Ternary conductive gas-sensitive sensing material adopting polymers, compatilizer and multiwalled carbon nanotubes as well as preparation method and application of ternary conductive gas-sensitive sensing material

A technology of multi-walled carbon nanotubes and gas-sensing sensing materials, applied in the direction of material resistance, can solve the problems of unstable electrical conductivity of composite materials, easy agglomeration of carbon nanotubes, poor sensing responsiveness, etc., and achieve good dispersion stability. , good stability and high response sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

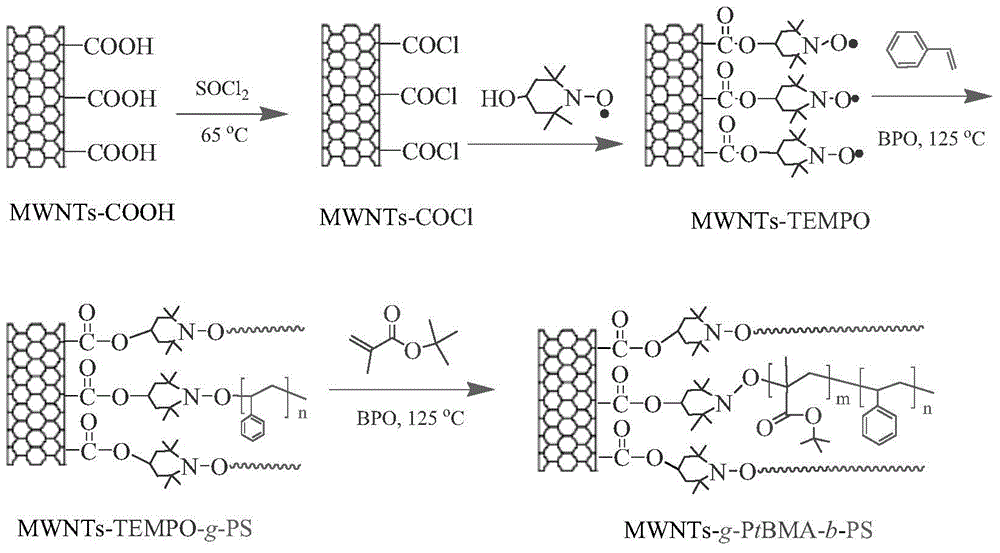

[0051] 1. Preparation of multi-walled carbon nanotube grafted poly(styrene-tert-butyl methacrylate) copolymer

