Patents

Literature

46results about How to "Improve artistic expression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous texture wallpaper paint and method for making same

The invention relates to a watercraft texture wallpaper paint, characterized in that the invention comprises the following components: 31 percent to 35 percent of styrene-acrylic emulsion, 23.94 percent of superfine weight calcium, 1 percent to 2 percent of nano-titanium dioxide, 10 percent to 18 percent of titanium pigment, 8 percent to 9.8 percent of calcined kaolin, 1.2 percent to 1.8 percent of ethylene glycol, 0.2 percent to 0.5 percent of hydroxyethylcellulose, 0.8 percent to 1.5 percent of film forming additive, 0.15 percent to 0.25 percent of multi-functional additive, 0.3 percent to 0.5 percent of dispersant, 0.1 percent to 0.2 percent of wetting agent, 0.15 percent to 0.21 percent of defoamer, 0.08 percent of anticorrosion and insecticide, 0.8 percent to 2 percent of thickener and 20 percent to 22 percent of water. The invention is the watercraft texture wallpaper paint, is environment-friendly, has strong elastic tension, has good covering and anti-cracking effect on the fine cracking of wall, and has good scrape resistance performance, greatly enhancing the degree of wall surface protection; meanwhile, the invention still has strong waterproof performance, without color-changing and decortication and mildew and can fully solve the common problems existing in wall decoration.

Owner:佛山市顺德区清大润彩涂料有限公司

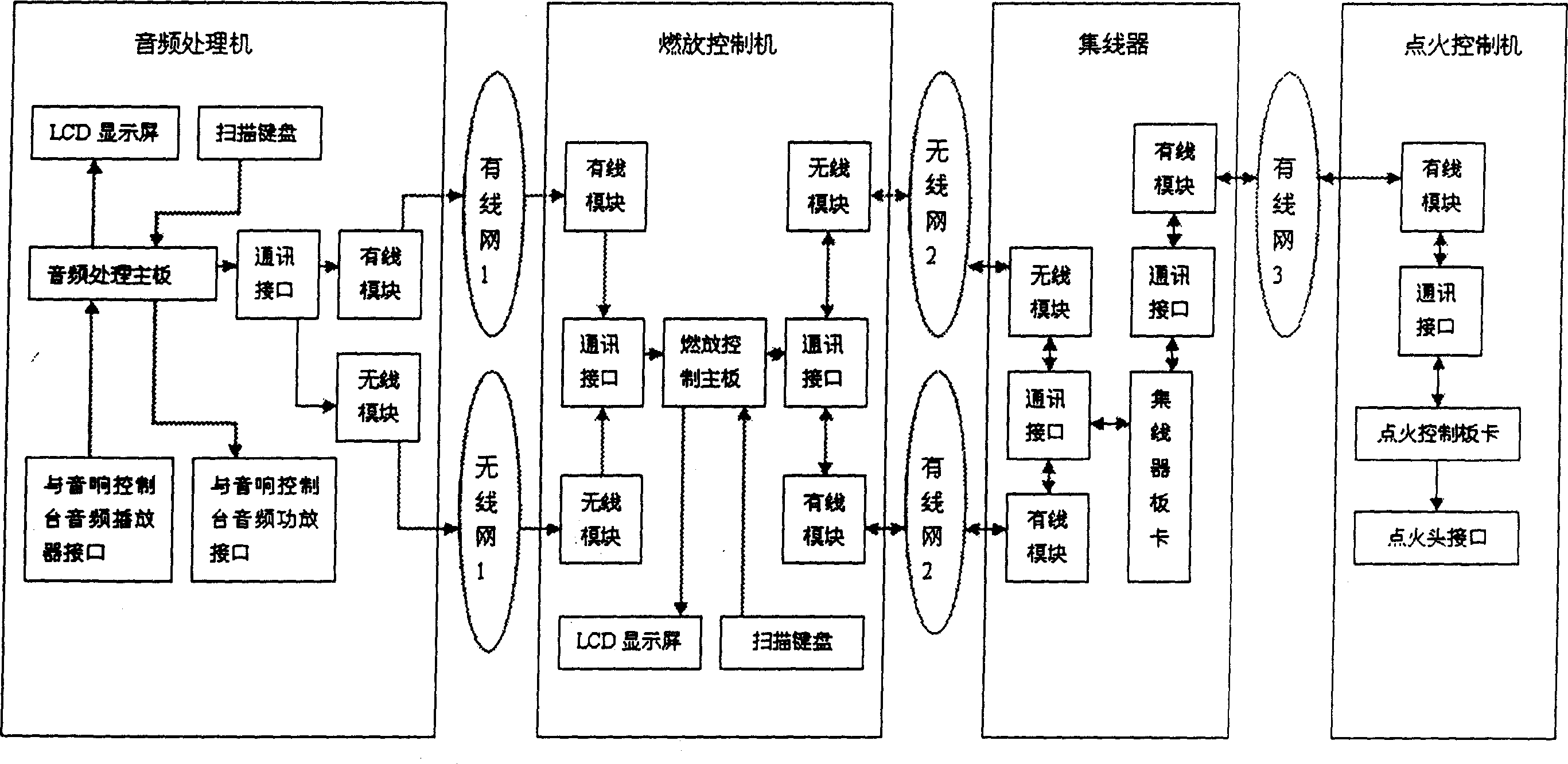

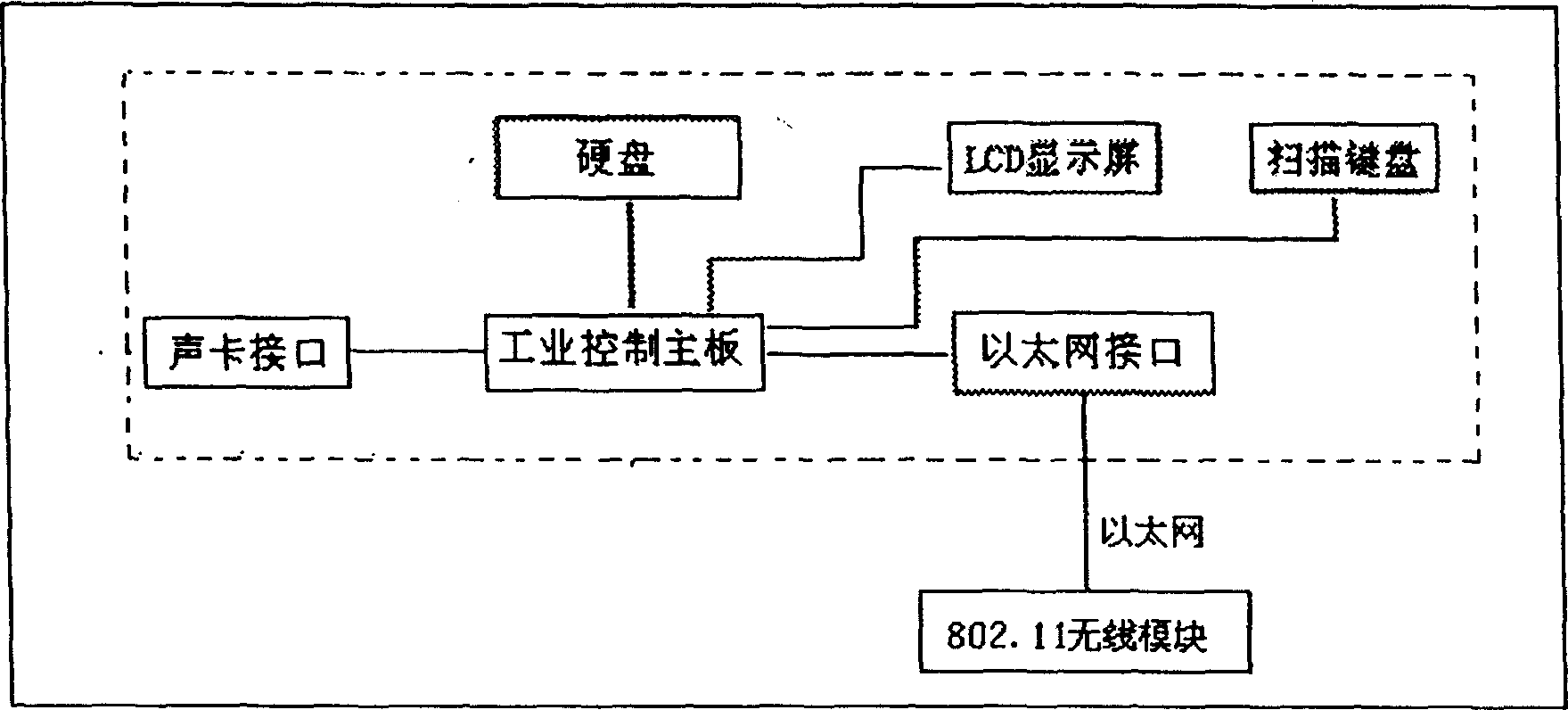

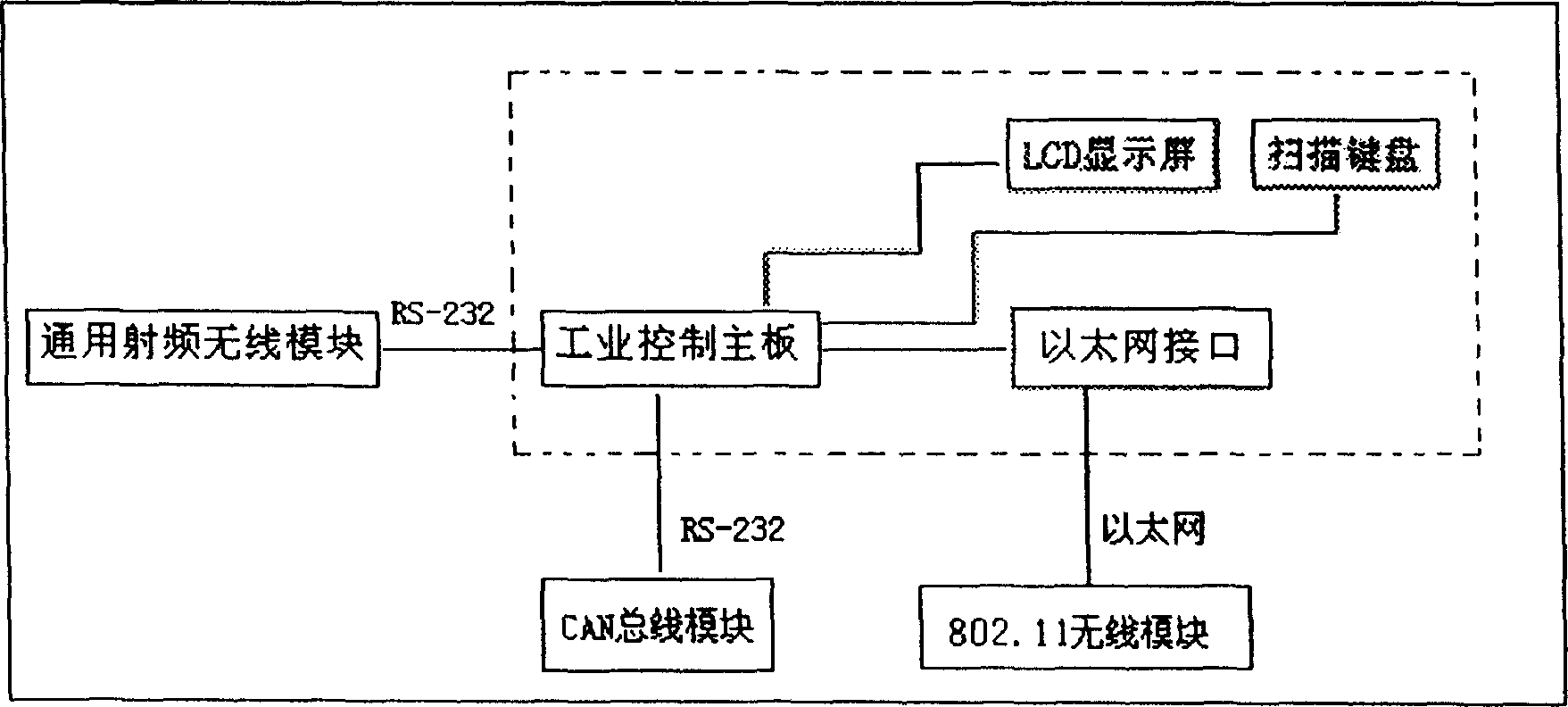

Control method and system for igniting fireworks

The present invention relates to a control method for lighting fireworks and its system. Said system includes two portions of pattern make-up system and lighting control system. Said pattern make-up system uses voice frequency waveform and playback time as main shaft to automatically form lighting time for lighting fireworks; the lighting control system is composed of four portions: namely voice frequency analysis processing machine, lighting control main machine, line concentrator and lighting controller. Said invention can implement the complete synchronization of music playback and lighting fireworks, and its reliability is high.

