Coating composition for protecting pattern layer for hydraulic transfer, decorated formed article and method for production thereof

A technology of hydraulic transfer printing and pattern layer, which is applied in the process of producing decorative surface effects, decorative arts, polyurea/polyurethane coatings, etc. It can achieve the effect of excellent pattern design, excellent film performance and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

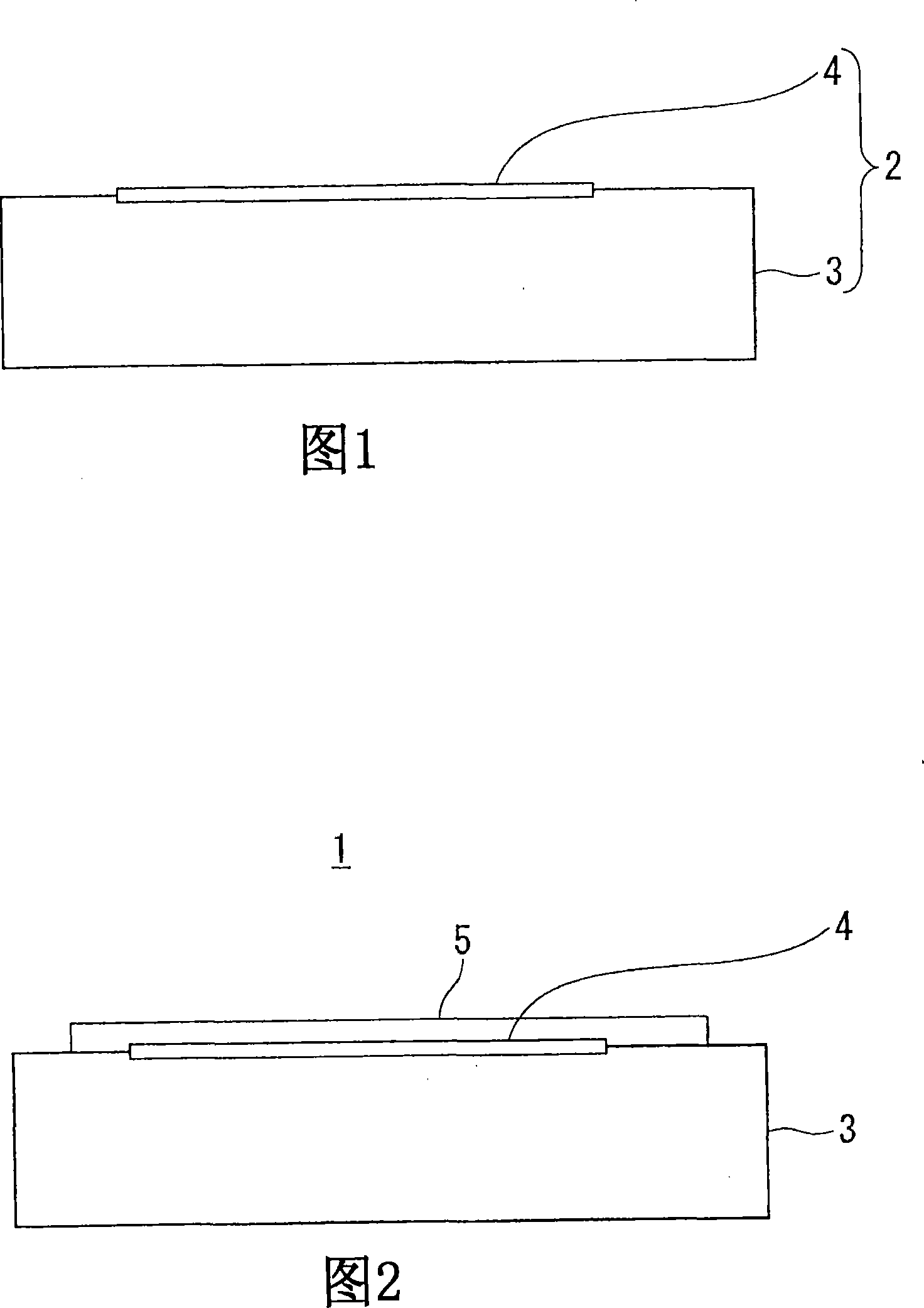

Image

Examples

Embodiment

[0118] Hereinafter, the present invention will be described by way of examples, but the present invention is not limited to these examples.

[0119] (Manufacture of hydroxyl-containing resin composition (P), Examples 1-2, Reference Examples 1-8)

[0120] In a four-necked flask with a volume of 1 liter equipped with a stirrer, a cooler, a thermometer, and a monomer instillation device, add the component (A) according to the composition shown in Table 1, and heat up to an internal temperature of 85°C while stirring. 85°C was maintained for 20 minutes. Then, component (B) was instilled over 2 hours, and after completion of instillation, component (C) was added and polymerized at 85° C. for 2 hours to obtain a solution of a hydroxyl group-containing resin composition (P). This solution was further diluted with toluene. It should be noted that in Table 1, the amount of each component is expressed in parts by weight.

[0121] To the solution obtained by diluting the obtained hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com