Spherical shape gauge for bevel planet gear

A bevel gear and planetary technology, which is applied in the field of planetary bevel gear spherical shape inspection tools, can solve the problems that the contact area between the planetary bevel gear and the mating surface cannot be less, the contact area cannot truly reflect the actual matching situation, and the lack of central axis positioning structure, etc. , to achieve the effect of simple operation, simple shaft positioning structure and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

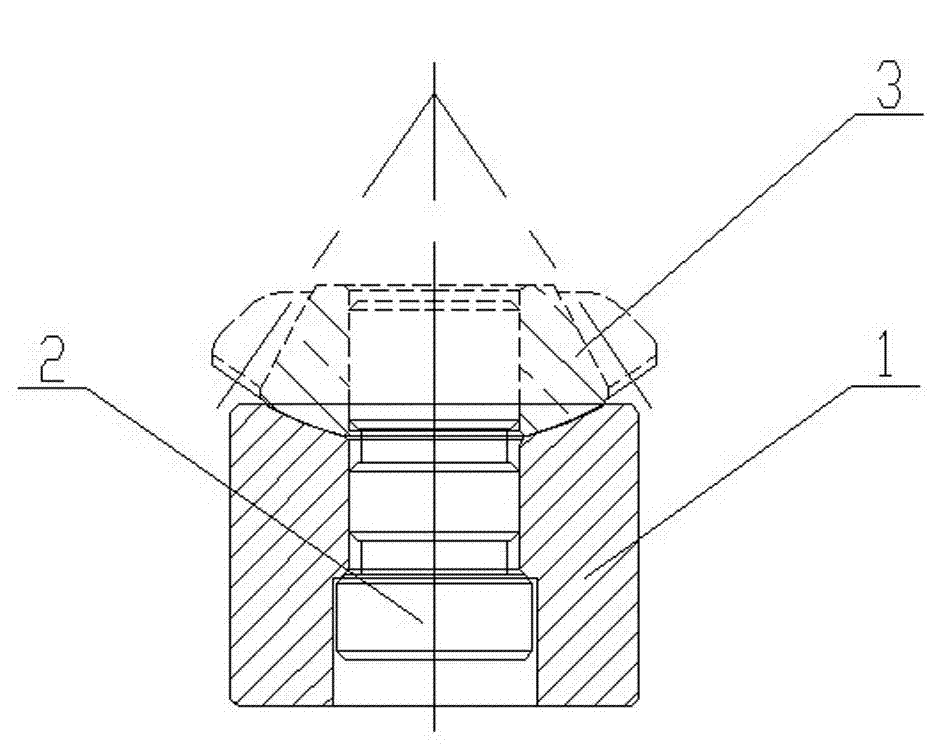

[0013] figure 1 The planetary bevel gear spherical shape inspection tool shown is composed of a die 1 and a mandrel 2. The die 1 is provided with three concentric cavities in the axial direction, the top surface is a spherical cavity, the bottom surface is a process hole, and the axial through hole in the middle runs through the spherical cavity and the process hole. In this embodiment, the workpiece 3 to be inspected is a planetary bevel gear with a spherical radius of SR41.6 mm, so the die 1 with a spherical cavity size of SR41.6 mm is selected. The mandrel 2 is a cylindrical shaft, which is a three-section joint shaft with a large bottom and a small top. The middle section is positioned in conjunction with the axial through hole of the die 1, and the top section is exposed from the spherical cavity of the die 1. The workpiece to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com