Fur brightener composition and preparation method and application thereof

A technology of brightener and composition, applied in the field of fur brightener composition and preparation thereof, can solve problems such as poor comprehensive performance of brightener and unstable emulsification system, and achieve the effects of good gloss and good antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 fur brightener composition preparation

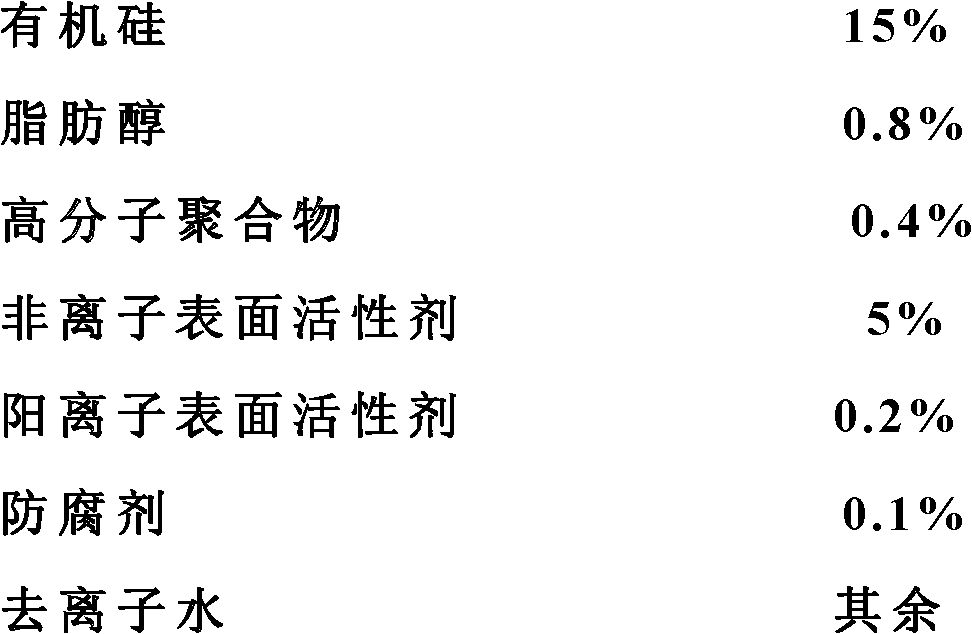

[0047] The fur brightener composition is calculated by weight percentage, and the composition and content of each raw material in the fur brightener are as follows:

[0048]

[0049]The organosilicon is polydimethylsiloxane;

[0050] Described fatty alcohol is cetyl / stearyl alcohol;

[0051] The high molecular polymer is hydroxyethyl cellulose;

[0052] Described nonionic surfactant is fatty acid polyoxyethylene ether;

[0053] The cationic surfactant is octadecyltrimethylammonium chloride.

[0054] The preparation method of above-mentioned a kind of fur brightening agent, comprises the steps:

[0055] (1) Add silicone and fatty alcohol into the oil phase pot, mix and heat to 40-90°C, and stir evenly;

[0056] (2) Add deionized water into the water phase pot, add polymer, nonionic surfactant and cationic surfactant, mix and heat to 40-90°C, and stir evenly;

[0057] (3) Add the oil phase components into the ...

Embodiment 2

[0061] Embodiment 2 fur brightener composition preparation

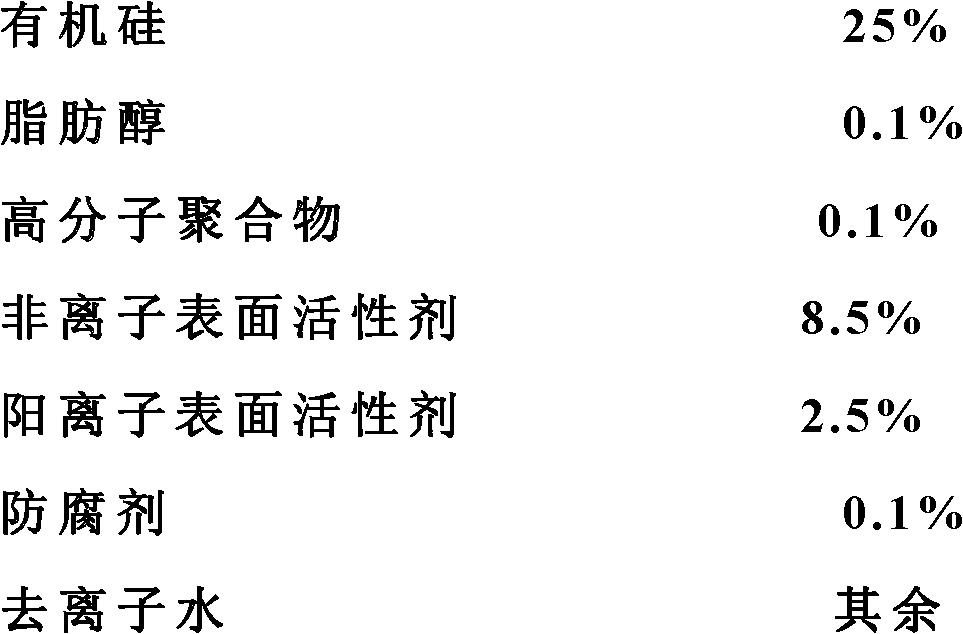

[0062] The fur brightening agent composition, calculated by weight percentage, the composition and content of each raw material in the described fur brightening agent are as follows:

[0063]

[0064] The organosilicon is polydimethylsiloxane and amino-modified silicone;

[0065] Described fatty alcohol is cetyl / stearyl alcohol;

[0066] The high molecular polymer is hydroxyethyl cellulose;

[0067] Described nonionic surfactant is fatty acid polyoxyethylene ether and polyoxyethylene polyol ester;

[0068] The cationic surfactant is cetyltrimethylammonium chloride.

[0069] The preparation method of above-mentioned a kind of fur brightening agent, comprises the steps:

[0070] (1) Add silicone and fatty alcohol into the oil phase pot, mix and heat to 40-90°C, and stir evenly;

[0071] (2) Add deionized water into the water phase pot, add polymer, nonionic surfactant and cationic surfactant, mix and heat to 40...

Embodiment 3

[0077] Example 3 Preparation of fur brightener composition

[0078] The fur brightener composition is calculated by weight percentage, and the composition and content of each raw material in the fur brightener are as follows:

[0079]

[0080] The organosilicon is polydimethylsiloxane and amino-modified silicone;

[0081] Described fatty alcohol is cetyl / stearyl alcohol and Virahol;

[0082] The high molecular polymer is hydroxyethyl cellulose;

[0083] Described nonionic surfactant is fatty acid polyoxyethylene ether;

[0084] Described anionic surfactant is fatty alcohol polyoxyethylene ether sodium sulfate;

[0085] The preparation method of above-mentioned a kind of fur brightening agent, comprises the steps:

[0086] (1) Add silicone and fatty alcohol into the oil phase pot, mix and heat to 40-90°C, and stir evenly;

[0087] (2) Add deionized water into the water phase pot, add polymer, nonionic surfactant and anionic surfactant, mix and heat to 40-90°C, and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com