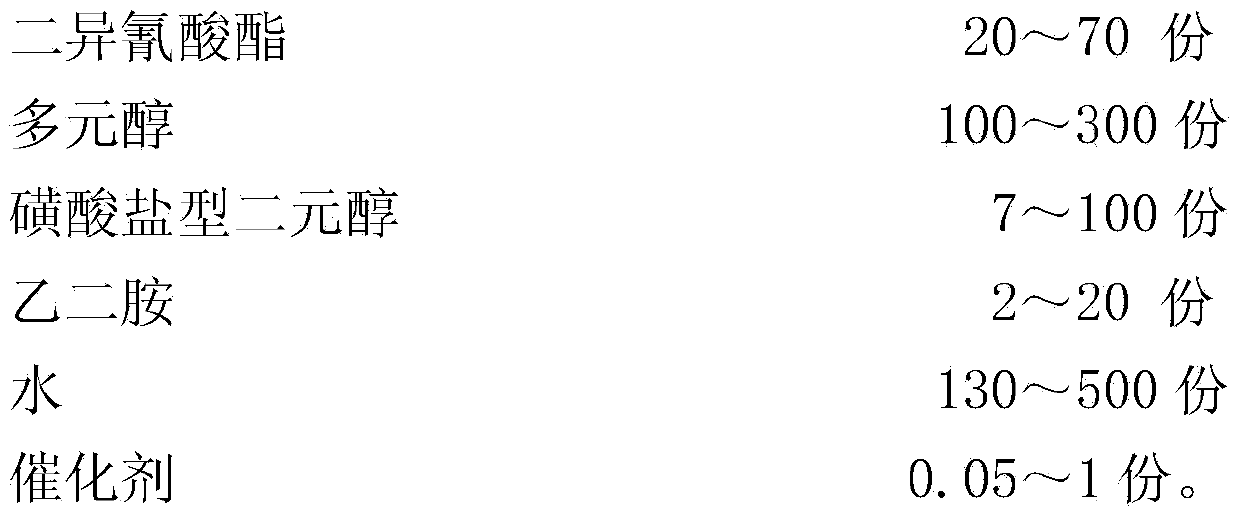

Sulfonate type water-based polyurethane emulsion and preparation method thereof

A water-based polyurethane and sulfonate-based technology, applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, adhesive types, etc., can solve the irritating odor of residual triethylamine and the stability of water-based polyurethane emulsion Reduce the problem of environmental protection, improve mechanical properties and heat resistance, and achieve the effect of high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

