Patents

Literature

114 results about "TERT-BUTYL METHACRYLATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

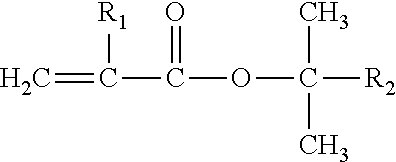

Tert-Butyl methacrylate 98%, contains 200 ppm monomethyl ether hydroquinone as inhibitor CAS Number 585-07-9. Linear Formula H 2 C=C(CH 3)CO 2 C(CH 3) 3. Molecular Weight 142.20 . EC Number 209-548-7. MDL number MFCD00048245. PubChem Substance ID 24870053

Aqueous compositions comprising polymeric duller particle

ActiveUS20070218291A1Improve clarityGood “hand feel”Liquid surface applicatorsLayered productsMeth-Single stage

The present invention provides aqueous matte coating compositions comprising a binder component B) and a polymeric duller component A) composed of particles of one or more multi-stage copolymer or single stage crosslinked (co)polymer, e.g. crosslinked t-butyl (meth)acrylate, the duller component particles A) having an average diameter of 1-20 μm. Components A) and B) are compatible. Preferably, the duller component A) is acrylic; more preferably, components A) and B) are acrylic. The aqueous compositions provide matte coatings having haptic or feel (soft touch) properties, film and appearance properties, including burnish resistance and low color loss.

Owner:ROHM & HAAS CO

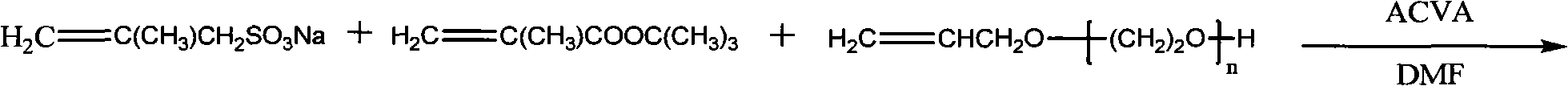

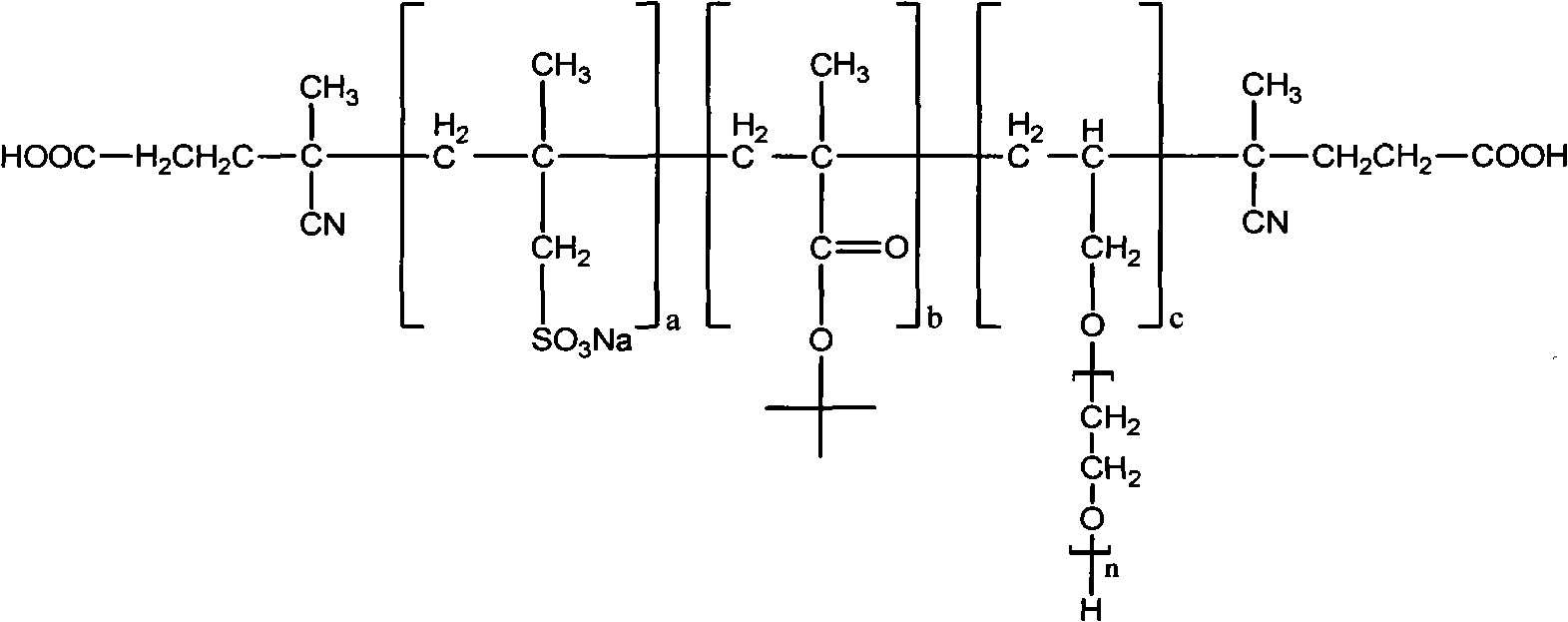

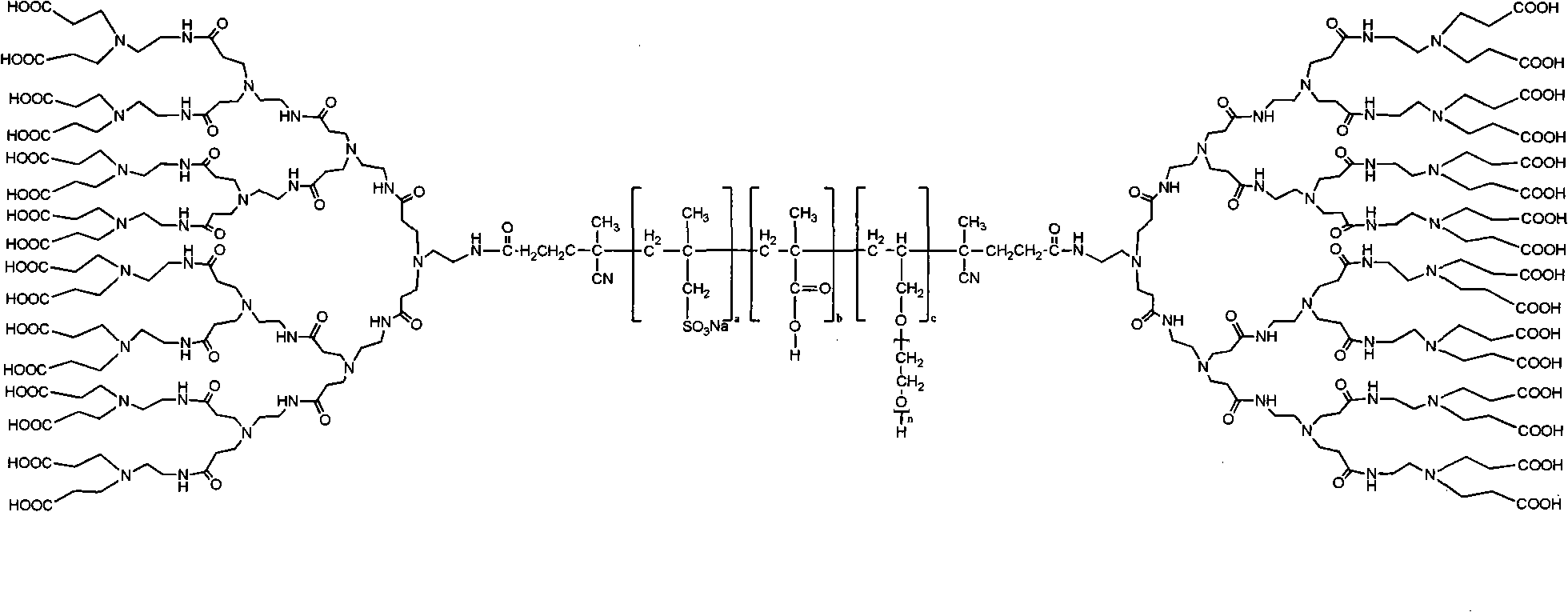

Hyper-branched polycarboxylate high-efficiency water reducing agent and preparation method thereof

The invention relates to a hyper-branched polycarboxylate high-efficiency water reducing agent and a preparation method thereof. The water reducing agent is prepared by polymerizing one of tert-butyl acrylate and methyl tert-butyl acrylate with sodium methyl-acryl sulfonate and allyl polyethenoxy ether to form a copolymer main chain, and then performing condensation polymerization on one of acrylic acid and methacrylic acid with ethylene diamine to form a hyper-branched polyamide structure which is grafted to two ends of the main chain. The preparation method comprises the following steps: (1) preparing the sodium methyl-acryl sulfonate into solution with DMF, and heating the solution in a nitrogen atmosphere; (2) dissolving the other two monomers and an initiating agent into the DMF to prepare mixed solution, and dripping the mixed solution into the step (1) to react for 1 to 20 hours; (3) adding a condensating agent CDI after the reaction and performing condensation reaction by using N-methyl morpholine as an organic base, the ethylene diamine and the acrylic acid as the monomers and the DMF as a solvent; and (4) performing vacuum distillation to remove the residual monomers and the solvent, and refluxing for 2 to 5 hours by using methylene chloride solution of trifluoroacetic acid to obtain the water reducing agent. The hyper-branched polycarboxylate water reducing agent has the advantages of low admixture, high water reducing rate, small slump loss, good compatibility with cement, no corrosivity to steel bars, strong frost resistance and the like.

Owner:厦门路桥翔通建材科技有限公司 +1

Photopolymerizable inkjet ink, ink cartridge, and inkjet printing device

To provide a photopolymerizable inkjet ink, which contains monomer components, and a polymer or a copolymer of styrene, styrene derivative, acrylic acid ester, or acrylic acid, or any combination thereof, wherein the monomer components contain: t-butyl methacrylate, n-pentyl methacrylate, or n-hexyl methacrylate, or any combination thereof; and glycerol dimethacrylate, and wherein the photopolymerizable inkjet ink is free from a diluting solvent.

Owner:RICOH KK

Binding agents for polyurethane-based paints

InactiveUS6130308ASynthetic resin layered productsPretreated surfacesTERT-BUTYL METHACRYLATEN-Butyl methacrylate

PCT No. PCT / EP97 / 00149 Sec. 371 Date Aug. 20, 1998 Sec. 102(e) Date Aug. 20, 1998 PCT Filed Jan. 15, 1997 PCT Pub. No. WO97 / 29142 PCT Pub. Date Aug. 14, 1997The invention relates to coating compositions for the production of coatings which are resistant to condensed water and comprise binders based on a polyurethane resin PUR which comprises alpha, omega-polymethacrylatediols (A) as structural units. The alpha, omega-polymethacrylatediols (A) preferably consist of the monomer units methyl methacrylate, ethyl methacrylate, propyl methacrylate, n-butyl methacrylate, isobutyl methacrylate, tert-butyl methacrylate, n-pentyl methacrylate, amyl methacrylate, n-hexyl methacrylate, n-octyl methacrylate, 2-ethylhexyl methacrylate, n-decyl methacrylate, cyclopentyl methacrylate, cyclohexyl methacrylate, 4-tert-butylcyclohexyl methacrylate, cyclooctyl methacrylate, phenyl methacrylate or isobornyl methacrylate or mixtures thereof. The present invention additionally relates to processes for the preparation of such coating compositions and to their preferred use as fillers, basecoats and / or topcoats, especially in connection with automotive production-line finishing and / or refinishing.

Owner:BASF COATINGS AG

Photopolymerizable inkjet ink, ink cartridge, and inkjet recording device

ActiveUS20140327719A1Low viscosityImprove curing effectDuplicating/marking methodsInksVinyl etherSkin sensitization

A photopolymerizable inkjet ink including: at least one selected from the group consisting of (meth)acrylic acid esters negative for skin sensitization and (meth)acrylamides negative for skin sensitization; and at least one selected from the group consisting of vinyl ethers negative for skin sensitization, t-butyl methacrylate negative for skin sensitization, n-pentyl methacrylate negative for skin sensitization, and n-hexyl methacrylate negative for skin sensitization.

