Polysiloxane-modified gelatin leather finishing agent and preparation method thereof

A technology of epoxy polysiloxane and leather finishing agent, applied in leather surface treatment, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve many problems Difficult gelatin performance changes, poor film-forming properties, strong water absorption, etc., to achieve the effects of good thermal stability and air permeability, low surface tension, and strong oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

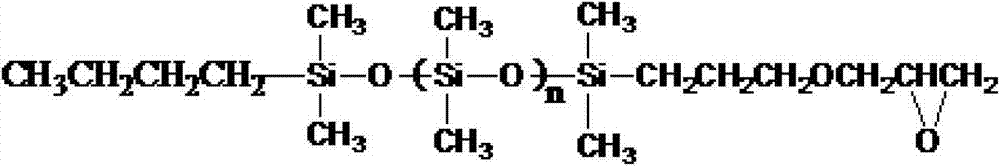

[0038] Add 12 grams of gelatin (accounting for 11.76% of the total mass) and 85 grams of deionized water into a three-neck reaction flask equipped with a thermometer socket, a sampling port, and a condenser socket, stir and heat to 50°C, and after the gelatin is completely dissolved, add 0.25 mL3 mol / liter of sodium hydroxide, adjust the reaction pH to 10.0, add 5.0g sodium dodecyl sulfate, sodium dodecylbenzenesulfonate and sorbitol mixed surfactant as emulsifier (accounting for 4.90% of the total mass ), of which sodium lauryl sulfate is 55% (w / w), sodium dodecylbenzenesulfonate is 20% (w / w), and sorbitol is 25% (w / w); continue stirring until ten After dialkyl sodium sulfate is completely dissolved, add epoxy polysiloxane (M w =1000), the reaction starts, and the content of primary amino groups in the system does not change after 24 hours of reaction, so stop stirring and heating.