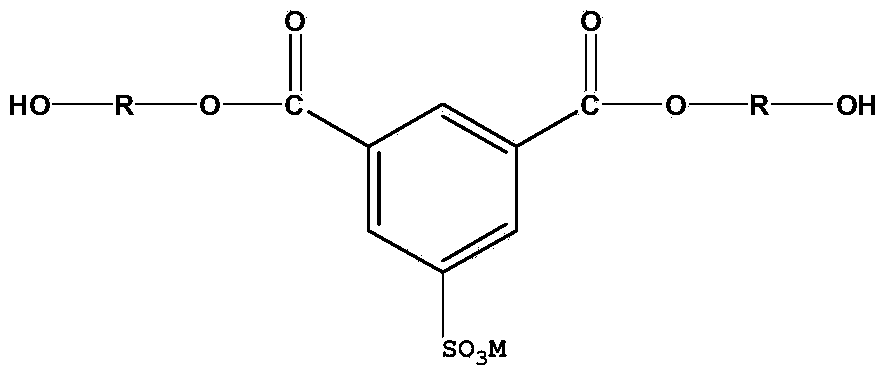

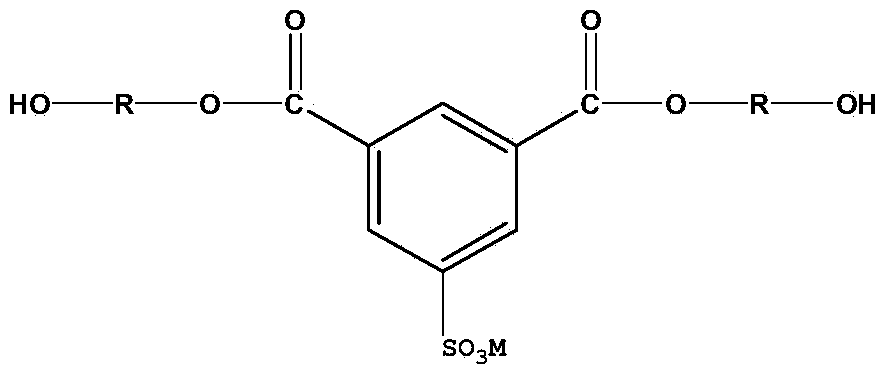

[0044] Synthesis of Diethylene Glycol Isophthalate-5-Sodium Sulfonate:

[0045] Under the condition of heating and mechanical stirring, 0.05mol dimethyl isophthalate-5-sodium sulfonate, 0.4mol ethylene glycol and 0.5wt% monobutyltin oxide are added in the there-necked flask equipped with a fractionation device, Under the protection of nitrogen atmosphere, the temperature was slowly raised to 180° C., and the reaction was carried out at this temperature for 7 hours. When there is no distillate from the fractionating head, replace the vacuum distillation device and continue the reaction at 220°C for 30 minutes. Cool down to room temperature and discharge to obtain a transparent liquid.

[0046] Synthesis of waterborne polyurethane emulsion:

[0047] (1) Add 17.6 parts by mass of diethylene glycol isophthalate-5-sodium sulfonate to a four-necked flask equipped with a reflux condenser, a thermometer, a stirrer and a nitrogen conduit, at a temperature of 80°C Dry and dehydrate u...

Embodiment 2

[0052] Synthesis of diethylene glycol isophthalate-5-sodium sulfonate:

[0053] Under the conditions of heating and mechanical stirring, add 0.05mol dimethyl isophthalate-5-sodium sulfonate, 0.3mol diethylene glycol and 0.6wt% monobutyltin oxide into a three-necked flask equipped with a fractionation device , under the protection of a nitrogen atmosphere, the temperature was slowly raised to 230° C., and the reaction was carried out at this temperature for 3 hours. When there is no distillate from the fractionating head, replace the vacuum distillation device and continue the reaction at 230°C for 30 minutes. Cool down to room temperature and discharge to obtain a transparent liquid.

[0054] Synthesis of waterborne polyurethane emulsion:

[0055] (1) Add 22.2 parts by mass of diethylene glycol isophthalate-5-sodium sulfonate in a four-necked flask equipped with a reflux condenser, a thermometer, a stirrer and a nitrogen conduit, and Vacuum drying and dehydration at a tempe...

Embodiment 3

[0060] Synthesis of Diethylene Glycol Isophthalate-5-Sodium Sulfonate:

[0061] Under the condition of heating and mechanical stirring, 0.05mol dimethyl isophthalate-5-sodium sulfonate, 0.2mol triethylene glycol and 0.7wt% zinc acetate are added in a three-necked flask equipped with a fractionation device. Under the protection of nitrogen atmosphere, the temperature was slowly raised to 230° C., and the reaction was carried out at this temperature for 3 hours. When there is no distillate from the fractionating head, replace the vacuum distillation device and continue the reaction at 230°C for 30 minutes. Cool down to room temperature and discharge to obtain a transparent liquid.

[0062] Synthesis of waterborne polyurethane emulsion:

[0063] (1) Add 26.6 parts by mass of diethylene glycol isophthalate-5-sodium sulfonate in a four-necked flask equipped with a reflux condenser, a thermometer, a stirrer and a nitrogen conduit, and at 110 Vacuum drying and dehydration at a tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage stability | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com