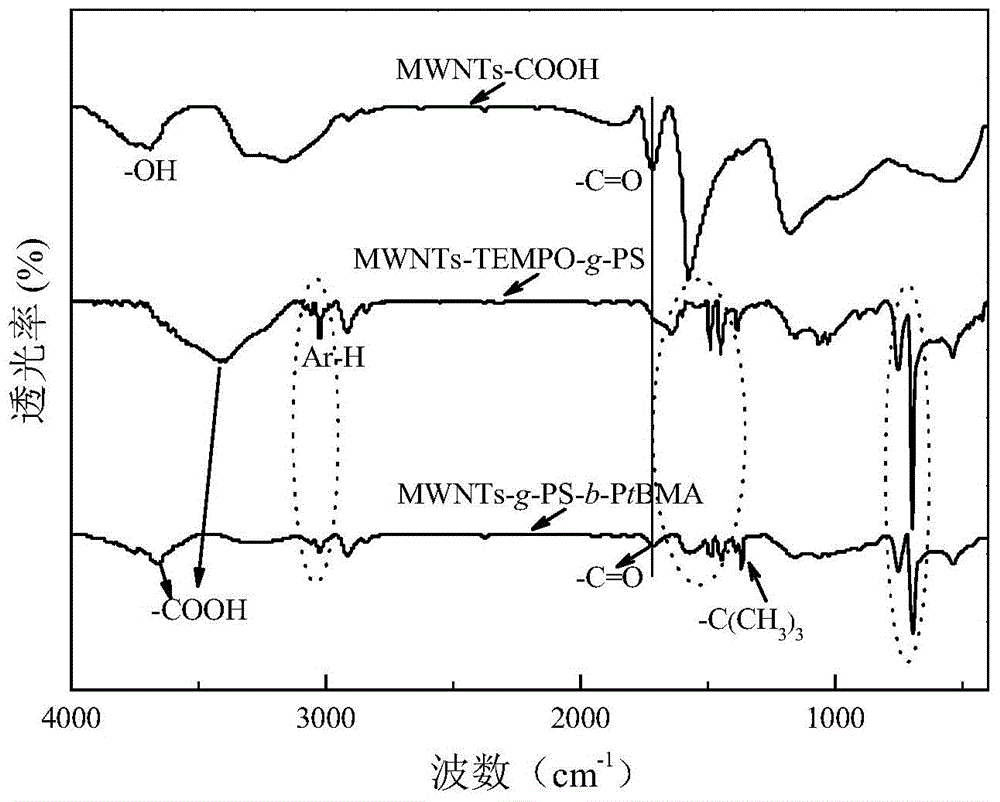

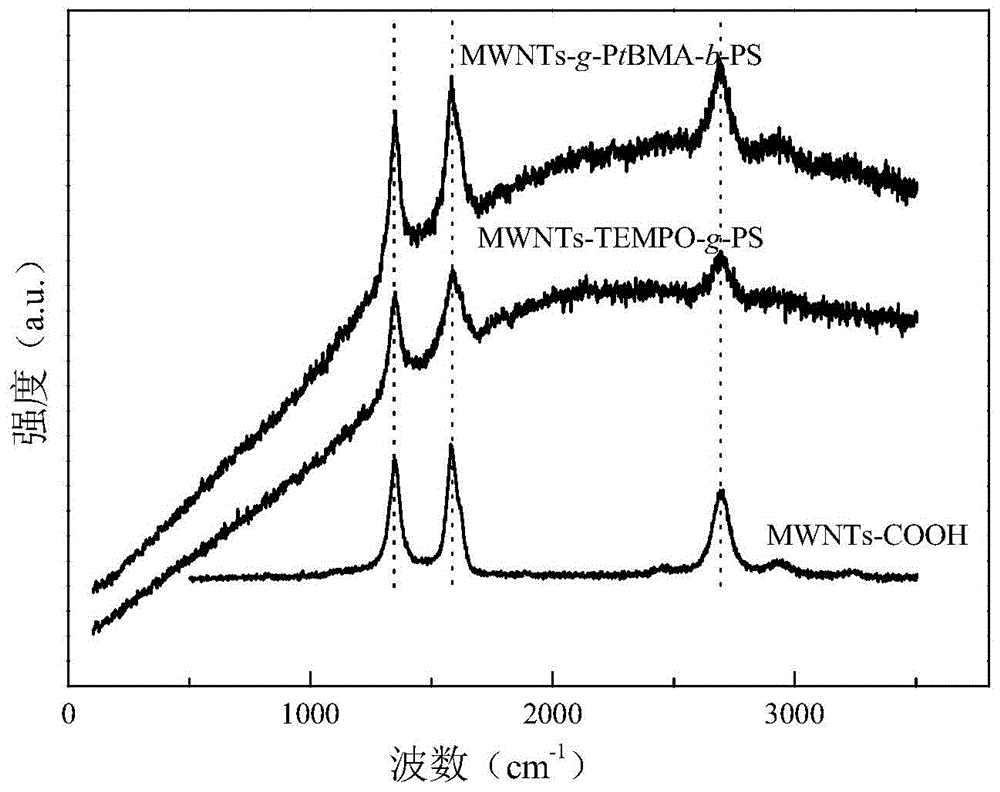

[0052] according to figure 1 The synthetic route of 2g carboxylated multi-walled carbon nanotubes (MWNTs-COOH), 25mL thionyl chloride (SOCl 2 ) into a 250mL single-necked round-bottomed flask, then dropwise added 0.2mL N,N-dimethylformamide, stirred in an ice bath for 0.5 hours, then stirred at 65°C for 24 hours, cooled, washed with tetrahydrofuran, and rotated Evaporation and vacuum drying at 50°C for 24 hours yielded 2.36 g of acyl chloride multi-walled carbon nanotubes (MWNTs-COCl).

[0053] Take 1.8g of acid chloride multi-walled carbon nanotubes (where the acid chloride group is 0.63mmol) and suspend and disperse them in 20mL of anhydrous tetrahydrofuran, add 0.43g (2.50mmol) of 4-hydroxy-2,2,6,6-tetramethylpiperene Pyridine-1-oxyl radical (TEMPO) and 2mL triethylamine were ultrasonically dispersed for 2 hours, then stirred and reacted at 60°C for 24 hours und...

Embodiment 2

[0062] The preparation method of multi-walled carbon nanotube grafted poly(styrene-tert-butyl methacrylate) copolymer and poly(styrene-tert-butyl methacrylate) copolymer in this example is the same as that of Example 1. In step 3 of Example 1, 0.25 g of carboxylated multi-walled carbon nanotubes was added into 3 mL of chloroform, ultrasonically dispersed for 2 hours with a 250 W, 45 kHz ultrasonic cleaner, and then 0.05 g of multi-walled carbon nanotubes were added to graft Poly(styrene-tert-butyl methacrylate) copolymer, 0.70g poly(styrene-tert-butyl methacrylate) copolymer were stirred at 60°C for 2 hours to obtain a uniformly dispersed black colloidal suspension, i.e. three Yuandong gas-sensitive sensing materials.

Embodiment 3

[0064] The preparation method of multi-walled carbon nanotube grafted poly(styrene-tert-butyl methacrylate) copolymer and poly(styrene-tert-butyl methacrylate) copolymer in this example is the same as that of Example 1. In step 3 of Example 1, 0.25 g of carboxylated multi-walled carbon nanotubes was added into 3 mL of chloroform, ultrasonically dispersed for 2 hours with a 250 W, 45 kHz ultrasonic cleaner, and then 0.10 g of multi-walled carbon nanotubes were added to graft Poly(styrene-tert-butyl methacrylate) copolymer, 0.65g poly(styrene-tert-butyl methacrylate) copolymer were stirred at 60°C for 2 hours to obtain a uniformly dispersed black colloidal suspension, i.e. three Yuandong gas-sensitive sensing materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com