Owner:RICOH KK

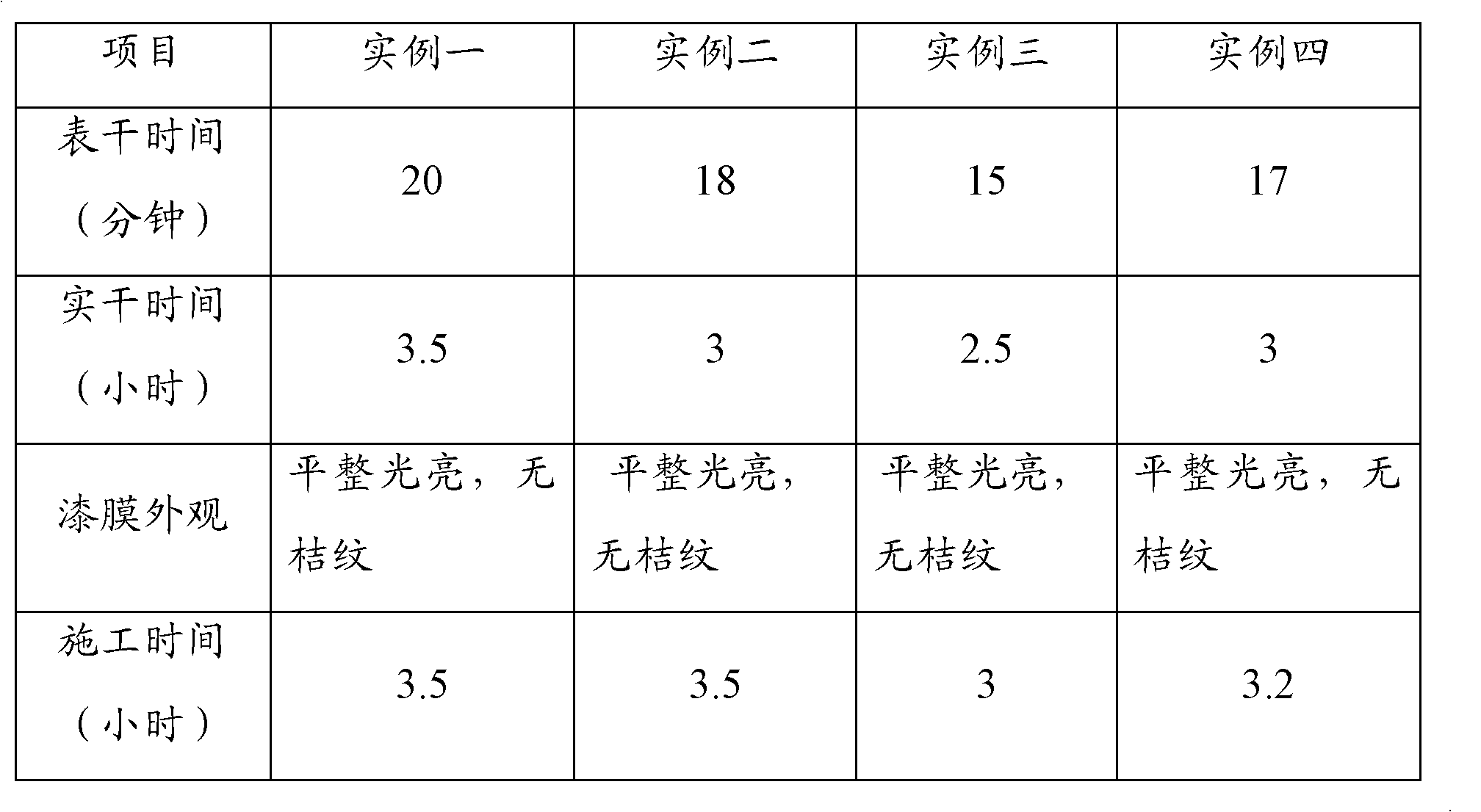

Hydroxy acrylic resin for ultra-fast dry automobile varnish and preparation method thereof

InactiveCN102153691AHas ultra-fast drying and curing propertiesImprove the level ofCoatingsPolymer scienceAcrylic resin

The invention discloses a preparation method of hydroxy acrylic resin for ultra-fast dry automobile varnish. The preparation method comprises the following steps of: 1) putting a material A into a reaction kettle, and heating the material A to the temperature of between 140 and 160 DEG C; 2) dripping a material B for 3 to 4 hours, and controlling the temperature in the reaction kettle at 140 to 160 DEG C; 3) after the dripping is finished, preserving the heat for 3.5 to 4.5 hours at the temperature of between 140 and 160 DEG C; 4) adding a material C, and performing heat preservation reactionfor 3.5 to 4.5 hours; and 5) cooling the reaction product to be less than 80 DEG C, and filtering the reaction product, wherein the material A comprises 10 to 15 weight parts of dimethyl benzene and 28 to 32 weight parts of trimethyl benzene; the material B comprises 20 to 25 weight parts of styrene or alpha-styrene, 12 to 15 weight parts of sec-butyl methacrylate or tert-butyl methacrylate, 10 to 12 weight parts of propyl methacrylate or ethyl methacrylate or ethyl acrylate, 2 to 4 weight parts of methyl acrylic acid, and 0.3 to 1.0 weight part of maleic anhydride or fumaric acid; and the material C is 6 to 9 weight parts of initiator. The hydroxy acrylic resin is applied to the varnish, and has ultra-fast dry curing property, good construction performance and varnish film appearance.

Owner:同宇新材料(广东)股份有限公司

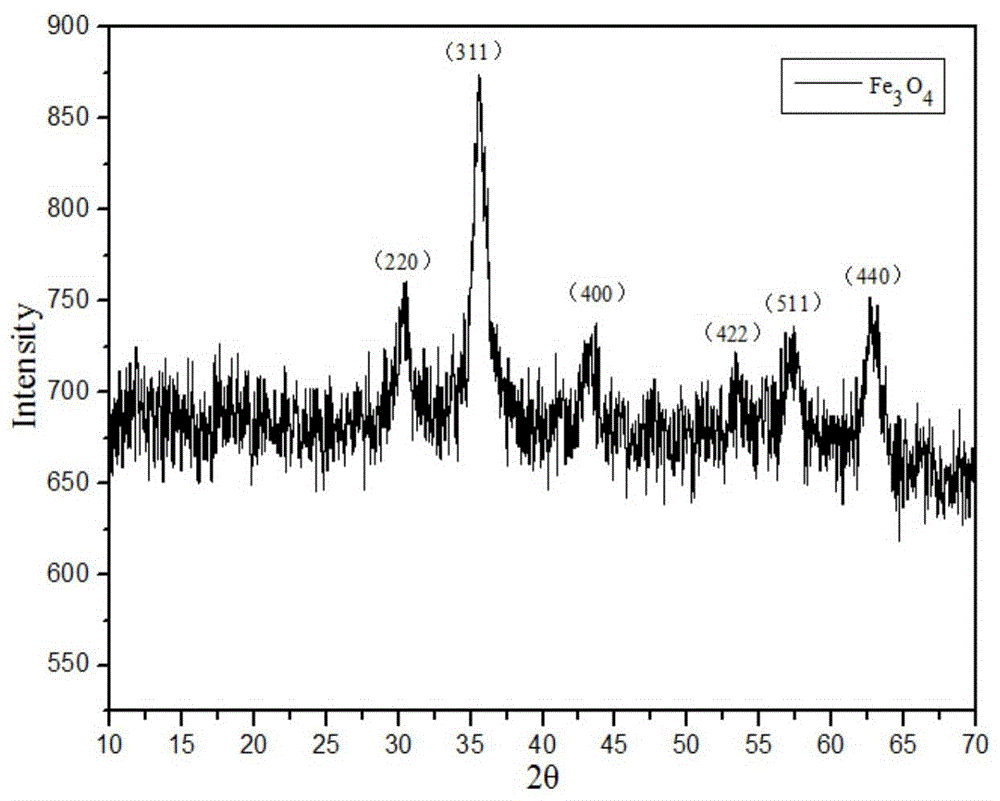

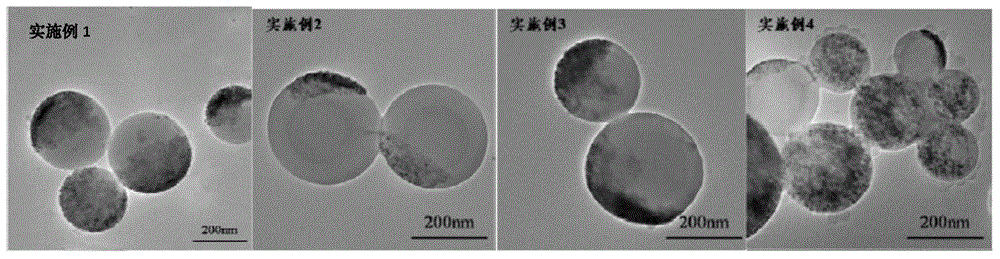

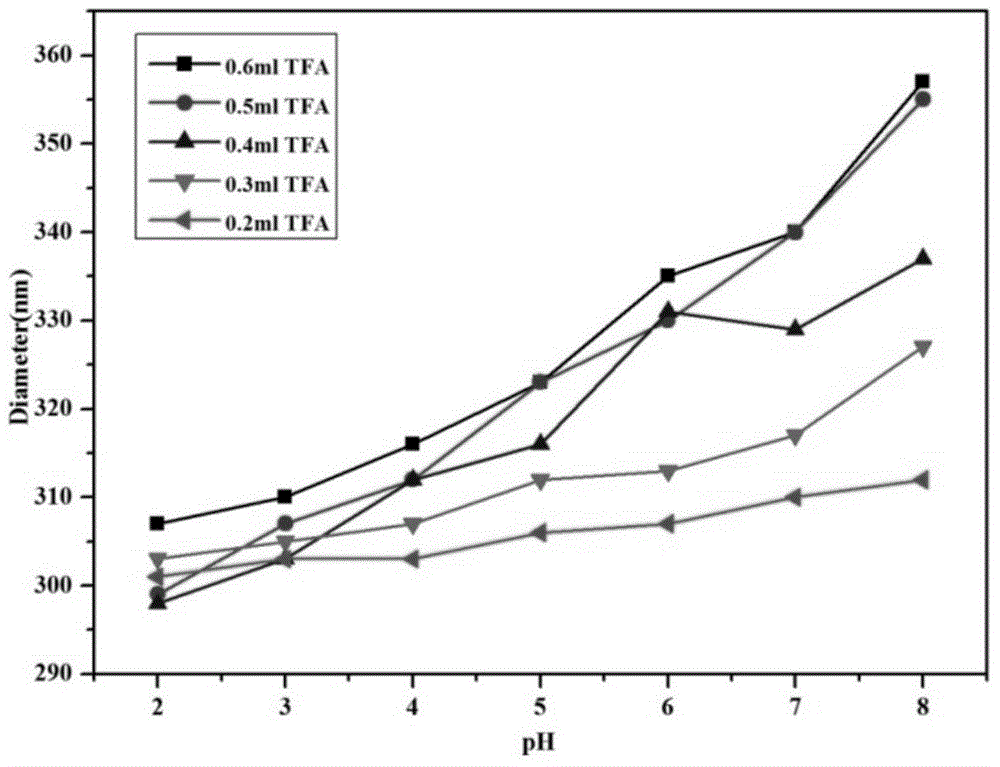

PH-responsive type magnetic composite microsphere with Janus structure, and preparation method thereof

InactiveCN104403041ASignificant structureSignificant pH sensitivityOrganic/organic-metallic materials magnetismMicroballoon preparationWater bathsMicrosphere

The invention relates to a pH-responsive type magnetic composite microsphere with a Janus structure, and a preparation method thereof, and belongs to the fields of composite materials and nanotechnologies. The pH-responsive type magnetic composite microsphere is of a core-shell structure, an inner core is made of polystyrene wrapped with Fe3O4, and a shell layer is made of poly(tert-butylmethacrylate). The preparation method comprises the following steps: preparing magnetic Fe3O4 nano-particles, then adding oleic acid, washing to neutral to obtain oleic modified Fe3O4 nano-particles, then dissolving in normal octane, adding a styrene monomer and a tert-butyl methacrylate monomer after ultrasound to obtain a magnetofluid, and adding in a bottle equipped with a reflux condensing tube and a thermometer, adding deionized water, lauryl sodium sulfate and NaHCO3 in sequence, heating in a water bath, then introducing N2, adding ammonium persulfate, preparing a magnetic composite microsphere solution with the Janus structure after emulsion polymerization, then centrifuging, separating a lower sediment, washing to neutral, putting in the container after drying, and adding deionized water and trifluoroacetic acid with different pH values to obtain a product.