Owner:彭军 +1

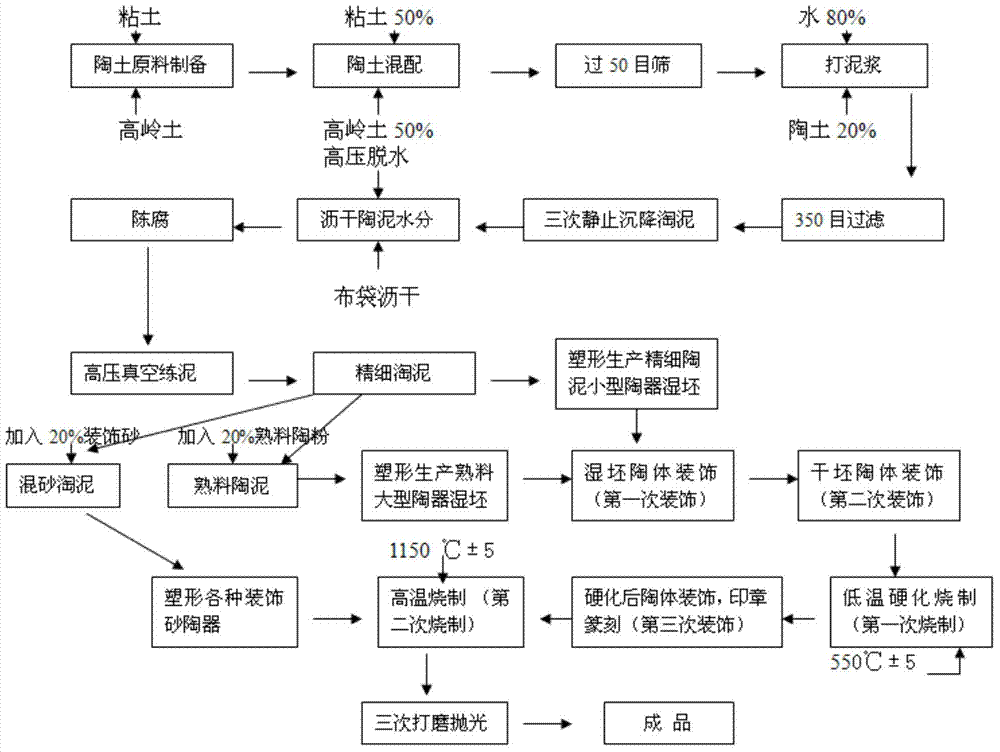

Method for preparing pottery with jade surface

ActiveCN103755319AOpaqueMicroporous and breathableDecorative surface effectsClaywaresSurface finishVolumetric Mass Density

The invention discloses a method for preparing a pottery with a jade surface. The method comprises the following steps of (1) argil raw material preparation; (2) fine clay preparation; (3) preparation of a greenware with the jade surface; (4) wet greenware body decoration; (5) dry greenware body decoration; (6) low temperature hardening and firing; (7) pottery body decoration and scribing creation after the low temperature hardening and firing; (8) high temperature firing; (9) three-time polishing and burnishing; and (10) finished product obtaining. The method for preparing the pottery with the jade surface, disclosed by the invention, has the advantages that the conventional production processes of potteries are changed but the basic properties of the potteries are not changed; the obtained pottery with the jade surface still has the characteristics of opaqueness, micropore breathability and water absorbability of the potteries; the important changes are that (1) the pottery hardness is increased and the Mohs hardness is up to 6.0-6.5, (2) the pottery density is increased to 2.65 and (3) the surface smoothness of the pottery is up to more than Hamiltonian 10; through the three important changes, the beating resisting ability of the pottery is increased, the artistic expression of the pottery is increased and the durability is increased.

Owner:赫忠友

UV (Ultraviolet) vacuum coating crackle coating and preparation method thereof

ActiveCN105505191AImprove artistic expressionGood low toxicityPolyurea/polyurethane coatingsEpoxy resin coatingsChemistryKetone

The invention relates to a UV (Ultraviolet) vacuum metalizing crackle coating, which comprises the following components: polyurethane acrylate, modified epoxy acrylate, thermoplastic acrylate, dipentaerythritol hexaacrylate, trimethylolpropane ethoxylate triacrylate, special tertiary amine acrylate, 1-hydroxy-cyclohexyl-benzyl ketone, butyl acetate, acetic ether, isobutyl alcohol and glycol ether. After the coating is cured through UV-irradiationUV irradiated so as to be cured, the surface of a coated parts shows a complex ice flower pattern effect instead of a boring mirror surface effect; the adhesive force of the coating is the same as that of the conventional coating, and the coating is resistant to boiling and synthetic perspiration; multiple experiments carried out on the components of the coating prove that the coating has better hypotoxicity compared with a traditional UV vacuum metalizing coating, is energy saving and environmental-ly friendly, simple and convenient to manufacture, and particularly suitable for a decorative effect of a cosmetics packaging structure and a special design of a panel for decoration.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

Painting Xuan paper treating method

The painting Xuan paper treating method can solve the problems of available Xuan paper, which is easy to shrivel, damage, contaminate, fade, moth bite, etc. The painting Xuan paper treating method includes the following steps: painting one layer of paste on palette, soaking silk with clear water and wringing, spreading the moistened silk on the paste layer, painting one other layer of paste onto the silk, flatening the Xuan paper to be painted on the silk for pasting, and drying before painting on the Xuan paper. After painting and drying, one layer of wax is painted to the surface and stoved at 45-300 deg.c to make molten wax penetrate into Xuan paper.

Owner:李文华

Semitransparent oil color and its preparing process

The invention provides a semitransparent oil paint consisting of oil, toner and transparent materials and a preparation method thereof. The oil paint is characterized in that the paint consists of cold pressed crude walnut oil and ripe walnut oil or crude and ripe flaxseed oil, pigment powder and transparent materials; the formulation proportion is as follows: 8 to 10 percent of the cold pressed crude walnut oil or flaxseed oil (including one percent of litharge), 8 to 10 percent of the ripe walnut oil or ripe flaxseed oil, 4 to 10 percent of the pigment powder, 0.2 to 3 percent of white powder and the remaining are other transparent materials; the various materials are mixed and heated to obtain the semitransparent oil paint. The invention has the advantage that the paint can be matched with cover type paint and transparent paint to be used on different occasions so as to improve the artistic expression of oil painting works.

Owner:TIANJIN LIGHT IND VOCATION TECHN COLLEGE

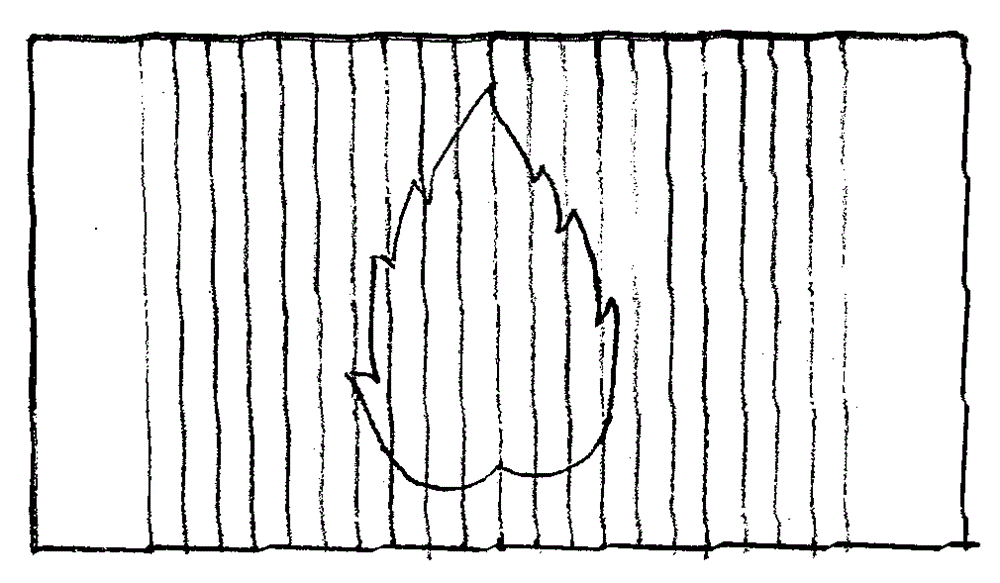

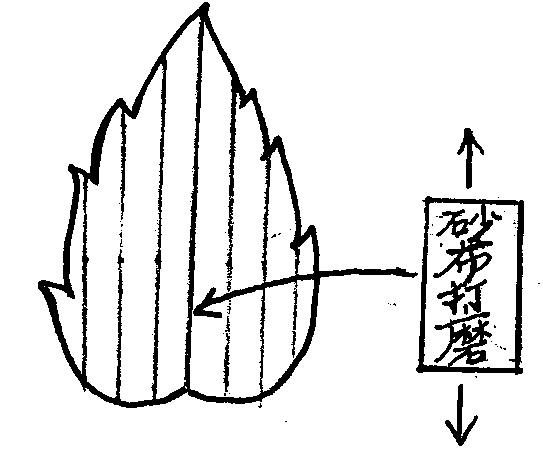

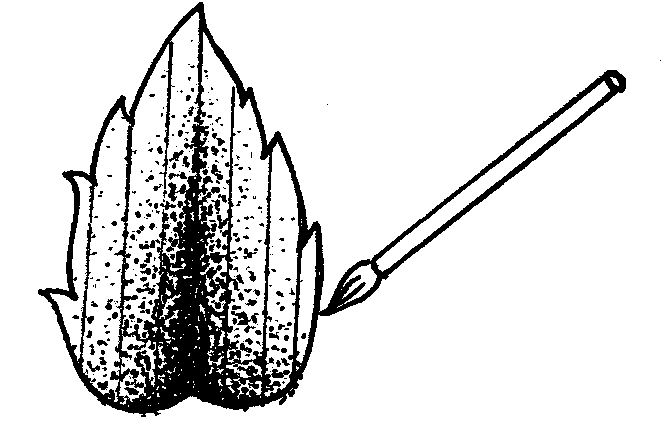

Colorful craft picture coloring method taking wheat stalks or reed stems as raw materials

InactiveCN104648030ANatural color transitionFull of layersSpecial ornamental structuresEngineeringColor changes

The invention discloses a colorful craft picture coloring method taking wheat stalks or reed stems as raw materials. The colorful craft picture coloring method is characterized in comprising following steps: 1, processed and flat wheat stalks or reed stems are joined together and pasted on paper with glossy surfaces upward so as to form a pattern, and a designed pattern is formed via engraving and cutting; 2, the parts of the designed pattern, i.e. the glossy surfaces of wheat stalks or reed stems, which are required to be colored are subjected to polishing using polishing tools; 3, the designed pattern obtained via polishing directly is subjected to handcraft coloring using liquid pigments on polished surfaces. According to the colorful craft picture coloring method, polishing and handcraft direct coloring are combined, so that color change and transition are natural, and pictures are vivid and are rich in layering sense.

Owner:邹晋洪

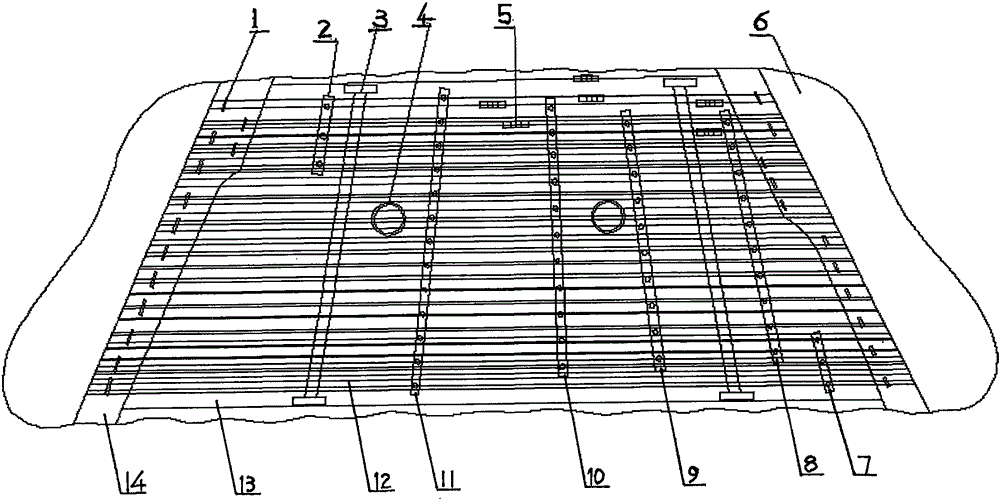

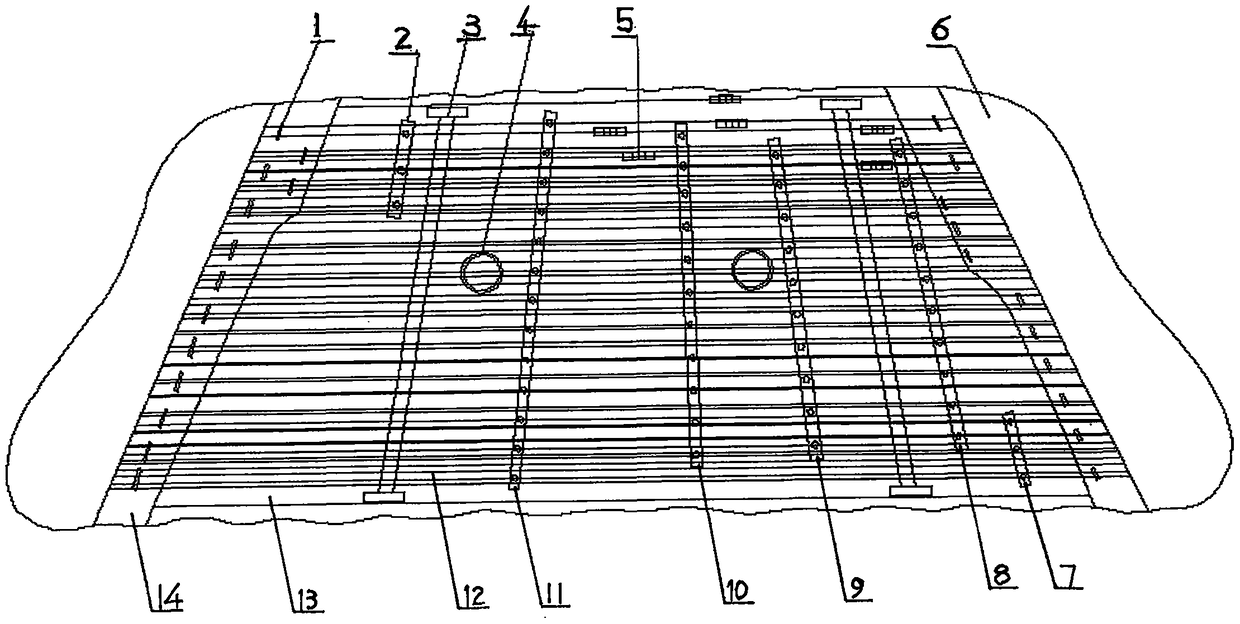

Bass dulcimer

ActiveCN105096915ALowered rangeExtended expressive rangeStringed musical instrumentsComputer scienceDouble bass

Owner:乐海乐器有限公司

Production technology for imitating batik fabric

ActiveCN106958158AAchieve diversificationBreak the limitationsDyeing processTextile shapingEngineeringHigh color

The invention relates to a production technology for an imitating batik fabric. The production technology comprises the following processing steps in turn: treating a base cloth surface, performing intaglio printing, baking under high temperature, dyeing in cold pad-batch, soaping for removing surface dyeing, and the like. The process of dyeing in cold pad-batch includes alkali liquor padding, dye coating and rolling cold stacking. According to the invention, the higher water repellency of a carbon fluorine waterproof agent is utilized and a pattern type roller with a natural ice pattern effect and a gradient chromatic halo effect is adopted for producing the fabric with a batik effect, so that the characteristics of the original batik fabric are remained and the style diversification can be realized through the combination and evolution of the styles, such as, pattern layout, chromatic halo effect, ice pattern effect and cracking effect; the limitation of dye color can be broken through, the dye is not limited to indigo blue dye, the color of the fabric is more abundant and the art expressive force is greatly increased; the production technology can realize the large-scale industrial production, has higher stability and reproducibility and high production efficiency, is more environment-friendly, can achieve higher color fastness to washing and has an excellent dry and wet rubbing fastness property.