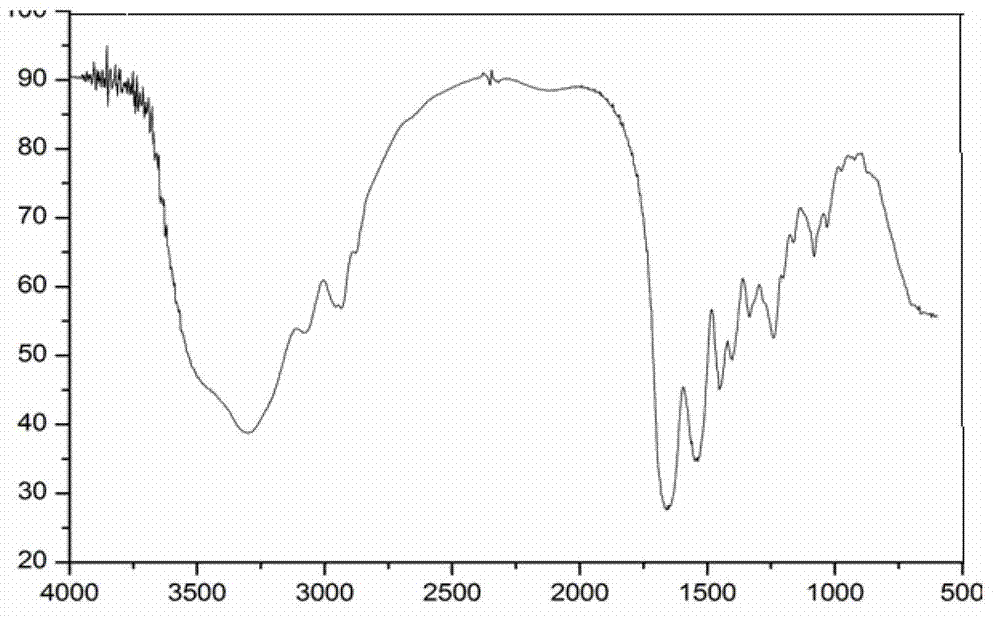

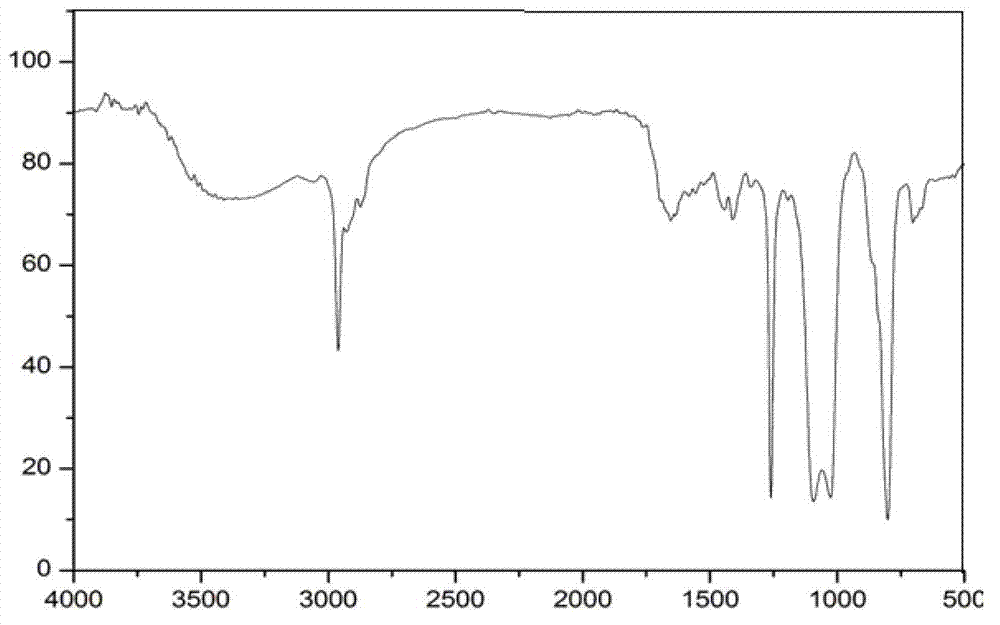

[0039] The infrared spectrogram of epoxy polysiloxane modified gelatin ( figure 2 ) appear...

Embodiment 2

[0042] Described method is consistent with embodiment 1, only difference is that tensio-active agent is replaced by sodium dodecyl sulfonate, sodium dodecylbenzene sulfonate and sorbitol mixed surfactant, wherein sodium dodecyl sulfonate is 55% (w / w), Sodium Dodecyl Benzene Sulfonate 20% (w / w), Sorbitol 25% (w / w).

[0043]The viscosity of the above-mentioned feed liquid is 580 centipoise (50°C), placed at room temperature for 48 hours to form a film, and dried at 60°C for 6 hours to further remove moisture and form a film with toughness. The Tg of the raw gelatin film is 215.7°C, and the Tg of the modified gelatin film is reduced by 15°C; NMR shows that the γ-C signal on the lysine and arginine molecules disappears, and the peak of silicone Si-C forms; XPS shows that the N The chemical shift shifted to 399.87, indicating C–N formation. The dissolution rate of the product in deionized water is 30-80% (the specific effect is affected by the length of the alkyl chain). The stri...

Embodiment 3

[0045] Described method is consistent with embodiment 1, and only difference is that tensio-active agent is changed into sodium lauryl sulfate and sodium dodecylbenzenesulfonate mixed surfactant, wherein sodium lauryl sulfate is 75% (w / w), sodium dodecylbenzenesulfonate is 25% (w / w).

[0046] The viscosity of the above-mentioned feed liquid is 660 centipoise (50°C), placed at room temperature for 48 hours to form a film, and dried at 60°C for 6 hours to further remove moisture and form a film with high strength. The Tg of the raw gelatin film was 215.7°C, and the Tg of the modified gelatin film increased by 15°C; NMR showed that the γ-C signal on the lysine and arginine molecules disappeared, and the peak of silicone Si-C formed; XPS showed that The chemical shift of N shifts to 399.87, indicating C–N formation. The dissolution rate of the product in deionized water is 60%. The dissolution rate of the product in organic solvents ethanol, acetone, and chloroform is 0.5%. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com