Owner:XIAMEN UNIV

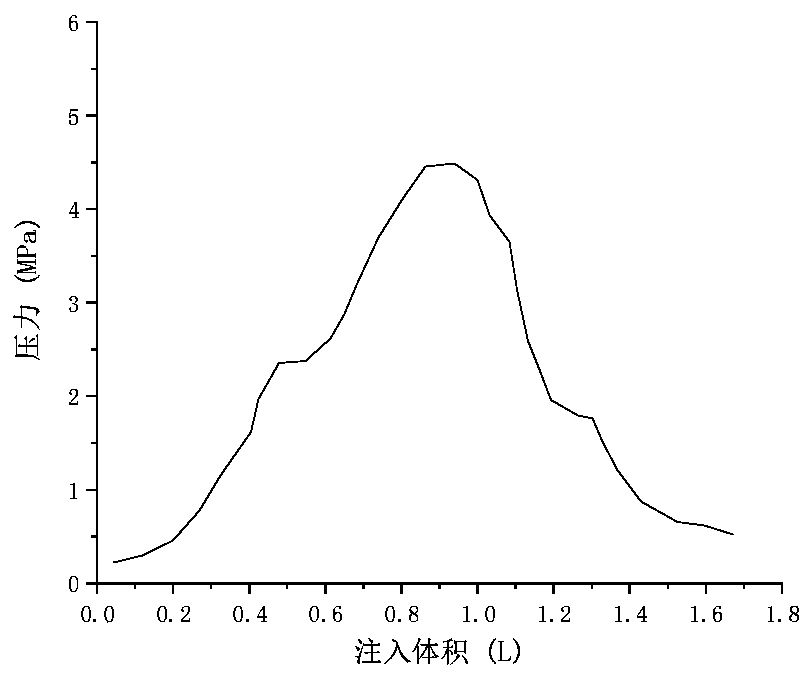

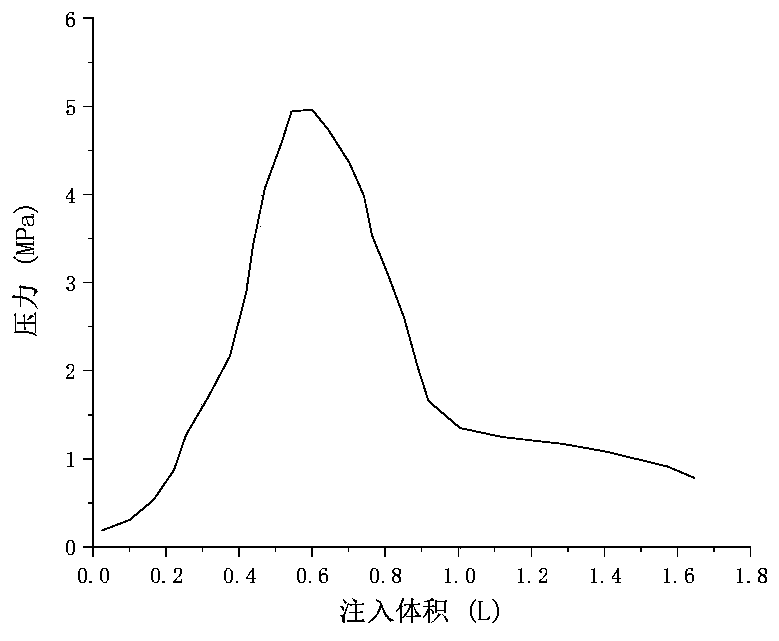

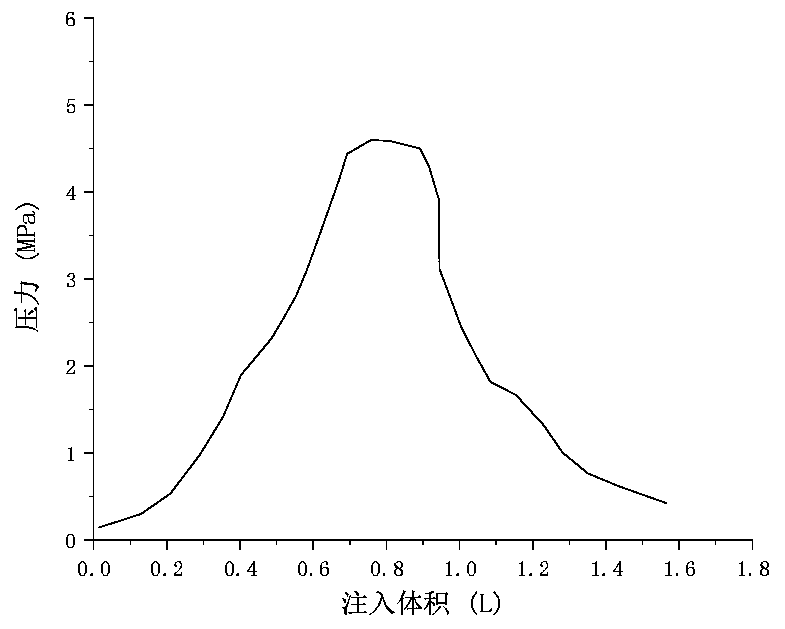

Hybrid gel particle while drilling plugging agent and preparation method thereof

ActiveCN110760296AEffective blockingImprove pressure bearing capacityDrilling compositionMeth-(Hydroxyethyl)methacrylate

The invention provides a hybrid gel particle while drilling plugging agent and a preparation method thereof. The hybrid gel particle while drilling plugging agent is prepared from the following raw materials in parts by mass: 20-35 parts of reactive monomer, 1.0-3.0 parts of a crosslinking agent, 0.3-0.5 part of an initiator, 3.0-5.0 parts of a silane coupling agent and 0.5-2.0 parts of nano-scalerigid particle; the reactive monomer is a composition of three or more than three kinds of methacrylamide, hydroxyethyl methacrylate, lauryl acrylate, tert-butyl methacrylate, dibutyl adipate, sodiump-styrene sulfonate, ethenyl-Benzenesulfonic acid or divinyl benzene; and the nano-scale rigid particle is a composition of one or more than two kinds of nano calcium carbonate, nano silicon dioxide,talcum powder or wollastonite powder. The gel particle plugging agent prepared by the preparation method has the advantages of high toughness, high temperature resistance, high pressure bearing capacity under high temperature and good plugging effect.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

(METH)acrylic resin composition, imidized (METH)acrylic resin composition, and film obtained by molding them

InactiveUS20100092792A1Good chemical resistanceGood alkali resistanceSynthetic resin layered productsOptical articlesPolymer scienceMeth-

The present invention provides a (meth)acrylic resin composition comprising a carboxylic acid group produced by heating a (meth)acrylic-based resin (C), wherein the (meth)acrylic-based resin (C) is obtained by polymerizing a monomer mixture (A) containing 80 to 99 wt % of a linear alkyl (meth)acrylate and 1 to 20 wt % of tertiary-butyl(meth)acrylate, in the presence of an acrylic acid ester-based crosslinked elastic particle (B) that is obtained by mixing and polymerizing 0.5 to 5 parts by weight of a polyfunctional monomer having at least two non-conjugated double bonds per molecule, with respect to 100 parts by weight of a monomer mixture containing 50 to 100 wt % of an alkyl acrylate monomer and 0 to 50 wt % of an alkyl methacrylate monomer. This composition can be used to produce a film having excellent chemical resistance (in particular, sun-screening agent resistance).

Owner:KANEKA CORP

Coating agent, the manufacture and uses thereof

InactiveUS6200639B1High hardnessImprove application reliabilityPretreated surfacesPolyester coatingsPolyesterMeth-

Coating composition suitable for multi-layer lacquerings, with a binder composition which comprises: A) 25 to 75 wt. % of carboxyl-functional (meth)acrylic copolymers and / or carboxyl-functional polyesters, the carboxyl functionality of which corresponds to an acid number of 15 to 300 mg KOH / g, B) 25 to 75 wt. % of epoxide-functionalized crosslinker resins, at least one of which is a (meth)acrylic copolymer which has been prepared co-using tert-butyl (meth)acrylate, C) 0 to 50 wt. % of polyols which have at least two hydroxyl functions in the molecule, D) 0 to 40 wt. % of components which crosslink with hydroxyl groups to form ethers, and / or of a crosslinking agent based on triazine, E) 0 to 40 wt. % of polyisocyanates, F) 0 to 50 wt. % of at least one organic polyanhydride with at least two cyclic carboxylic acid anhydride groups per molecule, G) 0 to 20 wt. % of reactive thinners with an epoxide function, H) 0 to 10 wt. % of one or more catalysts for the reaction of carboxyl and epoxide groups.

Owner:HERBERTS GMBH

Thermoplastic acrylic resin and preparation method for same

The invention discloses a thermoplastic acrylic resin. The thermoplastic acrylic resin is characterized by comprising the raw materials in parts by weight: 25-40 parts of methyl methacrylate, 20-30 parts of butyl acrylate, 15-30 parts of alkyl-containing acrylic monomer, 2-5 parts of hydroxyethyl acrylate, 1-2 parts of acrylic acid, and 1-2 parts of initiator, wherein the alkyl-containing acrylic monomer is one of isobornyl methacrylate, isobornyl acrylate, cyclohexyl methacrylate, tert-butyl cyclohexyl methacrylate and 3,3,5-trimethyl cyclohexyl methacrylate, or the compound thereof. The invention further provides a preparation method for the thermoplastic acrylic resin. The thermoplastic acrylic resin disclosed by the invention is high in Tg value, low in viscosity, good in application property, levelling property and dryness, full and bright in appearance, not easy to generate indentations, low in VOC (volatile organic compounds) discharge, and environment-friendly.

Owner:CHONGQING BODUO PAINT

Acrylic latex composition

InactiveUS6930143B2Improve moisture resistanceImproves UV resistanceOrganic dyesMixingOrganic solventEmulsion

An acrylic emulsion is disclosed. The emulsion comprises from about 30% to about 90% by weight of water, about 10% to about 70% by weight of an acrylic polymer, about 0.2% to about 10% by weight of a emulsifying agent, and up to 20% by weight of an organic solvent. The acrylic polymer contains from about 20% to about 80% by weight of recurring units of t-butyl acrylate or methacrylate. Latex coatings formulated from the acrylic emulsion show significantly improved resistance to moisture and corrosion.

Owner:LYONDELL CHEM TECH LP

Photosensitive degradable comb-like copolymer film with controllable surface appearance and performance

ActiveCN103524687APhotosensitivityDegradableEnergy modified materialsPharmaceutical non-active ingredientsGlycidyl methacrylatePolymer science

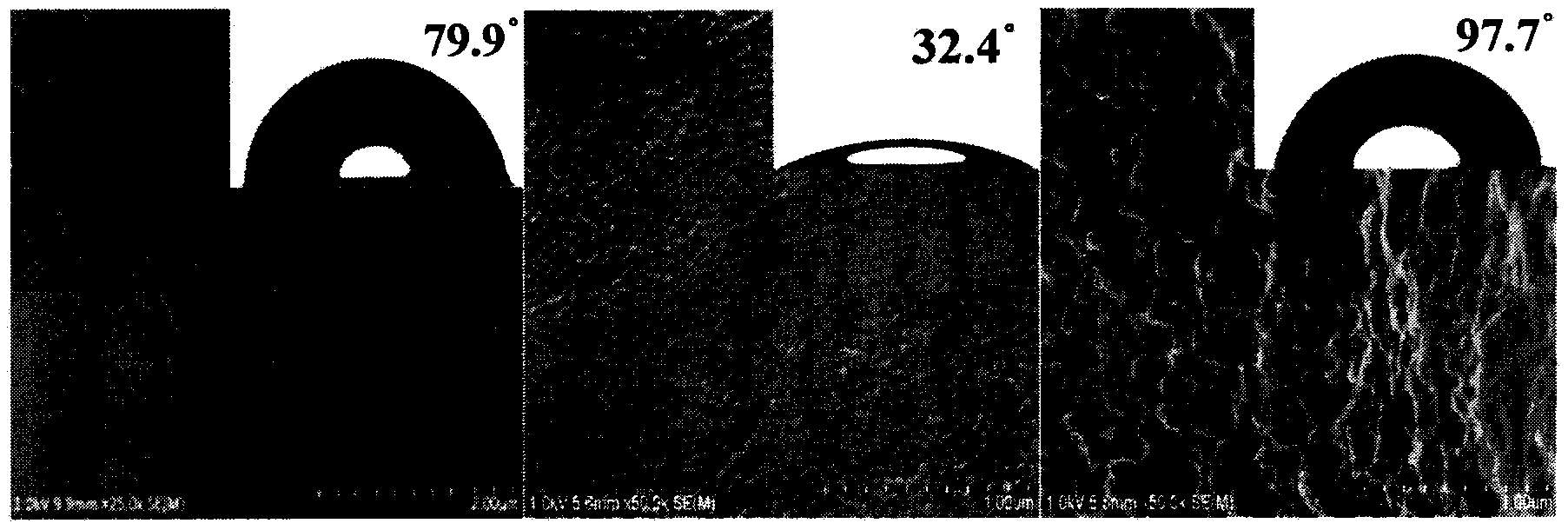

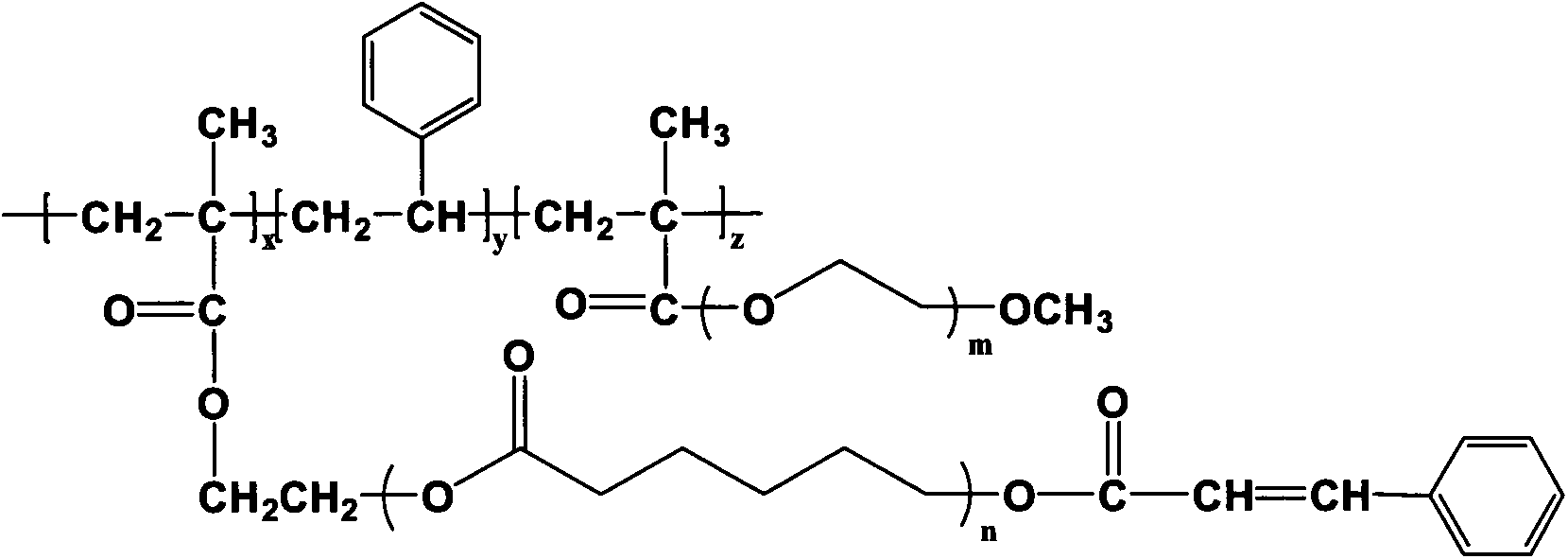

The invention relates to a photosensitive degradable comb-like copolymer film with controllable surface appearance and performance and belongs to the field of functional polymer materials. Firstly a reaction is carried out on cinnamoyl chloride (CC) and epsilon-caprolactone modified methacrylate (FMn, n is equal to 1-3), so that a series of photosensitive macromolecule monomers (FMnC) are obtained; the FMnC and polyethylene glycol methacrylate (MAPEG) are taken as a first monomer and a second monomer, then free radial copolymerization is carried out on the first monomer, the second monomer and a third monomer such as styrene (St), glycidyl methacrylate (GMA) and tert-butyl methacrylate (BMA), so that a photosensitive degradable terpolymer with a comb-like structure is prepared; a solvent volatilization method is adopted to prepare the product photosensitive degradable terpolymer with the comb-like structure into the film, and study shows that the photosensitive degradable comb-like copolymer film has photosensitivity and degradability; surface appearance and wettability of the photosensitive degradable comb-like copolymer film can be controlled by changing polarity and addition amount of a selective solvent. The obtained photosensitive degradable copolymer film with controllable surface appearance and performance is expected to be taken as an intelligent degradable material and widely applied to the fields of tissue engineering materials, medical materials and the like.

