Waterproof, grease proof treating compound of fluorine silicon modified polyurethane, and preparation method

A technology of polyurethane waterproofing and fluorosilicon modification, which is applied in fiber treatment, leather surface treatment, small raw hide/big raw hide/leather/fur treatment, etc. It can solve the problems of high cost, uneconomical transportation and storage, and save costs , Novel preparation method, good mechanical stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

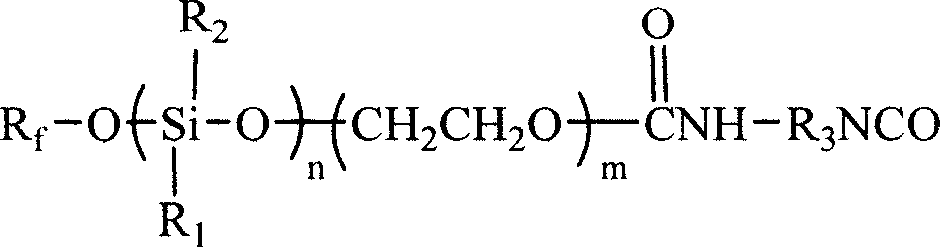

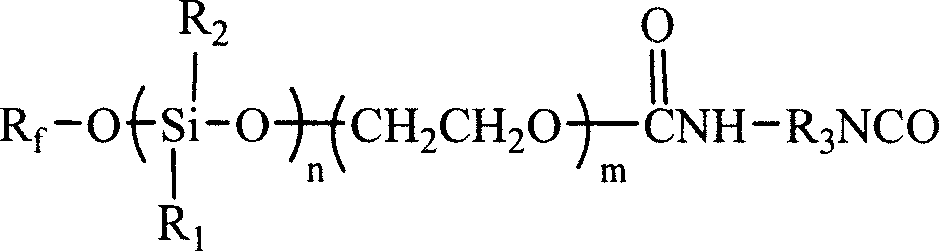

[0024] The preparation method of fluorosilicon modified polyurethane emulsion of the present invention is as follows:

[0025] The first step reaction: add perfluoroalkene to hydroxysilicone oil with a metering pump (the molar ratio of perfluoroalkene to hydroxysilicone oil is 1:0.5~1.2) within 1-2 hours, and keep stirring to control the temperature at 40- 50°C, and then heat preservation reaction for 3-5 hours to obtain perfluorosiloxane by liquid separation and purification.

[0026] The second step reaction: Add perfluorosiloxane and NaOH solution into the reaction kettle, control the vacuum degree below 13.5KPa, heat to 100°C-130°C to make it dehydrated. Replace with nitrogen three times. Then raise the temperature to 120-160°C, under the pressure of 0.1-0.4MPa, stir and add 2-10 times the amount of ethylene oxide of perfluorosiloxane substance. The temperature is controlled at 80-120°C, and the reaction is 2-5 hours. Obtain perfluoropolyether silicone oil.

[0027] The...

Embodiment 1

[0043] The first step reaction: the hexafluoropropylene trimer (C 9 f 18) with a metering pump to add the same amount of hydroxy silicone oil, within 1.5 hours, and keep stirring to control the temperature at 40 ° C, and then keep warm for 4.5 hours to separate and purify perfluorosiloxane.

[0044] The second step reaction: add perfluorosiloxane and 0.4% by mass of 30% NaOH solution into the reaction kettle, control the vacuum degree below 13.5KPa, heat to 120°C to dehydrate. Replace with nitrogen three times. Then the temperature is raised to 140°C, under the pressure of 0.2MPa, stir and add 4 times the amount of perfluorosiloxane substance ethylene oxide, the temperature is controlled at 100°C, and the reaction is carried out for 2 to 5 hours.

[0045] The third step reaction: use acetone as solvent with perfluoropolyether silicone oil and equal amount of diisocyanate, add 0.1‰ quality of dibutyltin dilaurate as catalyst in N 2 Under protection, react at a temperature of...

Embodiment 2

[0047] The first step reaction: tetrafluoroethylene tetramer (C 8 f 16 ) with a metering pump to add 1.2 times the amount of the substance into the hydroxyl silicone oil, and complete the addition within 1.5 hours, and keep stirring to control the temperature at 40°C, and then keep warm for 4.5 hours to separate and purify the perfluorosiloxane.

[0048] The second step reaction: add perfluorosiloxane and 0.4% by mass of 30% NaOH solution into the reaction kettle, control the vacuum degree below 13.5KPa, heat to 120°C to dehydrate. Replace with nitrogen three times. Then the temperature is raised to 140°C, under the pressure of 0.2MPa, stir and add 4 times the amount of perfluorosiloxane substance ethylene oxide, the temperature is controlled at 100°C, and the reaction is carried out for 2 to 5 hours.

[0049] The third step reaction: perfluoropolyether silicone oil and 1.2 times the amount of diisocyanate in acetone as a solvent, adding 0.2‰ of dibutyltin dilaurate as a cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com