Antibacterial waterproof electrostatic-resisting environment-friendly fabric

An antibacterial fabric and antistatic technology, applied in the field of fabrics, can solve problems such as discomfort, air pollution, and harmfulness to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

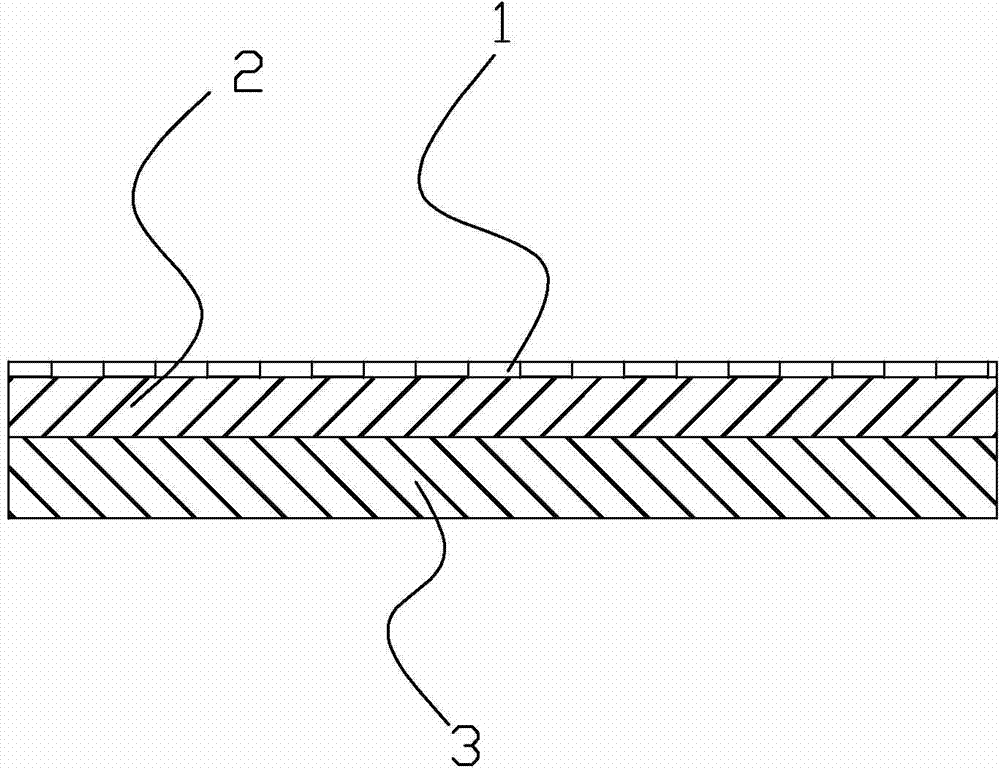

[0014] refer to figure 1 , an antibacterial, waterproof, antistatic and environmentally friendly fabric, comprising an antibacterial fabric layer 2, a fiber layer 3 disposed on the inner layer of the antibacterial fabric layer, a hydrophilic composite polyurethane film 1 disposed on the surface layer of the antibacterial fabric layer 2, and the antibacterial fabric layer 2 It is made of 10 parts by weight of bamboo fiber, 2 parts by weight of chitin fiber and 70 parts by weight of cotton fiber. It is made of mixed weaving of 16 parts by weight of colored cotton fiber yarn and 80 parts by weight of Tencel fiber. The weft thread is made of weft thread A and weft thread B. The soybean fiber of weight part and the tencel fiber of 40 weight part are mixed and woven, and described weft B is mixed and woven by the milk fiber of 30 weight part, the spun silk fiber of 55 weight part, and the length of described colored cotton fiber yarn The thickness of the antibacterial fabric layer ...

Embodiment 2

[0016] An antibacterial, waterproof, antistatic and environmentally friendly fabric, comprising an antibacterial fabric layer, a fiber layer disposed on the inner layer of the antibacterial fabric layer, and a hydrophilic composite polyurethane film disposed on the surface layer of the antibacterial fabric layer, wherein the antibacterial fabric layer consists of 12 parts by weight of bamboo fiber, 3 parts by weight of chitin fiber, and 72 parts by weight of cotton fiber blended and woven. The fiber layer is formed by interweaving warps and wefts according to the arrangement of two up and one down. The warp is made of 18 parts by weight of colored cotton Fiber yarn, 82 parts by weight of Tencel fiber are mixed and woven, and the weft thread is woven by weft A and B, and the weft A is made of 38 parts by weight of modal fiber, 22 parts by weight of soybean fiber and 45 parts by weight. Tencel fibers by weight are mixed and woven, and the weft B is woven by 38 parts by weight of ...

Embodiment 3

[0018] An antibacterial, waterproof, antistatic and environmentally friendly fabric, comprising an antibacterial fabric layer, a fiber layer disposed on the inner layer of the antibacterial fabric layer, and a hydrophilic composite polyurethane film disposed on the surface layer of the antibacterial fabric layer, wherein the antibacterial fabric layer consists of 14 parts by weight of bamboo fiber, 5 parts by weight of chitin fiber, and 75 parts by weight of cotton fiber blended and woven, the fiber layer is formed by interweaving warps and wefts according to the arrangement of two up and one down, and the warp is made of 20 parts by weight of colored cotton Fiber yarn, 84 parts by weight of Tencel fibers are mixed and woven, and the weft thread is woven by weft A and B, and the weft A is made of 45 parts by weight of modal fiber, 25 parts by weight of soybean fiber and 50 parts by weight. Tencel fibers by weight are mixed and woven, and the weft yarn B is woven by 45 parts by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com