Owner:JIANGNAN UNIV

Coating composition for protecting pattern layer for hydraulic transfer, decorated formed article and method for production thereof

InactiveCN101018677AEnsure tightnessGuaranteed water resistanceDecorative surface effectsPolyurea/polyurethane coatings(Hydroxyethyl)methacrylatePolyol

A coating composition for protecting a pattern layer for hydraulic transfer which uses, onto a transfer formed product obtained by the hydraulic transfer of a pattern layer having been formed through printing or application on a film base material being soluble in or swelling with water onto a polypropylene based resin formed article, a protective coating having adhesiveness to both of said polypropylene based resin formed article and said pattern layer, wherein use is made of a protective coating film obtained by curing a hydroxyl group containing resin composition (P) prepared by subjecting a resin component (A) comprising a chlorinated polypropylene based resin and a poly-ol component (B) comprising an acryl polyol selected among cyclohexyl methacrylate, t-butyl methacrylate, styrene and hydroxyethyl methacrylate to a graft polymerization, with a polyisocyanate based curing agent (Q).

Owner:ORIGIN ELECTRIC CO LTD

Polymer Composition prepared from acrylic polymer grafted with a functionalized block copolymers

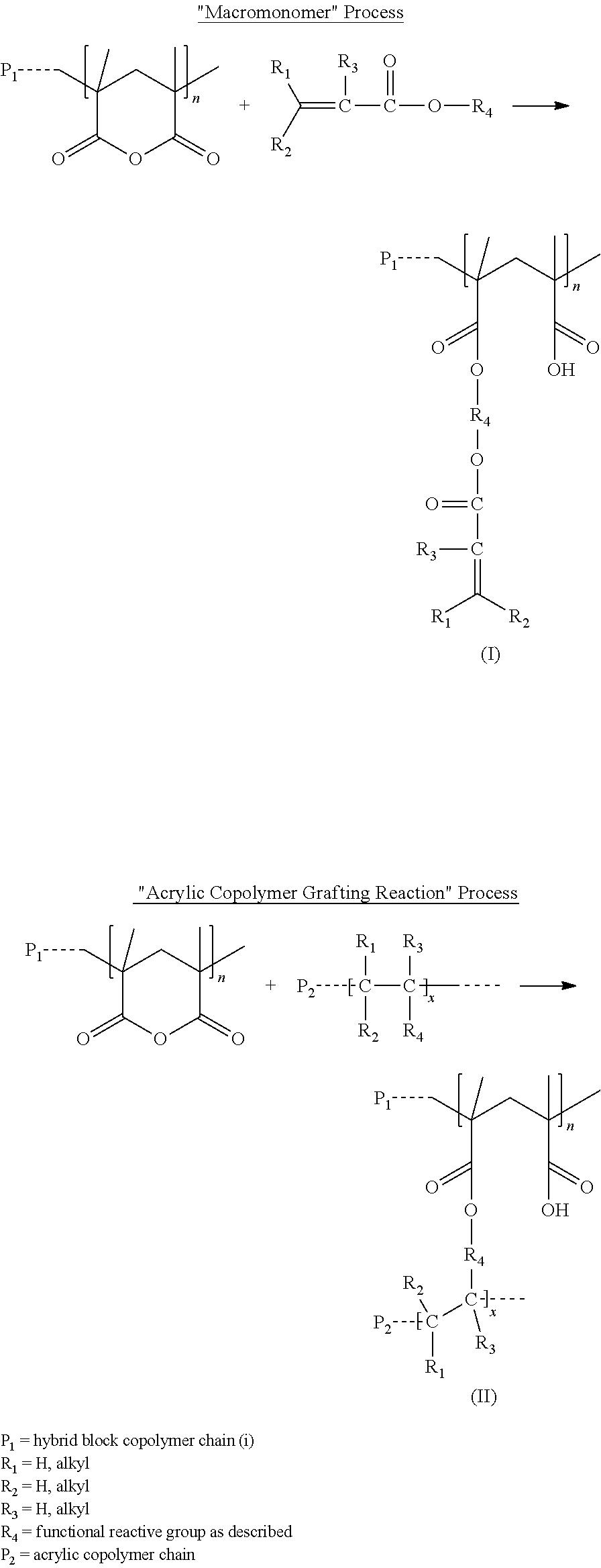

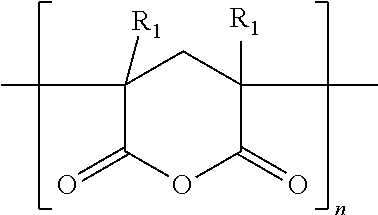

The present invention relates to various end use applications prepared from certain block copolymers. The block copolymers include one or more A or A′ blocks or B blocks plus one or more terminal M blocks. Each A and A′ is a block or segment comprising predominantly a polymerized alkenyl aromatic compound, each B is a block or segment comprising predominantly a polymerized conjugated alkadiene, and each M is a six membered anhydride ring and / or acid group. The anhydride rings are prepared by thermally decomposing adjacent units of (1-methyl-1-alkyl)alkyl acrylic esters such as t-butylmethylacrylate. A wide variety of polymers are disclosed having the stable anhydride rings in the polymer backbone. The invention relates specifically to various end uses prepared from the reaction product of such block copolymers with various reactive resins, reactive monomers and metal derivatives.

Owner:KRATON POLYMERS US LLC

Acrylic resin for transfer ink

The invention discloses an acrylic resin for transfer ink. The acrylic resin is prepared by performing copolymerization on soft monomers of which the glass transition temperatures are lower than 25 DEG C and hard monomers of which the glass transition temperatures are higher than 25 DEG C according to a mass ratio of 55 :45-95 :5, wherein the soft monomers are selected from at least one of 2-methylpropenoic acid dinbutyl phthalate, methyl acrylate, ethyl acrylate, butyl acrylate, acrylic di-iso-octyl sebacate, and 2-methylpropenoic acid glycerol trilaurate; the hard monomers are selected from at least one of 2-methylpropenoic acid methyl ester, 2-methylpropenoic acid ethyl ester, 2-methylpropenoic acid butyl acetate and cinnamene. The glass transition temperature of the acrylic resin provided by the invention ranges from 28 to 40 DEG C, the weight-average molar mass is 50,000 to 400,000, and the Tu-4 cup viscosity is 100-200 seconds. The acrylic resin has moderate adhesive force and better tenacity, and the acrylic resin can meet the requirement for the service performance of the transfer ink.

Owner:任婧

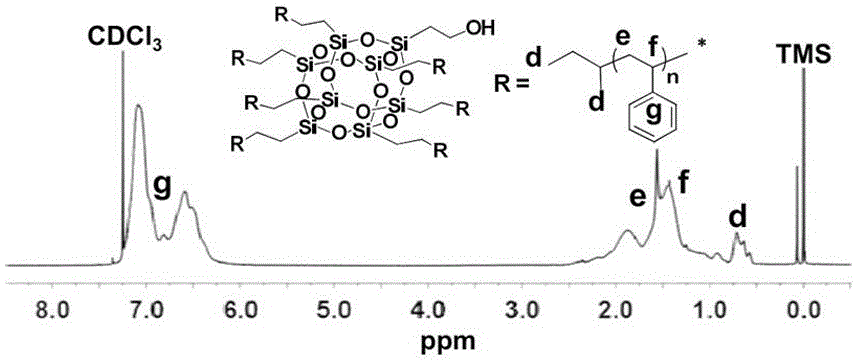

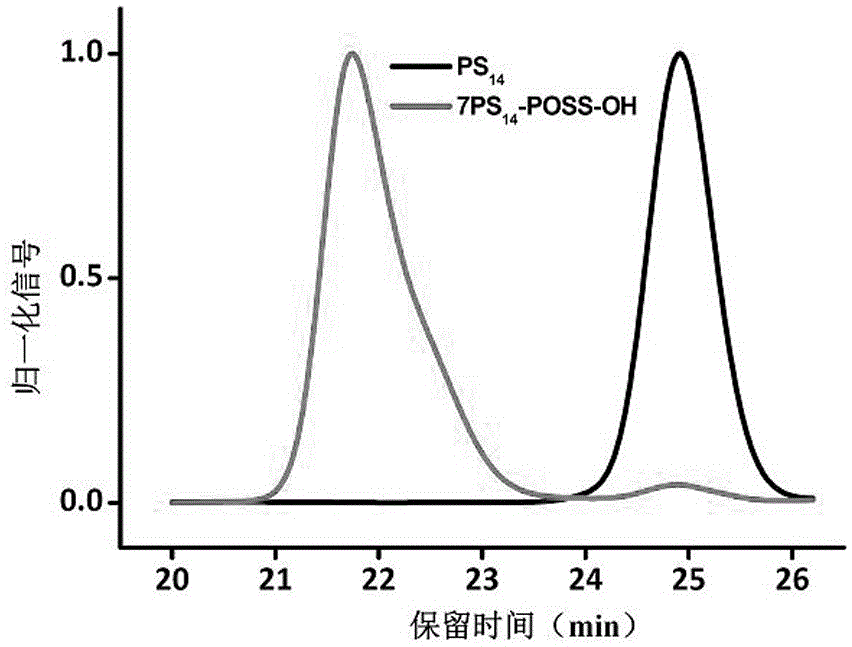

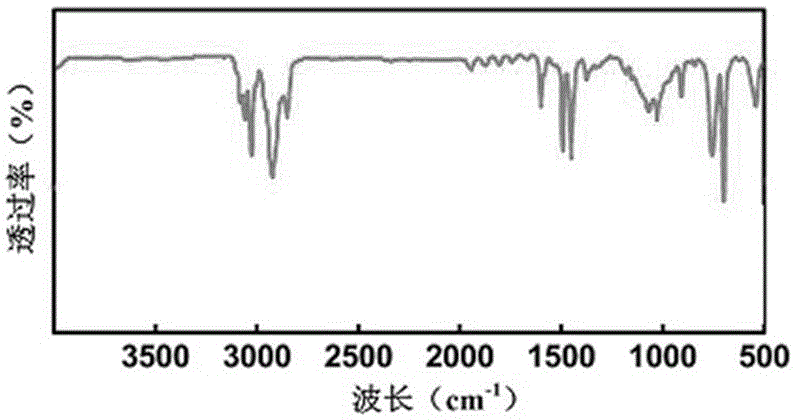

Eight-arm heteroarm star-shaped polymer and preparation method thereof

The invention discloses a preparation method of an eight-arm heteroarm star-shaped polymer. A polystyrene lithium compound is synthesized through a living anionic polymerization method, and then subjected to an addition reaction with monohydroxy heptaethylene polyhedral oligomeric silsesquioxane in benzene to obtain a seven-arm star-shaped polystyrene crude product; slightly excessive low addition products are removed by utilizing a fractional precipitation method, thus pure monohydroxy functional seven-arm star-shaped polystyrene can be obtained, and hydroxyls of the pure monohydroxy functional seven-arm star-shaped polystyrene are subjected to azide modification to obtain seven-arm star-shaped polystyrene containing azide groups. On the other hand, polycaprolactone, polyethylene glycol, polymethylacrylic acid-N, N-dimethylamino ethyl ester, and tert-butyl methacrylate of which the ends contain alkynyls are respectively synthesized, and subjected to cycloaddition reaction with alkynyls and azides at the generating end of the seven-arm star-shaped polystyrene containing the azide groups to obtain the product; the method has the characteristics of high reaction efficiency, mild reaction conditions and few side reactions. The star-shaped polymer prepared by the invention is controllable in structure and molecular weight, and relatively narrow in molecular weight distribution.

