Bus-system LED display system point-by-point fault detection method and application thereof

A technology for display systems and LED lamps, applied in general control systems, control/adjustment systems, test/monitoring control systems, etc., can solve problems such as lack of color, lack of emergency treatment mechanisms, and flickering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

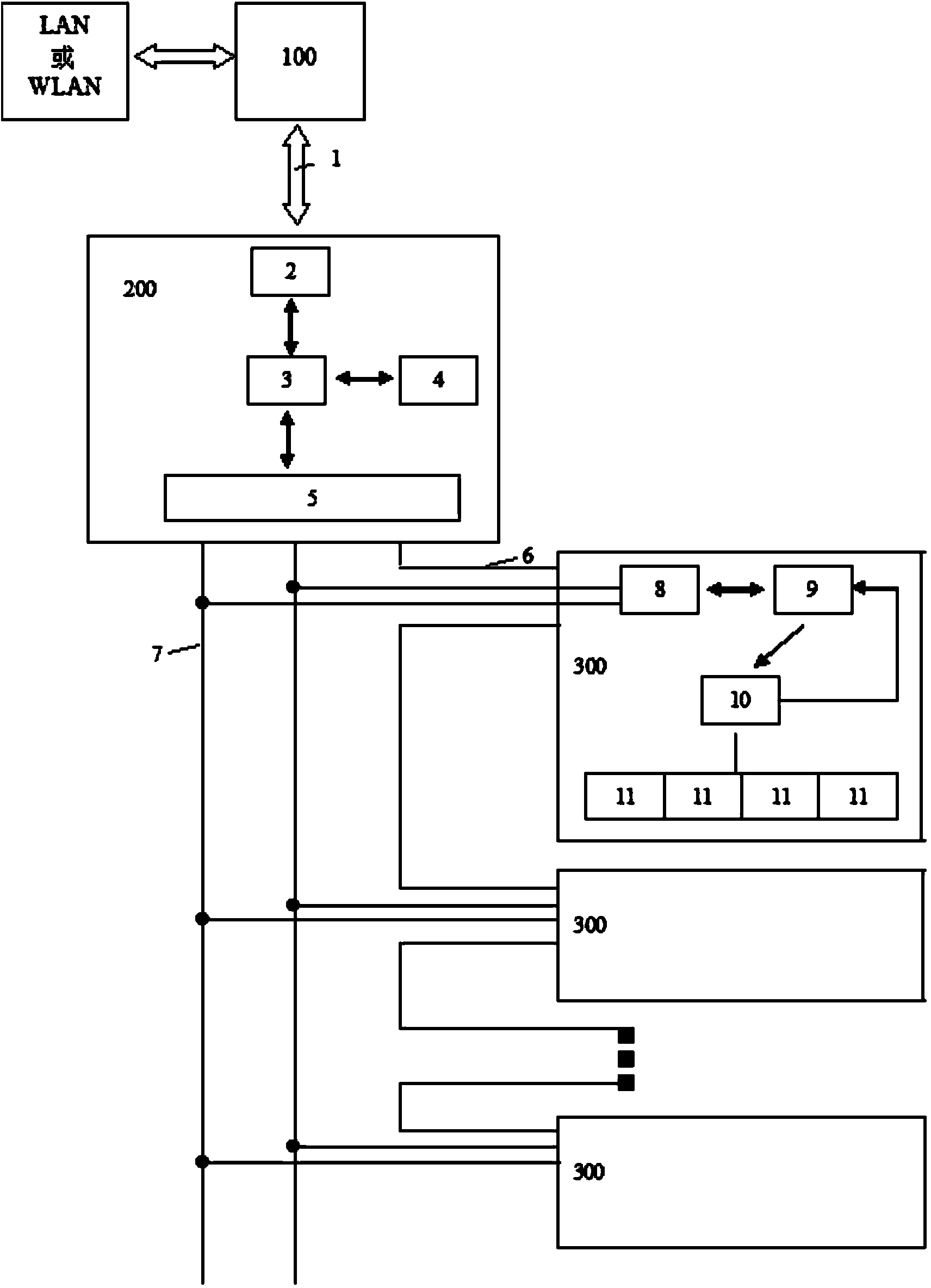

[0032] A point-by-point fault detection method for a bus-based LED display system, which is based on a parallel-based bus-based LED lighting control system. Such as figure 1 As shown: the LED lighting control system based on the parallel basis is composed of a host computer 100, an LED controller 200 and a number of LED lamps 300 controlled in parallel by the LED controller 200; Connected with the upper computer 100, the LED controller 200 consists of a TCP / IP communication module 2 (such as DM9000AEP, DM9008AEP, etc.), a central processing unit 3 (such as NUC130LE, SAM7S256, SAM7S64, etc.), an information storage module 4 (such as IS61LV5128, IS61LV2568, etc. ) and a first communication module 5 (such as MAX1487, MC3487, SN75176, MC3486, etc.); the LED lamp 300 is composed of a second communication module 8 (such as 6N137, SN75176, MAX1487, etc.) processor and data storage module 9 (such as 51 series , STC11F02 series, STC15W202 series, etc.), display monitoring module 10 (s...

Embodiment 2

[0039] This embodiment 2 is the application on the basis of the method of embodiment 1, and it further performs the following steps after step A4:

[0040] The fault point information is uploaded to the host computer 100 through the TCP / IP communication module 2, and the fault report is formed by the host computer 100, and transmitted to the end user through LAN or WLAN. In this way, the user can obtain the fault information in a very timely manner, and know the fault location accurately, which is conducive to timely repair and other processing.

Embodiment 3

[0042] This embodiment 3 is the application on the basis of the method of embodiment 1, and it is to further perform the following steps after step A4:

[0043] When the image is displayed, the central processing unit 3 transfers each frame of image data into the memory, reads the stored fault point information of the information storage module 4 at the same time, modifies the image data according to the fault point information, modifies the fault point position data to a black signal value, and modifies The final image information is output to the display module 11 for display through the first communication module 5, communication bus 7, second communication module 8, processor and data storage module 9, and display monitoring module 10, so that the black signal of the fault point is displayed, thereby realizing fault Click shield.

[0044] The application method in the above-mentioned embodiment 3 is an emergency treatment method, and this application can also be used in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com