Process method for preparing (methyl) tert-butyl acrylate through continuous method

A technology of tert-butyl acrylate and process method, which is applied to the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of complex procedures and low yield of tert-butyl acrylate, and achieve simple process steps , large social and economic benefits, and the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

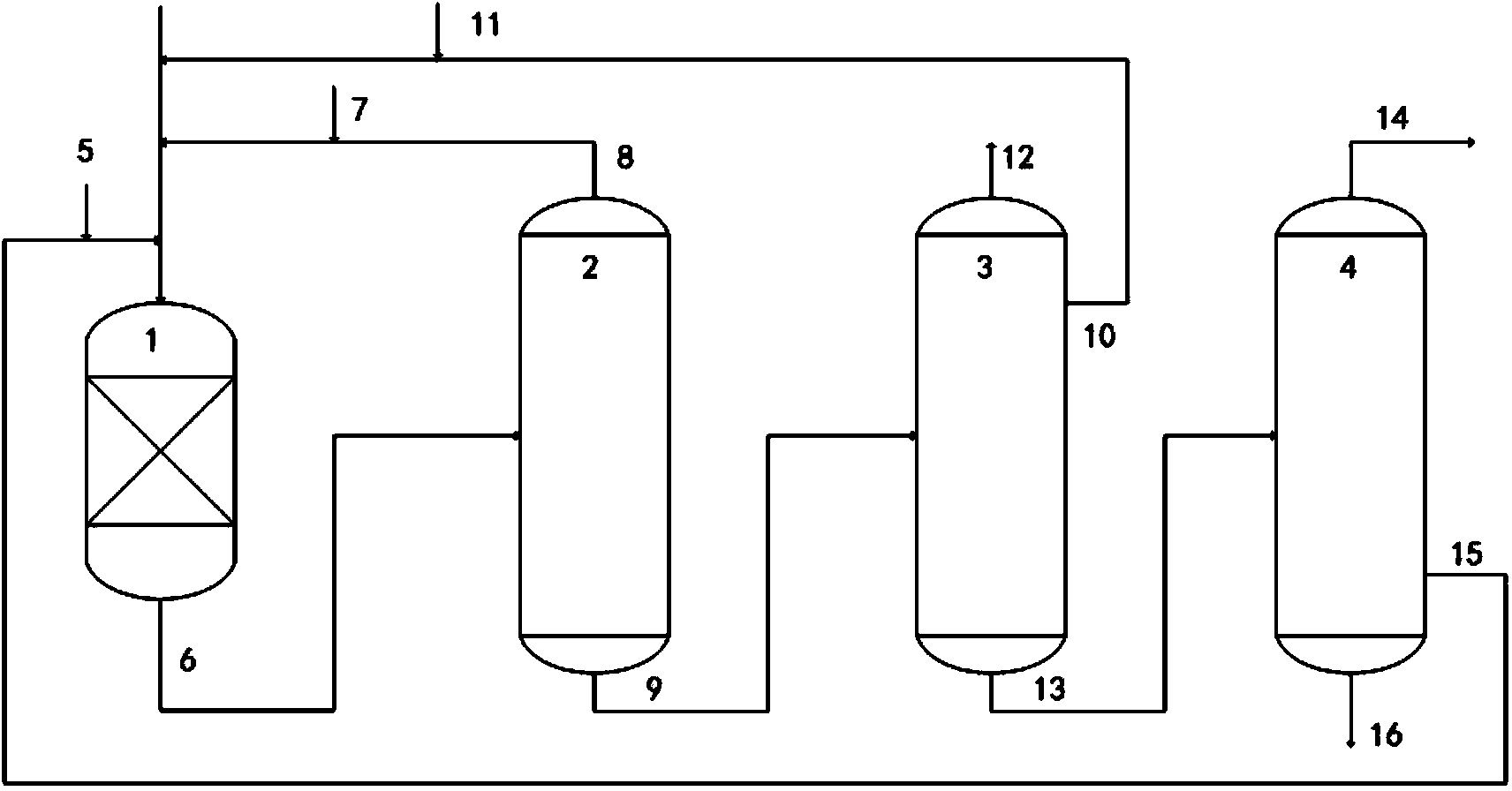

[0022] Methacrylic acid, tert-butanol and isobutylene are respectively passed through the first pipeline 5, the second pipeline 11, and the third pipeline 7 into the silica-supported phosphotungstovanadium heteropoly acid catalyst H 8 [P 2 W 16 V 2 O 62 ] / SiO 2 In the fixed bed reactor 1, the molar ratio of the controlled feed is 1: 0.1: 0.5, the pressure in the fixed bed reactor 1 is 0.15 MPa, the reaction temperature is 30 ℃, and the feed space velocity is 5 h -1 . The mixed reaction liquid enters the first distillation tower 2 through the seventh pipe 6 at the bottom of the fixed bed reactor 1. The first distillation tower is at atmospheric pressure and the temperature is 30°C. Isobutylene enters the fixed bed reactor 1 through the fourth pipe 8. Continue to participate in the esterification reaction. The high-boiling components tert-butanol, diisobutylene, (meth)acrylic acid and tert-butyl (meth)acrylate enter the second rectification tower 3 through the eighth pipe 9 to cont...

Embodiment 2

[0026] Methacrylic acid, tert-butanol and isobutylene are respectively passed through the first pipeline 5, the second pipeline 11, and the third pipeline 7 into the silica-supported phosphotungstovanadium heteropoly acid catalyst H 9 [P 2 W 15 V 3 O 62 ] / SiO 2 的fixed bed reactor 1. Control the feeding molar ratio of 1: 0.05: 0.7, maintain pressure 0.20MPa, reaction temperature 20℃, and feed space velocity of 7h -1 . The mixed reaction liquid enters the first rectification tower 2 through the seventh pipe 6 at the bottom of the fixed bed reactor 1. Under normal pressure, the temperature of the rectification tower is 30°C, and isobutylene enters the fixed bed reactor 1 through the fourth pipe 8 to continue to participate. In the esterification reaction, the high-boiling components tert-butanol, diisobutylene, (meth)acrylic acid and tert-butyl (meth)acrylate enter the second distillation tower 3 through the eighth pipe 9 to continue distillation, and the second distillation tower ...

Embodiment 3

[0031] Methacrylic acid, tert-butanol and isobutylene are respectively passed through the first pipeline 5, the second pipeline 11, and the third pipeline 7 into the silica-supported phosphotungstovanadium heteropoly acid catalyst H 6 [P 2 W 14 V 4 O 62 ] / SiO 2 的fixed bed reactor 1. Control the feeding molar ratio of 1: 0.15: 0.3, keep the pressure at 0.5 MPa, control the reaction temperature at 40°C, and feed the space velocity at 10 h -1 . The mixed reaction liquid enters the first rectification tower 2 through the seventh pipe 6 at the bottom of the fixed bed reactor 1. Under normal pressure, the temperature of the rectification tower is 30°C, and isobutylene enters the fixed bed reactor 1 through the fourth pipe 8 to continue to participate. In the esterification reaction, the high-boiling components tert-butanol, diisobutylene, (meth)acrylic acid and tert-butyl (meth)acrylate enter the second distillation tower 3 through the eighth pipe 9 to continue distillation, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com