Owner:SUZHOU UNIV

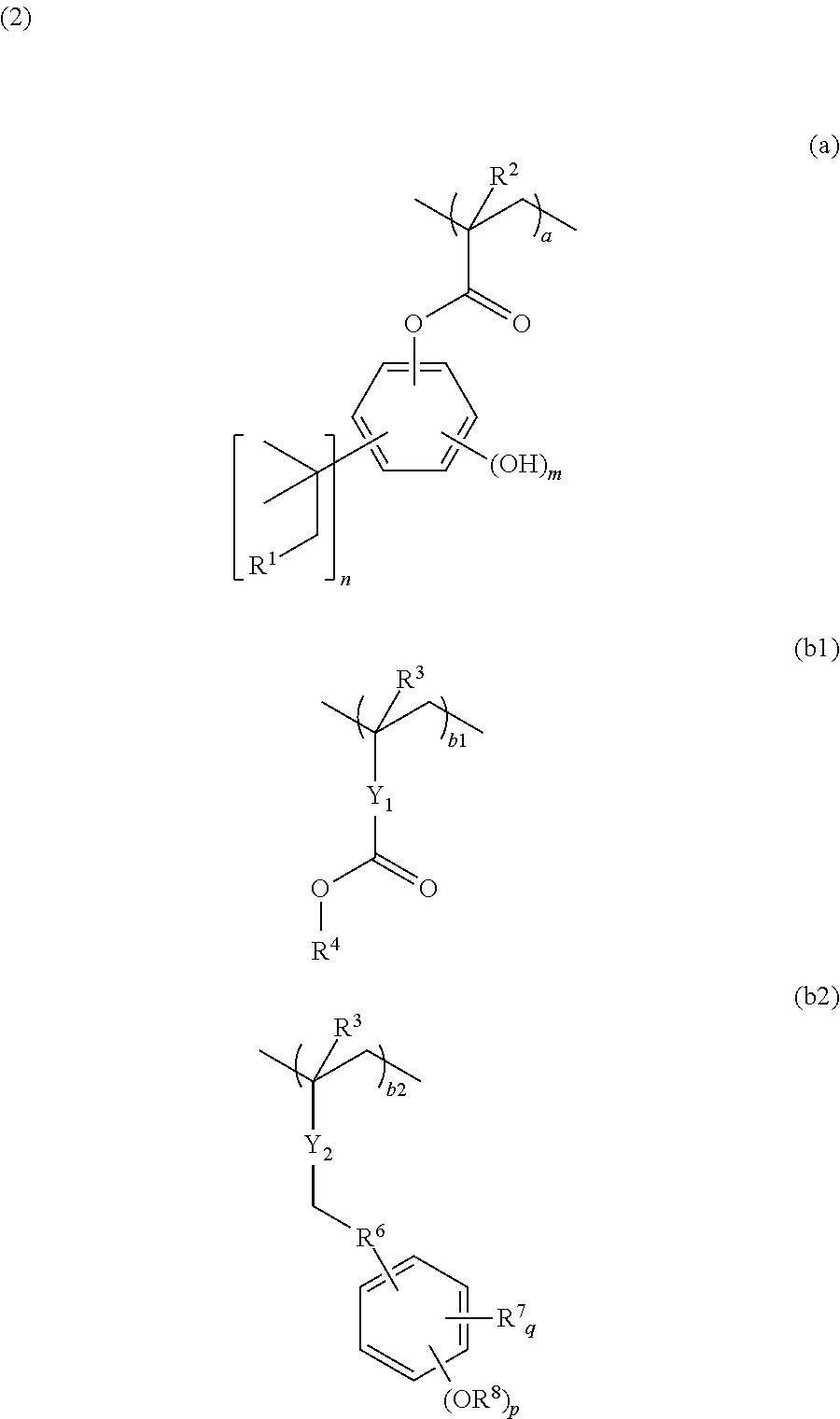

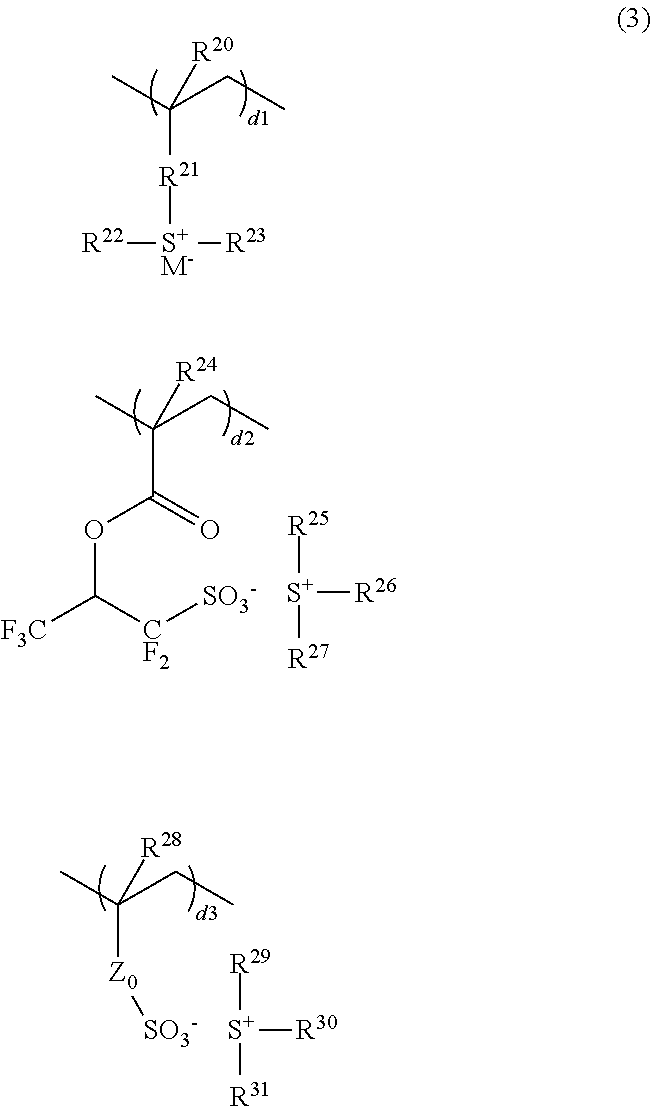

Positive resist composition and patterning process

ActiveUS9335632B2Satisfactory effect of suppressing acid diffusionHigh resolutionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPolymer scienceTERT-BUTYL METHACRYLATE

A positive resist composition is provided comprising a polymer comprising recurring units having a carboxyl and / or phenolic hydroxyl group substituted with an acid labile group and recurring units of tert-butyl or tert-amyl-substituted hydroxyphenyl methacrylate and having a weight average molecular weight of 1,000-500,000. The resist composition has a satisfactory effect of suppressing acid diffusion and a high resolution, and forms a pattern of good profile and minimal edge roughness after exposure.

Owner:SHIN ETSU CHEM IND CO LTD

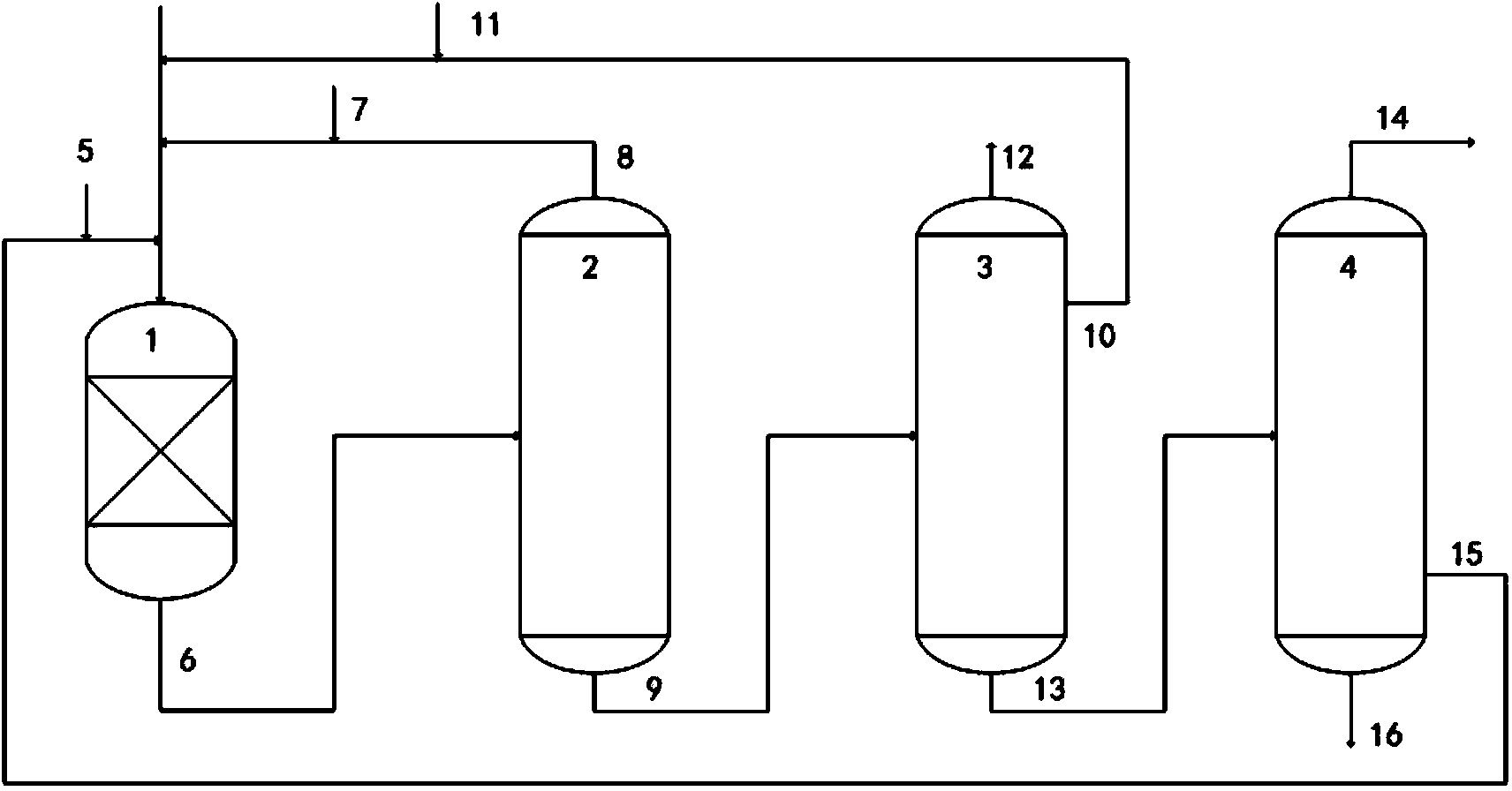

Process method for preparing (methyl) tert-butyl acrylate through continuous method

ActiveCN104030919AHigh yieldHigh selectivityOrganic compound preparationCarboxylic acid esters preparationMeth-Ptru catalyst

The invention provides a process method for preparing (methyl) tert-butyl acrylate through a continuous method. According to the method, the (methyl) tert-butyl acrylate is continuously produced by utilizing a fixed bed reactor and a rectification device, a silica-loaded phosphorus vanadium and tungsten heteropoly acid serves as a catalyst, and tertiary butanol serves as an olefin polymerization inhibitor. By adoption of the process method, the reaction speed is high, the yield of the product is greatly increased, and the whole set of process is simple in steps, low in cost and pollution-free and accords with atomization economy.

Owner:WUXI ACRYL TECH

Preparation method of monodisperse solvent-proof high-carboxyl-content polystyrene microsphere

InactiveCN108676112AHigh surface carboxyl contentHigh internal carboxyl contentPotassium persulfateMicrosphere

The invention provides a preparation method of a monodisperse solvent-proof high-carboxyl-content polystyrene microsphere. The preparation method comprises the following steps: taking styrene as a main polymerization monomer, ethyl methacrylate and tert-butyl methacrylate as comonomers, divinyl benzene, vinytriethoxylsilane and diacetone acrylamide as crosslinking agents, trimethylolpropane as a chain extender, and sodium bisulfite as an acrylic ester solubilizer, then the monodisperse solvent-proof high-carboxyl-content polystyrene microsphere is prepared through a soap-free emulsion polymerization reaction, adding styrene, divinyl benzene, trimethylolpropane and deionized water in a 250 mL three-neck flask during preparation, introducing N2, stirring for 30 min at a high speed, adding diacetone acrylamide, ethyl methacrylate, tert-butyl methacrylate and sodium hydrogen sulfite, heating to 70-85 DEG C, adding an initiator, namely potassium persulfate, and reacting for 6-24 hours. Thepreparation method can be used for preparing the monodisperse solvent-proof high-carboxyl-content size-controllable polystyrene microsphere.

