Ultraviolet curable anti-fog glue and preparation method thereof

An ultraviolet light, anti-fog technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of single surfactant component, short anti-fog aging, and insufficient durability Achieve the effect of avoiding dust adsorption, improving wear resistance, and increasing anti-fog effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

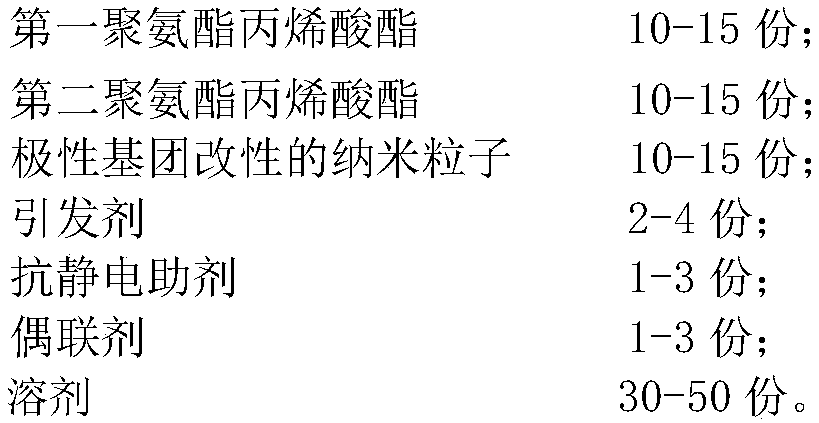

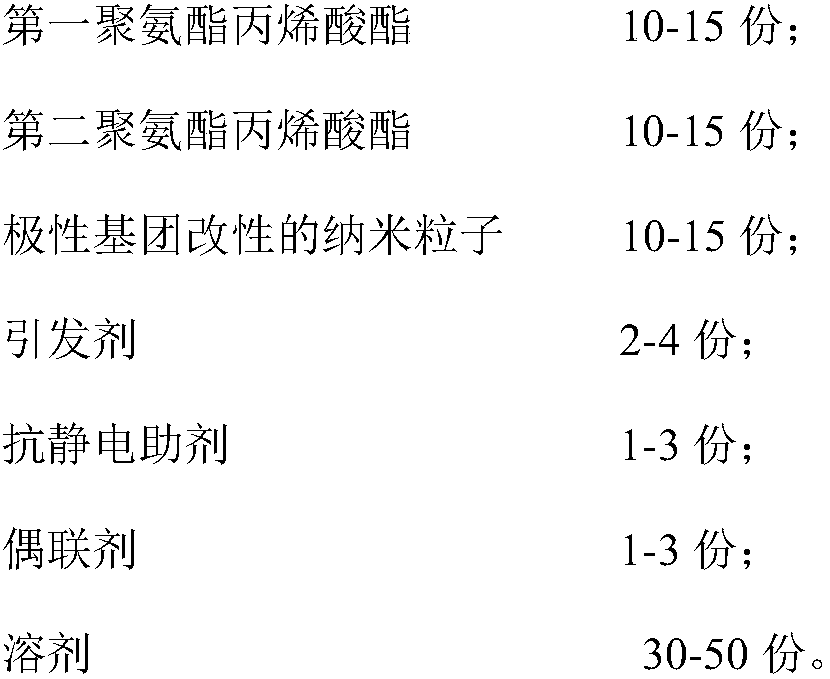

[0030] The mass parts of each component of the anti-fog glue are: 15 parts of Cytec EBECRYL8415, 10 parts of Cytec EBECRYL8713B, 3 parts of benzoin dimethyl ether, 10 parts of nano-zinc oxide modified by polar groups, coupling agent 3-formaldehyde 1 part of acryloyloxypropyltrimethoxysilane, 2 parts of lithium amine salt antistatic agent, and 30 parts of solvent.

[0031] Spray the paint on the glass, adjust the outdoor temperature difference to 20°C, observe after 24 hours, there is no fog on the glass, and the anti-fog effect is good. The glass that has been sprayed with the paint is tested for abrasion resistance, and there is no obvious scratch. The glass is tested for impedance, and the impedance is 1010, which has a certain antistatic ability.

Embodiment example 2

[0033] The mass parts of each component of the anti-fog glue are: Cytec EBECRYL8602 10 parts, Changxing DR-050M1 15 parts, initiator 2-methyl-1-[-4-methylthio)phenyl]-2-morpholine 3 parts of base-1-acetone, 10 parts of nano silicon oxide modified by polar groups, 1 part of coupling agent 3-methacryloxypropyl triethoxysilane, 2 parts of carbon nanotube antistatic agent , 30 parts of solvent.

[0034] Spray the paint on the glass, adjust the outdoor temperature difference to 20°C, observe after 24 hours, there is no fog on the glass, and the anti-fog effect is good. The glass that has been sprayed with the paint is tested for abrasion resistance, and there is no obvious scratch. The glass is tested for impedance, and the impedance is 1010, which has a certain antistatic ability.

Embodiment example 3

[0036] The mass parts of each component of anti-fog glue are: 12 parts of Sartomer CN9013NS, 13 parts of EBECRYL8713B, 3 parts of initiator 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, polar group 10 parts of modified nano-iron oxide, 1 part of coupling agent benzophenone, 4-benzoyl-4'-methyl-diphenyl sulfide, 2 parts of indium tin oxide antistatic agent, and 30 parts of solvent.

[0037] Spray the paint on the glass, adjust the outdoor temperature difference to 20°C, observe after 24 hours, there is no fog on the glass, and the anti-fog effect is good. The glass that has been sprayed with the paint is tested for abrasion resistance, and there is no obvious scratch. The impedance test of the glass shows that the impedance is 107, and the anti-static effect is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com