Method for padding dyed cellulose fabric with natural vegetable dye

A technology of natural vegetable dyes and cellulose fabrics, applied in the direction of dyeing, textile and paper making, etc., can solve the problems of poor color fastness to washing and low dyeing amount, so as to improve the color fastness to washing and increase the dyeing amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Get 20g, 30g, 40g, 50g of natural dye gardenia blue and dissolve in 1L of water, add 4g of cationic dye fixing agent, be made into dyeing working solution. Soak 6g of cotton cloth in the gardenia blue dyeing working solution to absorb the dye, roll it on a paddle car, then immerse it in the gardenia blue dyeing working solution for dyeing, and then roll it on the padding car (that is, two dips and two pads), so that the soaked The liquid carrying rate of the pad-dyed cotton cloth was 90% (ie 11.4 g), and then dried at 90°C. Wash the dried dyed cotton cloth in 500ml washing liquid containing 2g / L non-ionic detergent at 70°C for 15min, and finally dry it to complete the cotton cloth dyeing.

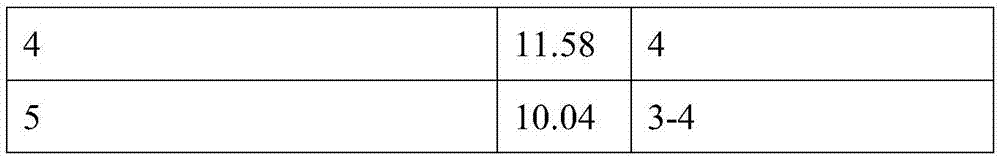

[0019] The K / S value of the dyed cotton cloth after washing and drying was detected by a color measuring instrument to characterize the dyeing amount of natural dyes, and the color fastness to washing of the dyed cotton cloth after washing was detected. The results are ...

Embodiment 2

[0023] Embodiment 2: Get 40g of natural dye gardenia blue and dissolve in 1L of water, add 0g, 2g, 3g, 4g, 5g of cationic dye fixing agent, be made into dyeing working solution. Soak 6g of cotton cloth in the gardenia blue dyeing working solution to absorb the dye, roll it on a paddle car, then immerse it in the gardenia blue dyeing working solution for dyeing, and then roll it on the padding car (that is, two dips and two pads), so that the soaked The cotton cloth after pad dyeing had a liquid retention rate of 90%, and was then dried at 90°C. Wash the dried dyed cotton cloth in 500ml washing liquid containing 2g / L non-ionic detergent at 70°C for 15min, and finally dry it to complete the cotton cloth dyeing.

[0024] The K / S value of the dyed cotton cloth after washing and drying was detected by a color measuring instrument to characterize the dyeing amount of natural dyes, and the color fastness to washing of the dyed cotton cloth after washing was detected. The results are ...

Embodiment 3

[0029] Embodiment 3: Dissolve 40 g of natural dye gardenia blue in 1 L of water, add 4 g of cationic dye fixing agent, and make dyeing working solution. Soak 6g of cotton cloth in the gardenia blue dyeing working solution to absorb the dye, roll it on a paddle car, then immerse it in the gardenia blue dyeing working solution for dyeing, and then roll it on the padding car (that is, two dips and two pads), so that the soaked The liquid-carrying ratios of the pad-dyed cotton cloths were 70%, 80%, 90%, and 100%, respectively, and then dried at 90°C. Wash the dried dyed cotton cloth in 500ml washing liquid containing 2g / L non-ionic detergent at 70°C for 15min, and finally dry it to complete the cotton cloth dyeing.

[0030] The K / S value of the dyed cotton cloth after washing and drying was detected by a color measuring instrument to characterize the dyeing amount of natural dyes, and the color fastness to washing of the dyed cotton cloth after washing was detected. The results ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com