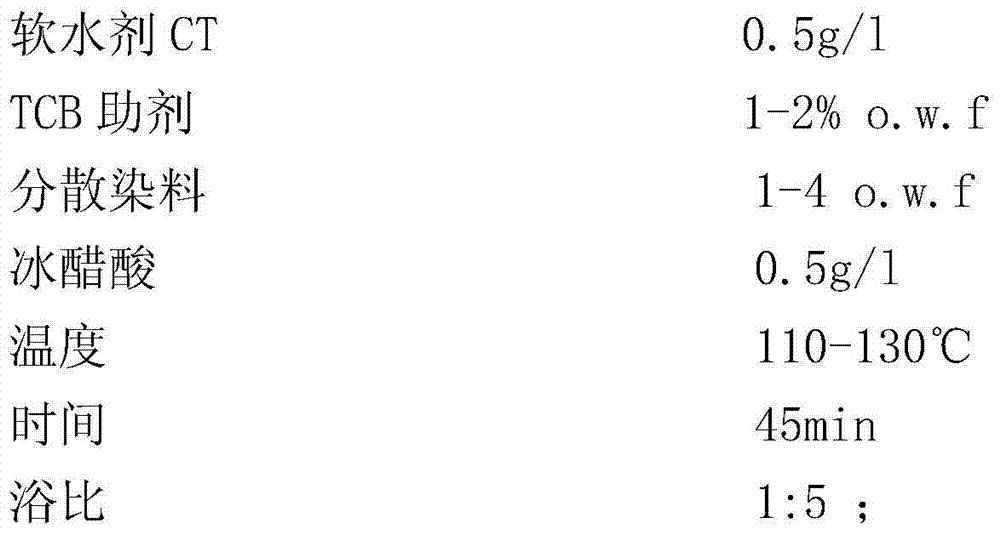

Method used

Image

Examples

Embodiment 1

[0039] The production process of coffee yarn pure spinning fabric is as follows: spinning - weaving - dyeing - finishing - finished coffee yarn pure spinning fabric.

[0040] 1. Spinning:

[0041] Using 100% coffee yarn as raw material, 26-40S yarns are made by vortex spinning or air-jet spinning respectively.

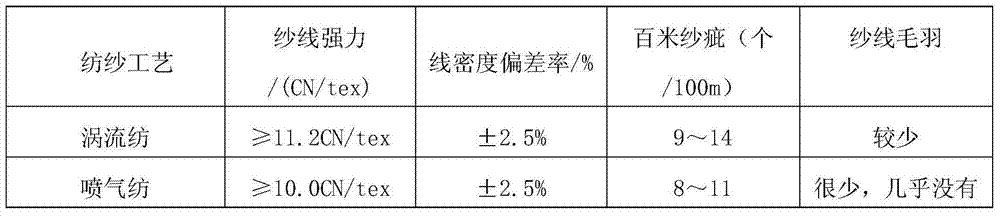

[0042] In order to spin 26-40S coffee yarn with uniform dryness, we tried vortex spinning and air-jet spinning, and the final sample test results are as follows:

[0043] Table 1. Performance indicators of coffee yarn produced by vortex spinning and air-jet spinning

[0044]

[0045] It can be seen from the above table that when 26-40S coffee yarn is spun by vortex spinning and air-jet spinning, the yarn strength of the two kinds of yarns can meet the requirements of knitting yarn, and the yarn defects of 100 meters are basically the same. Air-jet spinning is slightly better than vortex spinning in terms of thread apparent hairiness.

[0046] The aforesaid vortex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com