Processing method used for dyeing wool fabric with natural dye with high colour fastness

A technology of natural dyes and high color fastness, which is applied in dyeing, animal fiber, textiles and papermaking, etc. It can solve the problems of unsuitable textiles, difficult to obtain colors, and low utilization rate of dyes, so as to improve washing fastness and Effects of light fastness, saving energy consumption and cost, improving stability and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

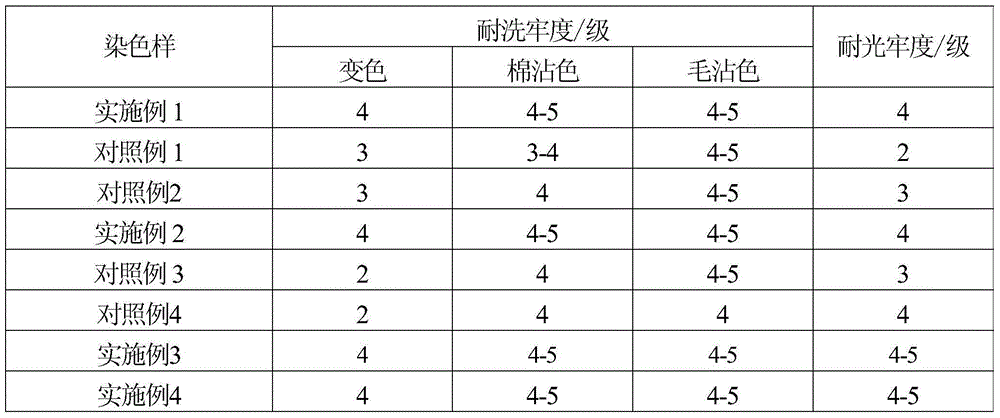

Examples

Embodiment 1

[0028] Wool fabrics were soaked in a treatment solution containing 1g / L wetting agent fatty alcohol polyoxyethylene ether AEO9 for 20 minutes, taken out, squeezed dry; put in a pH value of 3.6, containing 5% (owf) sorghum red pigment and 5% (owf) In the dyeing bath of Galla gall extract, the temperature was raised to 90° C. at 2° C. / min, and the dyeing was carried out at a constant temperature for 60 minutes. After taking it out, it was washed with water. Then adopt metal ion mordant to carry out mordant treatment according to the following process: Ferrous sulfate dosage 4% (owf), pH value 4.0, mordant temperature 60 ℃, mordant time 60 minutes. The mordanted fabric is steamed with saturated steam for 20 minutes at 100°C. Wash the fabric with hot water at 50°C for 20 minutes, wash in cold water after dyeing, dehydrate and dry.

[0029] The gallnut extract is extracted by ultrasonic-assisted extraction, and the extraction process is as follows: commercially available gallnut i...

Embodiment 2

[0035] Wool fabrics were soaked in a treatment solution containing 1g / L wetting agent fatty alcohol polyoxyethylene ether AEO9 for 20 minutes, taken out, and squeezed dry; put in a pH value of 3.6, containing 4% (owf) lac pigment and 4% (owf) In the dyeing bath of Galla gall extract, the temperature was raised to 95° C. at 2° C. / min, dyed at a constant temperature for 60 minutes, taken out, and washed with water. Then adopt metal ion mordant to carry out mordant treatment according to the following process: ferrous sulfate dosage 5% (owf), pH value 4.0, mordant temperature 60 ℃, mordant time 60 minutes. The mordanted fabric was steamed with saturated steam for 20 minutes at 100°C. Wash the fabric with hot water at 50°C for 20 minutes, wash in cold water after dyeing, dehydrate and dry. Galla gall extracting method is the same as embodiment 1.

Embodiment 3

[0041]Wool fabrics were soaked in a treatment solution containing 2g / L wetting agent JFC for 30 minutes, taken out, squeezed dry; put into pH 4.0, containing 5% (owf) lac pigment and 8% (owf) gallnut extract In the dyeing bath, raise the temperature to 95°C at 3°C / min, dye at a constant temperature for 70 minutes, take it out and wash it with water. Then adopt metal ion mordant to carry out mordant treatment according to the following process: ferrous sulfate dosage 7% (owf), pH value 4.0, mordant temperature 50 ℃, mordant time 70 minutes. The mordanted fabric was steamed with saturated steam for 30 minutes at 100°C. Wash the fabric with hot water at 60°C for 30 minutes, wash in cold water after dyeing, dehydrate and dry.

[0042] The extraction method of gallnut is as follows: dry and crush commercially available gallnut, take 15 grams of gallnut powder, add 400 ml of water, extract at a temperature of 60-70°C and an ultrasonic power of 400 watts, filter with suction, and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com