Method for preparing antifouling and wear-resistant automobile interior textile material

A technology for textile materials and automotive interiors, which is applied in the field of preparation of anti-fouling and wear-resistant textile materials for automotive interiors, can solve the problems of few practical applications and poor wear resistance, and achieve low heat generation and good cold resistance , good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

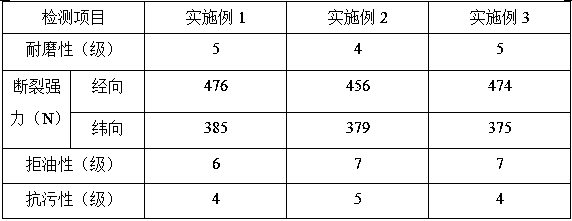

Examples

Embodiment Construction

[0032] Mix azobisisobutyronitrile, EVA and maleic anhydride at a mass ratio of 1:5:7, and stir for 5-10min at a stirring speed of 2000-2200r / min to obtain a mixture. Place the mixture in a twin-screw extruder When the temperature is 75~85℃, the main engine speed is 60~80r / min, the feeding speed is 20~30r / min, and the cutting speed is 180~200r / min, the semi-finished product is obtained by extrusion and granulation. After drying for 2 to 3 hours in an oven with a temperature of 70 to 75°C, it is placed in a Soxlet extractor and washed with deionized water for 20 to 24 hours to obtain a compatibilizer; the polyamide is mixed with a cistern at a mass ratio of 1:2 Mix butadiene rubber and stir at a high speed of 1600~2000r / min for 5~10min to obtain the matrix material. Mix the compatibilizer and matrix material uniformly according to the mass ratio of 1:5, and melt at the temperature of 280~300℃ After 30-50 minutes, cool to room temperature, the modified product is obtained; the mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com