Owner:福建省张氏新材料科技有限公司

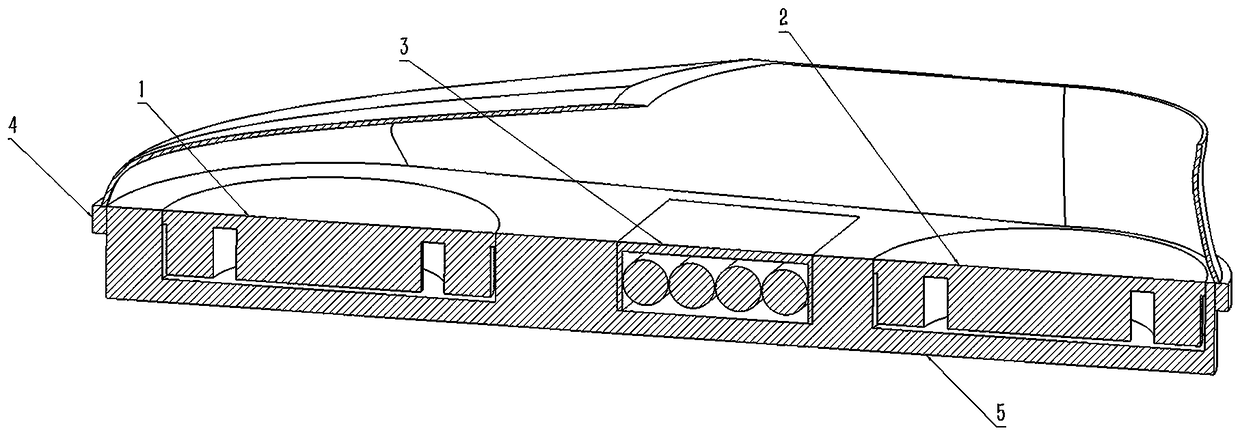

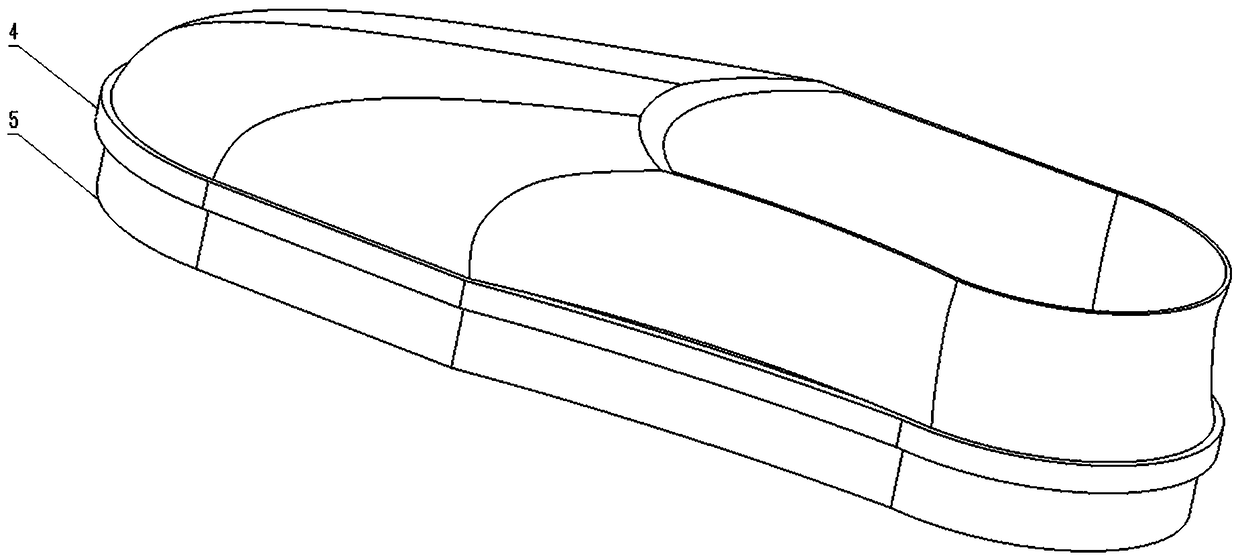

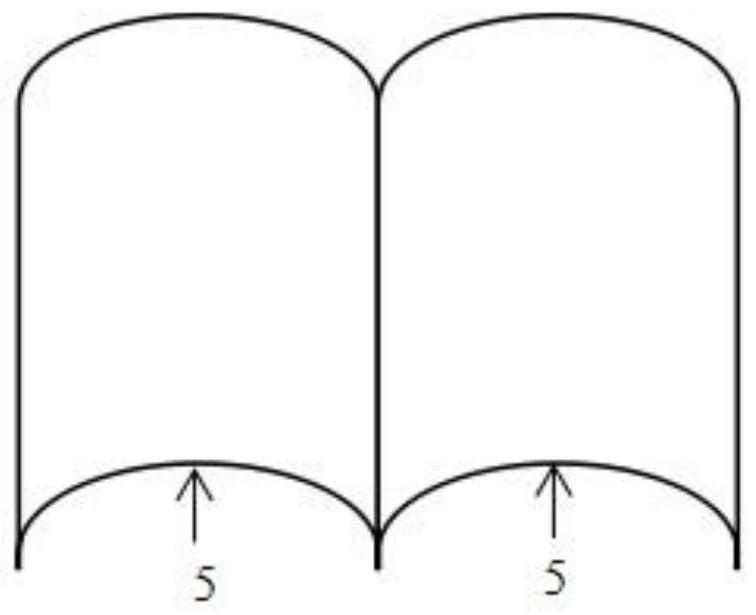

Dancing shoes focusing on user experience

InactiveCN108741378AIncreased dancing experienceImprove artistic expressionFootwearEngineeringFoot soles

The invention relates to dancing shoes focusing on interaction experience between a dancer and the shoes during dancing. Each shoe is composed of a front vibrating pad (1), a rear vibrating pad (2), abattery pack (3), an LED colored ribbon (4) and a shoe body (5). When the dancer's feet step on the dancing shoes, feedback is transmitted to the foot soles of the dancer through the front vibratingpads (1) and the rear vibrating pads (2); meanwhile, a corresponding light effect can be presented on the LED colored ribbons (4); in a dim dancing room, both the dancer and audiences can see the light effect. In a dancing room with excellent atmosphere, if rhythmic interaction between the dancer and the dancing shoes is performed at that time, under cooperation with dazzling light color performance, an amazing dancing experience is achieved.

Owner:吴涛

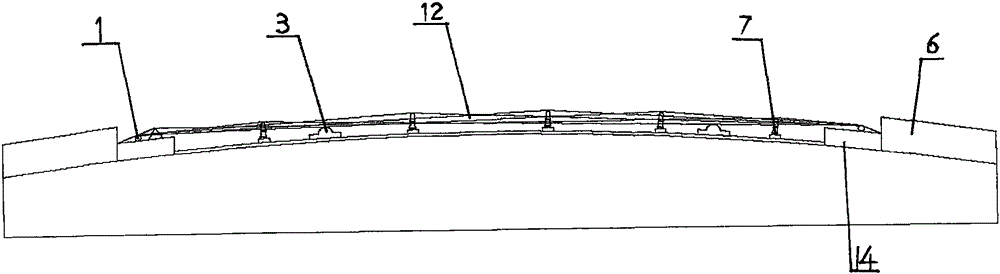

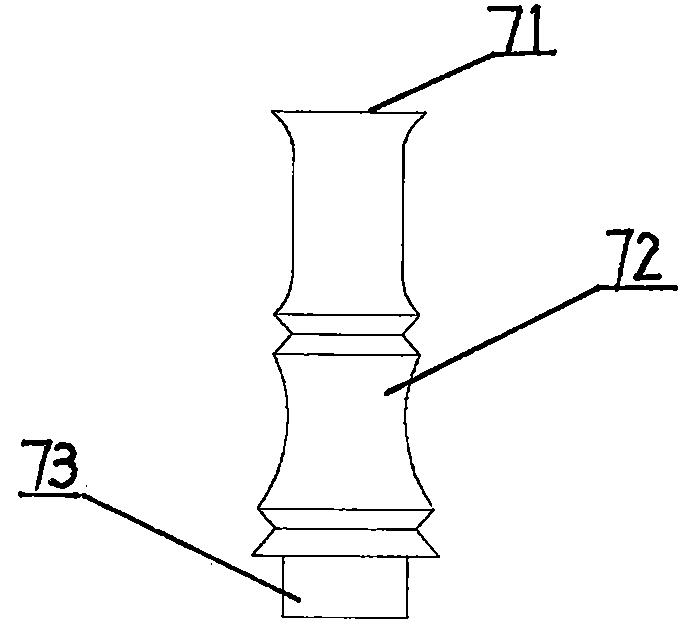

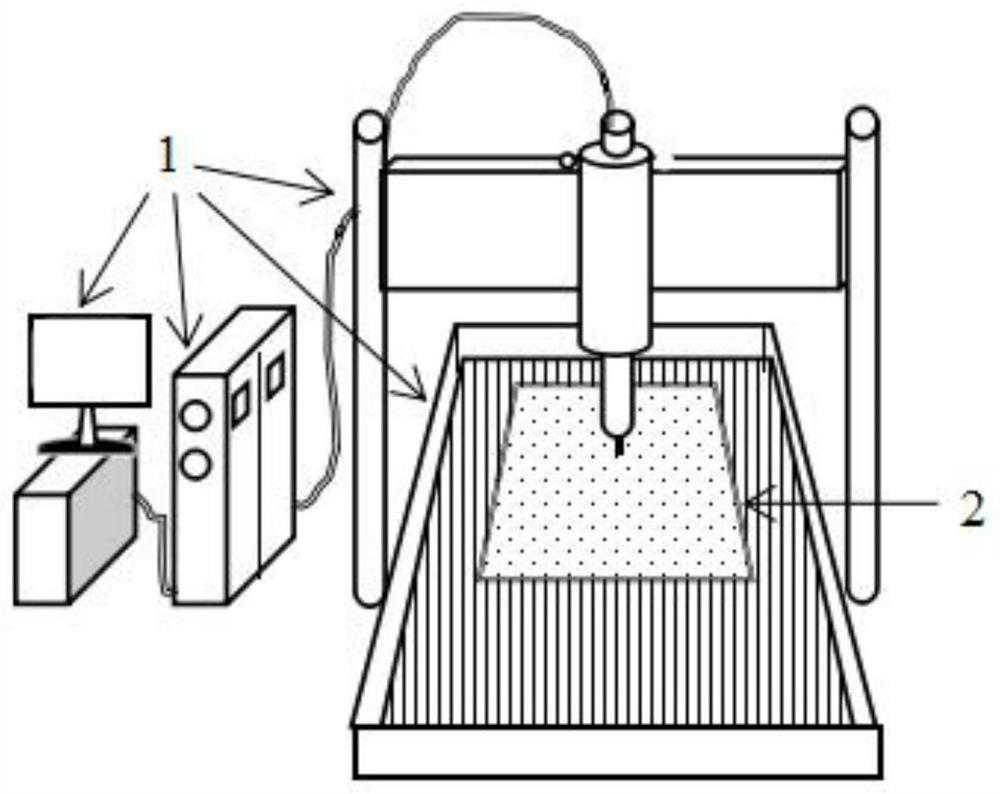

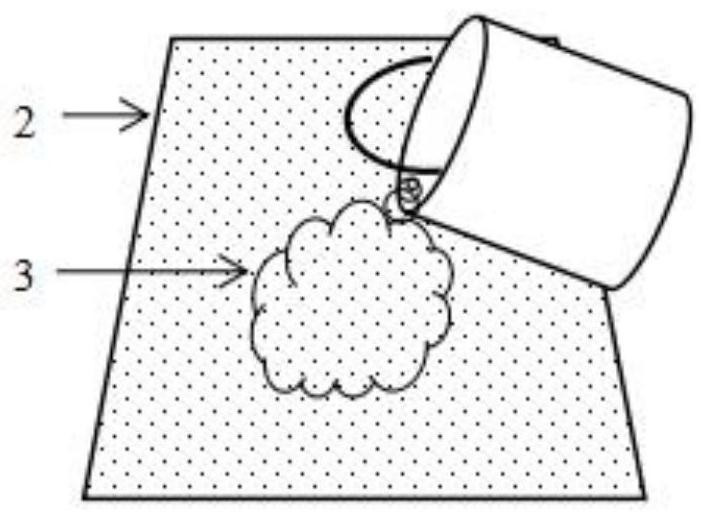

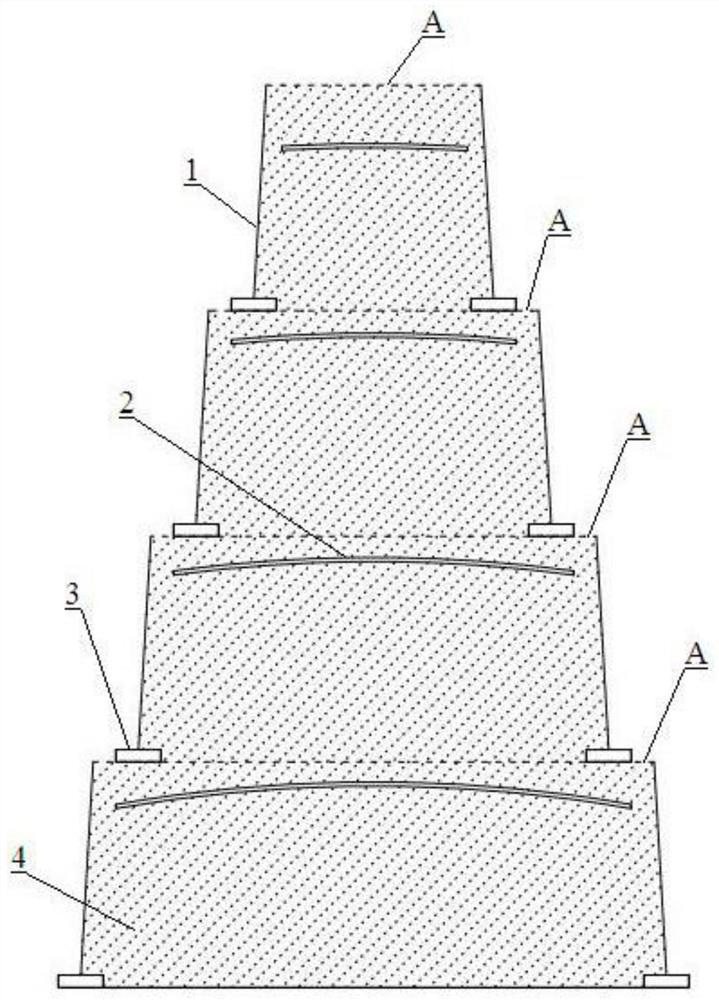

Preparation method of cement decorative column with three-dimensional appearance

InactiveCN112497991AEasy to operateLow costSpecial ornamental structuresCeramic shaping mandrelsNumerical controlCement mortar

The invention relates to a preparation method of a cement decorative column with three-dimensional appearance, and belongs to the field of buildings. The preparation method comprises the following steps that, a numerical control engraving machine engraves a three-dimensional pattern on a hard plate through a pattern to be formed, then soft mold cement gum is poured on the three-dimensional pattern, and a soft forming inner mold is obtained; and the soft forming inner mold is unfolded, a hard outer mold and the soft forming inner mold are closed and fixed to form a cavity, cement mortar or concrete is poured into the cavity, after the cement mortar or the concrete is hardened, the mold is disassembled, and the cement decorative column with the three-dimensional appearance is obtained. The preparation method of the cement decorative column with the three-dimensional appearance is easy in operation, low in cost and high in fineness, the additional value and the artistic expression of thecement decorative column are remarkably increased, meanwhile, the production efficiency of the cement decorative column is improved, and the high market competitiveness is achieved.

