PH-responsive type magnetic composite microsphere with Janus structure, and preparation method thereof

A magnetic composite microsphere and responsive technology, which is applied in the field of composite materials and nanometers, can solve problems such as lack of environmental response performance, and achieve the effect of simple method and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Oleic acid modified Fe 3 o 4 Preparation of nanoparticles

[0030] 8.19g FeCl 3 ·6H 2 O and 4.35 g FeSO 4 ·7H 2 O was dissolved in 50mL of deionized water, and added to a three-necked flask equipped with a reflux condenser to deoxygenate with nitrogen for 30 minutes; 5.31g of NaOH was dissolved in 10mL of deionized water, and then slowly added to the three-necked flask, reacted at 70°C for 1 hour, and then added to prepare 10mL mixed solution of oleic acid and ethanol (oleic acid:ethanol = 1:1), heated to 80°C and matured for 1h, to obtain magnetic Fe with a size of 2-10nm and superparamagnetism 3 o 4 nanoparticles. Modification of oleic acid to Fe 3 o 4 The nanoparticles were washed three times with 10 mL of ethanol and deionized water to neutrality, and dried for later use.

[0031] (2) Preparation of magnetic fluid

[0032] Take 0.5g oleic acid modified Fe 3 o 4 Nanoparticles were dissolved in 0.5 mL of n-octane, ultrasonicated for 10 min, then 2 mL ...

Embodiment 2~4

[0038] With embodiment 1 technique, change Fe in (2) 3 o 4 The feeding materials are 0.1g, 0.3g, 0.7g respectively.

Embodiment 5~8

[0040] With the process of Example 1, change the content of trifluoroacetic acid in (4) to 0.2mL, 0.3mL, 0.4mL, 0.6mL respectively.