Owner:SUZHOU ZEMAN BIOTECH CO LTD

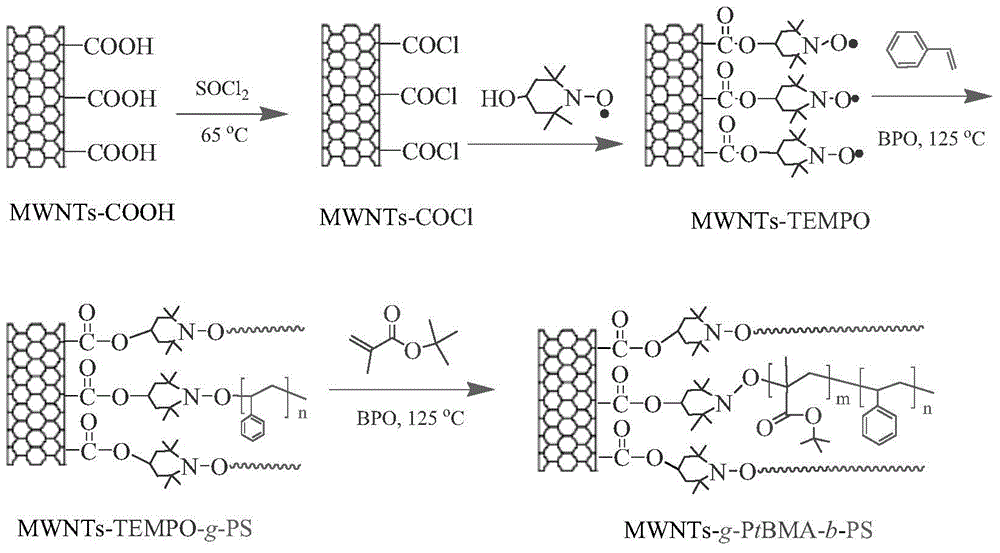

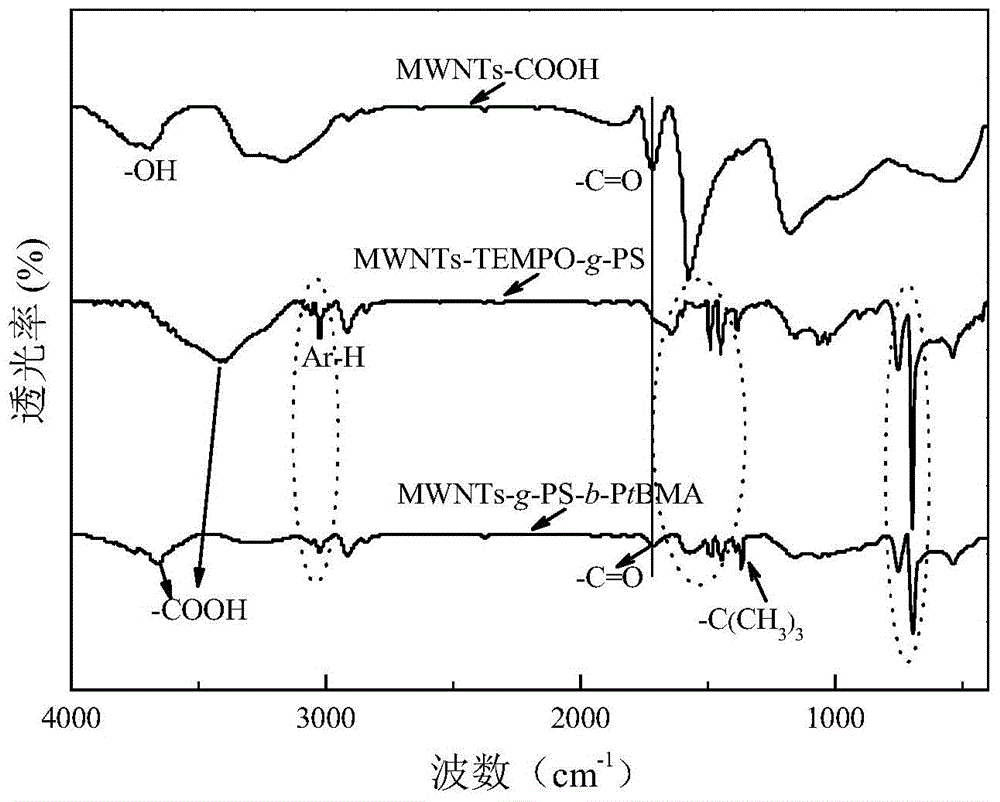

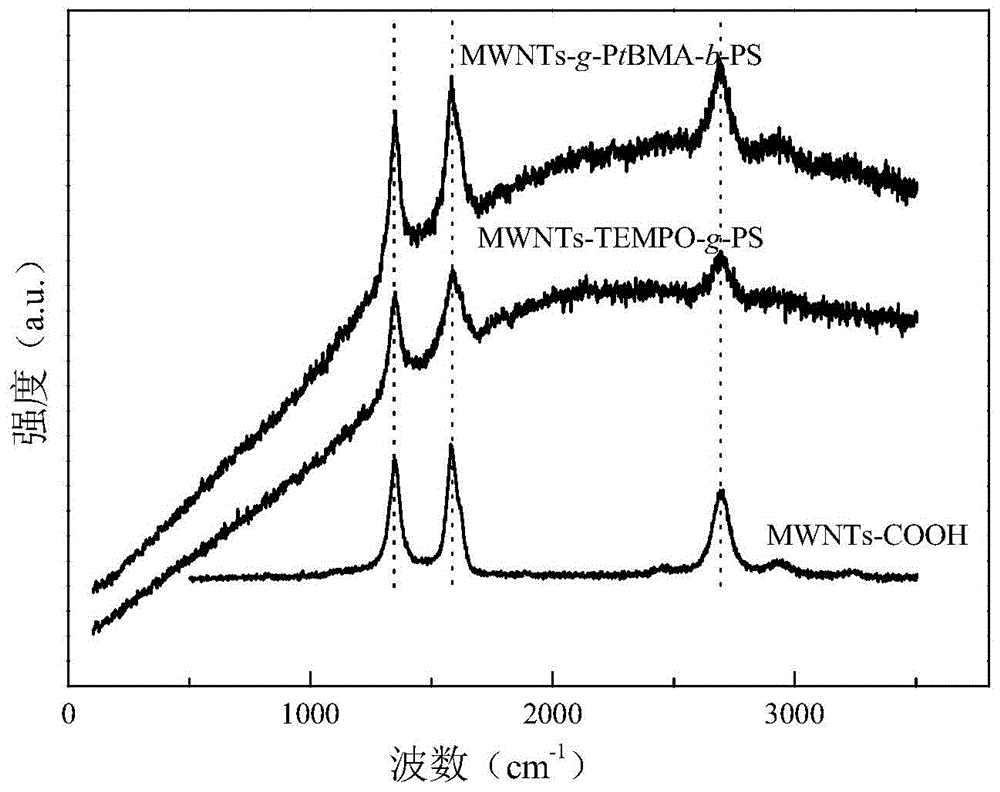

Ternary conductive gas-sensitive sensing material adopting polymers, compatilizer and multiwalled carbon nanotubes as well as preparation method and application of ternary conductive gas-sensitive sensing material

InactiveCN104559008AImprove dispersion stabilityImprove stabilityMaterial resistanceDispersion stabilityOrganic solvent

The invention discloses a ternary conductive gas-sensitive sensing material adopting polymers, compatilizer and multiwalled carbon nanotubes as well as a preparation method and an application of the ternary conductive gas-sensitive sensing material. The ternary conductive gas-sensitive sensing material comprises components in percentage by mass as follows: 5%-72% of multiwalled carbon nanotube grafted poly (styrene-tert-butyl methacrylate) copolymer, 13%-45% of carboxylic multiwalled carbon nanotubes and 10%-80% of poly (styrene-tert-butyl methacrylate) copolymer, wherein the compatilizer is prepared from the multiwalled carbon nanotube grafted poly (styrene-tert-butyl methacrylate) copolymer and the poly (styrene-tert-butyl methacrylate) copolymer with a nitroxide-mediated stable free-radical polymerization method, and the conductive gas-sensitive sensing material is prepared with a solution mixing method. The conductive gas-sensitive sensing material has good dispersion stability, can be used for assembling a gas-sensitive sensing film to detect steam of weak-polar organic solvents such as trichloromethane, dichloromethane and tetrahydrofuran, and has the characteristics of high responding sensitivity, good stability, quick response and the like.

Owner:SHAANXI NORMAL UNIV

Thermal fluidity modifier for powder coating material, method for producing the same, and powder coating material

InactiveUS20110003935A1Excellent in appearance and glossNice appearanceOrganic chemistryPowdery paintsTert-butyl acrylatePowder coating

Disclosed are a thermal fluidity modifier for a powder coating material, which contains a polymer containing t-butyl (meth)acrylate units and having a glass transition temperature (Tg) of 20 to 120° C. as calculated by the following equation (1):1 / Tg=Σ(wi / Tgi) (1),wherein wi represents a mass fraction of monomer i which constitutes the polymer and Tgi represents a glass transition temperature of a homopolymer of the monomer i; and a powder coating material containing the thermal fluidity modifier.

Owner:MITSUBISHI CHEM CORP

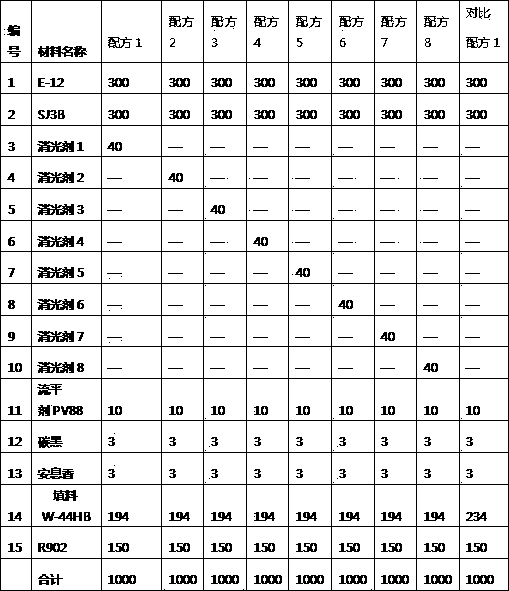

Pollution-resistant epoxy-polyester powder paint flatting agent and preparation method thereof

The invention provides a pollution-resistant epoxy-polyester powder paint flatting agent and a preparation method thereof. The pollution-resistant epoxy-polyester powder paint flatting agent is composed of 15-50 wt% of wax or wax analog, 3-10 wt% of metallic salt or organometallic complex and 40-80 wt% of acrylic resin, wherein the acrylic resin contains 40-70 wt% of tert-butyl acrylate and (or) tert-butyl methacrylate. The flatting agent is prepared by proportionally pulverizing and mixing the synthetic acrylic resin, wax or wax analog and metallic salt or organometallic complex at normal temperature. The flatting agent can enable the epoxy-polyester powder paint to simultaneously have the application effects of pollution resistance and flatting.

Owner:六安科瑞达新型材料有限公司

Epoxy modified electroplated silver resin and preparation method thereof

The invention discloses epoxy modified electroplated silver resin, comprising a first component, a second component, a third component and a fourth component, wherein ingredients of the components and the weight percentage of each ingredient in the epoxy modified electroplated silver resin are as follows: the first component comprises toluene and butyl acetate; the second component comprises methyl methacrylate, tert-butyl methacrylate, lauryl methacrylate, hydroxyethyl methacrylate, glycidyl methacrylate, an AB-4 monomer and tert-butyl peroxybenzoate; the third component comprises butyl acetate and tert-butyl peroxybenzoate; and the fourth component comprises methyl isobutyl ketone. The invention further discloses a preparation method of the epoxy modified electroplated silver resin.

Owner:东莞市比翼新材料科技有限公司

Positive resist composition and patterning process

ActiveUS20150064626A1Satisfactory effect of suppressing acid diffusionHigh resolutionPhotosensitive materialsElectric discharge tubesMethacrylateTert butyl

A positive resist composition is provided comprising a polymer comprising recurring units having a carboxyl and / or phenolic hydroxyl group substituted with an acid labile group and recurring units of tert-butyl or tert-amyl-substituted hydroxyphenyl methacrylate and having a weight average molecular weight of 1,000-500,000. The resist composition has a satisfactory effect of suppressing acid diffusion and a high resolution, and forms a pattern of good profile and minimal edge roughness after exposure.

Owner:SHIN ETSU CHEM IND CO LTD

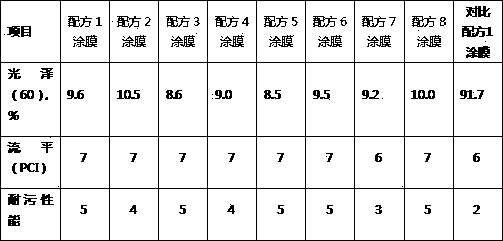

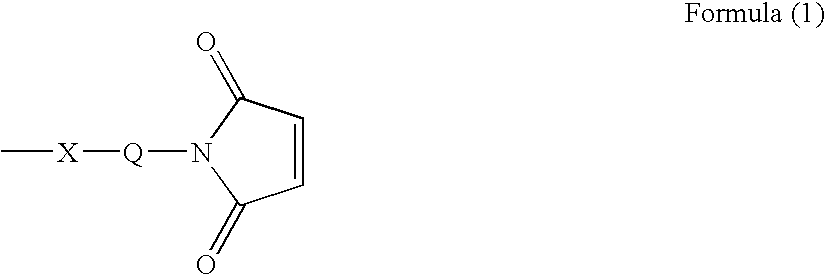

Ligand immobilization support

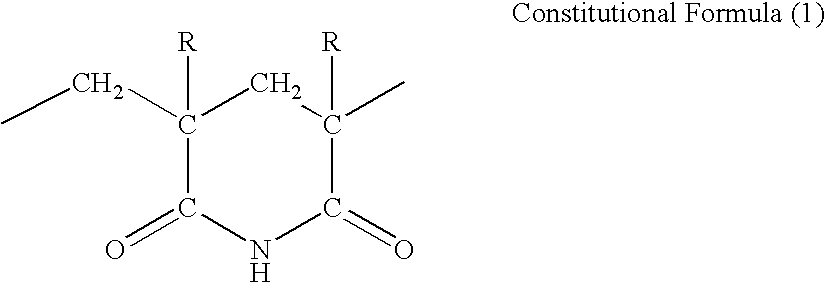

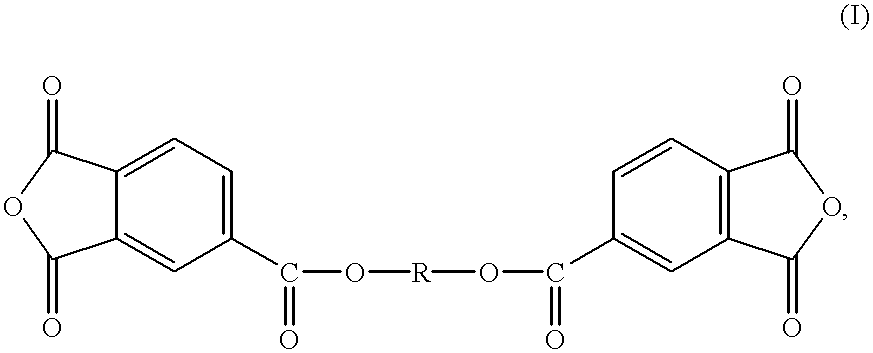

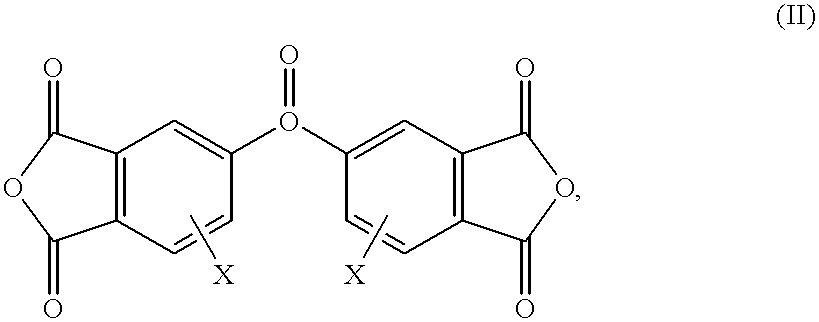

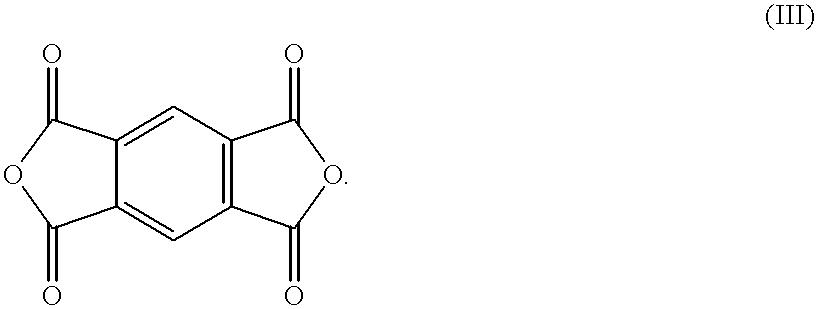

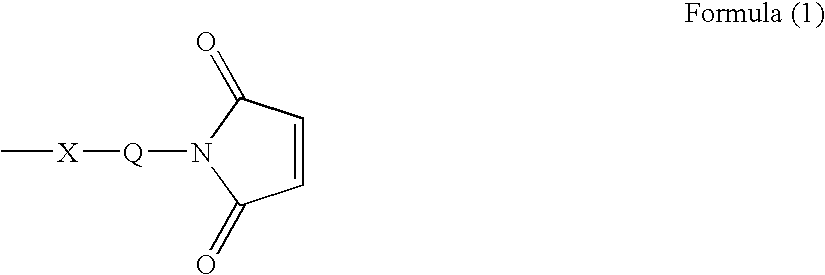

A polymer comprising a styrene-based monomer and t-butyl methacrylate, wherein a proportion of the styrene-based monomer in the polymer is 30% by mol to 90% by mol and the polymer has a functional group represented by the following formula (1) which includes a maleimidyl group: wherein in the formula (1), X represents —O— or —NH— and Q represents a spacer group. A ligand immobilization support comprising the polymer.