Owner:TONGJI UNIV

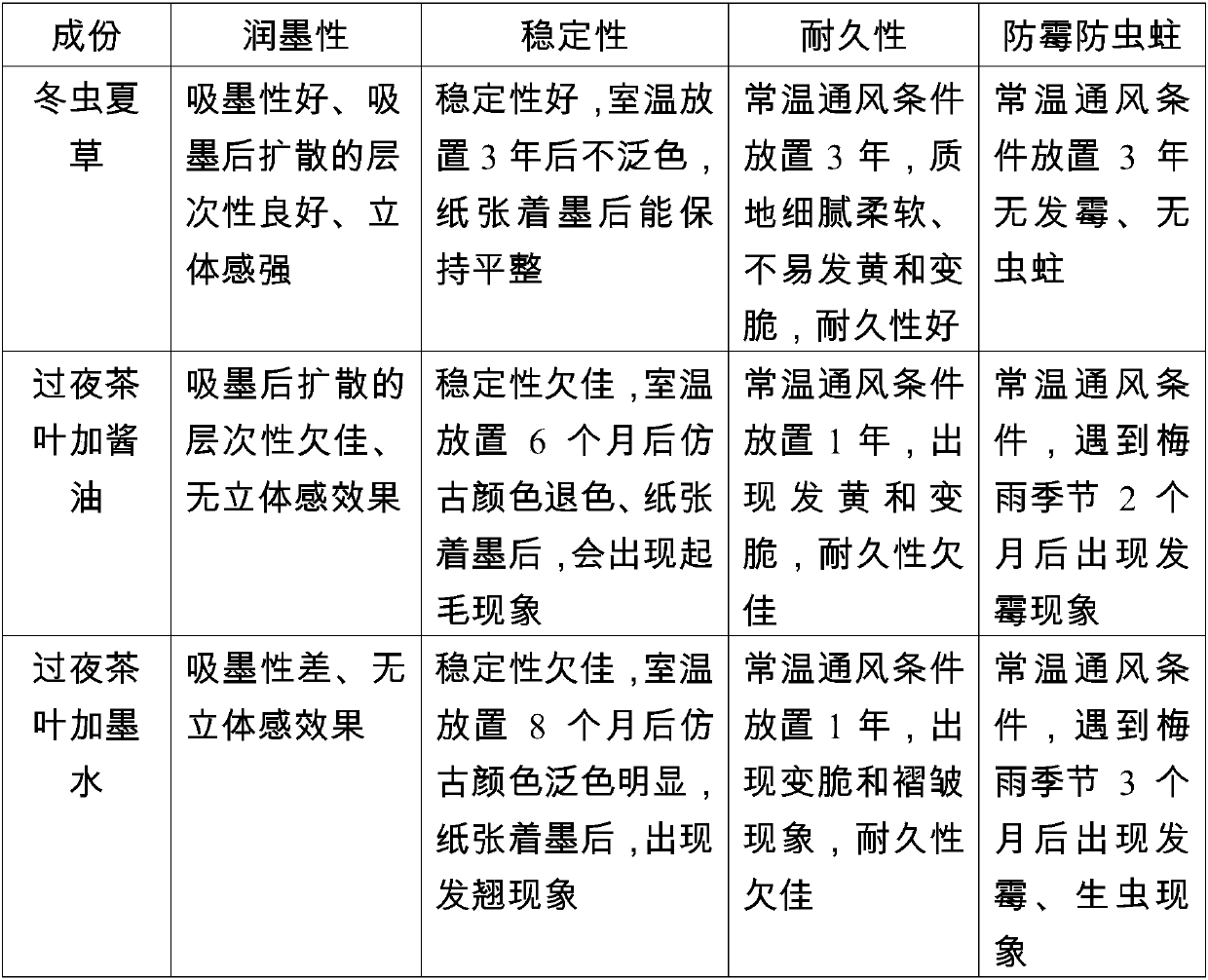

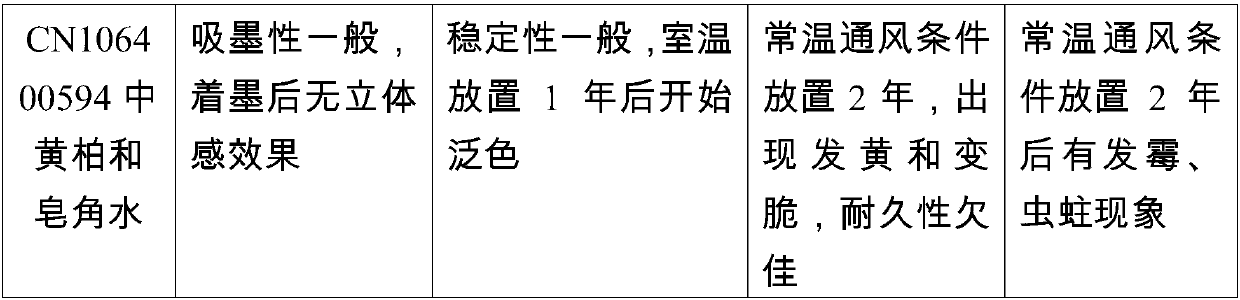

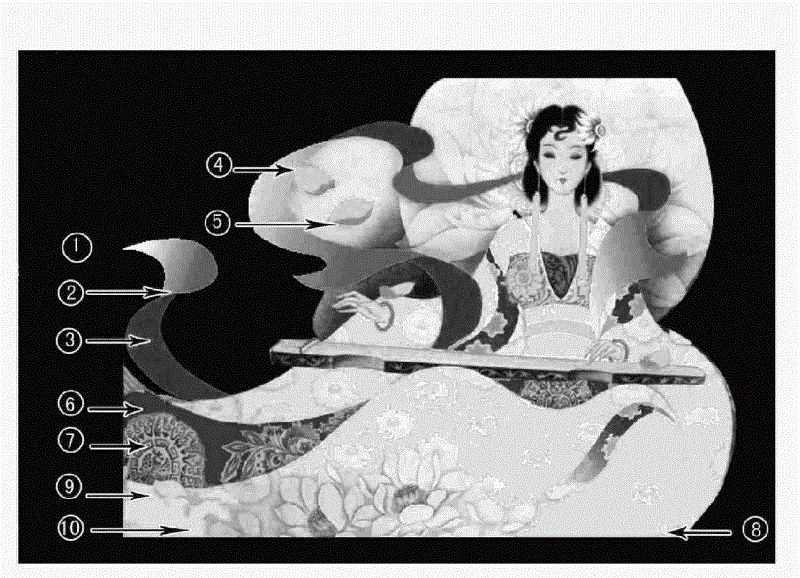

High-quality antique drug Xuan paper and preparation method thereof

InactiveCN107620223AInk color is distinctClear hierarchyCoatings with pigmentsPaper/cardboardFiberMedicine

The invention belongs to the technical field of Xuan paper and particularly relates to antique drug Xuan paper and a preparation method thereof. The high-quality antique drug Xuan paper is prepared byapplying ordinary Xuan paper, an antique coloring solution, a PH modifier and a mold-prevention insecticide; PH value of the ordinary Xuan paper is adjusted to be weakly alkaline, and durability of the antique Xuan paper is improved; during preparation of the antique coloring solution, a moderate amount of cordyceps sinensis and kaolin are added, excellent performance of green sandalwood fibre inthe Xuan paper can be changed via drying, and problems that an existing preparation process of the antique drug Xuan paper is irregular, dyed colors are prone to color bleeding, and the Xuan paper isprone to mold and damage by worms, poor in variety and the like are solved; the high-quality antique drug Xuan paper is distinct in ink shade, clear in layer, strong in three-dimensional effect, goodin stability and durability and high in pest resistance, and different artistic creations are satisfied in a diversity manner.

Owner:泾县麦蓝网络技术服务有限公司

Novel ceramic ink for inkjet printing of ceramic tiles and preparation method thereof

PendingCN107057462AImprove color rateImprove adsorption capacityInksPigment treatment with macromolecular organic compoundsRare earthMetal-organic framework

The invention discloses a novel ceramic ink for inkjet printing of ceramic tiles. The novel ceramic ink for inkjet printing of the ceramic tiles is prepared from, by weight, 20-45% of composite perovskite type inorganic pigment, 1-2% of dispersant and the balance water, wherein the composite perovskite type inorganic pigment is a powdery material prepared by mixing rare earth oxide, transition metal oxide, a metal organic framework material and a fluxing agent according to the molar ratio of 1 to 1 to (0.01-0.05) to 0.001, performing grinding and dispersion and then performing high-temperature calcination, carbon removal and grinding, and the particle size of the powdery material is 0. 01-1 micron.

Owner:安徽省亚欧陶瓷有限责任公司

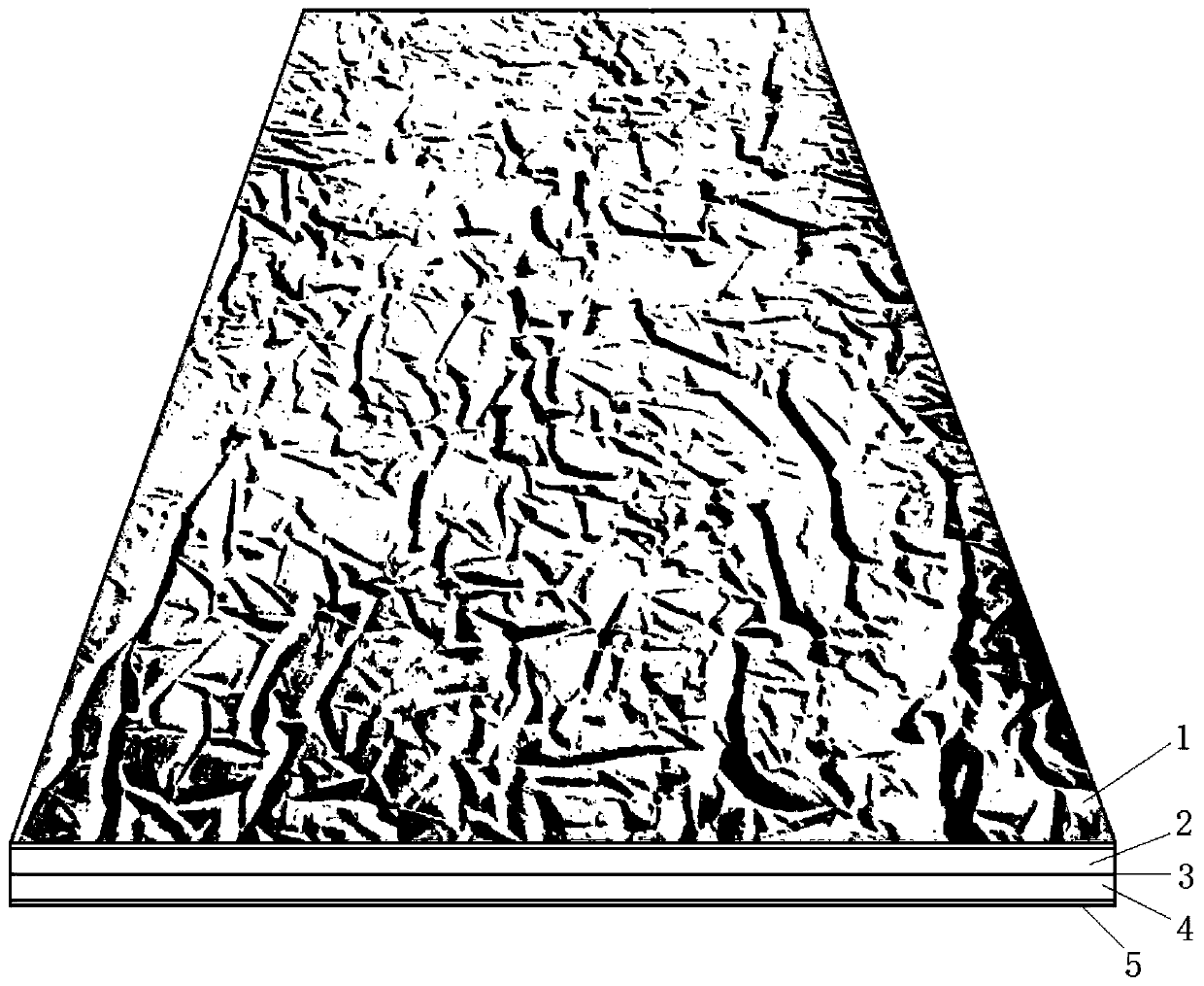

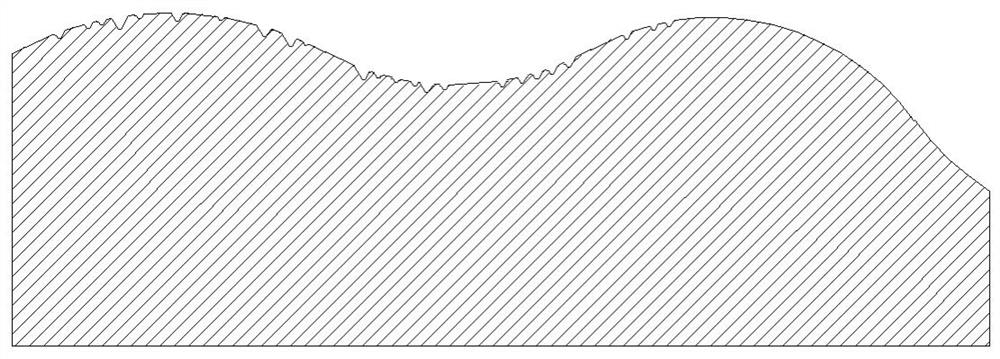

A kind of anti-wrinkle paper and the process of making cloth stickers with strong three-dimensional effect by using the anti-wrinkle paper

