Light emitting diode element capable of preventing electrostatic damage

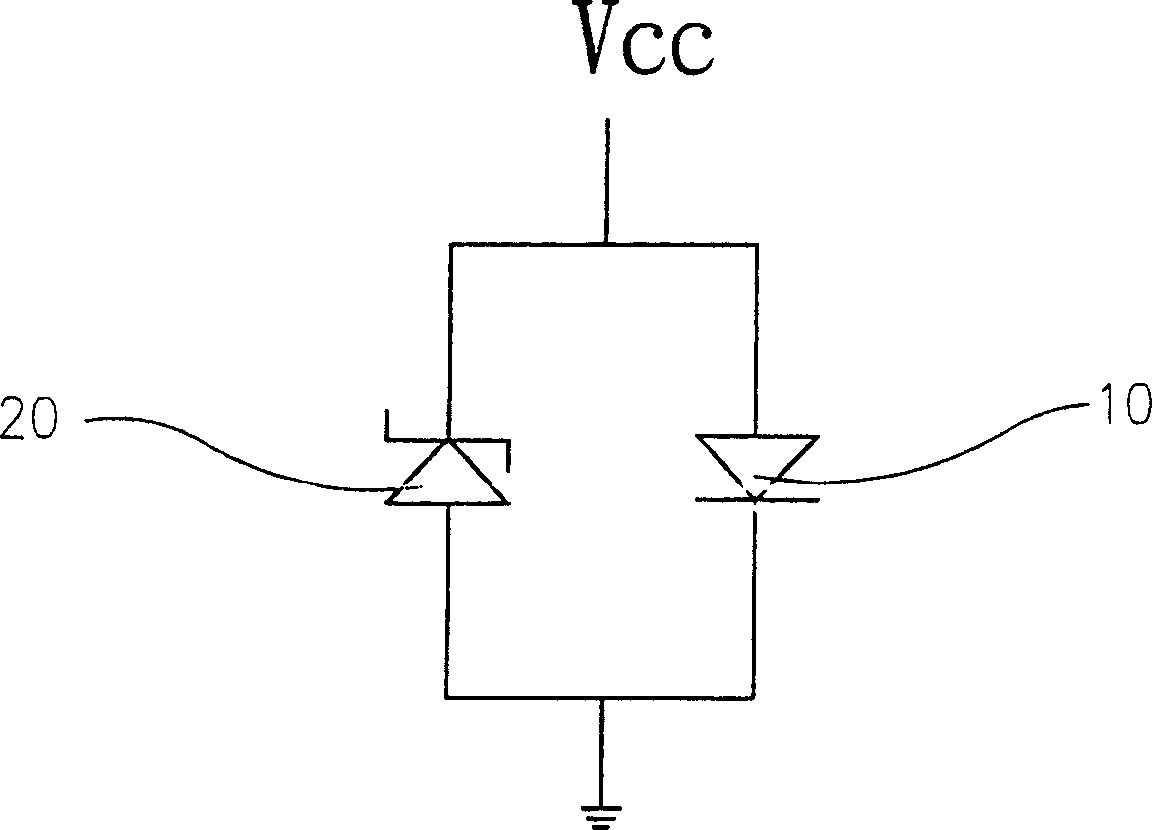

A technology for light-emitting diodes and static electricity destruction, which is applied to electrical components, electric solid-state devices, circuits, etc., and can solve the problems of waste of materials, manufacturing costs, cost, and the large volume of Zener diodes 20

