Method for forming multilayer coating film

A multi-layer coating and coating technology, which is applied to devices, coatings, conductive coatings and other directions for coating liquids on the surface. It can solve the problems of inability to ensure quality requirements, and achieve the effects of excellent appearance and excellent low temperature impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0149] The invention will now be elucidated in more detail by using working examples, without being limited thereto. In the working examples, the term "part" means "part by mass", and the use of the symbol "%" in relation to the mixing amount and content value means "% by mass" unless otherwise clearly stated.

[0150] The non-chlorinated polyolefin resin aqueous dispersion used in the present invention is prepared using the following three-step method.

[0151] (i) The first step: preparation of non-chlorinated polyolefin resin

[0152] 110 mL of deionized water, 22.2 g of magnesium sulfate heptahydrate, and 18.2 g of sulfuric acid were placed in a 1000 mL round bottom flask and dissolved with stirring. 16.7 g of commercially available granular montmorillonite was dispersed in the solution, heated to 100° C. and stirred for 2 hours. The dispersion was then cooled to room temperature and the resulting slurry was filtered to recover a wet cake. The recovered filter cake wa...

preparation Embodiment 2

[0160]

[0161] Aqueous primer composition WP-1 was prepared by mixing 1.66 parts of conductive carbon black "Printex XE2B" (manufactured by Degussa), 12.55 parts of titanium dioxide "JR600-E" (manufactured by Tayca Corp.) and 0.93 parts of pigment dispersant "Disperbyk 191" (produced by BYK Chemie, solid content 98%, acid value 31 mg KOH / g, amine value 20 mgKOH / g) was added to 26.5 parts of polyurethane resin "Impranil DLU" (produced by Covestro Japan Ltd., solid Resin content is 60%, Tg is -83 ℃, elongation is 800%), disperse these components by means of a disperser, add 21.0 parts of non-chlorinated polyolefin resin aqueous dispersion P-1, 1.5 parts of curing agent "DURANATE WM4 4-L70G" (a water-dispersible blocked polyisocyanate compound produced by Asahi Kasei Chemicals Corporation with a solid resin content of 70%), 33.96 parts of deionized water, 0.8 parts of leveling agent "BYK-348" (produced by BYK Chemie) and 1.1 parts of thickener "Rheovis AS S130" (manufactured b...

preparation Embodiment 3

[0162]