ActiveCN103343492BImprove artistic expressionEnhance the infectious powerSpecial paperDecorative surface effectsPulp and paper industryPaper sheet

Owner:李治

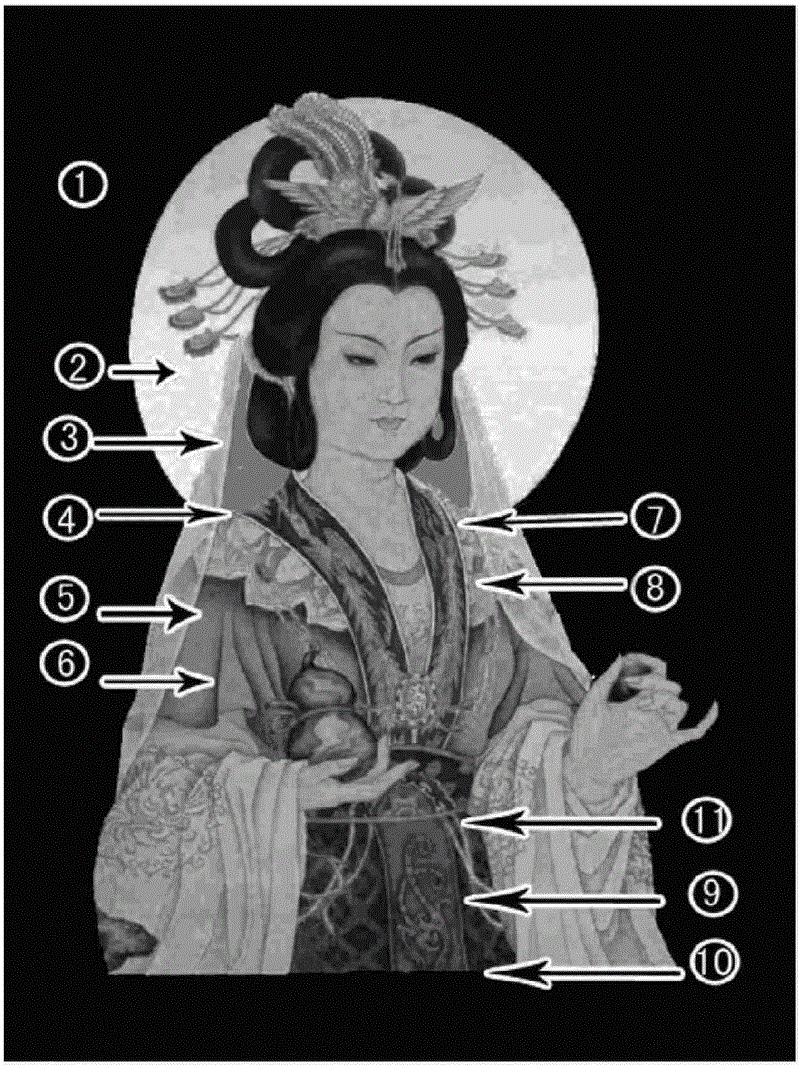

Mulberry bark paper embroidery technology capable of expressing texture effect of work

InactiveCN104862900AImprove artistic expressionHigh artistic valueEmbroidering machines apparatusPulp and paper industry

The invention relates to a mulberry bark paper embroidery technology capable of expressing the texture effect of a work. The mulberry bark paper embroidery technology comprises the following steps: (1), painting and calligraphy mulberry bark paper made of pure mulberry bark is taken as an embroidery substrate; (2), a pattern designed by a computer is printed on the painting and calligraphy mulberry bark paper to form an embroidery draft; (3), the embroidery draft is totally or partially crumpled with a paper crumpling method, and the crumpled draft shows criss-cross, uneven and irregular texture lines and is fixed; (4), a silk thread is adopted for embroidery needle manipulation with different needling methods in the embroidery draft with the texture effect so as to form embroidery stitches; (5) a leading seal or a name seal of an embroidery worker is stamped in a sealing position of the pattern, and a painting and calligraphy visual effect is obtained. According to the technology, the traditional embroidery technology is combined on the basis of inheritance of traditional Chinese painting texture production techniques to transplant painting and calligraphy to embroidery, the painting and calligraphy embroidery with the texture effect is formed, unique charm is provided, the pattern texture is rich, and the artistic expression force of the embroidery is improved.

Owner:TAIYUAN UNIV OF TECH

Crease-resistance paper and technology for producing cloth-pasting pictures with strong stereoscopic impression by crease-resistance paper

ActiveCN103343492AStrong sense of hierarchyImprove artistic expression and appealSpecial paperDecorative surface effectsTextilePulp and paper industry

Owner:李治

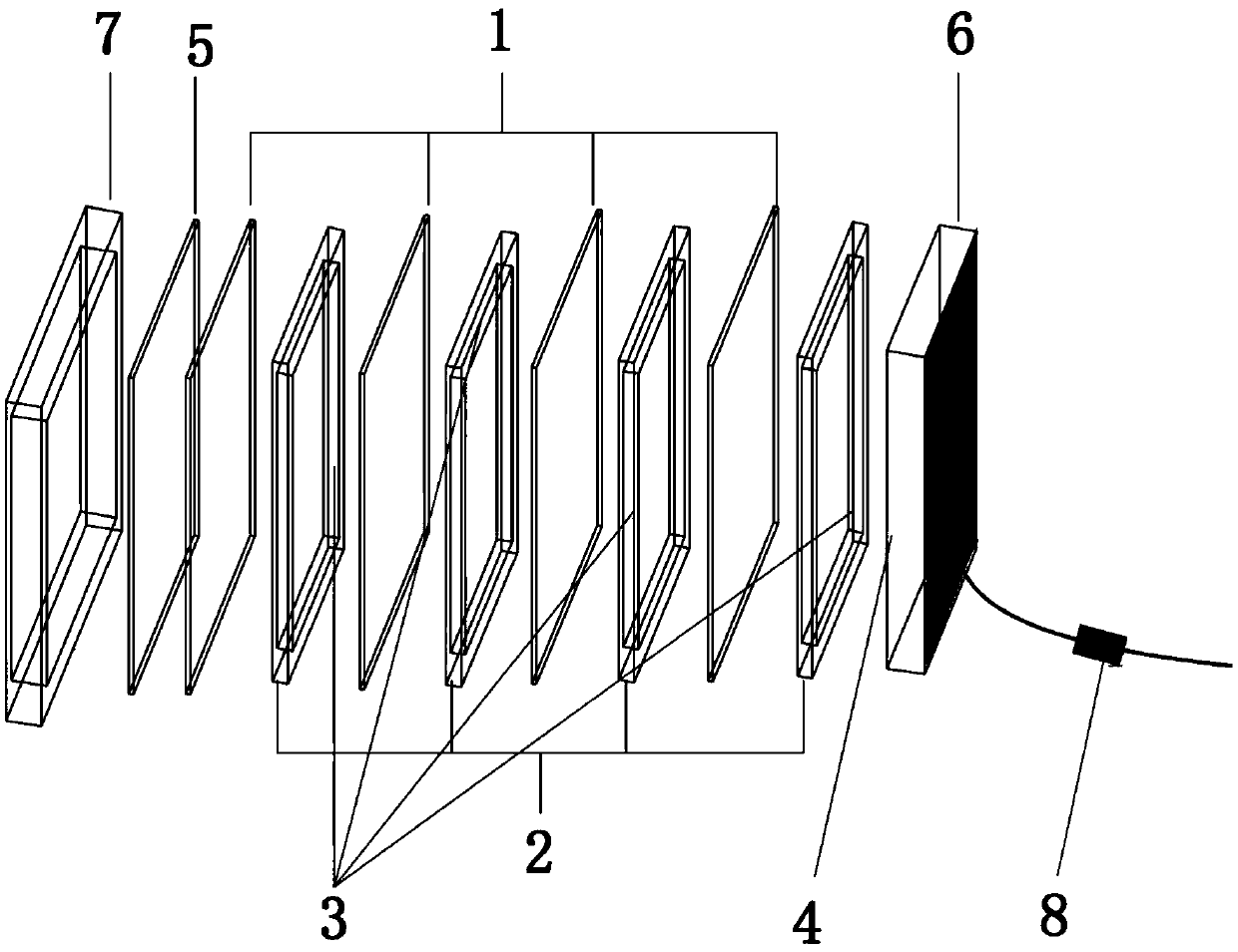

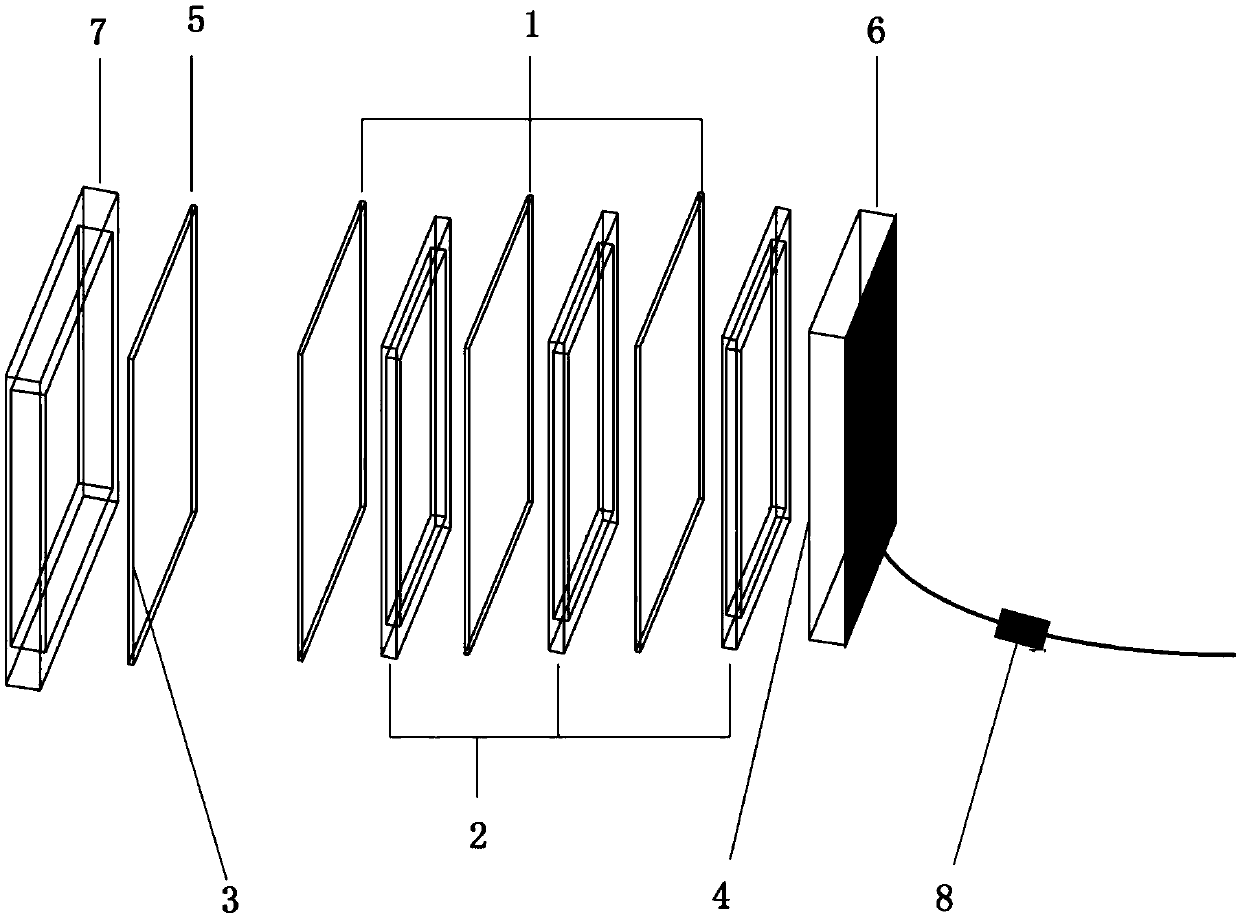

Colorless fluorescence carved lamp

PendingCN109578836AHigh expressionBreak through the single colorLighting elementsSpecial ornamental structuresGraphicsFluorescence

The invention relates to a carved lamp and specifically relates to a colorless fluorescence carved lamp. In order to solve the problems that the existing paper carved lamp is single in paper process and single in light source, the invention provides the colorless fluorescence carved lamp which comprises a carved pattern, a rear cover plate, a partition plate frame, a laser source, an ordinary light source and a power adapter, wherein the carved pattern is formed by forming a caved graphic through multi-layer carving in a hollow manner and printing colorless invisible ink pattern; the partitionplate frame is located between the carved pattern and the rear cover plate; the laser source corresponds to the carved pattern; the ordinary light source is mounted on the rear cover plate; when thelight source is turned off or the ordinary light source is turned on, the appearance of a product is similar to that of the traditional paper carved lamp; when the special laser source is turned on, the special laser source is projected on a multi-layer paper sculpture, so that information hidden originally can be presented to form a colorful pattern. The colorless fluorescence carved lamp has theadvantages that the representation form of the colorful pattern is added, so that the colorless fluorescence carved lamp is more novel and more unique, the artistic expressive force is improved, andthe defects that the traditional paper carved lamp is single in color and simple in structure are overcome.