Owner:FUJIFILM BUSINESS INNOVATION CORP

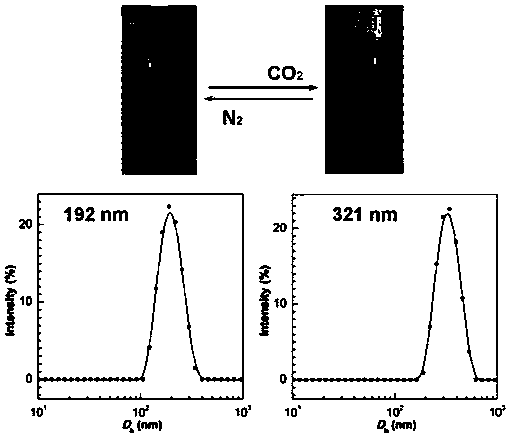

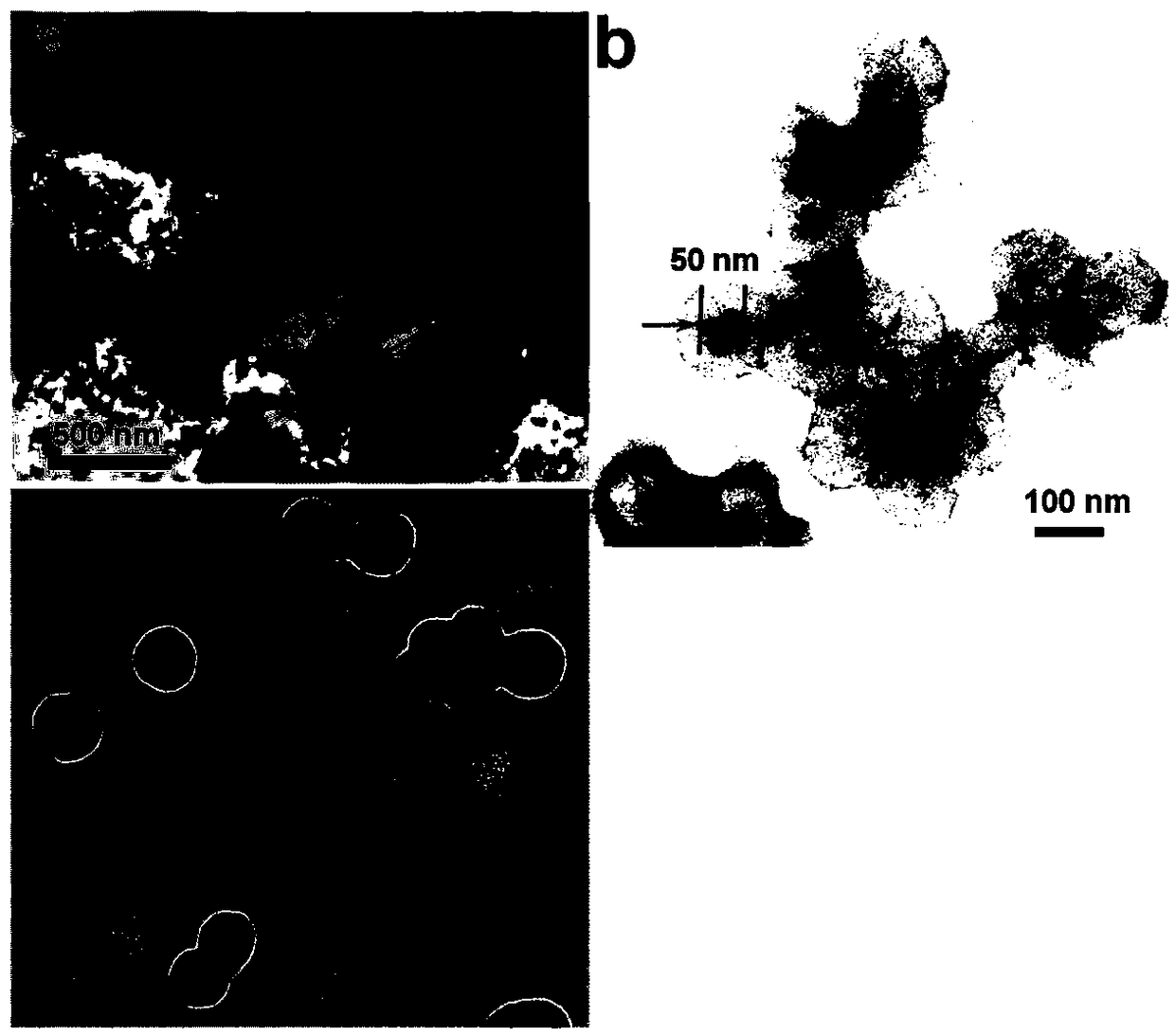

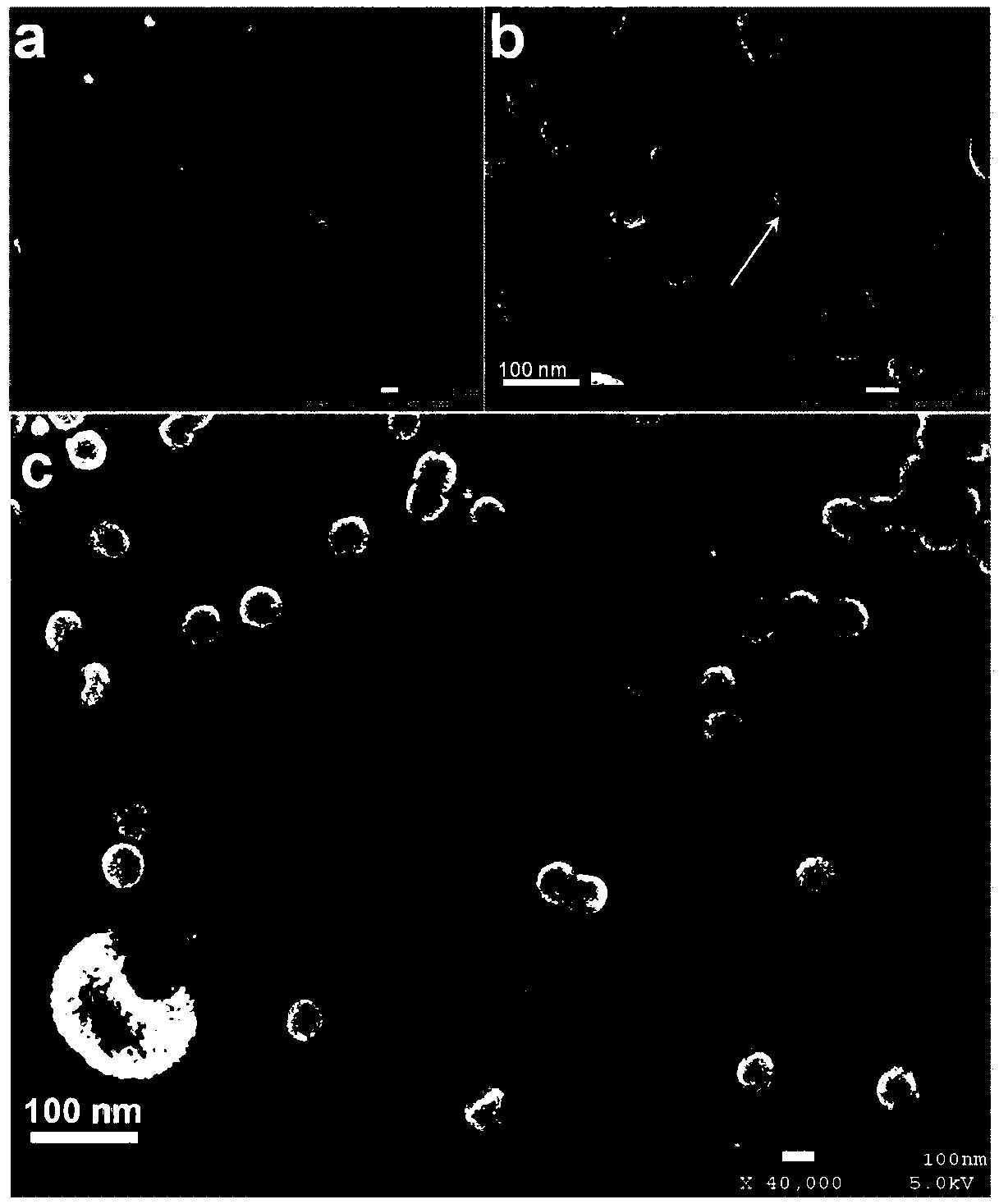

CO2 response polymer hollow microsphere and preparation method thereof

InactiveCN108659161AAchieve no irritating residueImplementing an Environmentally Friendly Response PatternMicroballoon preparationMicrocapsule preparationEtchingMicrosphere

The invention provides a preparation method of CO2 response polymer hollow microspheres. The preparation method comprises the following steps: firstly, enabling a monomer, namely styrene, methyl methacrylate, tert-butyl methacrylate, butyl acrylate or hydroxyl styrene, to react with an initiator and an emulsifier, so as to obtain a seed microsphere emulsion; secondly, simultaneously dropping a mixture of a compound A and a crosslinking agent, and the initiator into the seed microsphere emulsion, and carrying out a reaction so as to obtain a core-shell microsphere emulsion; mixing the core-shell microsphere emulsion with organic solvents, namely tetrahydrofuran (THF), chloroform, ethyl acetate, methylbenzene and the like, and carrying out selective etching. By adopting the preparation method, intelligent hollow microspheres of hollow structures with CO2 response are prepared, irritation residue-free and environmental-friendly response modes of a hollow microsphere material can be achieved, and in addition, the microspheres are controllable in morphology and CO2 irritation response.

Owner:SICHUAN UNIV

Asphaltic resin composite spherical activated carbon with expanded graphite enhanced oil absorption property and preparation method therefor

InactiveCN105032349AUniform sizeLarge specific surface areaOther chemical processesAdditive ingredientMaterials science

The invention discloses asphaltic resin composite spherical activated carbon with an expanded graphite enhanced oil absorption property. The asphaltic resin composite spherical activated carbon is characterized by being prepared from the following raw materials in parts by weight: 40-43 parts of tert-butyl methacrylate, 40-42 parts of ortho-methylstyrene, 25-28 parts of ethanol, 2-3 parts of tert-butyl hydroperoxide, 1.5-2.5 parts of bisphenol A epoxy dimethyl acrylic acid, 2-3 parts of gelatin, 0.5-0.8 part of OP-10, a proper volume of distilled water, a proper volume of acetone, 25-28 parts of sulfonated asphalt powder, 4-5 parts of expanded graphite, 2-3 parts of clay powder, 3-4 parts of corncob powder, 2-3 parts of 1% sodium hydroxide solution, 3-4 parts of citric acid and 2-3 parts of emulsified paraffin. The asphaltic resin composite spherical activated carbon contains ingredients such as the modified expanded graphite, the clay powder, the corncob powder and the like, and the modified expanded graphite and the like exist in three-dimensional fiber-net-shaped molecular structures, so that a large number of oil molecules can be adsorbed, meanwhile, the oil absorption speed is high, the oil-water selectivity is high, and the oil retention property is good.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

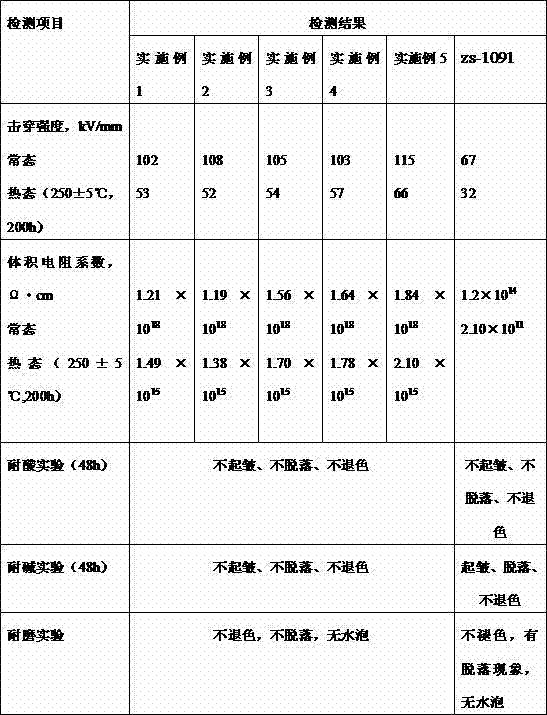

Corrosion and wear resistant insulating varnish and preparation method thereof

InactiveCN104774487AHigh insulation performance levelAccelerated corrosionAnti-corrosive paintsBreakdown strengthDibutyl tin dilaurate

The invention discloses corrosion and wear resistant insulating varnish. The insulating varnish mainly comprises the following components: xylene modified phenolic resin, lauric acid modified alkyd resin, phenyltrimethylsilane, phthalate, kaolin, isophorone diisocyanate, dibutyltin dilaurate and tert-butyl methacrylate. The corrosion and wear resistant insulating varnish has the advantages that the corrosion and wear resistant insulating varnish is an H-level insulating material and has good insulating properties; the insulating varnish also has excellent corrosion and wear resistance; the breakdown strength of a film is higher than 100kV / mm and the volume resistivity is 1018ohm.cm; the film is continuously heated for 200 hours in a range of 250+ / -2 DEG C; the breakdown strength of the film is about 55kV / mm and the volume resistivity (in heat state) is 1015ohm.cm; the film shows better properties in acid-base resistance experiments (48h) and does not wrinkle, fall off or fade; wear resistance experiments show that the insulating varnish has good wear resistance.

