Coconut-carbon blended yarn, moisture-absorbing and quick-drying anti-ultraviolet shirt fabric, spinning method and production process

A coconut-carbon blended and blended yarn technology, which is applied in spinning methods and production processes, moisture-absorbing and quick-drying anti-ultraviolet shirt fabrics, blended yarn fields, can solve unfavorable spinning webs and weaving, high fiber quality specific resistance, Reduce wearability and other problems, achieve good development prospects, reduce spun yarn hairiness, and improve product grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

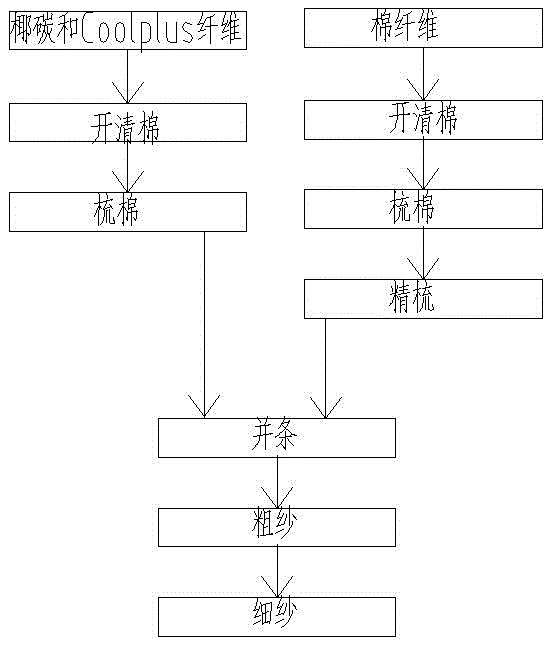

[0022] The invention provides a coconut carbon blended yarn, the coconut carbon blended yarn is coconut carbon / cotton / Coolplus blended yarn, the blended weight ratio of coconut carbon / cotton / Coolplus is 60:30:10, and the blended yarn is 60:30:10. The linear density of the spinning yarn is 9.8tex (tex specifically refers to the weight in grams of a 1000-meter-long yarn at a predetermined moisture regain).

[0023] The present invention also provides the spinning method of the above-mentioned coconut-carbon blended yarn, which includes five processes in sequence.

[0024] The first process is to open and clean the coconut carbon / Coolplus fiber and cotton fiber respectively (that is, ordinary carding); The yarn oil is evenly sprayed; the spinning oil includes an antistatic agent and a softener. Adding spinning oil when opening and cleaning can control the static phenomenon in the spinning process, make the fibers mix evenly, and avoid the uneven mixing caused by adding antistati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com