Owner:XIAN XIZHENG PRINTING

Manufacturing technology of multilayer chromaticity cloth engraving picture

InactiveCN101633280BRich artistic techniquesImprove artistic expressionDecorative surface effectsFiberManufacturing technology

The invention relates to a manufacturing technology of a multilayer chromaticity cloth engraving picture, comprising the following steps: selecting needed single-color chromatic cloth as base cloth according to the requirements of a picture draft; tracing the picture draft on various needed specific chromatic silks or other cloth with chemical fibers according to the color requirement of the picture draft; ironing; processing in a gummed mode; branding or engraving the picture draft on the silk on the base cloth by high-temperature electric iron or an engraving cutter; overlaying the needed chromatic cloth on the base cloth by a block and color separating mode layer by layer; and ironing the surface of the cloth after the picture draft is accurately and finely engraved in a layer and color separating mode. The multilayer chromaticity cloth engraving picture integrates the advantages of cloth sticking pictures, cloth stacking pictures and electro cauterization pictures, overcomes the limitation of various pictures, can use hundreds of kinds of color cloth and various drawing techniques, sufficiently, detailedly and accurately express various complicated and various color varieties,greatly increase and widen the expression subjects and the artistic appeal of the cloth engraving picture art, achieve the exquisite technical effect that the multilayer chromaticity cloth engraving picture can not be completely copied and open a specific and exquisite art expression technique of the cloth engraving picture.

Owner:陈荣浩 +1

Making method of GRC exterior wall cladding

InactiveCN110173085AImprove artistic expressionGood textureCovering/liningsReinforced concreteConvex structure

The invention provides a making method of a GRC exterior wall cladding. The making method comprises the following steps: preparation of GRC (Glass fiber Reinforced Concrete); making of a decorative layer and a structural layer of a GRC cladding: adopting an injection or pouring process to arrange the GRC on the surface of a lining mold with a concave-convex structure corresponding to the decorative layer of the GRC cladding; connection of a steel frame to the back of the GRC cladding; and curing of the GRC. According to the making method of the GRC exterior wall cladding, in the making processof the GRC cladding, the special lining mold is used; during the injection or pouring process, the outer surface of the GRC cladding is allowed to form the decorative layer with a preset texture; andthrough the texture, quality and concave-convex structure of the lining mold, in combination with a ratio of raw materials and a preparation process, the artistic performance of the GRC product can be innovated and improved. Moreover, because the decorative layer of the GRC cladding is molded in the injection or pouring process, the texture and quality of the decorative layer are better, and theproduct has rich decorative effects, high gloss and good artistic performance.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

High-scratching-resistance wear-resistant paint capable of producing ice crack like effect and preparation method thereof

InactiveCN107227109AImprove artistic expressionPolyurea/polyurethane coatingsWear resistantDissolution

The invention discloses a high-scratching-resistance wear-resistant paint capable of producing an ice crack like effect and a preparation method thereof. The paint is prepared from the following raw materials in parts by weight: 40 parts of polyurethane-acrylate resin, 20 parts of amino resin, 6 parts of cracking initiator, 0.5 part of polyether modified siloxane, 1.5 parts of talcum powder, 0.5 part of wetting and dispersing agent, 1.5 parts of leveling agent and 1 part of defoaming agent. The preparation method of the high-scratching-resistance wear-resistant paint capable of producing an ice crack like effect comprises the following steps: stirring the cracking initiator, the polyether modified siloxane, the talcum powder and the wetting and dispersing agent according to the preset ratio until complete dissolution; and adding the polyurethane-acrylate resin and the amino resin, and performing sufficient and uniform stirring. The paint naturally produces an ice crack like effect in a drying process, and has excellent skid resistance, scratching resistance and wear resistance.

Owner:安徽康瑞高科新材料技术工程有限公司

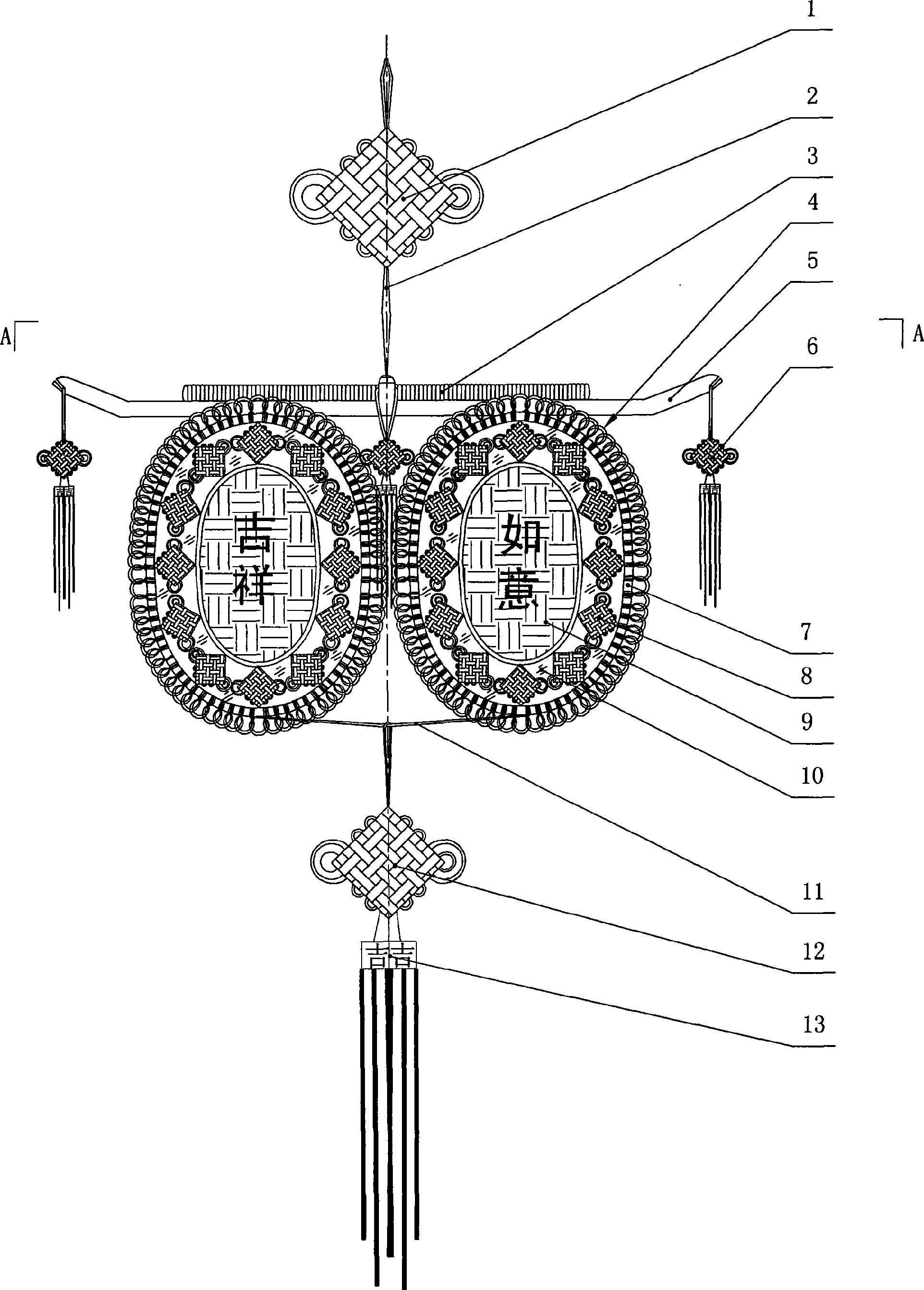

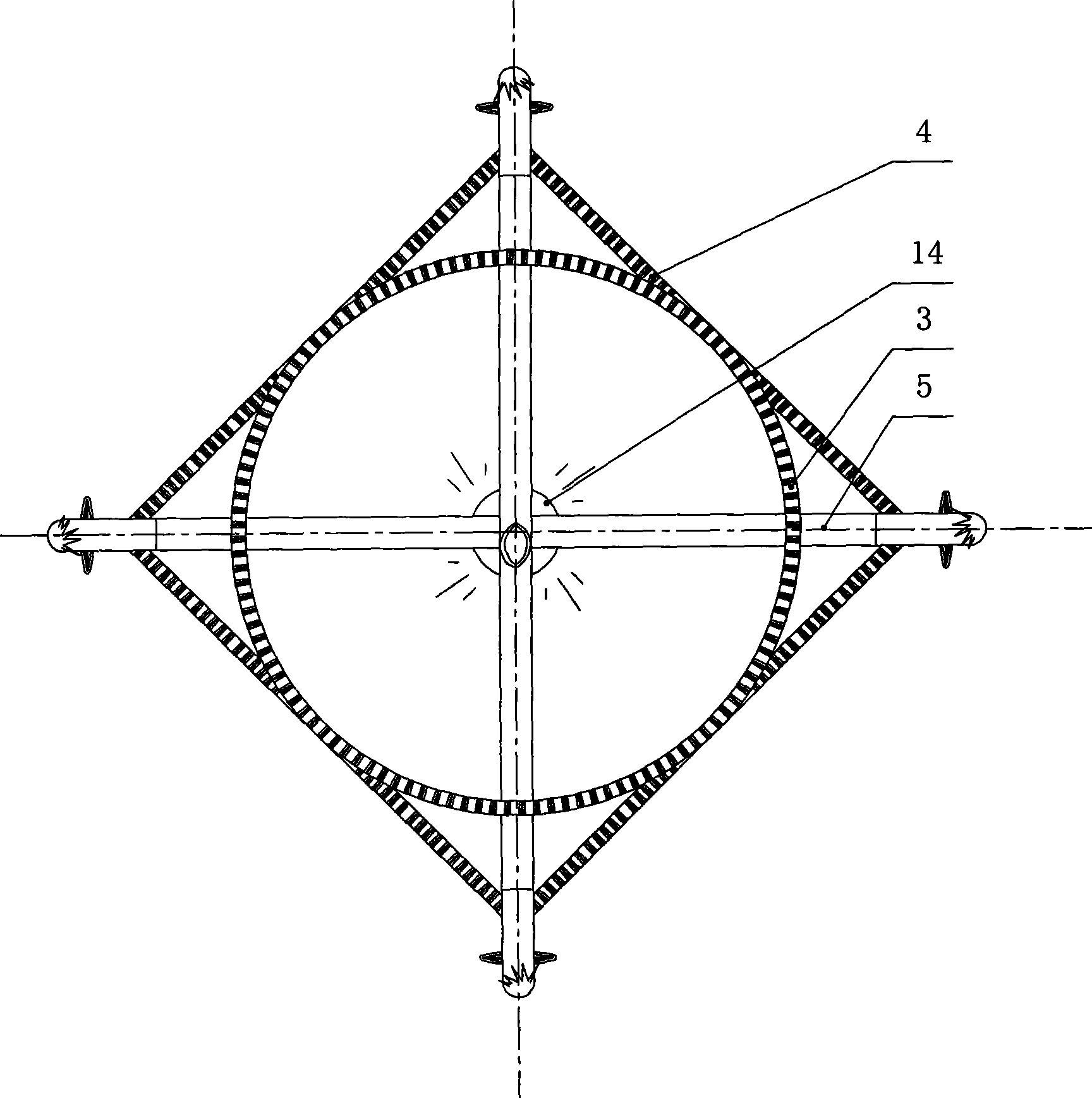

Chinese knot artistic palace lantern

InactiveCN101398143AImprove artistic expressionUnique combinationNon-electric lightingPoint-like light sourceEngineeringLantern

The invention relates to a Chinese knot artistic palace lamp which is composed of a pendant cord, a lamp holder, a lampshade and a lamp. The lampshade is installed at the lower part of the lamp holder and the lamp is installed at the central part under the lamp holder. The Chinese knot artistic palace lamp is characterized in that: the lampshade is a shade body enclosed by 3 to 12 Chinese knots which are provided with loop frames and connected in sequence, and shade sides are arranged in the disk surface areas inside the loop frames of each Chinese knot. The Chinese knot artistic palace lamp is unique in design and novel in structure. The combination of the Chinese knots and the palace lamp, both of which are traditional artworks for increasing festival atmosphere, makes the lamp be bright in colors, and beautiful and elegant in appearance, thus being full of artistic flavor and expression.

Owner:TIANJIN HEDONG AIXIN HAND KNIT PROD

Plant root-lifting cultivation method

ActiveCN113812299APlanting less laborSave time and costCultivating equipmentsHorticulture methodsPlant rootsPlanting seed

The invention discloses a plant root-lifting cultivation method. The plant root-lifting cultivation method comprises the following steps of firstly, manufacturing a plurality of circular-truncated-cone-shaped molds with upper and lower openings, placing a first layer of mold on the ground, adding nutrient soil, enabling the middle of the soil surface to be high and the periphery to be low, paving a root control film on the soil surface, ensuring that a gap is reserved between the edge of the root control film and the inner wall of the mold, continuously adding the nutrient soil until the soil surface is flush with the upper openings of the molds, uniformly arranging a circle of cushion blocks on the soil surface at intervals, placing a second layer of mold on the cushion blocks and aligning the second layer of mold with the first layer of mold, and repeating the process until all the molds are sequentially placed from bottom to top; uniformly sowing plant seeds at the opening of the top-layer mold and gaps between the adjacent molds, thinning seedlings, filling gaps with the seedlings, and performing planting management; and finally, retaining branches and leaves of the plants of the top-layer mold, only retaining roots of other plants, removing all the molds, washing with water, and trimming to obtain the target root-lifting nursery stocks. By means of the method, and the root-lifting nursery stocks with developed, thick and exposed root systems can be produced in batches within a short time.

