A wet spinning device and wet spinning process

A spinning spindle and yarn guide hook technology, which is applied in the textile industry, can solve problems such as reducing yarn strength, increasing spun yarn hairiness, and limiting spinning count, etc., to achieve increased yarn strength, reduced spun yarn hairiness, and improved spinning The effect of count

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

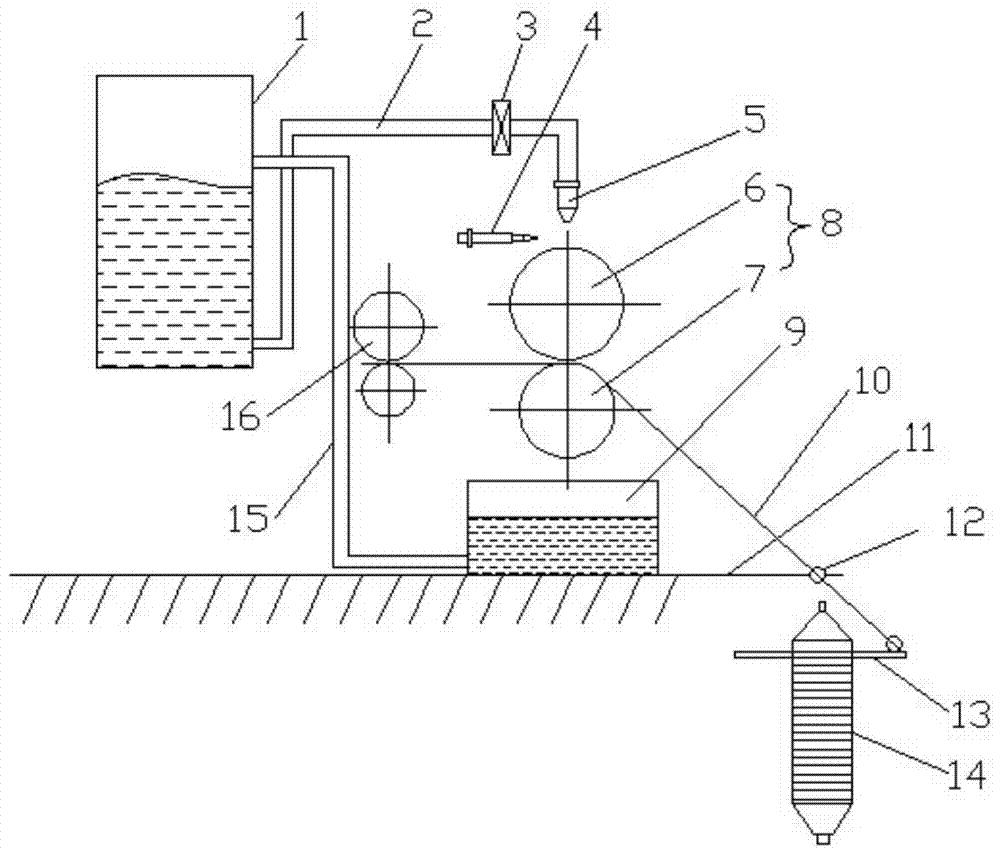

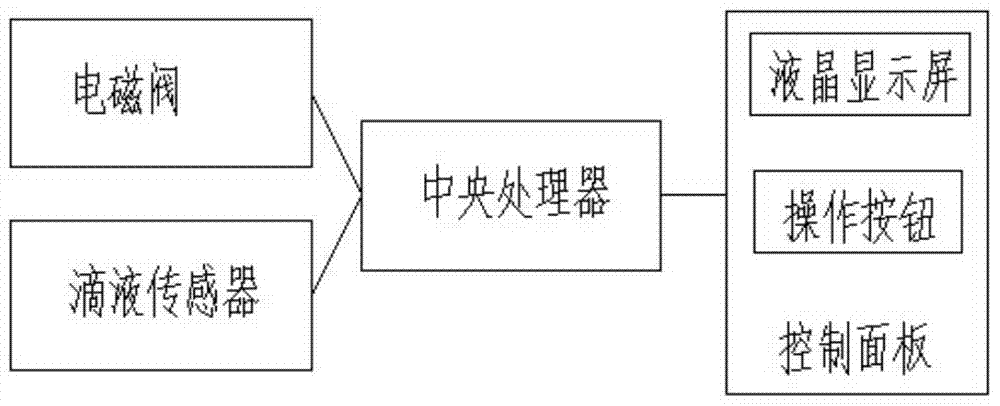

[0034] like figure 1 As shown, the wet spinning device of the present invention comprises a frame 11 and a front drafting roller 8, a rear drafting roller 16, a guide hook 12, a traveler 13 and a spinning spindle 14 arranged on the frame 11. , the front drafting roller 8 includes an upper drafting roller 6 and a lower drafting roller 7, the upper drafting roller 6 is arranged on the top of the lower drafting roller 7 in parallel, and the upper drafting roller 6 is a top roller, and the above-mentioned device also includes a fiber wetting device, the fiber wetting device includes a water tank 9, a return pipe 15 located on the water tank 9, a dripping device and a liquid supply device 1, the water tank 9 is located below the lower drafting roller 7, and the dripping device and the return pipe 15 are connected to the supplying device respectively. The liquid device 1 is connected, and the dripping device is arranged above the upper drafting roller 6 to provide liquid for soaking...

Embodiment 2

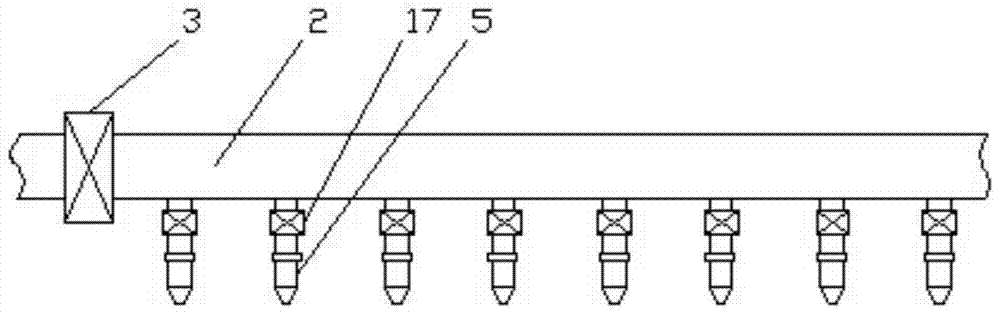

[0047] For the first embodiment above, according to the number of front drafting rollers on the existing spinning machine, multiple dripping heads 5 can be set on the conduit 2 of the fiber wetting device, and each dripping head 5 corresponds to a pair of front drafting rollers. The upper drafting roller of the roller, the solenoid valve 3 is set on the main road of the conduit 2 to control the flow of all the dripping heads 5, and a manual valve 17 is also provided between the dripping heads 5 and the conduit 2 to control the corresponding dripping The flow rate of liquid head 5 improves the wetting effect of fibers, such as image 3 shown.

[0048] Application prospect of the present invention:

[0049] 1. Since the present invention is superior to the current dry spinning and wet spinning processes, it can be used not only in hemp spinning, wool spinning, silk spinning, and cotton spinning, but also in chemical fiber spinning, and has a wide range of uses.

[0050] 2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com