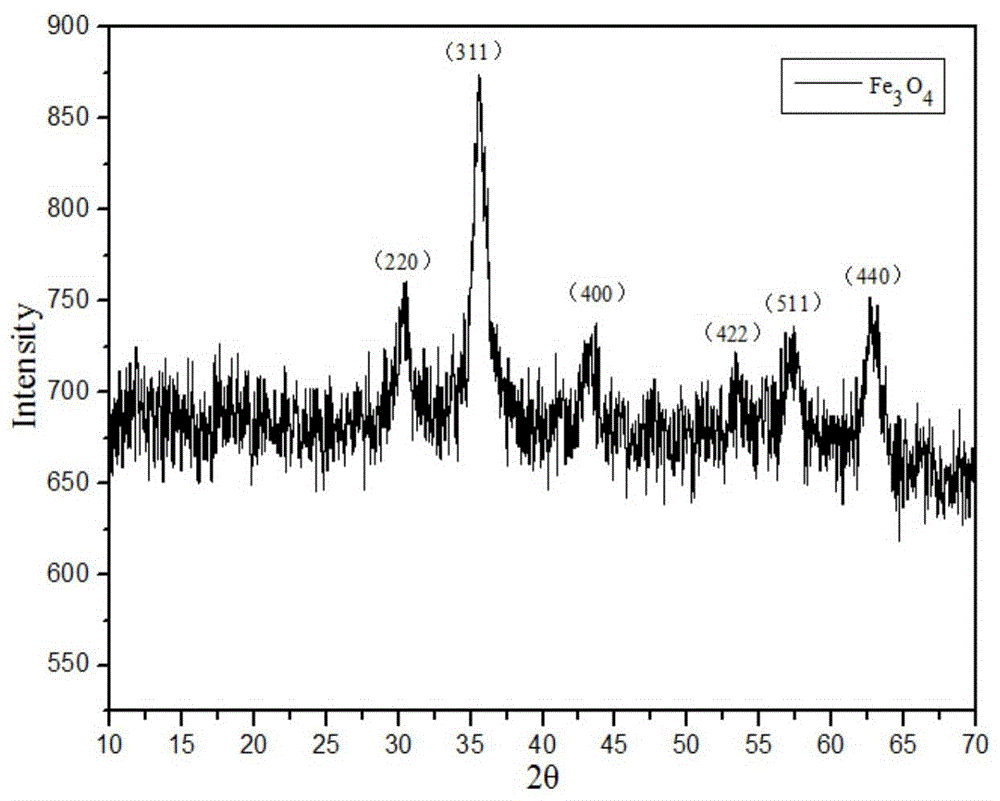

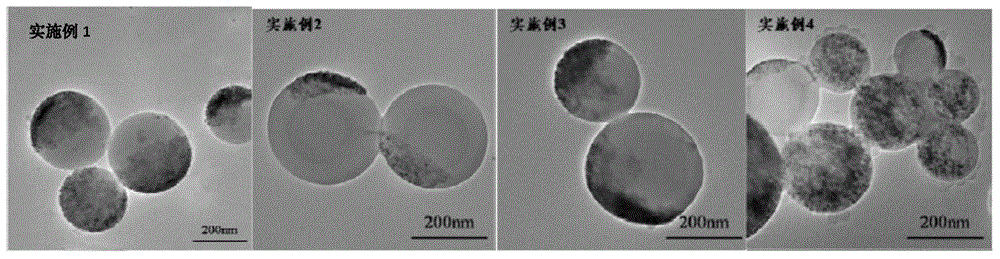

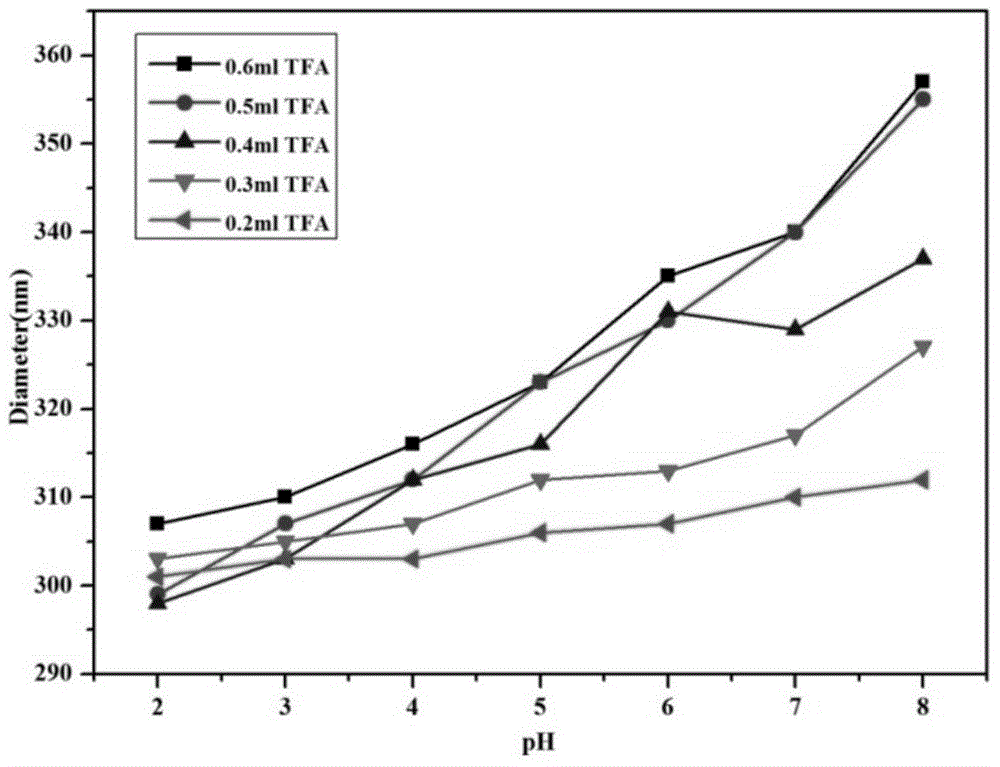

[0041] The obtained oleic acid modified Fe 3 o 4 The nanoparticles were characterized by XRD ( figure 1 shown), the structure of the obtained pH-responsive magnetic composite microspheres with Janus structure was characterized by transmission electron microscopy ( figure 2 As shown), it can be observed that the prepared microspheres have obvious Janus structure and core-shell structure, and the particle size is about 300-500nm. Among them, the core layer is polystyrene, the shell layer is polymethacrylic acid, Fe 3 o 4 The nanoparticles segregate inside the microspheres. From image 3 It can be observed that when the pH value is changed, the particle size of the microspheres changes, showing pH responsiveness.

[0042] The present invention utilizes emulsion polymerization to prepare a kind of magnetic composite microsphere (Fe 3 o 4 —...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com