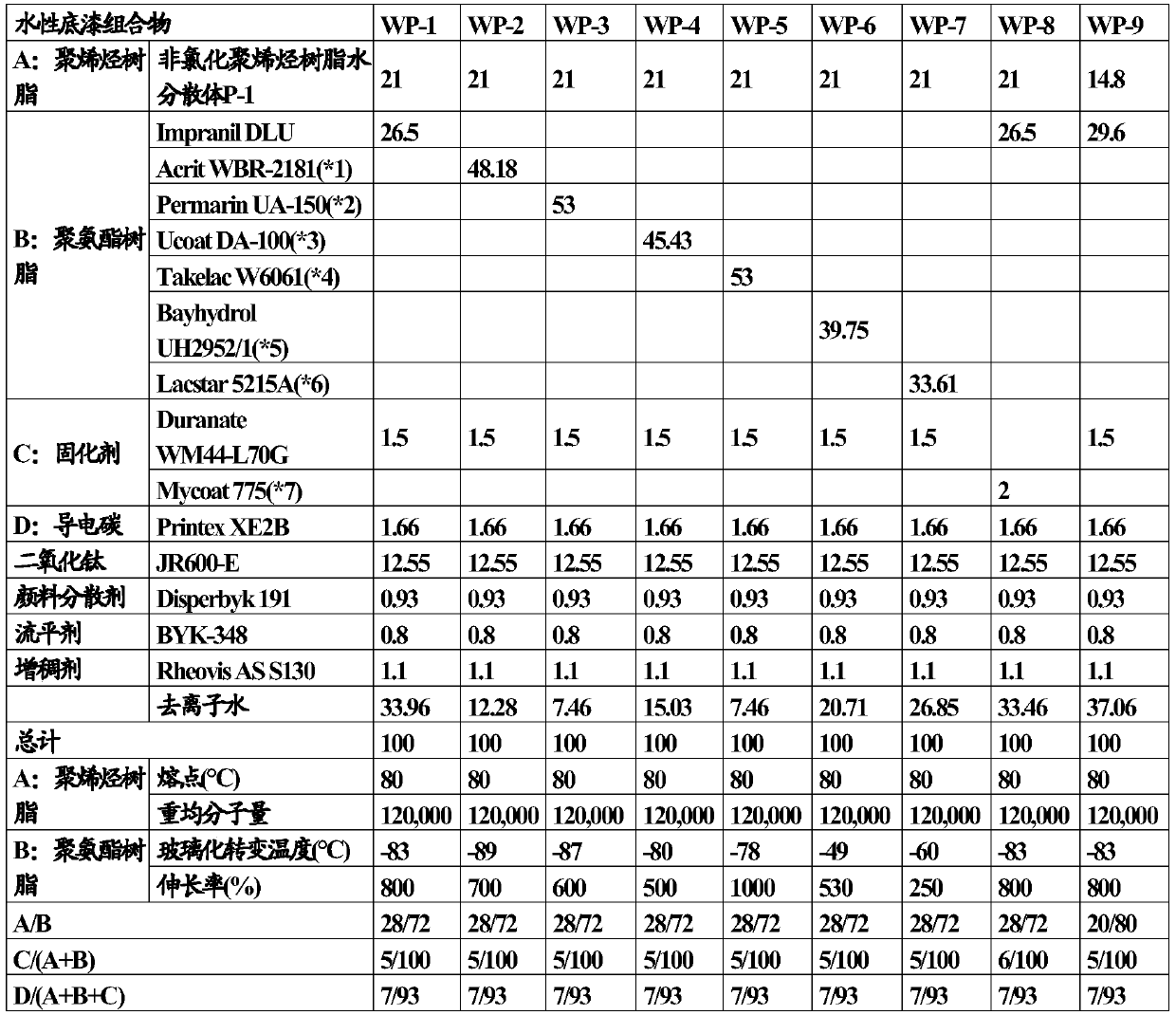

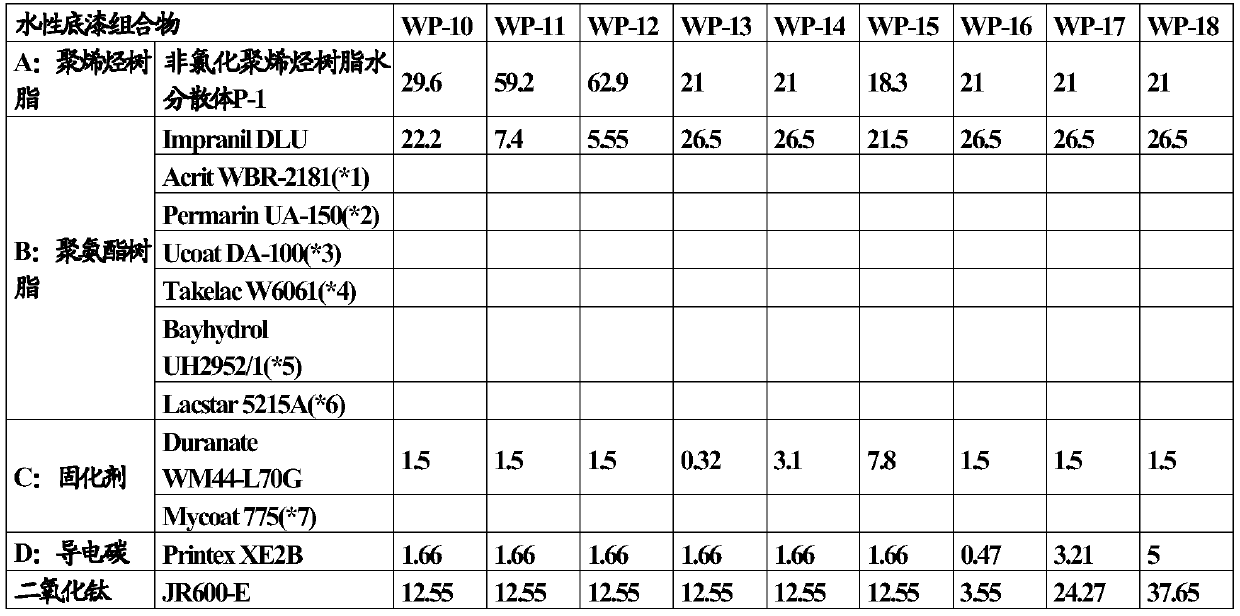

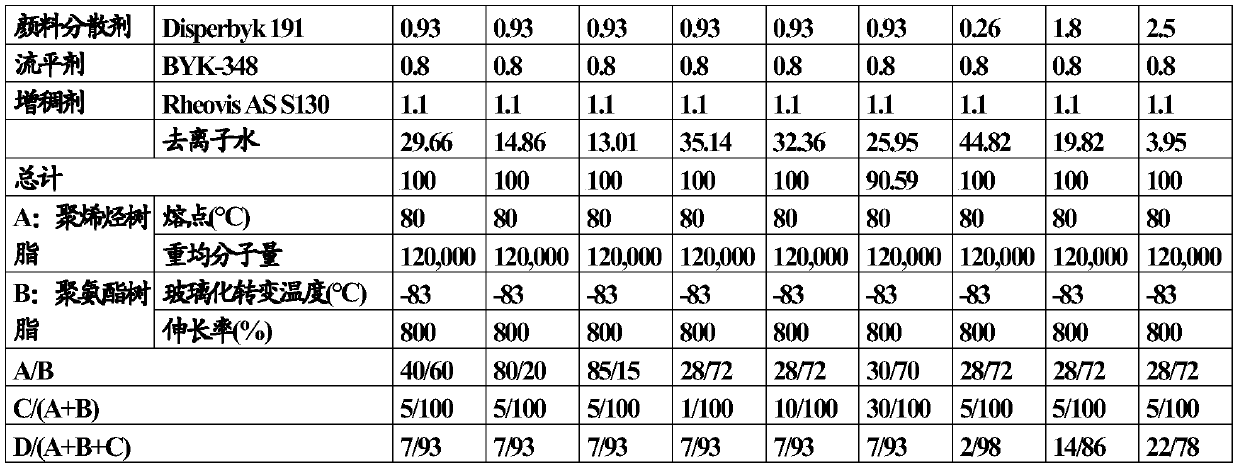

[0163] Using the same method as used in Preparation Example 2, water-based primer compositions WP-2 to WP-18 were obtained based on the formulations shown in Table 1.

[0164] [Table 1]

[0165] Table 1-1

[0166]

[0167] Table 1-2

[0168]

[0169]

[0170] Details of the mixing components shown in Table 1 are as follows.

[0171] (*1) Acrit WBR-2181 (manufactured by Taisei Fine Chemical Co., Ltd., solid resin content 33%, Tg -89°C, elongation 700%)

[0172] (*2) Permarin UA-150 (manufactured by Sanyo Chemical Industries, Ltd., solid resin content 30%, Tg -87°C, elongation 600%)

[0173] (*3) Ucoat DA-100 (produced by Sanyo Chemical Industries, Ltd., solid resin content of 35%, Tg of -80°C, elongation of 500%)

[0174] (*4) Takelac W6061 (manufactured by Mitsui Chemicals, Inc., 30% solid resin content, -78°C Tg, 1000% elongation)

[0175] (*5) Bayhydrol UH2952 / 1 (manufactured by Covestro Japan Ltd., solid resin content 40%, Tg -49°C, elongation 530%) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com