Owner:长沙市雨花区求实苗木场

A concave-convex texture mold and its manufacturing method and application

ActiveCN110712443BHighlight the three-dimensional effectEmbossed effectDecorative surface effectsOrnamental structuresStructural engineeringEmbossing

Owner:CHENGDU BANKNOTE PRINTING +1

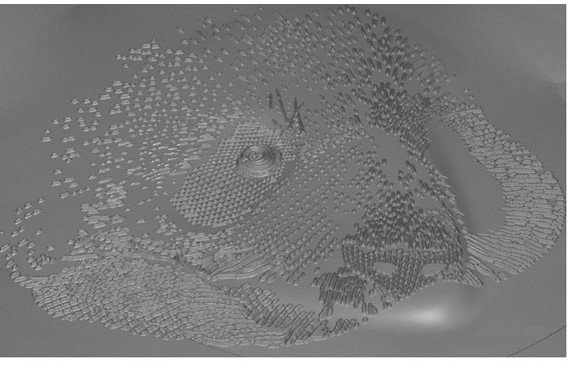

Embroidery stitch for disordered needlework

InactiveCN105734860AImprove artistic expressionFree and flexible linesAutomatic machinesHair streamsSingle point

The invention discloses an embroidery stitch for disordered needlework. The embroidery stitch comprises the following steps: 1) embroidering a disordered needlework product; 2) performing point positioning on lines; 3) shearing; 4) treating; and 5) mounting. According to the method disclosed by the invention, due to use of a point positioning disordered needlework method, a disordered needlework method is enriched, and the artistic expressive force of the disordered needlework product is enhanced. Therefore, the line of the work is free and flexible, solid and broken line joint is natural, the needlework is neat and fluffy, and the stereoscopic impression is enhanced, particularly hair of animals and characters, mows and the like are effectively treated.

Owner:丹阳正则绣艺术有限公司

Aqueous texture wallpaper paint and method for making same

The invention relates to a watercraft texture wallpaper paint, characterized in that the invention comprises the following components: 31 percent to 35 percent of styrene-acrylic emulsion, 23.94 percent of superfine weight calcium, 1 percent to 2 percent of nano-titanium dioxide, 10 percent to 18 percent of titanium pigment, 8 percent to 9.8 percent of calcined kaolin, 1.2 percent to 1.8 percent of ethylene glycol, 0.2 percent to 0.5 percent of hydroxyethylcellulose, 0.8 percent to 1.5 percent of film forming additive, 0.15 percent to 0.25 percent of multi-functional additive, 0.3 percent to 0.5 percent of dispersant, 0.1 percent to 0.2 percent of wetting agent, 0.15 percent to 0.21 percent of defoamer, 0.08 percent of anticorrosion and insecticide, 0.8 percent to 2 percent of thickener and 20 percent to 22 percent of water. The invention is the watercraft texture wallpaper paint, is environment-friendly, has strong elastic tension, has good covering and anti-cracking effect on the fine cracking of wall, and has good scrape resistance performance, greatly enhancing the degree of wall surface protection; meanwhile, the invention still has strong waterproof performance, without color-changing and decortication and mildew and can fully solve the common problems existing in wall decoration.

Owner:佛山市顺德区清大润彩涂料有限公司

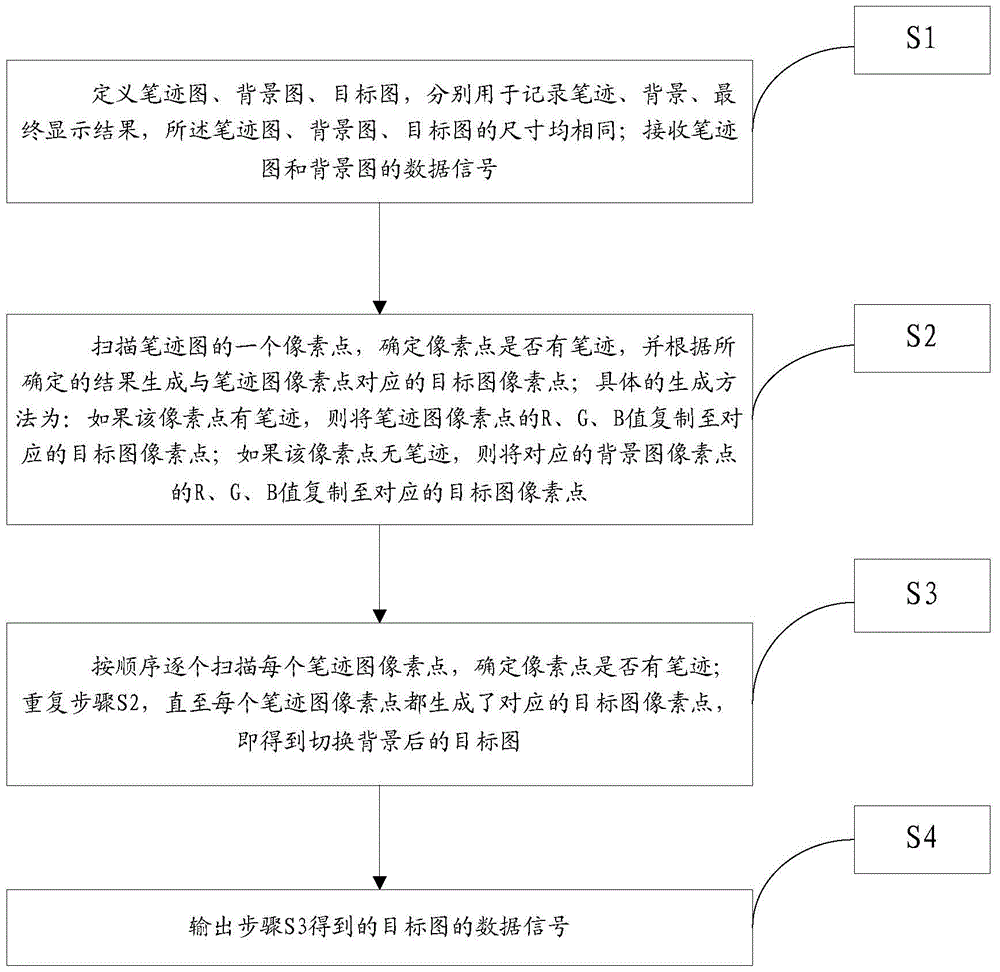

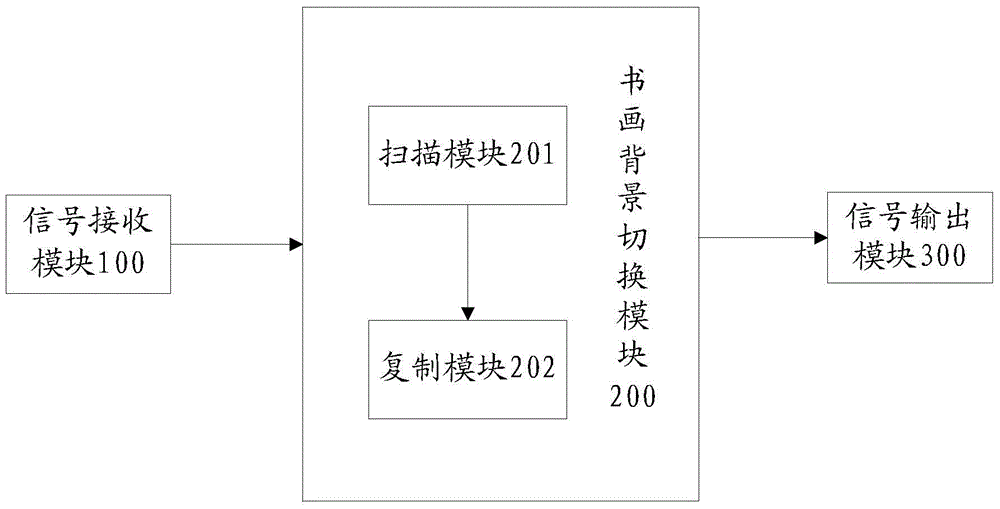

A method and device for switching the background of digital calligraphy and painting

ActiveCN103578124BImprove artistic expression2D-image generationHandwritingComputer graphics (images)

Owner:INLIFE HANDNET CO LTD

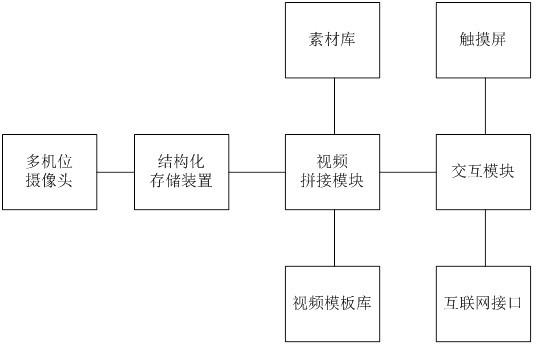

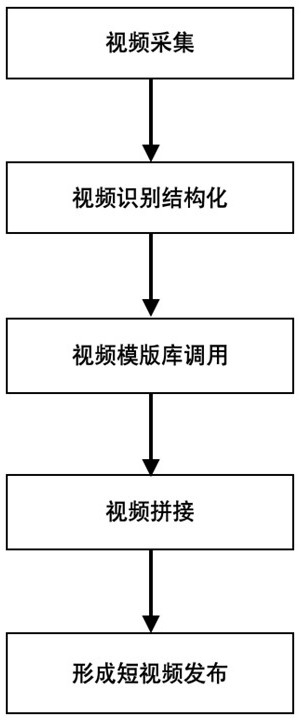

Blood donation promotion method and blood donation vehicle

PendingCN112702650AEasy to publishImprove experienceTelevision system detailsColor television detailsSocial mediaMediaFLO

A blood donation promotion method comprises the following steps: S1, in the blood donation process, carrying out the step-by-step and visual-angle video fragment collection on the blood donation process of a blood donator, wherein the collection process comprises portrait collection; S2, cutting and splicing the video segments collected in the step S1 with videos in a material library, wherein the material library is a pre-stored video set used for increasing video expressive force and event descriptiveness; S3, forming a short video after splicing, and publishing the short video to social media or the Internet by the blood donator. According to the invention, the blood donation process of the blood donator is subjected to video acquisition and publishing, and a short video which can be easily published on social media and the Internet by the unpaid blood donator is formed through visual angle selection, video cutting and material library video combination, so the unpaid blood donator is publicized positively, and the blood donator can be publicized negatively, and unpaid blood donation behaviors are popularized in the forms of Wechat Moments and the like.

Owner:成都数字博览科技有限公司

double bass

ActiveCN105096915BLowered rangeExtended expressive rangeStringed musical instrumentsComputer science