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

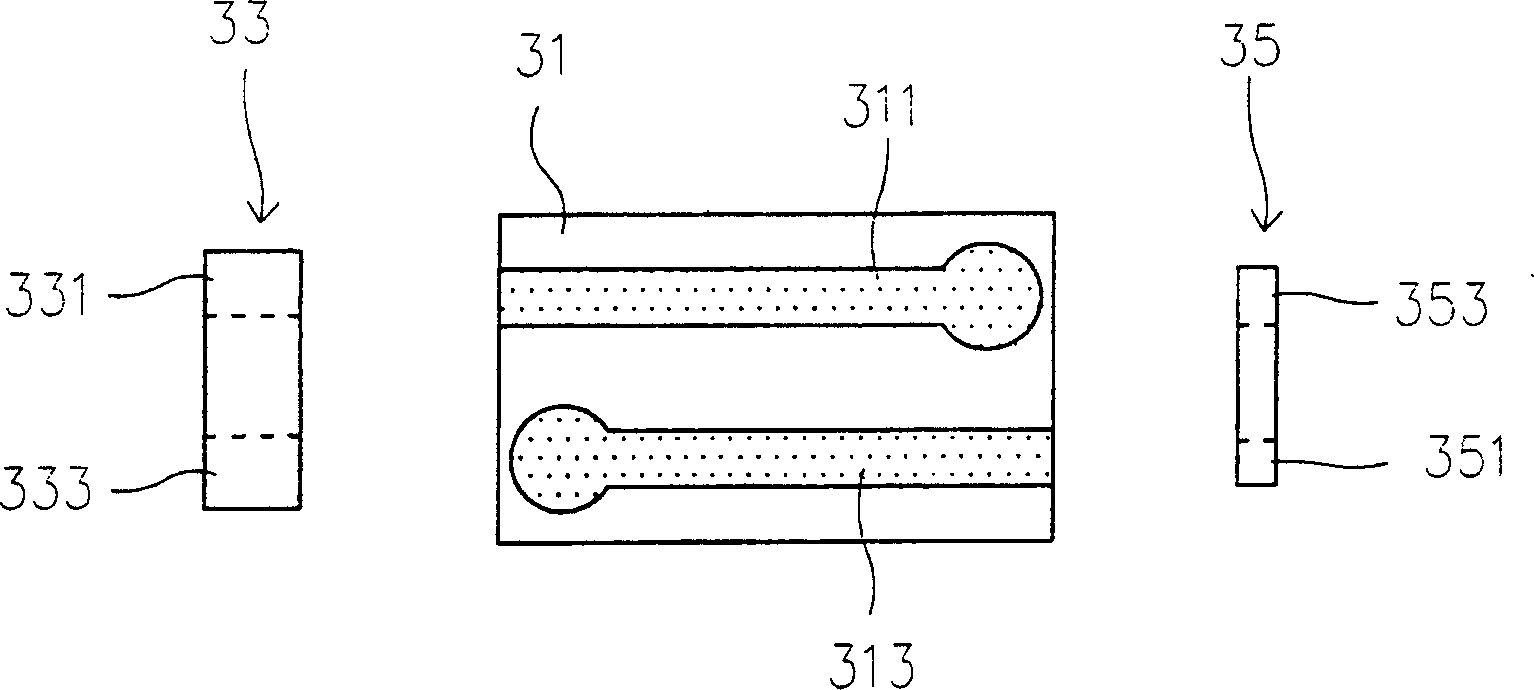

[0039] First, see Figure 3A and Figure 3B , is an exploded schematic diagram of the structure of a preferred embodiment of the present invention and a schematic diagram of its combination; After flip-chip flipping, the device (ESD) 35 is bonded on the surface insulating substrate 31 having at least one first power supply circuit 311 and at least one second power supply circuit 313 .

[0040]Wherein, the light-emitting diode 33, such as the planar light-emitting diode shown in this embodiment, has a LED second electrode 333 and a LED first electrode 331; and the antistatic protection element 35 also has an ESD second electrode 353 and an ESD the first electrode 351 . When bonding the LED 33 to the surface insulating substrate 31 , the second LED electrode 333 is electrically connected to the second power supply circuit 313 , and the first LED electrode 331 is electrically connected to the first power supply circuit 311 . On the contrary, the ESD first electrode 351 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com