Owner:深圳市富贵花实业有限公司

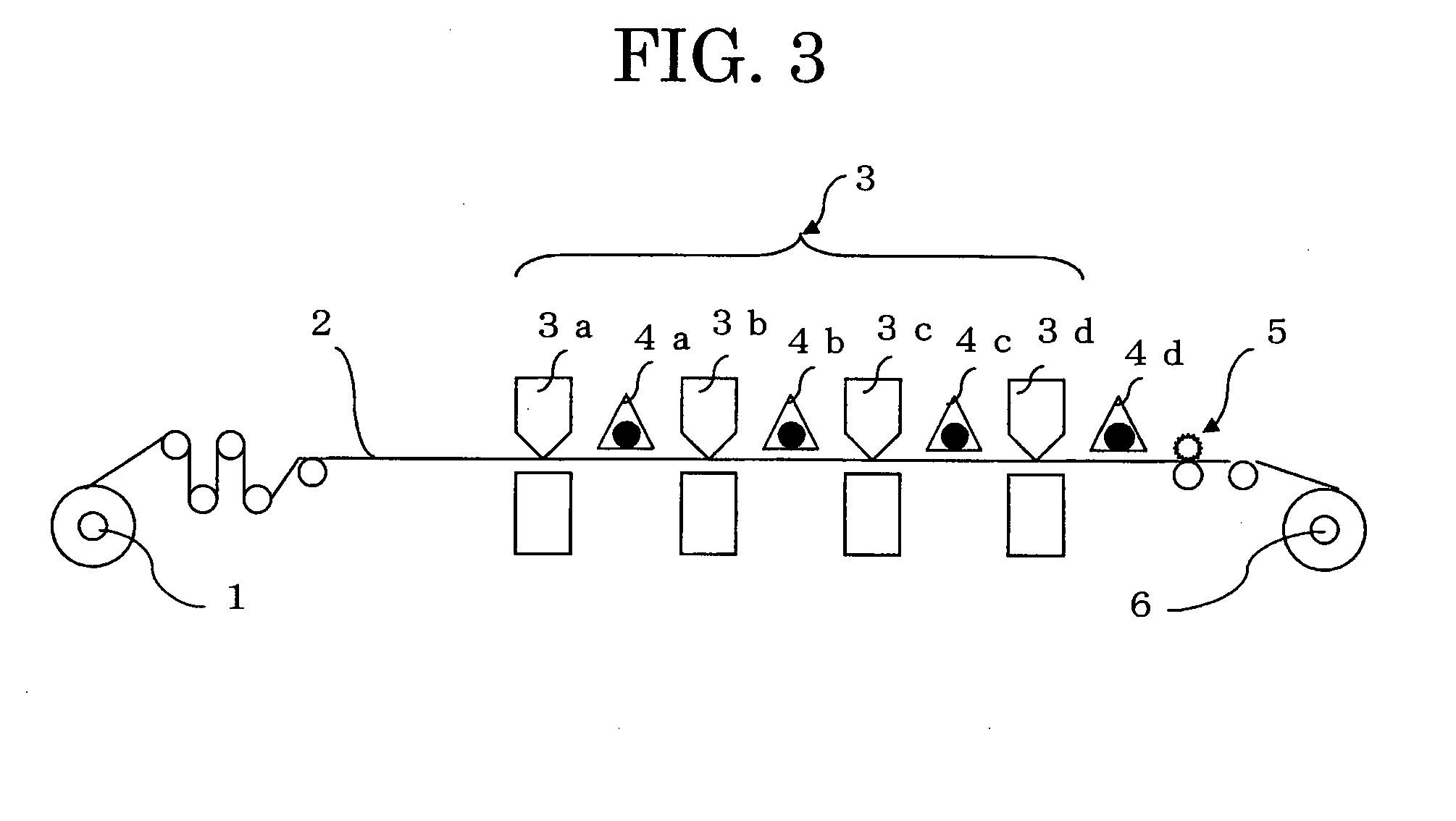

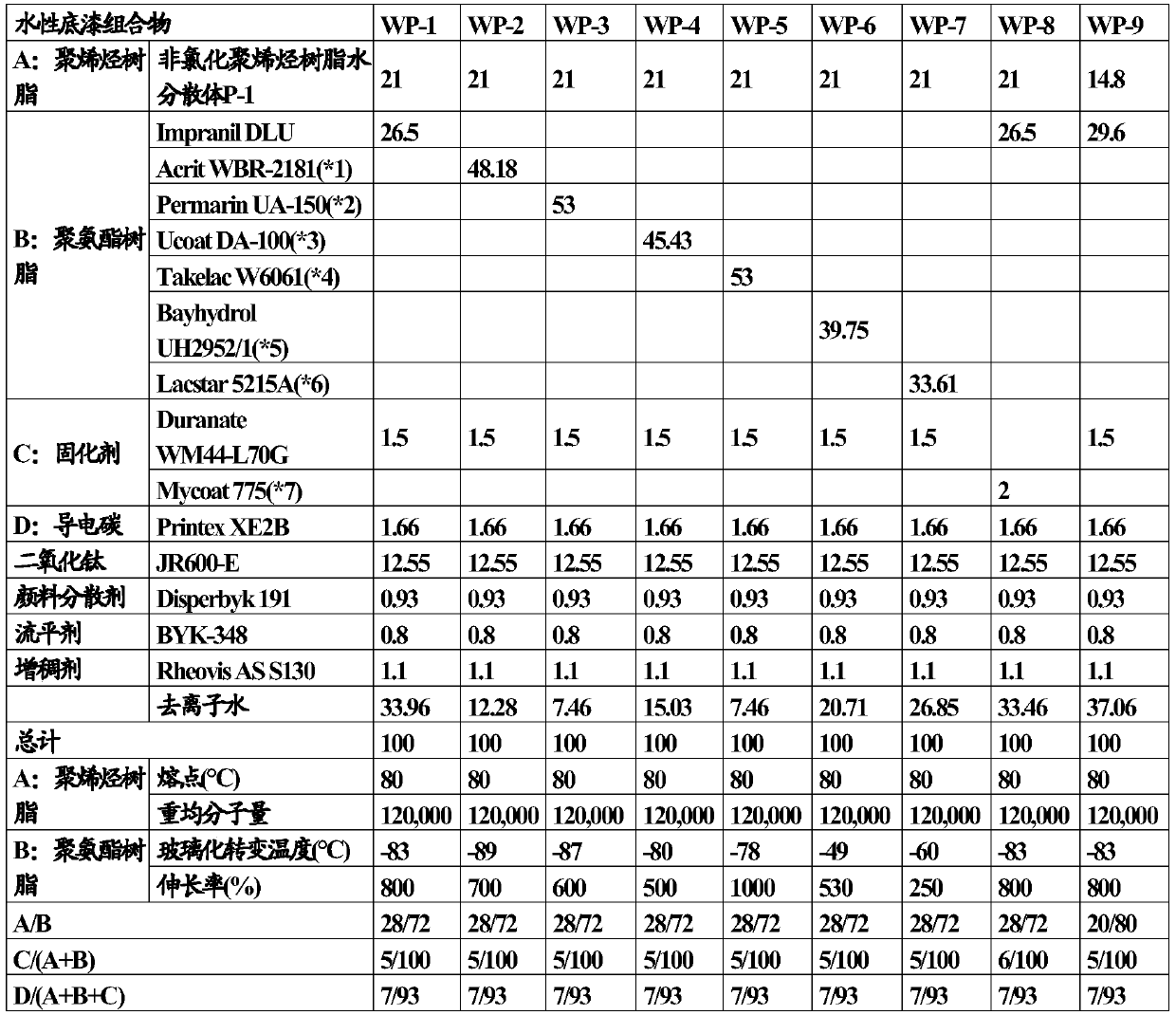

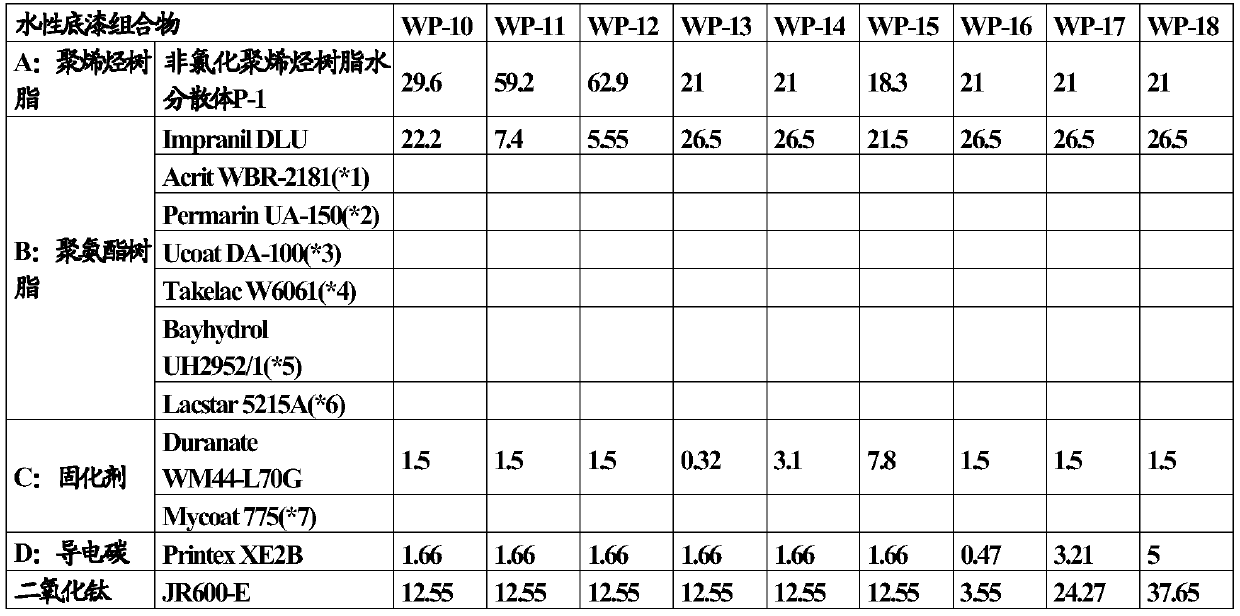

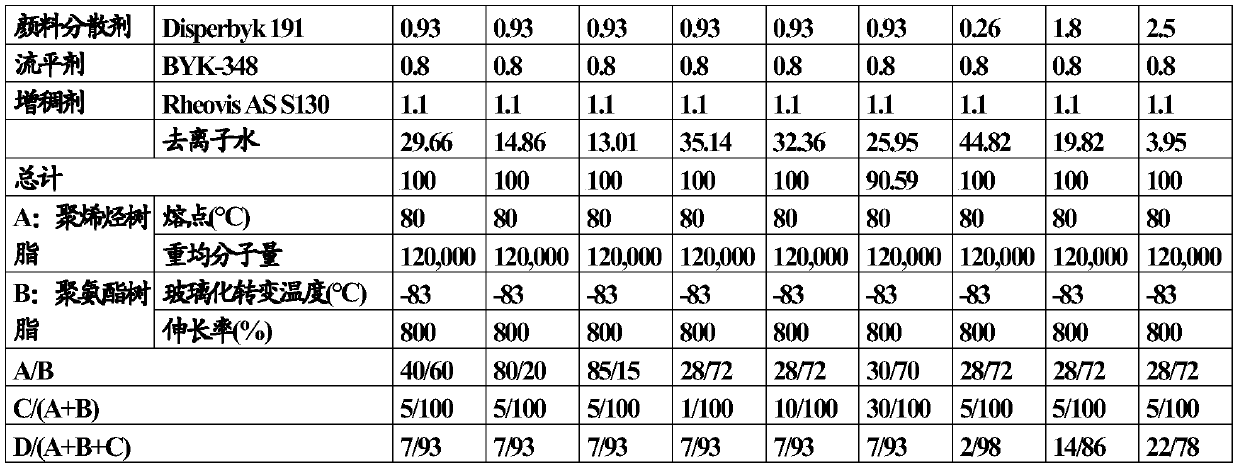

Method for forming multilayer coating film

InactiveCN110461955ALiquid surface applicatorsPolyurea/polyurethane coatingsPolymer sciencePolyolefin

To improve the appearance, chipping resistance, adhesive properties and low temperature impact properties of a coating film. The method for forming a multilayer coating film of the present invention comprises coating an aqueous primer coating composition, an aqueous first colored coating composition, an aqueous second colored coating composition and a clear coating composition in that order. The aqueous primer coating composition contains a component (A) which contains a polyolefin resin having a melting point of 60DC to 100DC and a weight average molecular weight of 50,000-250,000, a component (B) which contains a polyurethane resin having a glass transition temperature of -100DC to -70DC and an elongation percentage of 500% or more, a curing agent (C) and electrically conductive carbon (D). The aqueous first colored coating composition and aqueous second colored coating composition each contain a core / shell emulsion. The clear coating composition contains a hydroxyl group-containingacrylic resin containing 20 mass% or more of t-butyl methacrylate, a polyisocyanate and a melamine resin, and a coating film of the clear coating composition has a glass transition temperature of 70DCor higher and an elongation percentage of 3% or less.

Owner:BASF COATINGS GMBH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com