Method for preparing pottery with jade surface

A technology of pottery and jade surface, which is applied in crafts for producing decorative surface effects, clay products, decorative arts, etc. It can solve problems such as rough surface, low hardness, poor wear resistance and impact resistance, and improve performance ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

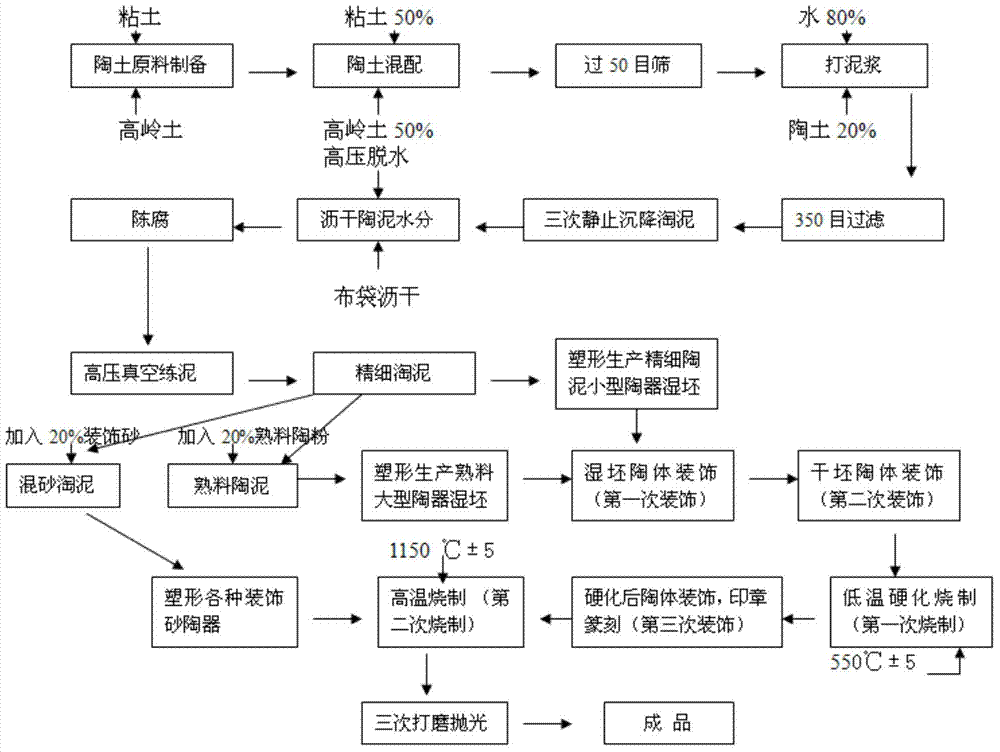

[0033] The preparation method of jade surface pottery of the present invention includes the following steps:

[0034] (1) Preparation of pottery clay materials: mix 50% by weight of ordinary clay and 50% by weight of kaolin, and then pass through a 50-mesh sieve; the raw material for pottery production is clay, which is widely distributed in my country. Because clay is not resistant to high temperatures, it is fired The temperature is only between 700-900℃, so the hardness of the pottery is not high. More importantly, the pottery clay has large particles, high sand content, low density and poor finish. Therefore, the material of jade surface pottery is mixed clay. The proportion of mixed clay is 50% ordinary clay and 50% kaolin used for porcelain production. After mixing, its chemical composition is SIO. 2 46%, AI 2 O 3 39%, H 2 O14%, and a small amount of KO 2 , Fe 2 O 3 , MO, etc. The particle size is below 3um, the hardness is close to 1 degree Mohs, and the specific gravity is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com