Owner:乐海乐器有限公司

Multifunctional wire hanger

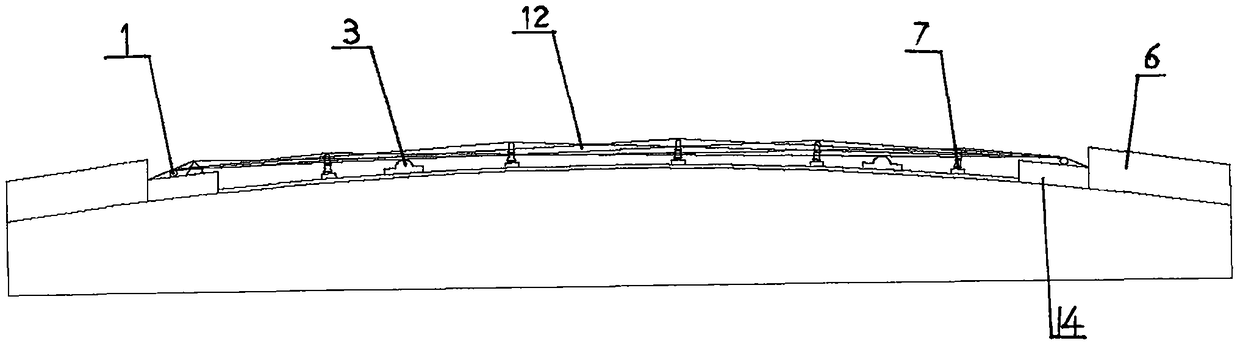

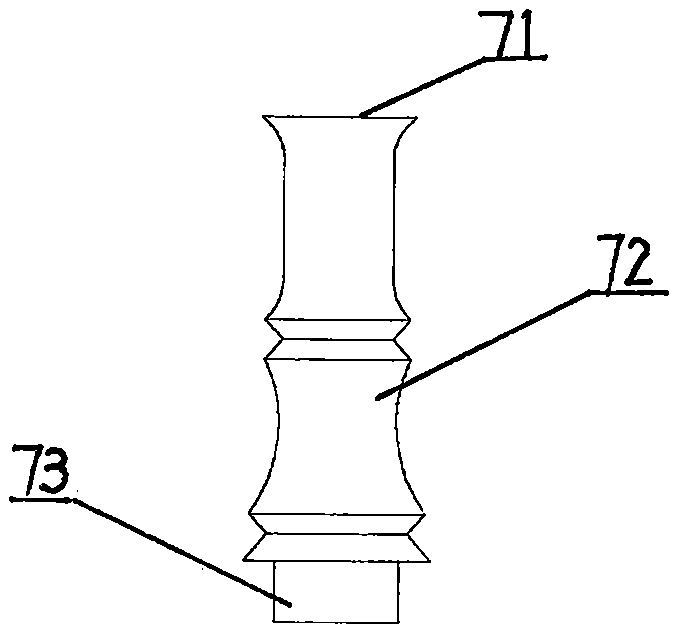

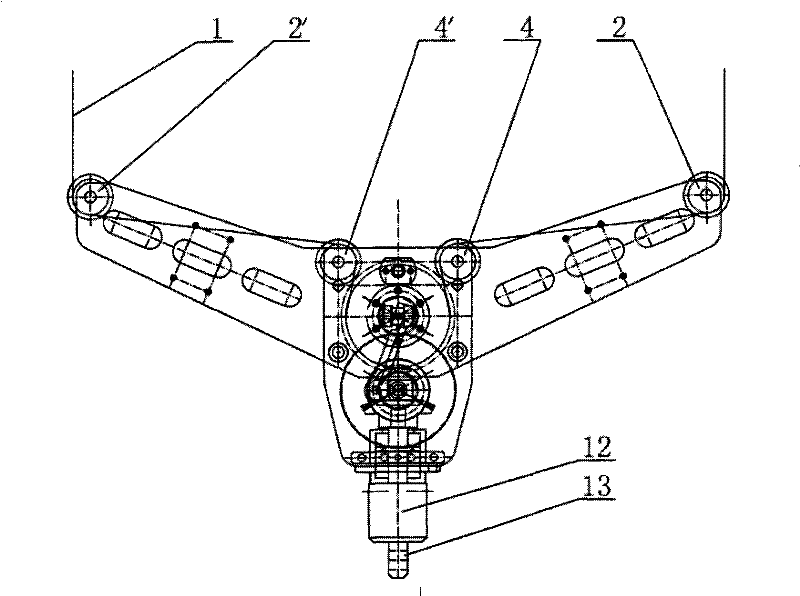

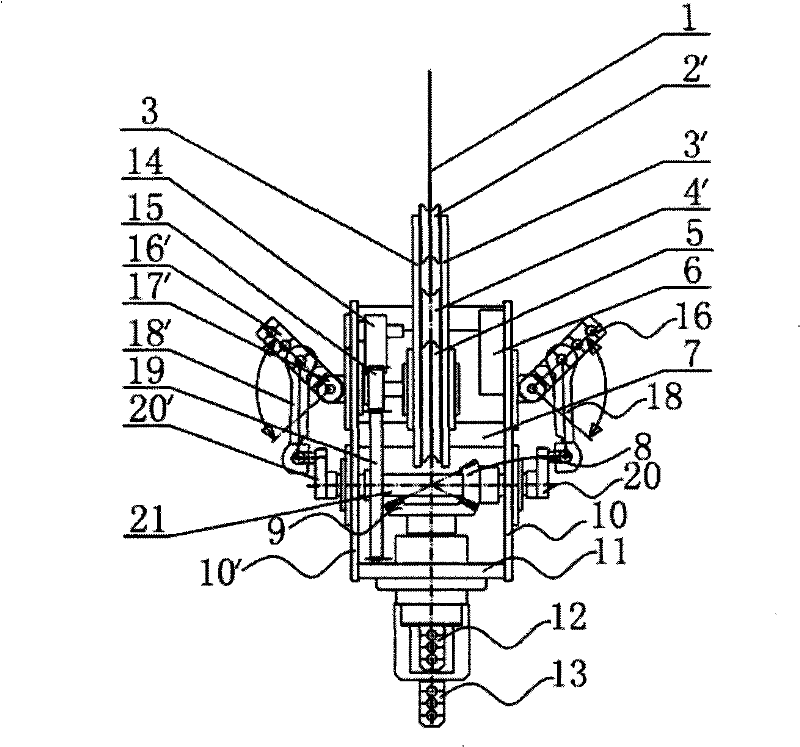

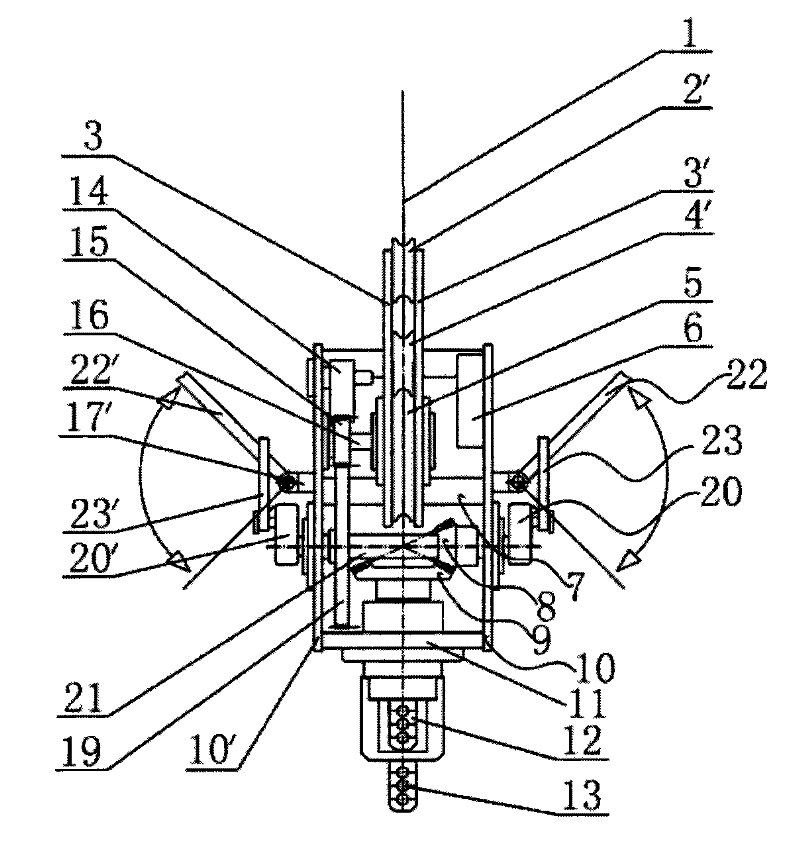

InactiveCN101518691BImprove artistic expressionSimple structureStage arrangementsGear wheelEngineering

The invention discloses a multifunctional wire hanger which is characterized in that hoisting pulleys (2,2') are respectively mounted at both sides of the tops of Y-shaped connecting plates (3,3'), a The invention discloses a multifunctional wire hanger which is characterized in that hoisting pulleys (2,2') are respectively mounted at both sides of the tops of Y-shaped connecting plates (3,3'), adriving pulley (5) is mounted in the middles of the Y-shaped connecting plates (3,3'), and two guide pulleys (4,4') are respectively mounted at both sides above the driving pulley (5); a pinion (15) idriving pulley (5) is mounted in the middles of the Y-shaped connecting plates (3,3'), and two guide pulleys (4,4') are respectively mounted at both sides above the driving pulley (5); a pinion (15) is mounted on a spline shaft at one side of a center shaft of the driving pulley (5) and engaged with a large gear (19); eccentric wheels (20,20') are respectively mounted at both ends of a connectings mounted on a spline shaft at one side of a center shaft of the driving pulley (5) and engaged with a large gear (19); eccentric wheels (20,20') are respectively mounted at both ends of a connectingmain shaft (21) of the large gear (19), one end of one space universal connecting rod (18) and one end of the other space universal connecting rod (18') are respectively connected with eccentric shaftmain shaft (21) of the large gear (19), one end of one space universal connecting rod (18) and one end of the other space universal connecting rod (18') are respectively connected with eccentric shafts of the eccentric wheels (20,20'), and the other end of the space universal connecting rod (18) and the other end of the other space universal connecting rod (18') are respectively connected with swis of the eccentric wheels (20,20'), and the other end of the space universal connecting rod (18) and the other end of the other space universal connecting rod (18') are respectively connected with swing stems (18,18'); the connecting main shaft (21) is provided with a small bevel gear (8), a large bevel gear (9) is mounted at the upper part of a rotary connector (12), and the lower part of the rotng stems (18,18'); the connecting main shaft (21) is provided with a small bevel gear (8), a large bevel gear (9) is mounted at the upper part of a rotary connector (12), and the lower part of the rotary connector (12) is connected with a pin hole. The multifunctional wire hanger can make rotary or linear hoisting motion, can make models, such as swinging, rotating, fixedly walking, and the like iary connector (12) is connected with a pin hole. The multifunctional wire hanger can make rotary or linear hoisting motion, can make models, such as swinging, rotating, fixedly walking, and the like in the long-distance hoisting, advancing or retreating process, greatly widens the artistic presentation form of the in-air molding of the wire hanger and has the advantages of simple structure, safetyn the long-distance hoisting, advancing or retreating process, greatly widens the artistic presentation form of the in-air molding of the wire hanger and has the advantages of simple structure, safety, reliability, low manufacture cost, convenient operation, and the like., reliability, low manufacture cost, convenient operation, and the like.

Owner:北京龙影文化艺术发展中心

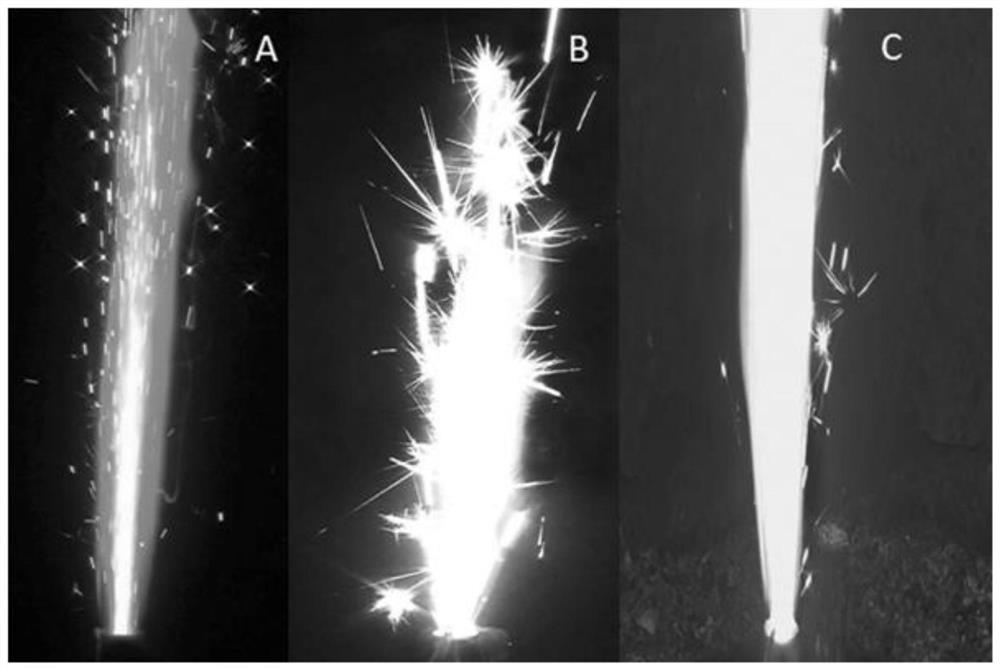

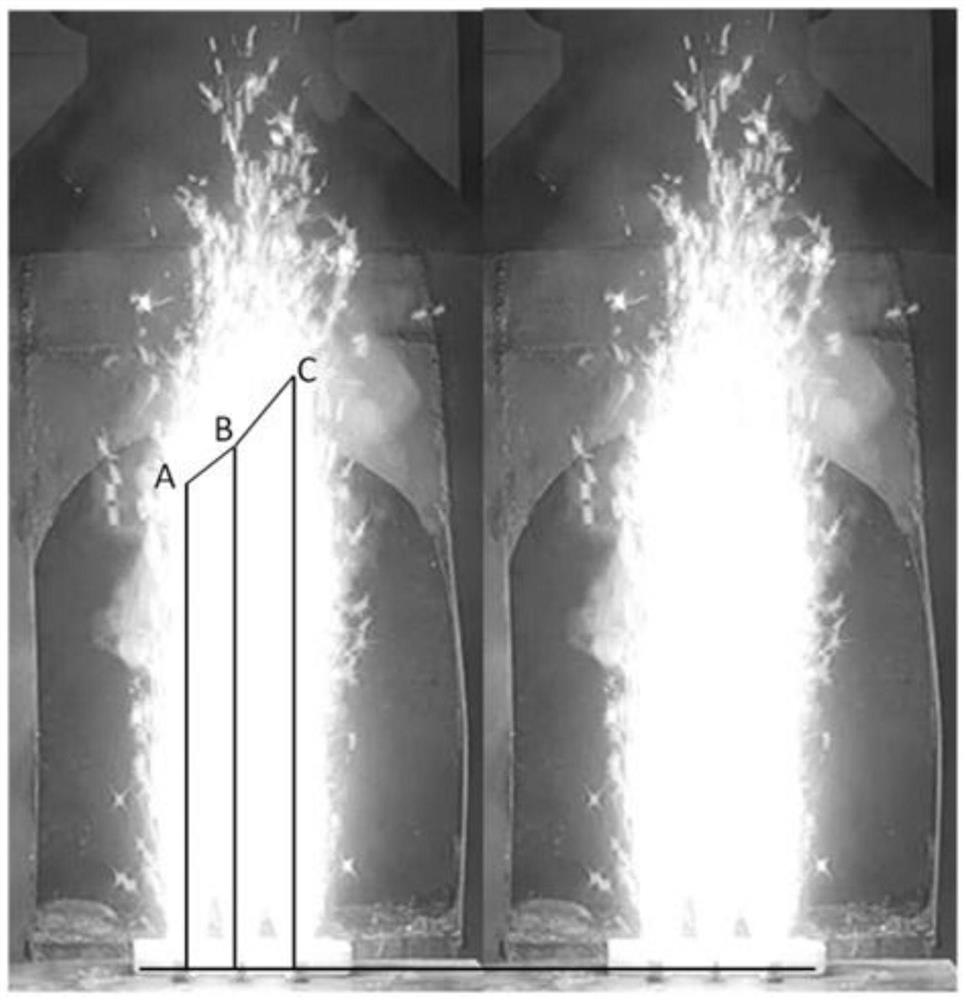

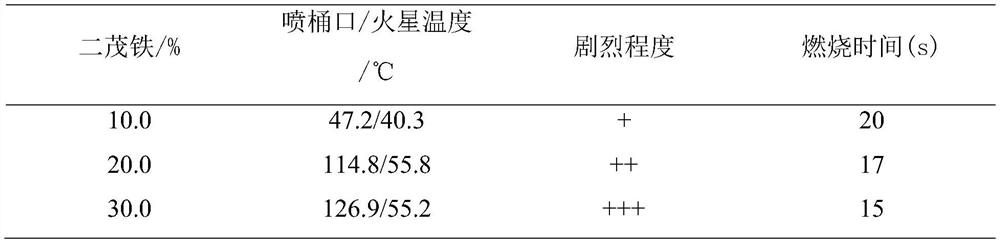

Environment-friendly cold firework and preparation method thereof

InactiveCN113461468ANo irritating smellImprove artistic expressionNon-explosive/non-thermic compositionsPtru catalystFireworks

The invention discloses an environment-friendly cold firework and a preparation method thereof. The environment-friendly cold firework comprises a colorless cold firework body and a colored cold firework body. The colorless cold firework body comprises 50-60 parts of nitrocotton; 10-12 parts of ferrocene; and 25-30 parts of titanium powder. The colored cold firework body comprise 37-48 parts of nitrocotton, 13-15 parts of ferrocene, 20-25 parts of titanium powder and 15-28 parts of flame color material. According to the environment-friendly cold firework, ferrocene serves as a catalyst and is combined with oxygen in air to serve as an oxidizing agent in the firework combustion process, nitrocotton obtained after smoke abatement treatment serves as a combustible agent, passivated titanium powder serves as a functional additive, and therefore the environment-friendly formula technology which is free of toxicity, smoke and pungent smell is achieved. Different colors can be generated according to different configured flame color materials, the artistic expressive force of the fireworks is improved on the premise that the raw material cost and the production cost are not increased and safety is guaranteed, and the firework product can explore more application scenes.

Owner:NANJING COLLEGE OF INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com